-

Posts

13742 -

Joined

-

Last visited

-

Days Won

67

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by JMortensen

-

-

I pulled one apart maybe 10 years ago. All I remember about it is that it's not a big deal at all. I had the spring out and all that, I think my purpose was to clean and grease the bearing. Take the column out of the car and figure it out. Just not that complicated.

-

16 hours ago, clarkspeed said:

...As you can see, the door has a lot of resin in it and that equals thickness and weight. It's got to be 2 or 3 lbs heavier than it should be. And of course I laid in 1 or 2 more layers than I needed to.. I was just happy to get a ready to paint door out of the process...

But the other thing I learned in this process is I don't like it! It is quite tedious mixing resin, applying layer, repeat, repeat, repeat. The bigger the part, the more you repeat. You can only get so much down in 20 minutes. I mix a quart of resin each round. So my conclusion is small parts and repairs are fine, body panels are a total pain in the ass. Much cheaper and easier to purchase, if you can.Yep, my front end is way heavier than it needed to be also. Didn't want to make a mold. Also went twice thickness on Knytex, which was totally unnecessary in retrospect.

Totally agree about it being a PITA and not fun, but I want to do a diffuser and floor pan, some diffusers for the front splitter, dive planes, some other stuff. Stuff you can't purchase, or that wouldn't fit my car if it was made to fit a stock one. -

It looks like you just molded it, no vacuum. Is that right? I bought a vacuum pump and haven't used it yet. Can infuse resin or lay it up wet and then apply vacuum, and can get fairly complicated. I got majorly sidetracked, but would like to get back to it at some point.

-

Cary's problem is he doesn't talk enough; the dude is a reservoir of knowledge. Pretty much every time I was waffling on some part of my car, he made an argument and I went the way he suggested. That I have 257 "reputation points" and he has 28 shows the errors of the reputation point system.

-

The newer cars on AC often have it integrated into the dash display, and you see it there. Older cars will give you sector times, but not real time data. I guess it's more realistic that way, but like you, I really love having the data realtime. "Oh, I got on the gas earlier and I made .2 seconds by the end of the straight" kinda stuff.

-

Isn't the factory alternator 40A? Is the tractor one smaller, or internally regulated? Why not just use a good stock setup?

-

This was one of the few allowed brake upgrades in VARA racing 10 or so years ago and many people ran it. It's a huge increase in heat capacity over stock and very worthwhile if it's your only option. If you have other options, there are better, lighter BBKs out there - but they mostly require bigger than 15" wheels. And yes, matching front to rear and getting the bias right is important.

-

I wanted to go VR but didn't have the PC to run it and was worried about getting motion sick. From what I've read having a really really fast PC and being able to up the frame rate helps a lot. With the curved monitor I'm running a $500 i7 that I bought used off of Amazon. Had to add a cheapo graphics card for $150, but runs the ultrawide monitor just fine. I was tempted to go crazy and get a real gaming computer and VR, so that means it will probably happen in another couple years.

Motion rigs are also super cool. Saw one that just does yaw for $2K, and you can get them with yaw, pitch, and heave for $6K. I've seen them used with monitors, but seems like VR is definitely the thing to do if you're going that far. There are prebuilt systems that go all the way up to $30K+ as well. It's definitely an advantage for a racer to be on a sim. As you say, all the pros are practicing on these, and I've found that at least in the sim I've made big improvements. Like you I haven't been racing in a while, covid + health issues. Ready to get back out there, but now looks like I'm going to cash out on this house which has about doubled in value in the past 2 years and move so maybe no racing in '21. We'll see.

I developed a strategy for tuning my driving skills which might help someone else. The gist is to stick to one track and run it with as many different cars as possible.

I had a couple cars that I was immediately fast with, like the Alfa 155 touring and Jim Clark's Lotus F1 from the 60s. When I tried with GT3 cars or GTP cars, ALMS prototypes, just about anything else I'd get my ass handed to me by the AI, which I always have set as high as it goes. The ALMS prototypes would just walk me so badly I couldn't figure out how they could possibly keep it on the track, and I knew the AI isn't that fast. Could not figure out what I was doing wrong, could not follow them to try and find a different line either because they'd leave me so quickly. I would also try one car at Spa, then another at Zandvoort, then another at Laguna Seca, then another and Nurburgring, etc. Finally I decided just to run one track, Nordschleiffe. I picked it because it's long, has just about every kind of turn imaginable, and it's fun. Then I picked a GT3 car that I didn't know at random. BMW Z4 was the first one. Worked on it until I could win. Then switched cars. Did the same thing. After about 10 GT3 cars I went back to my favorite, the 911 RSR, and knocked 10 seconds off of my lap time. Granted, it's a long lap, but that's still a huge gain. Now I can put 16 cars in the field, pick just about any GT3 car (there are a couple dogs), and get the lead in about 2 laps.

ALMS cars are easy to beat now too, but I still can't drive the Player's Special 79 Lotus F1 very well, so I'm going to keep working at it. When I get that one down, there is a mod to make the AI faster in AC, I'll do that next. The gains didn't really come from adjusting the line, only minor adjustments there. It was getting the front end turned in, aka not overdriving into corners, and getting on the gas sooner, and adjusting suspension/tire pressure settings to get heat in the front tires. -

Started out on PS4 with GT Sport, Assetto Corsa, Assetto Corsa Competitione, and Dirt 4.

