-

Posts

174 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by zxtman

-

-

I've had a red top for more than 12 years and it's still cranking.

-

Ah yes ...my thoughts as well.

-

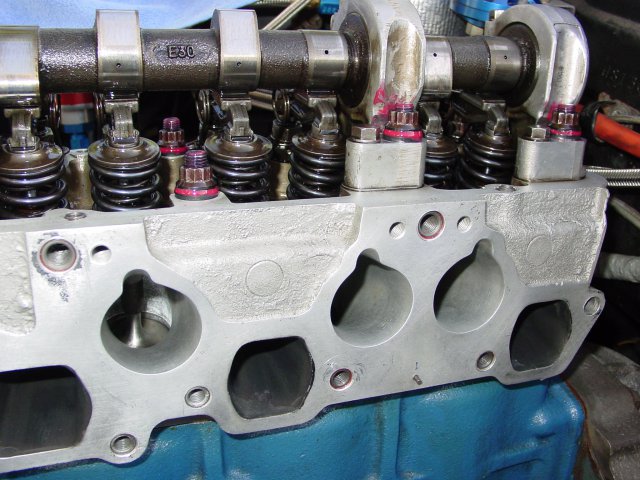

Great info. Did you check if the water jacket above 3&4 is continuous?

-

Very nice... Are you satisfied with the location? Is there room to go larger than 1/4 NPT? Are you planning to do #3? Great pics, Thanks.

-

Thanks. I sent JeffP an email.

-

Before I start making swiss cheese out of my P90, I'd like to know where the water passages are above 3&4, and whether one fitting is needed above each, or one fitting for both (centered between 3&4)??? I've noticed this as well: looks like -8 minimum, maybe even -10 was used on the Electromotive car. Originally, my plan was to use 1/4 NPT to -6 fittings, but I am considering going with 3/8 NPT to -8. I just need to resolve the issue with 3&4. Thanks..

-

Were you successful at installing fittings at 3 & 4??

-

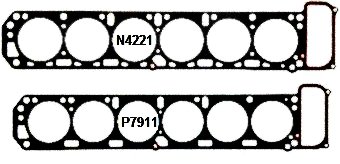

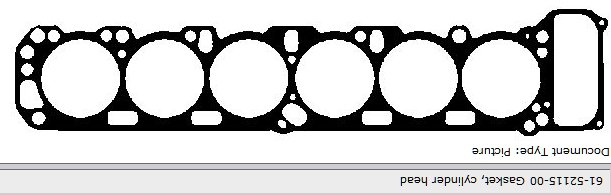

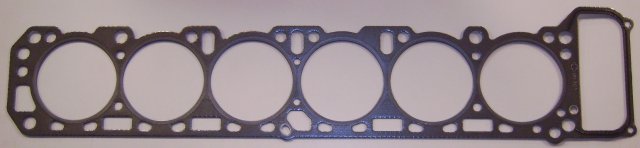

Observation: All 3 gaskets shown have the same water passages; which is no different from the N42 gasket available here in the States. Anyway, I'm glad this thread came along; it finally answered questions I've had for a long time

-

Well said. That pretty much sums it up.

-

...so what I'm reading here is that the Kameari gasket is a duplicate of the N42 gasket and that it's ok to use with the F54/P90 combination. If what Tony says is true: "...get as much flow to the head as you can get. Period." then why didn't Kameari make a 2nd gasket to match (F54/P90 combination) with more holes? ...or all holes opened up? Probable answer: Cost, make one gasket to be used universally (copy the N42 gasket and call it a day). Is it the best gasket for every combination? I don't know... So Tony, is the answer to use a gasket that matches the exact coolant passages for whichever block/head you are running? This would be a modified or custom gasket, of course.

-

...that makes alot of sense, and to re-iterate what my Nissan guy said (with regards to the P79 gasket for the P90 head+F54 block combination): "Nissan would not have made the changes if they weren't necessary". Let me also add that the P79 gasket does not block coolant flow to the head at the (2) holes that Steve mentions in post #4.

