-

Posts

169 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by jmead

-

-

so in order to shift, you just ease up on the throttle and slip the gear in while the motor is idling?

Thats it, its suprisingly easy to do. If your going down a gear you just blip the throttle and ease it in, it will shift when you get the rpms right, pretty similar for upshifting. You let the synchros do the work, but the motor is very light and doesn't have alot of intertia so they can match its speed easily. It doesn't put nearly as much stress on the tranny as trying to do the same thing with a full engine attached.

-

this might sound really dumb but I have not seen anyone ask this yet.

so the setup weights some 800+ pounds with those heavy 30+ pound batteries. Is it possible to use light weight batteries that weight around 12 pounds like deka etx series or braille batteries for example?

Sure, generally larger batteries can put out more amps, or the same amps for longer period of time. For a strictly drag race only vehicle you could use a pack of lightweight high amperage batteries for short blasts down the track. The batteries white zombie uses I believe are 16lbs each.

-

with the instant torque a electric motor can kick out, why even bother with 1st gear? i mean people can slip the clutch on gas motors to leave the line in second... seems like 1st is pointless.

The motor draws less amps in first. It uses the same amount of power total (volts x amps) but the amperage is higher (and the voltage lower) in a higher gear so the motor would produce more heat.

-

Dumb question..

but if its a manual transmission how to you connect this to the motor?! I was wondering if you bolt on a flywheel to the electric motor?! (or bolt on a flex plate for an automatic transmission)

you can bolt on a flywheel, but I chose not to. Instead there is an adapter thamates the motor shaft and the transmission shaft.

-

How do you charge it out of curiosity? Looks awesome!

I'm still working on the charger. In the fuel filler door there is going to be a male connector, you will just plug it in and it will go into recharge mode. I hope to charge at about 25 amps from a 240 line, maybe 15 amps from a 120v circuit. Its going to be a two phase system with the pack charging up to 90% quickly and then bulk charge will shut off and several intelligent smaller chargers will top each battery off one by one until they are each completely full. This way I can get back on the road quickly from a nearly empty pack, but when it is plugged in for longer periods (over night) it will do battery maintenance.

-

So and idea how much it's costing in electricity? I'd think here in California it'd cost just as much as gas, as electricity isn't cheap.

Battery's aren't cheap to replace I'm sure, but I'd imagine overall maintanence goes down quite a bit.

Electricity is about $.10 per kwh. My pack holds 10 kwh, so, $1 for a full charge. Let me see you drive 40 miles on $1 worth of gas.

Here is a quick little video I took today while I was testing the motor mount.

http://www.jumpcut.com/view/?id=CEEFB4120A8211DD8F60000423CEF5B0

-

Agreed. There's a reason why so many people break driveline parts at the track. Do you think those people really don't go that hard on their car on the street? Most tracks are WAY stickier than street asphalt and provide a lot more traction, meaning people can launch at higher RPM sending more torque through the driveline.

If you're keeping the tires stock then I doubt there will be much issue. I'm more curious what driveability is like. Seems like it'd be weird driving a manual eletric car. I'm curious what clutch you're using though, as I'd imagine the massive torque from the motor to take it's toll when feathering the clutch.

No clutch, solid coupler from the motor to transmission. You don't need a clutch because you don't need to idle, when the car isn't moving the motor is simply off, plus pretty much all driving can be done in second. I saved quite a bit of rotating mass this way, and opened up a vent for air flow from the motor to exit the transmission.

-

I think you should use the FS5R30A Transmission rather than the FS5W17B or C.

if it has to take near 400 torque from an electric motor, which is almost instantaneous compared to the stock L engine, you may see exploding tranny bits soon.

I also think my tires will act like a "mechanical fuse" by loosing traction. If my motor is making 250ft/lbs but the tires break loose at anything over 175...then the transmission never "sees" more than 175. Right? I've heard it is good up until 250 or so. I've got a spare 5spd sitting here that I guess I'll hold onto for now, just in case.

-

I think you should use the FS5R30A Transmission rather than the FS5W17B or C.

if it has to take near 400 torque from an electric motor, which is almost instantaneous compared to the stock L engine, you may see exploding tranny bits soon.

