-

Posts

118 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by whatnow123

-

Just a quick update on this. I've put about 350 miles or so since installing the CV's, mostly spirited driving . About 240 miles of that was with a local Z club that went on a drive last weekend up in the AZ mountains. Pretty much a strait shot there and very twisty smooth road on the way back so I got to stretch her legs a bit. Anyway, about 35 miles from home I started to get a vibration above 50 mph and was thinking it was the CV's after I just beat on them (got up to about 130 at point). I pulled both CV's only to find the axles I modified had stayed put . Turns out one of the C clips holding the u-joint cups in place on the drive shaft came loose and the bearing cup was backing out causing slop in the drive shaft. I guess it's best to always check others work! Cheap easy fix and was relieved it wasn't something more and it happened close-ish to home. Anyway, so far so good on this MOD!

-

Reb, Maybe we have different CV axles, but the outer CV cup of my axles has about 2 1/2 inches of movement (<-- this is wrong, I forgot about the bearing cage, it's probably closer to 1 to 1 1/4 inches as stated below) within the cup (which is why I even considered this). I did pop off the outer cover to judge where the bearings were riding within the cup at installed length, and they were about in the middle of the CV cup, maybe a little towards the wheel. I can't take a measurement right now since the axles are installed, but just from memory and looking at the above photos of the stock length axles and where the bearing rides; when it would bind from the axle being to long as you mentioned, I can see how the bearing could be on the outer edge of the cup and flipping the cage actually moves where the bearing rides in the CV cup closer to that outer edge (the bearings are in the center of the outer cage, but sit on the first 1/3 of inner race which is secured to the axel), so I can understand how the bearing could bind up in such a situation. While I took off 5/8 of an inch on axle length, I only moved the bearing back on the axle maybe 1/2 an inch with the cages flipped. Given what you have described above about to long an axel (I'm assuming stock) and to short of one, the 1/2 inch I moved the bearing should be in the sweet spot of the CV Cup for movement.

-

So I installed my newly shortened CV axles yesterday. I installed the pass side first and then the drivers side. When I installed the drivers side, I had the control arm supported higher then when I did the pass side (I don't like the suspension to hang from the top hats). Anyway, both popped right in without removing the strut and I had at least 1/2 inch of clearance. I then took her for a drive and it might be my imagination but it seems much smoother so drove on over to the freeway to test her out and no issues at all and it got rid of the slight vibration I used to have at 90+. When I got home I pulled one of the axles (drivers side) to check to make sure the cage stayed put and it did. So, about 30 miles and so far so good. I will keep this post updated as I put more miles on my conversion. I might add that my car is only lowered about an inch.

-

Hey Reb, I did it with a hose clamp and an angle grinder.

-

REB, It won't hurt the heat treatment and it's on the very end of the shaft so it wouldn't really effect the shaft. Also, if you look at the 4th photo, the "weak link" would be the grove for the CV boot. I will slide them right in this weekend and report back.

-

So I have a set of Z31 turbo CV axles that have been staring at me in the garage and I have recently ordered the MM CV companion flanges. I have been reading about what it takes to install them (flip the bearing cages) and I have also read they are just a touch to long and load the ring gear in the rearend. I have a rock solid r200 LDS and don't want to F- it up. Anyway, I took the CV's into work to flip the cages and got to looking at it. The bearing cages are held onto the shaft by a couple of C clips at both ends and then slides within the CV housing. After flipping the cage, the axle itself is now the longest point. I got to thinking about this, it's the CV axle shaft that makes contact with the stub axle causing the binding which in turn pushes against the diff and can wreck the ring gear/carrier bearings. This is why MM sells shorter axles (by 1/2 inch I believe). So I got to thinking, why not just move the channels where the C clip secures the bearing cages and cut down the remaining axle? There is plenty of spline left on the axle for the bearing cage, the new grove I cut in the axle is still larger than the factory indentation for the CV boot, so I didn't compromise strength at all, so I'm not sure why no one has done/thought of this. With that said and considering CV axles are way cheaper than a R200 LSD, I busted out the grinder and shortened the axles by about 5/8 of an inch. I made 2 new groves for the C-clips and I believe I have a very inexpensive solution to buying shorter axles. I just wanted to post this and to see if anyone can chime in to a potential problem that I'm not seeing as this seems like very simple and cheap solution.. I stole a couple of photos from another web site as I didn't take a photo of what just flipping the cages looks like. One is as it sits, the other is when it is flipped... and then on from there.

