-

Posts

174 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by zxtman

-

-

I've had a red top for more than 12 years and it's still cranking.

-

Mirroring the #4 hole over #3 would allow more flow from both...

Ah yes ...my thoughts as well.

-

It clears both intake and exhaust manifolds so I guess I'm satisfied. I forgot to mention that the top of that hole is at the very top of the internal ceiling of the water jacket. You go any higher and you will cut into the ceiling wall.

I also plugged the internal bypass hole and drilled out almost every coolant hole in the block and head that was present in the N42 MLS gasket. There was one hole in the head (P90A) that wasn't present in the gasket or head. I didn't mess with the gasket for fear of tearing it up.

I figured that the hole above #4 is close enough to 3 to count for both

.

. I think you would have to scarf out the manifolds to get a larger fitting in there. At least a fitting like the one I have that is removable with the manifolds attached. There is only .06" between the tips of the fitting nut and the intake manifold. You could move the hole a little aft to gain more clearance to the exhaust.

Great info.

Did you check if the water jacket above 3&4 is continuous?

-

I tapped 1/4 npt above #4.

Very nice...

Are you satisfied with the location? Is there room to go larger than 1/4 NPT?

Are you planning to do #3?

Great pics,

Thanks.

-

You need to send JeffP a PM or e-mail. I believe he did a single tap abouve 3/4 because of the proximity of the exhaust. He can tell you in thousandths of an inch where he tapped referenced off some existing hole or stud or whatever.

Thousandths of an inch...

Thanks. I sent JeffP an email.

-

Yes, it was a successful install.

Before I start making swiss cheese out of my P90, I'd like to know where the water passages are above 3&4, and whether one fitting is needed above each, or one fitting for both (centered between 3&4)???

Reviewing archival photos recently with a caliper in-hand, the stuff used in the past was much larger!

I've noticed this as well: looks like -8 minimum, maybe even -10 was used on the Electromotive car.

Originally, my plan was to use 1/4 NPT to -6 fittings, but I am considering going with 3/8 NPT to -8. I just need to resolve the issue with 3&4.

Thanks..

-

Ok so with all of this discussion, I think I am going to jump off this cliff and have the cylinderhead done from #2-#6. I don't think #1 is really an issue as it is right at that large hole for the thermostat housing. I have completed #5 & 6, and was intending on doing # 3 but between 3 & 4 is difficult to do. I have already invested about 300 in what I have done, but the union T I used (swedgelock) is to big to get between 3 & 4 so a redesign is in order.

I will get the 1/4 NPT fittings, do the intake clearancing for 3-4 use the A/N fittings and run the tubes to a common tube 1/2" but instead of using fittings have each tibe TIG welded to the common return pipe. I use a local welder here Master Craft Welding to do the work. This guys TIG welding is the best I have ever seen, very percise and very clean. I have him do the work I want to look good and be strong. I have already bought all of the -6 45 1/4" NPT fittings. Getting around the head stud between 3-4 is going to be the tough one, but I think it is doable. And just to make sure where it needs to go, I have a good door stopper P90 head I will section to make sure of the fitting locations.

Why is it that every time I get involved in this stuff it starts costing me lots of money LOL, but its only money right? Anyway this is just part of the crap I am working on right now, and since I just dropped close to 4 grand on components for a race head what the hell!

Were you successful at installing fittings at 3 & 4??

-

Nissan headgaskets.....the blue packaged ones are made in Oz buy a company called ACL for Nissan. The others "may" be directly from Japan but who knows?

I know, I've got too many hg's, and that's not all of them

Observation: All 3 gaskets shown have the same water passages; which is no different from the N42 gasket available here in the States.

Anyway, I'm glad this thread came along; it finally answered questions I've had for a long time

-

How easy is it to matchport a gasket...

Well said. That pretty much sums it up.

-

One interesting side note since I posted this question.

I purchased this .6mm, 90.5mm Kameari HG from Brian at Z car customs JDM (zccjdm.com). I sent these pics and basically asked the same question I did here.

He contacted Mr. Miro, who, I understand designs many Kameari products and or founded Kameari...I'm sure someone here knows the story. Anyway, Brian at zccjdm forwarded Mr.Miro's response, to quote:

"I designed the KAMEARI L6 head gasket so that F54(P90 HEAD) could share it with N42.

When F54(P90 HEAD) compares the port of the gasket, there is a different place.

However, there is no problem to use it.

Please do not worry."

Interesting.

Steve

...so what I'm reading here is that the Kameari gasket is a duplicate of the N42 gasket and that it's ok to use with the F54/P90 combination.