I'm thinking its going to peak at 250 ft/lbs or so

400 is more the territory of twin motor / 2000A controller setups

-

A separate generator/alternator for regen braking would work, though it makes for a "messy" system. My motor has a shaft at each end, so I do have a point where I could attach a pulley that ran a load, perhaps with an electromagnetic clutch for on/off control to minimize parasitic drag. It would need to be pretty big, the 10,000 watt generator I have for the APU weighs 90 lbs and delivers 70 amps peak at 144 volts, which would probably take well over 30 seconds to slow the car down from 55mph to 10mph (this number is a complete guess, but probably accurate). Would still be usefull, I live in a very hill location so you could recover much of the energy used climbing a hill if you can spread the the regen recharge over a long period of time and not expect to come to a complete stop, just maintain a constant speed by adding load. Its such a cool concept to "take energy" out of your car's momentum, store it, and then turn it back into movement later.

I'm going to try it with manual for now, but it is common for EVs to have a small vacuum pump installed for brake assist. I will add this if necessary.

I'm hoping the weight out front wont make a big difference. The total weight of the front is about the same, but shifted a few inches forward. I could have but the batteries on their sides and had a taller pack that was more over the axle, but it came down to a trade off between body roll and steering response. I decided to go with the lower center of gravity. I will push it soon and see how it performs, but there are a few things I need to attend to first. I'm reinforcing the motor mount (I just learned that the motor may make even more torque than I thought, twice that of the stock motor) against twisting, and I need to attend to the rear brakes. One is dragging and the other is without shoes/drum at the moment. I may switch over to discs for simplicity, but they weigh more and I want to minimize rotating mass/unsprung weight.

-

I see you're running or going to be running a 144V system. All 12 batteries in series, correct?

Yes, the batteries are all in series for 144v.

I'm a little more than looking into doing this with my 1985 GMC Jimmy.

While not the most aerodynamic vehicle you will at least have a lot of capacity for batteries. Generally lighter vehicles are better but there is nothing wrong with a heavy one as long as you have a proportionately larger pack. Bigger GVW inflates the cost of the conversion because you'll need a larger motor and more powerfull motor controller to achive the same relative performance.

I'm also looking at using a generator for longer trips and possibly heavy loads. The SUV, which I am currently naming SUVolt, still needs to act like a utility Vehicle, and so it still needs to tow, and get around long distances.

You will probably need a fairly large genset for pulling loads and such, I'd guess around 20-30kw for any sort of long distance use. This would require a engine with around 60 hp constant output.

Where did you source your parts from? The guy that I have helping me thinks that I will have more or almost what you have into the entire car, just in the electric conversion.

The controller is from Logisystems, the motor was found on ebay, along with the wiring, battery lugs, shunts, contactors, etc. I had alot of patience, if I were to have been building it over a shorter timeframe I probably would stick to one of the several EV suppliers.

I had considered two banks of batteries, but I think I also want to go with a 144V system, the advantages of the higher voltage system seem to outweigh the lower voltage.

One bank is definitely the way to go for simplicity and ease of balancing. For such a large vehicle I think you'd need a bank of around 24 6v flooded "golf cart" batteries. These are around 200+ amp hour generally so you'd have more than twice the capacity (~28kwh) vs my 10kwh.

Any information you have would be helpful. I have been reading over some posts from a mailing list that is nothing but EV related, I wish I had considered this possible a few years ago, I might actually have started buying some of the needed parts before now.

Pretty much everything you need to know is out there, you just have to dig through multiple sources to get a pretty complete picture. EVDL.org and EVTech Digest in particular are great resources. Any problem you might have has already been solved by someone else somewhere, better to learn from their mistakes than make them yourself (cheaper too). I'd be glad to help with any specific details you need as I've probably read every page/post/forum/article on EVs out there. I guess I'm a little obsessive.

-

"This works out to 156hp, but several hundred ft/lbs of torque"

If you can make power like this, why is big companies having so many problems??? I think i know, but i hate to think it's true....

I'm using a brushed DC system, whereas every production EV uses a AC induction setup.

AC Advantages:

Regenerative braking

No brush maintenance

Higher efficiency

Higher RPM range (no transmission needed)

Can be sealed from environment

Can be water cooled

AC Disadvantages:

Waay more expensive

Lower peak power

Complex motor controller

DC Advantages:

Much higher peak power

Waay cheaper

Simple motor controller

DC Disadvantages:

Lower efficiency

No regen braking

Brush replacement every 100,000 miles

Must be air cooled (brush dust needs to go somewhere)

I can see why AC is the system of choice for production vehicles, and I'll admit that some of the benefits are very enticing, I really want regenerative braking for instance. But a DC system is still has so many advantages over a gasoline engine that the difference isn't worth the price difference in my mind. If you look at http://www.nedra.com/, the National Electric Drag Racing Association, all of the fastest electric vehicles in the world use DC systems.