-

limiting front differential mount movement

whatnow123 replied to whatnow123's topic in S30 Series - 240z, 260z, 280z

Does anyone have a decent photo of the SW Motorsport mount? It looks like that might be a good option.. -

Just an update. Well I hush matt'ed the interior, pretty cool stuff but hope I never have to pull it up for some reason as it will be PITA. I was also happy to find ZERO rust on the floor pans. Got lucky finding a car garaged it's whole life! I've been driving her around bit and happy to report that other than a loose radiator hose and a slight leak on the power steering rack fitting (both easy fixes) she is running like a champ! She drives awesome, goes right were you point it and is surprisingly comfortable. I could drive this car everyday and have ZERO issues doing that, which isn't what I will do, but I wanted to build something that could be driven daily, or anywhere for that matter. Also, again, anyone considering doing the Subaru rack swap, I highly highly recommend it. I also love how she sounds, good deep rumble and sounds like road race car! After driving it about 500 miles or so and getting the engine broke in (as well as everything else I changed), I found (and after doing some research on the mustang forums) that the stock intake for the 5.0 was limiting her full potential. The bottom end has been fully machined and balanced, bored, squared and zero decked, the heads have had some work done to them including milled and a small bump in cam over the HO version, the intake was keeping her "flat" after about 4700 RPM and couldn't keep up. So I found a tubular GT40 upper intake and matching lower, (the stock GT 40 lower intake doesn't flow as well as it could, so it is also now ported and port matched that as well, again thanks to the mustang forums). So I installed the intake, got a 65mm throttle body to replace the stock 60mm and also 70mm MAS (mass airflow sensor) to replace what looks like a 30mm stock unit. I also installed some crane 1.7 roller rockers to get a little more lift at the valve. Fuel injection is a whole nother animal but I think I'm getting it. These mods most definitely woke that engine up after 3000rpm! I'm guessing I'm close to 300hp now cuz she flies and my fuel mileage hasn't suffered at all. I'm still pulling 25+ on the freeway. I will be honest, it's nice driving a "hot rod" that can pass a gas station unlike my other cars I have built. The last thing of note that I'm still experiencing.... I can not believe all the people that not only know what the older Z's are, have some sort of connection to them, but appreciate them as well! There isn't a time I drive it that someone doesn't give me a nod, thumbs up or rolls down the window at lights to complement the car (or ask what in the hell is in that as it doesn't sound anything like a Z they remember). I find it funny since there aren't a lot of them running around and aren't as common like old Camaros! I actually had a Harley dude who looked like The Count from the show Counting Cars (and acted like him as well) come over while I was at the gas station and just gush over the Z and then freaked when I popped the hood. I will admit, I like the attention. Anyway, here are some photos!!

-

Hey Everyone! Has anyone figured out a decent way to limit the movement on the snout of the differential? I know about the pinion snubber and JTR (I think) way of wrapping a cable around it. The problem I'm having is on hard deceleration due to the larger U joint flange from the 280zx, it's hitting the swaybar. I thought about moving down the sway bar a bit but that doesn't really fix the problem and I don't want to go to a solid diff mount as I've heard the noise is just horrible. I also can't reverse mount the sway bar to the rear as I have a Camaro tank and that will get in the way. Anyone come up with a way to modify the stock mount or modifying a solid mount to accept urethane bushings to limit both up and down movement on front snout of the diff? Just an FYI, but I have a billet MS bar and urethane bushings there so I'm assuming that is limiting some movement already. Thanks in advance!

-

Nice!! I just did this swap myself, you should check out my build 280z 5.0 ford build thread. I think it's an awesome engine to go into this car!!

-

They are 73mm. Nice find on that car by the way.

