jersey280

Members-

Posts

48 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jersey280

-

Morning all, 76 280z owner here. Just wondering if anyone has been able to source male/female electrical connectors that came on the factory gauges and interior harness? Thanks!

-

1976 Alternator Upgrade issue--Please help!

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Alright, Green on the plug was a no go. I did however temporarily rig it to a switched to a switched green I had inside the cabin. 14v immediately on start and she turned off as soon as I turned the key off..Problem solved, thanks again! -

1976 Alternator Upgrade issue--Please help!

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

I'm diagnosing her now. I think I found a green in the old plug that is switched power and I'll see if she wont turn off. -

1976 Alternator Upgrade issue--Please help!

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Thanks NewZed! It's easy to find a 12v source that comes on with key in the ON. Unfortunately, I cant seem to find one that gets 12v at ON, but turns off after car starts. Any suggestions? -

Hey guys, Recently completed the internally regulated alternator swap on my 76 280z. I utilized a brand-new alternator from a 1983 280zx NA. I followed the directions from atlanticz, specifically the part for the 1976. The issue I am having is the alternator will not start charging the battery until I rev the engine over 3.5k. Once I do, it maintains a constant 13.8+ and works perfectly. I began testing and noticed the bottom plug to the "T connector" has zero reading at all times, including in the ON position when it should have 12v. I believe this is called the "L" connection. From what I believe I have gathered from searching, this is some-how tied to charging lamp, but also the excite for the alternator to start charging? If so, I have removed all stock gauges and went with speedhut gauges. Is it possible that the lack of a charging light is causing a break in the connection and causing this issue? if so, any suggestions how to work around this? Thanks so much! p.s..The new gauges also eliminate the parking break indicator, so I just cut the yellow wire under the passenger seat to solve the battery drain issue that is specific to the 76.

-

Bunkhouse, It sits well over 12.5 volts, gives every indicator of a good battery.

-

Hey guys, Been dealing with an issue regarding starting for a while now. I own a 1976 280z, which struggles to get started but runs fine once it is (separate issue all in itself I am tackling). The issue I need help with today is the quick drawing of my battery while attempting to get it started, I almost always have to use a jump pack to assist. The battery is a couple year old optima red top that once off the trickle charger is around 13.6. It also has new battery cables, reman starter, new ignition switch as well. I can really only crank it for about 15-20 seconds and the battery becomes basically dead without the assistance of a jumper pack. While searching for answers, a couple posts have suggested a possible grounding issue, so I cleaned up the battery to starter ground (top bolt of starter) and the main body ground above the battery. Other than that, I am at a loss for what is causing this large draw. Any suggestions would be great! Thanks again!

-

Fuel pump safety-Please help!

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Newzed, this indeed solved the issue! Bent the tiny rod just so slightly and now the pump stops when stalled. Additionally, it solved the continuous pump running problem while in "on" position. Thanks for your help! -

Fuel pump safety-Please help!

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Thanks Zed, I will try that. Is this the only thing that controls the safety shut off of the pump? The pump continuously runs in the "on" position prior to turning it over to start as well. I believe it was determined that is correct on my year, can you agree? Thanks again -

Hey gents! I own a 1976 280z, in which the previous owner swapped out the engine for one from a 1978 (N42 head, n42 block). Additionally, the fuel system has been modified to use a walbro external pump with a palnet fuel rail, with an after market FPR. The issue I am having is after I force the car to stall, the fuel pump continuously runs and does not turn off as it should to prevent a humam BBQ! I did notice that the 78 requires a 2 blade style oil pressure sender, and the 76 a bullet style. Currently, there is a bullet style connector on it. Would this possibly be causing the pump to run continuously due to the wrong sending unit? I am at work but I believe the wire leading to it is a single green. Any suggestions would be great!

-

Trouble on initial starting..please help

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Thanks for all the suggestions guys. Newzed, I have an aftermarket FPR, without a check valve currently. I suspected this may cause an issue, but I always allow 30 seconds(ish) before cranking for the pump to prime. Other than that, ive replaced all senors related with NOS and adjusted timing/replaced cap rotors ect (she runs great when I get her going). -

Trouble on initial starting..please help

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Great idea thanks! I will get around to that shortly. If this works, any idea what may be causing the pump to stop pumping during the turn over? -

Hey guys, Own a 78 280z. I am having the issue of a "cold start", when its not "cold". Whenever I want to start the car initially for the day, it takes me 4-5 good rounds of cranking to get her going. This happens at any temperature outside. I feel like the fuel pump may be shutting off once I begin cranking? Any ideas what may be causing this? Thanks in advance!

-

I'm about push this in a lake..Plz help!?

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Most were too loose, I cant say by how much, i just corrected. The bucking/stumbling is more accurate description then "rough". Ive read small things like pedal adjustment/replacement and throttle linkage repair or replacement may help, yet I feel its more deep the these adjustments.- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

I'm about push this in a lake..Plz help!?

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Appreciate all of the great ideas. I had originally adjusted the valve lash. Drove the car about 70miles. Then issues had arouse on the trip home (loss of power, backfiring out exhaust). I checked valves again, appeared to be slightly off. I adjusted again to cold setting of .008/.010 and started her up again. I was able to eliminate the intake backfire by advancing timing to about 13BTC. Took her for a spirited drive, no issues. Car just seems to have a rough low rpm driveability, bad boy wants me to pedal down. Wondering what would have caused the valves to go out of spec so quickly?- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

I'm about push this in a lake..Plz help!?