-

very cool i was thinking about doing that aswell do you have any batterys where the gas tank "was"

how much do the batt's and electric motor weight compared to the gas engine?

The total system weight is about 850 lbs for batteries/motor/transmission

I've seen the stock engine quoted at 600lbs. Plus I removed the gas tank, radiator, engine starting battery, and the rear spare, so the total weight is probably about the same.

Lukaniuk - One charge should be good for about 40 miles on the highway, or 50+ miles around town at a lower speed. My commute is 25 miles each way, so with a short charge during class I can do 95% of all my driving gas free. (I've got plans for a small auxiliary generator when I need to make longer trips)

There is a pack of 4 batteries in the rear to even out the weight distribution.

That gaping hole is the future home of the generator. If I weren't going that route I could have put the rear batteries there and kept the car looking totally stock.

I plan on making the generator a modular unit that can be easily removed and replaced with a second smaller battery pack for longer range, or, in the future a ultra high tech LiFePO4 pack for 100+ mile range.

-

At the request of a few members here I would like to share my current progress on project AmpEater - the electric 240z.

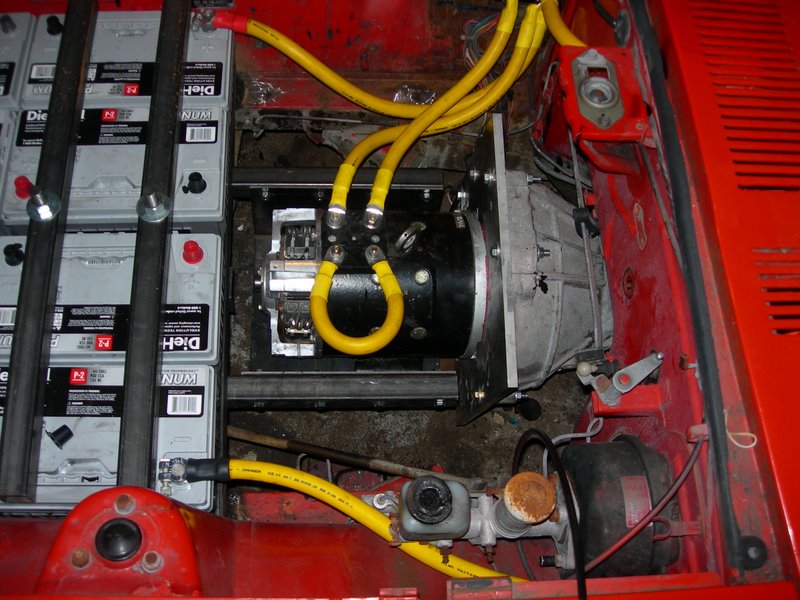

The motor is a 9" kostov 144v, rated to produce 15kw continuously (I'll be pushing it much harder than this in short bursts). The battery pack consists of 12x DieHard "Platinum" 12v 73AH AGM batteries which are actually rebadged Hawker Odyssey. Combined they weigh 720lbs and can produce well over 200,000 peak watts. The motor controller is a 144v/156v unit capable of 1000Amps, pumping out 144,000 watts peak. This works out to 156hp, but several hundred ft/lbs of torque.

The motor is connected to the stock 4spd transmission via a solid metal coupler (no clutch). This was made by welding the hub out of the clutch onto a metal cylinder bored to fit the 1 1/8" shaft from the motor. I had this done professionally as I don't trust my welding skills for such a critical piece. The car will stay in 1st gear pretty much all the time, even when stopped (electric motor does not need to idle). 2nd may be used for the highway. 3rd and 4th are not needed.

Acceleration should be quite a bit better than stock in the low end. I have not had a chance to really push it yet as the car is not yet inspected.

I have $6200 total into the car right now, including every bolt and connector purchased so far.

-

I think they are 10mm x 1.25 pitch.

Just the info I needed! Thank you so much

-

I seem to have misplaced the bolts used to mount the transmission crossmember to the mounts in the tunnel, and I have an electric motor waiting to be bolted in. I've tried every size I've got on hand and none seem to fit.

-

The side that bolts to the engine is what I'm after.

-

I'm in need of a bellhousing diagram for a 70 manual 4 spd (though I'm pretty sure they're all the same anyhow). Does anyone know where I could find this? I've googled around and can't find anything.