-

There's an obvious difference (# of holes for coolant) between the early N42 gasket and the later P79 gasket. So what is sounds like you're saying is that the N42 gasket is more beneficial (more holes to allow unrestricted flow) for the later model head/block combinations over the P79 gasket??? Increasing flow to the head seems to make more sense; so, why did Nissan change it?

-

Here's some good email correspondence with my Nissan guy that I would like to share. Me... "I'm having sealing issues with the 1mm HKS metal head gasket, so I have decided to o-ring the block and use the factory head gasket instead. The question is which is the correct gasket to use?" Nissan guy... "I have attached some pics so you can compare the gaskets." "The part numbers referenced in the pics are: 11044-91MM1 is the HKS metal headgasket that Nissan Motorsports and others including myself were selling- it is now NLA. (You will notice that the metal gasket is pretty much identical to the early OE gasket in the oil and water passages) 11044-N4221 is the factory non-turbo gasket that was used from 1975 to 02/1981 11044-P7911 is the factory non-turbo and turbo gasket that was used from 03/1981 thru 1983." "The HKS gasket is just a big-bore, metal version of a 75-80 (N4221) gasket." "The thing about metal head gaskets is that the head and block surfaces need to be a near-mirror finish(low Ra or RMS numbers) for best sealing. I have kinda always had heartburn about using the (early style) metal gasket on the later blocks/heads." "You are probably on the right track with the o-ring+OE gasket setup, however, the turbo engine(P90 head+F54 block) calls for the P79 headgasket, so if you are going with OE, be sure to use the P79 one." "I remember when Nissan made the changes to both the P79 & the N42 & also the 240Z gasket back in the early 80's and arguing with the mechanics that Nissan would not have made the changes if they weren't necessary, and to trust that the Nissan engineers know what they are doing. It was something about keeping the water in the head longer for better heat transfer to the coolant."

-

Overheating? There is no mention of overheating in Ricky's post. Ricky, it would help to know what temperature you were experiencing after the 10 laps before the by-pass, ...190 degrees is awfully cool for 10 laps of racing.

-

I notice the 3 lines from 4,5,&6 return into the coolant flow after the thermostat housing. Are you using a thermostat or restrictor? Where is the temp sensor located? If you are taking the temp reading at the thermostat housing, that might explain the temp drop: hot coolant from 4,5&6 is by-passing the sensor.

-

You obviously have internet access, ...so search next time. See attached. autometer pyrometer temperature module installation.pdf

-

Wow! That's impressive.

-

L28 injector spacing & port dimensions

zxtman replied to Ferrariferg's topic in Fabrication / Welding

Understood. Let me know what you decide. Thanks. -

L28 injector spacing & port dimensions

zxtman replied to Ferrariferg's topic in Fabrication / Welding

Hey Ron, is this flange available? I was planning on cutting and modifying a stock flange for a new intake manifold, but this is a better option. I sent you a pm on this. Thanks. -

L28 injector spacing & port dimensions

zxtman replied to Ferrariferg's topic in Fabrication / Welding

...just an observation, the injector holes for cylinders 3 & 4 (on this drawing) should be on the opposite side of the runner centerline. That's how their shown and dimensioned on the previous injector spacing drawing. Again, just an observation. -

Looking for rack lock nut on driver side...HELP!

zxtman replied to jacob80's topic in Brakes, Wheels, Suspension and Chassis

...glad I could help. Ditto. -

Looking for rack lock nut on driver side...HELP!

zxtman replied to jacob80's topic in Brakes, Wheels, Suspension and Chassis

HRP World has them (p/n FLR-KML14x1.5). Click on the link below. Here -

...completely irrelevant. Agreed.

-

For obvious reasons, I think you should change the title of this post to "Short Burnout Video of a heavily modified 280ZX Turbo".