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

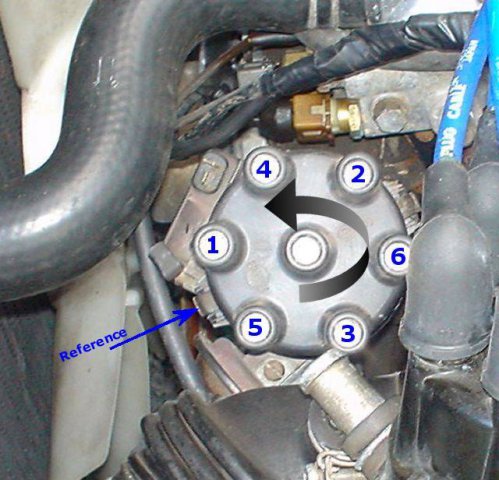

Zhoob, I checked with a screw driver down the plug hold and it definitely feels to be TDC. I also used the photo graph attached to verify. Is it possible my injector connectors got swapped? how can i verify? edit: couple days ago I also adjusted all valves to spec, which werent off by much.- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

I'm about push this in a lake..Plz help!?

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Newzed, i believe i am doing this correctly. See attached photos verifiying. It all looks squared away to me? Timing mark on crank at 0 to verify TDC Sproket hole 1 Oblong ridge lines with V perfectly- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

I'm about push this in a lake..Plz help!?

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Thanks Newzed, ill take a look at it tommorow and check back in.- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

Hey guys, I'm nearing my wits end with my car (76 280z with a 78 engine n42head n42block). The P.O seems to have deleted all of the emissions and most of the vacuum lines (egr, pcv, bcdd all blocked off). I am having this issue now where i have back firing from the intake at idle (dozen or so per minute) and after warm backfiring out the exhaust and loss of power while on the road. Additionally, the car seems to start at a very high idle. The fuel system is all custom cell with -AN set up (pressure great), valves adjusted to spec, injectors rebuilt with new gaskets, pintels, screens ect, Vacuum was checked and rechecked including with carb cleaner trick. Timing checked, temp senor replaced, all connectors replaced with new, all new plugs wires cap and rotor, new coil with internal regulator (external resistor bypassed), AFM checked for any possible signs of wear or anything, shows nothing looks great. TPS looks good, engages when suppose to. I am obsessive and have done tons of research and I cant seem to figure this out. Can anyone save this Z from being driven into a lake due to frustration? Thanks!

- 13 replies

-

- backfiring

- high idle

-

(and 1 more)

Tagged with:

-

Brake safety switch delete...please help?!

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

JHM- Thanks for the response. It appears that the safety switch feeds from the front and rear master. It then has 2 lines for the front and 1 for the rears. Is there some sort of bridge you used to connect the 2 fronts to feed to the single proportioning valve? SleeperZ- I agree, the safer the better. I assumed the brake gauge light was inside the cluster that I have removed? Which would cause me to no longer be able to read the signal it produces. Additionally, we are driving tin cans which weren't designed to be on the roads today (for example: federal speed limits were 55 in 1973, the advent of airbags and crumble zone technologies) they really don't get any more unsafe then they already are. -

Brake safety switch delete...please help?!

jersey280 posted a topic in S30 Series - 240z, 260z, 280z

Hey guys, Own a 76 280z with the brake safety switch block that is leaking (the thing under the booster that looks like a proportioning valve). I have replaced all of my gauges with a modern style and have no need of the indicator light that would be displayed by the safety switch. Has anyone ever deleted the switch? Does it cause proportioning issues? If you did any tips or ideas on how to rerun the lines? Thanks! -

Hey guys, I own a 76 280z and recently purchased a intellitronix fuel gauge. The gauge only reads the following ranges. 73 to 10 ohms 0 to 90 ohms 10 to 180 ohms (or 0 to 30) And 240 to 33 ohms From my research, it appears that our stock fuel sending unit is 90ohms empty 10ohms full. The closest range appears to be 73 to 10. Will that give me close to an accurate reading or is there a sender I can use with the stock tank to make this work? any ideas would be great thanks!

-

Hey guys, 1978 280z L28E. Whenever I turn the key to any position forward the fuel pump runs constantly. Isn't it suppose to prime for a few seconds and then stop prior to turning the car over? Appears to be a replaced fuel pump by P.O looks relatively new. Any suggestions would be great. Thanks guys

-

Hey guys, Just replaced all of my bulbs with LED bulbs in my 78 280z. All work fine except my rear hazards. My front LED turn signal bulbs blink fine for turn or hazard mode. As soon as I remove and replace both original halogen rear bulbs, they turn solid and no longer flash. I can replace one rear with an LED and another with a halogen and they blink. It appears the old style rear bulbs are causing something to happen that the new LED's are not. Any idea what is going on? Appreciate it!

-

Injectors making clicking noise?? PLZ HELP

jersey280 replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Thanks for the reply. Issue is, car never did it for years, now it does. It definetly doesnt sound like something that it should do either. It sounds just like a rapid fire clicking for about 1.5 seconds then goes away. Very odd.