If what Tony says is true:

"...get as much flow to the head as you can get. Period."

then why didn't Kameari make a 2nd gasket to match (F54/P90 combination) with more holes? ...or all holes opened up?

Probable answer: Cost, make one gasket to be used universally (copy the N42 gasket and call it a day). Is it the best gasket for every combination? I don't know...

So Tony, is the answer to use a gasket that matches the exact coolant passages for whichever block/head you are running? This would be a modified or custom gasket, of course.

-

Question,

having the water holes on the exhaust side of the head ( less on the spark plug side), will this increase the amount of the water moving past that side of the head, and thus reducing the chance of spot boiling, and helping reduce heat faster ?

Nigel

...that makes alot of sense, and to re-iterate what my Nissan guy said (with regards to the P79 gasket for the P90 head+F54 block combination): "Nissan would not have made the changes if they weren't necessary".

Let me also add that the P79 gasket does not block coolant flow to the head at the (2) holes that Steve mentions in post #4.

-

The dyno testing we did under load says otherwise, increasing flow to the head seemed to carry more heat out more efficiently than the original gasket configuration with restricted flow to the head.

The gaskets restrict flow INTO the head, not out. That causes spot-boiling---look at any industrial exchanger and you will see unrestricted FEED side lines, and any throttling for temperature control is done on the OUTLET of the heat exchanger!

Same goes for the L-Head: get as much water as you can into it, then play with getting it out. Restricting flow on the inlet side is not good as it can contribute to cavitation, etc.

There's an obvious difference (# of holes for coolant) between the early N42 gasket and the later P79 gasket.

So what is sounds like you're saying is that the N42 gasket is more beneficial (more holes to allow unrestricted flow) for the later model head/block combinations over the P79 gasket???

Increasing flow to the head seems to make more sense; so, why did Nissan change it?

-

First, thanks for the responses.

Block is the F54. The only passageways in the block which don't have a matching hole in the gasket are circled.

See below:

Here's some good email correspondence with my Nissan guy that I would like to share.

Me...

"I'm having sealing issues with the 1mm HKS metal head gasket, so I have decided to o-ring the block and use the factory head gasket instead. The question is which is the correct gasket to use?"

Nissan guy...

"I have attached some pics so you can compare the gaskets."

"The part numbers referenced in the pics are:

11044-91MM1 is the HKS metal headgasket that Nissan Motorsports and others including myself were selling- it is now NLA.

(You will notice that the metal gasket is pretty much identical to the early OE gasket in the oil and water passages)

11044-N4221 is the factory non-turbo gasket that was used from 1975 to 02/1981

11044-P7911 is the factory non-turbo and turbo gasket that was used from 03/1981 thru 1983."

"The HKS gasket is just a big-bore, metal version of a 75-80 (N4221) gasket."

"The thing about metal head gaskets is that the head and block surfaces need to be a near-mirror finish(low Ra or RMS numbers) for best sealing.

I have kinda always had heartburn about using the (early style) metal gasket on the later blocks/heads."

"You are probably on the right track with the o-ring+OE gasket setup, however, the turbo engine(P90 head+F54 block) calls for the P79 headgasket, so if you are going with OE, be sure to use the P79 one."

"I remember when Nissan made the changes to both the P79 & the N42 & also the 240Z gasket back in the early 80's and arguing with the mechanics that Nissan would not have made the changes if they weren't necessary, and to trust that the Nissan engineers know what they are doing. It was something about keeping the water in the head longer for better heat transfer to the coolant."

-

But if the engine was overheating then it will still overheat.

Overheating? There is no mention of overheating in Ricky's post.

Ricky, it would help to know what temperature you were experiencing after the 10 laps before the by-pass, ...190 degrees is awfully cool for 10 laps of racing.

-

My attempt at reducing the temperature above the 6th, 5th and 4th exhaust ports.

This change has stopped the temperature from slowly creeping up after 10 laps and it now peaks at 190 degrees and stays there.

The lines are dash 3 brake lines which are well rated for the heat and pressure and are cheap.

I notice the 3 lines from 4,5,&6 return into the coolant flow after the thermostat housing.

Are you using a thermostat or restrictor?

Where is the temp sensor located?

If you are taking the temp reading at the thermostat housing, that might explain the temp drop: hot coolant from 4,5&6 is by-passing the sensor.

-

You obviously have internet access, ...so search next time.

See attached.

-

Here's the most detailed S130z model scale i've ever seen!

Wow! That's impressive.

-

I did receive your PM. I have one left, but I haven't decided if I want to sell it or for how much. Give me a little time.