-

You have a project on your hands with the rust, but from the glimpse of the partner the Z has in the garage, you should be just fine bringing it back to life. I too lurked on this forum for a bit before I pulled the trigger on my Z. I bought a near perfect Z then upgraded everything as I have done the rust repair in the past and just wasn't motivated enough to do it again. I wanted to keep mine fairly stock looking but bring everything up to modern standards however, I just got my Z driving with the new engine/suspension and I just love that car! Good luck on the build, the forum is full of awesome advise!

-

78 280z - Easier Engine Swap L28ET or SBF 302?

whatnow123 replied to jlurton's topic in S30 Series - 240z, 260z, 280z

The L28et would be the easiest, but the ford 302 does not require a whole lot of fab work. I bought an engine cradle but after receiving it, it would not be hard at all to build one. The cool thing about the 302, it sits behind the front wheel centerline and it's way cheaper to get some power out of it than a L28et. Look at my build thread if you want to see how it fits. You can also google 240z 302 ford and get brian Laines build, he goes into detail about the swap and has the prints to build the cradle. -

"That's one classy chassis!" Thank you! I have really only driven it around once (which was yesterday) and can't believe how many thumbs up, looks and "nice car" I got. I really wasn't expecting it to draw that much attention, but I guess it does!

-

Well, I finally got around to installing the 240z bumpers that welded all the holes shut and painted, also painted the grill while it was off as well as the underside of the hood and the rear taillight cover. The rear cover I'm going to have to remove and re-do as I took a short cut and rattle canned it and the nozzle was messed up, but that's what I get for thinking I could do a "short cut". I just hope I can get it removed without braking it. Anyway, I've taken her on a few short trips around the hood as I didn't really trust everything yet, but today I installed the hood and took her for an actual drive and I just LOVE this car. It's just awesome to drive, handles great, stops great and sounds mean! I do need to get the AC hooked up and running and I'm going to have to Dynomat the interior as it's a little loud as well as find a home for some front speakers as the little 4 inchers that I replaced in the factory location behind the seats just aren't enough.

-

Rear control arm drop mounts and dog bone bracket.

whatnow123 replied to mig20's topic in Parts Wanted

I have a 180 MS bar... -

Which rear brake conversion to use?

whatnow123 replied to rus's topic in S30 Series - 240z, 260z, 280z

I will chime in here. I did rear disks on my car strictly for vanity reasons and left the front alone other than new disks/brake lines. I bought a "kit" with maxima rear calipers and 280zx rear disks. I didn't build it to be a track car otherwise, like Miles mentioned, go with a complete front/rear and MC kit as it will be a better balanced system to start with. I'm not sure how to calculate brake bias as Miles mentioned, but my brake system seems to be fairly well balanced and the car will stop fast enough to lose your gum without locking up the rears. It's probably due to the near even weight distribution these cars have or maybe I just got lucky with my car weight, springs, weight transfer to match up with brake system I have. If you read this Miles, what is a good brake bias for these cars and how to did you go about calculating it? I'd like to do it to my car as the %'s you show above really seem about right to me for a street car, but again I don't really know. -

I have got one. It's a 3:70 and the gear set is worn. Do you need the complete diff or just the carrier?

-

Not to much to update. Haven't done much else to the ride other than "fixin". I took her out for a drive and the summit shifter I bought got jammed into 5th gear and I had to limp her home. I thought it was something in the trans that went south, I was relieved when it was just the shifter. The shifter had great reviews on the mustang forums and Summit, turns out it wasn't machined enough on the ball to handle and the "half moon" from the transition to the flat part of the shifter got caught. Cheap and fairly quick fix and I don't have to pull the trans. Anyway, welded all the holes shut in the 240 bumpers and laid some very nice black paint on there. Going to get them installed this weekend and hopefully get the fan, tach and possibly the AC hooked up this weekend so I can take her down to get an alignment.

-

Not to revive an old thread, but this is what I followed on my steering rack (I went with the Volvo tie rods way that LT1 figured out). Anyway, I love driving the car now and this is an upgrade worth doing!

-

That's a pretty cool video!! I'm wondering, is that the same car? The video states a 280 with a 347 but this thread has it being a stock 302 out of town car.

-

As long as you can mount an AC compressor, you can keep the AC.

-

Not sure what you mean by everything, but I have the front mount (I think it's called a tranverse link) and I also have the rear curved suspension mount, 280z 27 spline axles and a LSD carrier for a r200. Let me know what you need.

