DuffyMahoney

-

Posts

444 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by DuffyMahoney

-

-

11 hours ago, Tony D said:

He's diagnosed it properly, and this is a known issue. The angle the injectors enter the bodies will impact the wall of the curved runners and make one hell of a Tau Layer causing those cylinder to run richer.

The issue isn't really 3/4 running rich, its that the other four are running lean and the spark knock is coming from the hottest cylinders. Cool off 5/6 at a minimum to resist hotter conditions that promote the knock, as well as dropping the thermostat value to 160/72C.

Jet/Tune for 1-2-5-6 best lean torque or best rich torque depending on your tuner's preference and learn to live with that compromise....Or switch to a Sequential Unit like MOTEC and then cut cylinder fuelling on 3 & 4, (and maybe ignition if necessary) on those two cylinders. This is common in high end turbo builds where you have to pull timing per cylinder based on the results from the dyno pulls. Make sure you have EGT and/or WBO2 on EACH cylinder and data log it during the pulls and you can dial it out with a MOTEC (maybe others, I've only been around MOTECs doing this type of tuning.)

For the $5000 the MOTEC will cost to fix it... likely just instrumenting up properly, fixing the cooling on the rear cylinders, and tuning for them and not off 3 & 4 and leaving them run rich will be the chosen approach.

NOW ALL THAT SAID...

For all those who poo-poo the Shorty Mikuni Manifold, these issues DO NOT exist with it, because almost every injector angle will impinge on it's back wall and make a big Tau Layer of fuel on which to draw... it's make for hell tuning for transitional emissions, but for quick and dirty tuning where you are not very strictly emissions controlled that is a way you get homogenized fuel mix in each cylinder because all the cylinders make the same "sharp turn down" before making any other adjustments for the head entry.

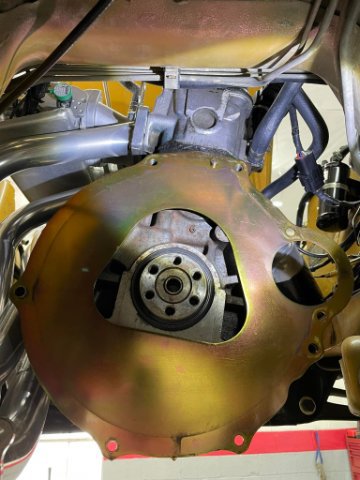

If you can find one, that is a cheaper option than going fully sequential and all that it entails.This is one of the reasons I am trying to move my ITB to a fuel rail/ injectors at the head. I plan to use my sk throttes, or go EFI hardware. Then a balance tube at my throttle bodies with hollow injector bungs. This intake out of Japan.

-

So it has to be some sort of injector issue, since thats really the only difference. Glad you are up and running

-

Most people use LS coils. I used R35 coils. None of the coils are smart:) Most have igniters built in these days.

-

On 4/25/2022 at 7:09 AM, Dat73z said:

Yeah I did some test pieces over the weekend and any sugaring from the small tacks is consumed on full penetration.

Really I shouldn't be penetrating through to the other side on tacks but that is mostly due to alignment (ex partially cut mandrel radii where the tube ends arent perfectly concentric so there's only 1/2-2/3rds wall thickness joint to joint at some areas) and my lack of skill.

Since I'm just a hobbyist I'm still trying to find ways to save any gas especially with the way prices are nowadays. High priced gas prices to drive to get more high priced argon adds up.

I've been thinking perhaps for the longer sections where the welds are close to the ends of the tube I could crumple an AL ball with some gaps around the edges and shove it into the pipe to produce a smaller argon "chamber" as opposed to filling the whole pipe every time. Either way I'm about 1/2 done with my first full custom SS exhaust project now so I may as well keep experimenting and learning

As an aside another reason I've been going through so much gas is I've found SS can really move around a lot when welding. So most of the backpurge gas I've used is due to purging the pipe, welding a bit, then walking away to let the part cool. I've found the part doesn't move much when I do this. If I could weld an entire section in one go instead of constantly coming back and repurging then I could save a lot of gas

We use tin foil over the end, then poke a few holes, let it purge/ fill for 10 or so minutes for a longer piece. Keep the gas going while welding. The joints should be clean and as close as possible. No filler rod

-

-

-

A little update on my ITB build. In the middle of this build I decided to buy a historic building and renovate it, then have my first child, so everything got pushed to the back. I am finally finding time to work on it all again.

I think one of my biggest issues was voltage from my old alternator, upgrading that has made everything more happy.

Well finally got my osgiken clutch out and went with a stage 1 from exedy with a lightened steel flywheel. The osgiken was way too hard for me to street drive and my wife hated it. It was poorly installed by me and it's a pretty racey clutch.

I sent to Z car off to a guru. Andrew Kazanis, he swapped the clutch, found my clunk (exhaust hitting during load) and change my rear main seal. Then his buddy Matt finally fixed my passenger regulator. Which hasn't worked in years. I went with a repopped one. Matt thinks my rear end is a little noisy, but Andrew can't hear it. I cannot thank Andrew enough for all his help. He is a friend and just an all around great guy.