Understood. Let me know what you decide.

Thanks.

-

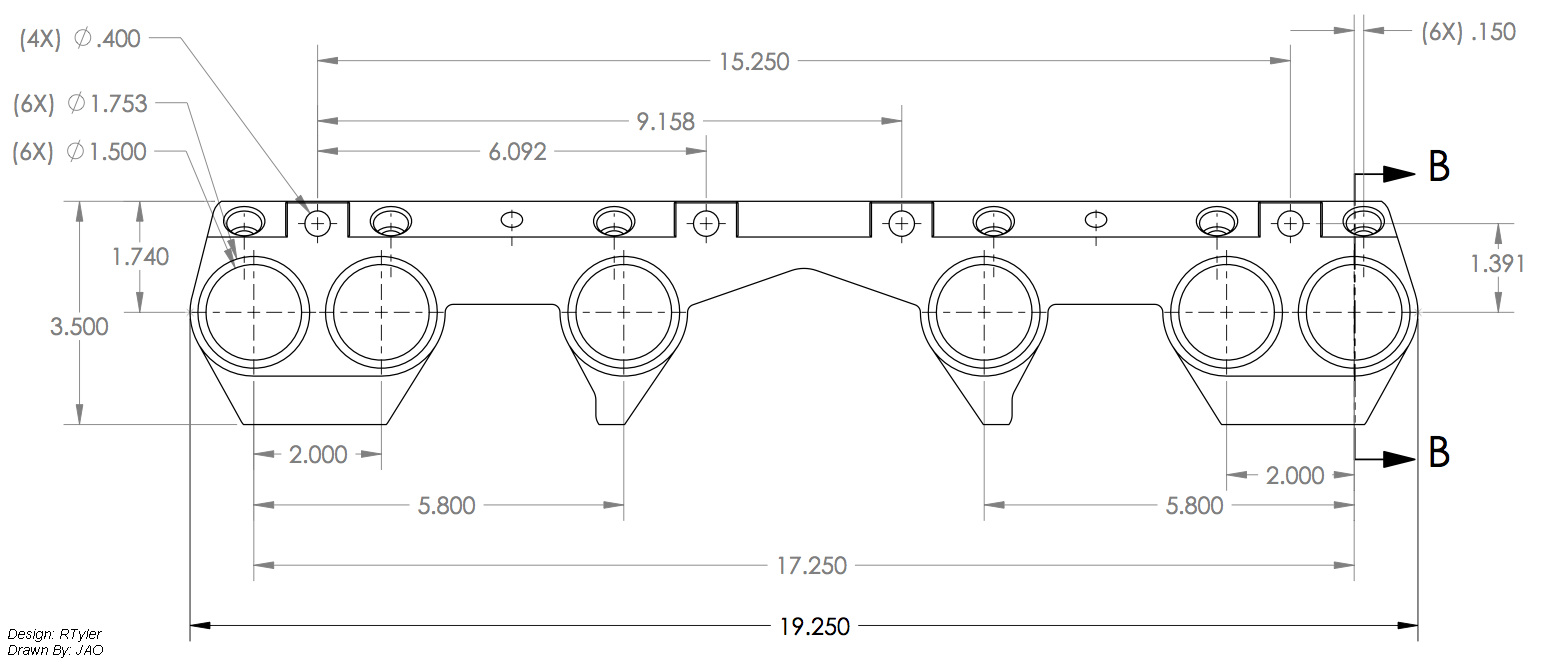

This was designed for 1.5" ID runners, and it put the runner floor even with the port floor (raised the port centerline).

Hey Ron, is this flange available? I was planning on cutting and modifying a stock flange for a new intake manifold, but this is a better option. I sent you a pm on this.

Thanks.

-

This was designed for 1.5" ID runners, and it put the runner floor even with the port floor (raised the port centerline).

...just an observation, the injector holes for cylinders 3 & 4 (on this drawing) should be on the opposite side of the runner centerline. That's how their shown and dimensioned on the previous injector spacing drawing. Again, just an observation.

-

...glad I could help.

This is why I love this site . . . every member (well . . almost every member) is a wealth of knowledge! Its the reason I come back day in and day out.

Ditto.

-

-

...completely irrelevant.

Sigh. People don't care about the other cars you have built.Agreed.

-

For obvious reasons, I think you should change the title of this post to "Short Burnout Video of a heavily modified 280ZX Turbo".

Broke a dratted stud!!!!!!!!!!!!!!

in Nissan L6 Forum

Posted

...weld a stud in place? I don't think so.

Have your shop use Timeserts.

Like this...