-

I've got a 240z shell with a blown engine, everything else in good condition.

LD28 engine w/ 5 speed transmission - $1700

L28ET turbo and exhaust manifold - $400

Intercooler - $250

Heavy duty springs for extra weight in front - $400?

Propane Injection System - $250 (diy)

New fuel lines, wvo tank, filter, heater - $500 (some diy)

extra $500 for spare parts and because nothing ever goes according to plan

so I've got $4k to take a lifeless shell and turn it into a one-of-a-kind "sports" car that potentially has little to no fuel costs, and at very least somewhat comparable performance to the original engine while getting double the normal gas milage. Seems fair to me

I'm not really expecting this swap to pay for itself anytime soon, if ever. Really, I just wanted a project that comined my interests and had a result that was worth the money invested, at least to me.

And I also doubt I'd be considering this if it werent for the fact that I've got a beautiful shell just waiting for an engine and I happened to be reading alot about biodiesel at the same time. Plus I've got a free summer and a little extra money....not for long

-

Im sure the exhaust manifold will bolt on. The LD intake bolts on to a normal L motor' date=' and the LD exhaust ports are the same looking as your N42/P90/any squareport head.

One big issue your going to have to take care of is the LD uses a front sump oil pan where the Z uses a rear sump. Im going to say its a matter of fabbing up a oil pickup and installing the Z pan.[/quote']

Thanks, that is all I needed to know. Will make things much easier, though I'm still going to think about that super charger for the future. I think I'm going to go with a rebuilt turbo instead of one off of a 100k+ mile car, since they are only a couple hundred $$. Anybody have suggestions for a diesel turbo?

-

One more question....how do diesels like super chargers? I'm worried about not being able to find a turbo manifold since I've heard that the exhaust ports are different. A super charger, however, solves that problem, as well as another. Diesels make most of their power lower in the rpm band, they dont hit the high revs most gassers make their max power at. A turbo, however, is best suited for high output at high revs, but most dont seem to make much boost at lower speeds. A supercharger, however, makes a fixed amount of boost from idle all the way up to redline, seems like a perfect fit. Not only that, but there are eaton superchargers made for imports that have electric clutches and the 2.5 - 3 L range. This could even concievably be paired with a turbo, also, for more low-end boost to help the turbo spool. The diesel engine has AC and PS, neither of which will I be needing, so one of these spots should be perfect for a SC

-

does the 280zxt exhaust manifold bolt up to the LD28? I've read on zcar.com that it does not, but I've also read that it does. Anybody have any knowledge on this? How did the other diesel 240z turbo that engine?

-

what size turbo should I be looking for? I want something that will spool quickly and devlop full boost pretty quickly. Diesels make most of their power lower in the rpm range, so a turbo that doesn't spool until 4000 rpms is as good as worthless. I dont want a ton of boost, either, just enough to pick up performance to a reasonable level. Engine life is just as important as power

-

I have been thinking about the turbo path. I have questions about how well a turbo mixes with alternative fuels. Does diesel have any "octane" rating like petrol does? It seems to me that dino diesel/bio diesel/WVO/SVO would all have different characteristics, but I dont see how you tune to engine to run with these differences when your fuel isn't always consistant.

Also, I've been doing some reading on propane injection as a possible turbo alternative. I've read that a conventional diesel only burns ~75% of the fuel to produce power, the rest is expelled as smoke and soot that gives diesels their characteristic dirtyness. I've read that with the addition of propane, this burning becomes much more effecient and this number jumps to ~95%, not only making the engine much cleaner, but producing more power at the same time. Does propane really enchance the combustion this much? Why doesn't everyone run propane?

Electric 240z Project Pics

in Other Engines

Posted

I don't have the spedo hooked up, but it pulls so hard i've probably hit 50 in that little parking lot i've been testing it out in. I can't begin to tell you guys how much fun it is. I used to think it was a fast car in stock form, now its almost silly. I used to be able to chirp the tires in a straight line, now I can roast them.

Careless - why wait? Sounds like your dad knows everything needed to build an EV. I think most starter motors operate at lower voltages than most street vehicles, but their operation is the same. There are lots of EV suppliers, though I got my motor on ebay actually. NetGain makes several sizes that appear very solid, if anything happens to my motor I'll probably switch to one of theirs.

Gollum - That thing is a beast! Their curve ends at 450 amps but that is just a fraction of what it can handle. At 1000 amps you're talking like 280 ft/lbs! At 2000 Amps.....

Just $4000....hmm....