-

So today I finished up hooking up some hoses, filled the radiator and fired it up to check for leaks. So far so good.. so I then got a wild hair up my butt and decided to zip tie some wires out of the way, secure a couple of sensors the same way (I will do it correctly when I start buttoning up the wiring) but I wanted to take the car for it's first spin. All I can say is wholly sh--t this thing moves!! What a difference some HP makes to these cars! I bought the engine from a guy on craigslist (I was freaked out a little when I bought it as I trust few other than myself) but the engine was never fired and came with the build sheet to the tune of $2100 just for all the machine work, assembly and rebuild of the heads (the lower end was a sealed power kit supplied by the previous owner to the machine shop) so I took a chance on it and they did an awesome job! The engine is very powerful and smooth as butter! Not to mention the engine came complete with all the brackets, sensors ect.. including new water pump, balancer, painted and all the parts sandblasted. So I think I scored! I also wanted to check out how I would like the Subaru power steering rack I installed. Anyone considering this mod, I give it TWO THUMBS UP! It completely changes the car for the better! It's a quicker ratio than the stock rack, plenty of "road feel" but not to light, it feels more like power assist than power steering. Turning into the driveway is now a pleasure and I'm far more comfortable tossing the car around a corner as I'm not fighting the wheel. With that said, the car feels way more modern now! I haven't driven it more than a few miles, but I'm quickly forming an opinion this might be the most fun car I have driven! I can't wait to button her up, work a couple of bugs out and drive this thing! A V8 and the Subaru rack is how they should have built the Z in the first place!!

-

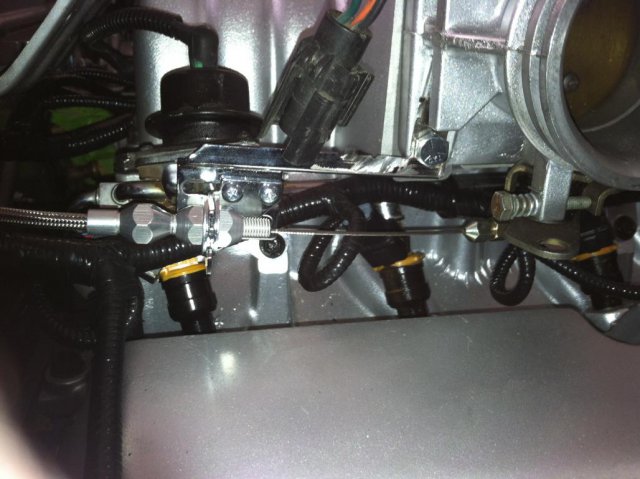

Just an update. Well, I ended up buying a "universal" Lokar throttle cable and figured I would try to make it work with the Ford 5.0 intake and the Z throttle linkage and it works perfectly! I needed to cut off the "peg" that connected to the Z engine linkage and attach the "y" fitting that came with the lokar kit. I also picked up a cheap bracket kit and with a slight modification, it worked perfectly!! I also got the clutch adjusted, first time I fired the car I wasn't sure the clutch set up I did was going to work as I couldn't get it to go into gear. Turns out the shaft I made for the slave cylinder, the outside nut was bottoming out on the bell housing towards the forward opening. Spent the morning grinding a U shape into the bell housing for the nut to clear.. and now it works perfectly! I didn't post any of the slave/MC combo I did when I did it as I didn't know it would work, but now since I does work and work well, here it is. I took a heavy piece of angle iron and made an L shape, welded it, drilled two holes to mount on the bell housing and two more holes for the slave cylinder. Slave Cylinder is part # 11887, it's for a Toyota Tacoma $11 bucks at the Zone. Long bolt, cut off the end, round it on grinder and use two nuts with washers to attach it to the clutch fork. Wilwood master cylinder, part number 260-6765 Summit $49 Braided line from Summit 14" for $15 and couple of brake lines from the Zone. The Wilwood master fits the Z perfect, (I did switch out the shaft from the stock master). The clutch petal is awesome, maybe a little firmer than stock, but very do-able. So I can now recommend this set up if anyone needs this.