If I was to start this over, I would pick an ECU that someone in the area knows. I think ITB is something I jumped into, without enough knowledge or money. So many small issues popped up, and all stopped or slowed me down massively. You really end up chasing your own tail a lot, trying to do all of this. A few on here and on facebook have helped a ton. Tioga, Richard Boyk, Rodney have helped so much. I can't thank them all enough. Maps, settings etc... Somehow they have completely different views on pretty much all of the maps, but all are very knowledgeable and all know a ton more then me. It will be interesting as I road tune which maps/ settings I like more.

Haltech is nicely made stuff, but I found their original software extremely hard to figure out. They have since done a massive massive upgrade (NSP) and it's much easier to use now and much more intuitive. Also tells you when settings and maps are in conflict. Which is huge! I am getting pretty confidante and I think I have all the small ECU settings correct. The ECU should start self tuning. So time to drive her and get it running right. I literally got stuck for months from one stupid box being checked, I couldn't get the idle right during cold starts!

IAC or not. I will most likely attempt to use IAC again. I have it fully plumbed and wired, it's also a learning feature of the ecu, so it should be the best route for cold starts. I will turn it off after say 100 degrees, which the motor idles fine after that. My hand throttle works, also using timing to help cold starts also helps a ton.

Also don't rip out perfectly good jenvy throttles, for vintage SK throttles unless you are dumb:)

-

1

1

-

-

18 hours ago, Dat73z said:

@DuffyMahoney yeah thinking about it more as I own my argon bottle and get discounts at my local gas supplier...another $100 of argon won't break the budget when I'm already a few hundred in stainless tube.

I am curious how many actually backpurge their tacks for exhaust work. Some youtube vids show most don't. I can understand why for the food industry you wouldn't want and defects or crevices in the welds at all

It's a better weld for sure, it's easy to see if it is. Is the weld raised? Or is it flush or sunken slightly? I would say most wouldn't care, but any high end exhaust would be purge welded.

-

I own a brewery, everything gets purge welded. Fairly easy to do.

-

Were the injectors flow tested on the Heritage?

-

Whats your rational for it? Ford guy? DOHC v8?

-

3 hours ago, madkaw said:

I would start swapping what you can . Injector connectors , injectors , coils .

Good idea, also test to see if all coils are firing.

-

Could the Coil on plug not be firing and causing unburnt fuel?

-

That injector angle looks fine. Is there flow data entered into the ECU? 350cc seems big, but not crazy over the top. I doubt that is the issue.

-

Flow tested injectors? Then setup per cylinder injection till it's perfect? I have full sequential injection and setup each injector based off flow data.

-

15 minutes ago, calZ said:

I saw the snippet about 3/4 when reading about the head yesterday. Do you know if he did anything specific to alleviate the 5/6 problem? Is his plan for that just the internal changes being enough?

I don't know his english is pretty hit or miss.

-

On 1/10/2018 at 7:47 PM, Nismospek said:

Found a nifty calculator. Decided to convert everything to 25 inches which is what I believe Rebello uses.

100 lift 58 cfm

200 lift 117 cfm

300 lift 158 cfm

350 lift 178 cfm

400 lift 189 cfm

450 lift 192 cfm

500 lift 200 cfm

550 lift 205 cfm

600 lift 213 cfm

650 lift 219 cfm

Mine actually flowed the best at .500 lift. 235. Interesting that his flows higher as lift goes up.

-

Ken is a great guy. I am stoked for his project.

Question Cylinders 3/4 also seems to have the same shape and size as other cylinders. Why?

Answer: This is to make the exhaust flow velocity uniform in all cylinders. In addition, a new water jacket is installed between the EX3 / 4 ports, which tend to accumulate heat, to make the head temperature between cylinders uniform.

This is done to ensure the consistent exhaust flow velocity in all cylinders. In addition, a new water jacket is installed between EX 3 and 4 ports, which tend to accumulate heat, to make the head temperature between cylinders steady. -

The casting quality and the effort that went to this head is just amazing.

-

Unless Mikuni starts remaking them (they should), prices will continue to rise.

-

Yeah I was told to stay away from the Hanshin coils. I have the hitachi. The audi coils get used a lot in the Z world. Nice looking as well. The hitachis are around 50$ here. So it's fairly hard to beat price wise.

-

I hope you find them.

-

In testing the R35 coil came in 2nd against the coils they tested. No clue on the P100-T. The r35 coils are 40-50 each new.

-

On 1/2/2022 at 12:34 PM, 240Z Turbo said:

Bosch P100-T coils are twice the spark energy as the R35 coils and about $100/coil.

Any data to back that up? Interesting looking coil

Anyone seen this L6 head project?

in Nissan L6 Forum

Posted

He is claiming he wants to remake the FIA head. Time will tell, he seems to have deep pockets.