GTS was great in that I could run with people over the net, but I got really tired of being punted going into turn 1, or assholes brake checking to spin you out when you started putting the pressure on, or people running into you and then you get the penalty. Ended up going to PC. I tried iRacing and didn't like the price, also hated that if you whif when practicing you need to go back to the pits to fix damage. It's a friggin game. I understand if you want to make the races go that way, but in practice it should be looser and more fun. I understand my lack of a DD wheel is what made the steering feel like a 70s Cadillac on iRacing and RF2. Just not enough feedback. I've been running Assetto Corsa pretty much exclusively. Steering feel is the best of any of the sims I've tried, including its successor ACC. There are also a ton of tracks and cars that you can download for minimal $$$.

For the sim I have a Ferrari Alcantara TH300 and Fanatec pedals, TH8A shifter, and a 32:9 monitor. I bought a pedal/wheel stand off of ebay that you set in front of a chair. Kept pushing it away, so I eventually got out to the shop and welded up a base that attached to the original stand and used an old Recaro from the Z's street days, complete with slider. -

Looks like one of the pages accepted, the other didn't but the one that did has 41K members, so I expect that will help. GLWS.

-

Hey I tried to post this for you on FB, but because the title says LSD FB thinks it's drugs. Just FYI. If you want, repost and I'll post a link there for you. It will sell right away.

-

On 7/2/2021 at 7:04 PM, clarkspeed said:

My fallback has always been Puhn's How to Make Your Car Handle. It's an old one but i think it covers the basics well.

Plus you can see my ex-boss from the Porsche shop I worked at 20+ years ago in there. Well, his hand, anyway. "Guy Ober squares the suspension on his race Pinto using a plumb bob." Something like that. LOL

Best thing I've seen on tuning race cars in a long while was about running sweeps. By sweeps I mean go too far one direction all the way to too far in the other direction, then find your happy setting. When I first started racing in the mid 90s, my roommate was a Nissan master tech who had been autocrossing for years. Among his pearls of wisdom were: "Never go bigger than a mild cam on an L series, because you'll lose bottom end" and "run about 1.5 degrees negative camber in the front, slightly more in the rear" and "V8s are too heavy and a Z won't turn with one." He had learned these rules from somewhere and parroted them exactly. I listened to him because I didn't know any better and he was the expert. Then Carl Beck's Z car email list started up and I got on it and people were running big cams and had V8 autocross cars with 3+ degrees of camber. He said: "You don't know who you're listening to when you get advice on the internet." That's true, at the time I didn't know John Coffey, Pete Paraska, Gary Savage, etc at the time, but man, were they right and he was wrong. Great to find out we were doing it wrong, but doing sweeps would have told me that without having to run into the right people.

Start with too little camber. Go run it. Keep adding neg camber until the inside is obviously too hot, then back it off to where it makes the tires happiest. If I had done that I would have found the answers years earlier and been a lot faster. A quick way to shorten this whole idea up would be to say: "If you haven't gone too far, you may not have gone far enough."

BTW that button clutch is hawt. I love my dual 7.25". Not very streetable, but man does my T56 shift fast with one. -

Sure, separating the flow entirely would work too. I wouldn't put it right at the air dam though. Oil is a surprisingly big fire hazard, so I'd set it back and keep your frame work out in front to protect it. You don't need that much open space to cool the car either, I'd block the top grill entirely (with black material recessed a bit if you don't want it obviously blocked off, and then split the opening at the bottom to feed both the rad and the oil cooler.

-

I would build a duct from the front bodywork to the rad to force all the air that goes in to pass through the radiators, and then put the oil cooler on the backside of the rad. That's how I did mine after emailing with one of the oil cooler companies about it. Can't remember which company I was talking to (C&R?), but the idea was that the oil gets hotter than the coolant, so you want coolant first. They also steered me away from a rad/oil heat exchanger.

The main point I got out of it was that the bigger the temp difference the better it will cool, so by putting your oil first you're raising the temp of the cooling air hitting the rad rendering it less effective, and done the other way there will still be a significant difference between the air exiting the rad and the hotter oil, so it will still have enough capability to cool the oil, assuming all the rads are sufficient size, and it looks like that's not a problem. -

If I ever redo my headers I'm going Tri-Y out to the side pipes. Looks good! Did you dyno with the previous ones? Would be curious to see numbers on both.

-

Forgot to mention, the problem you run into with adjustable LCAs is running out of threads on the tie rods. If you go to a turnbuckle style you can make it a little longer to start with and then you're length adjustments are split between both sides, instead of all the adjustment happening on the inside as it works stock.

-

1

1

-

-

I drilled the knuckles out to 5/8 and used a bolt. Originally I was planning on using the stock rack and so I made my own tie rods by cutting the ends off of a stock set and welding them to a swaged 5/8 steel circle track tie rod. Wasn't hard. If you do this just order a really long one and cut in half and use the LH threaded side with the RH threaded stock end and vice versa.

-

It's Jon, but everyone does that.

You don't need a spacer in front. Adding one doesn't change geometry, it will just reduce available bump travel, and gaining some travel is really the main point of sectioning struts.

You will need a spacer in back. The rear strut housing should be 2" longer than front on a 240, 3" on a 280. If you don't have a spacer in back, the suspension will be really extended as compared to the front. If the rear tops out too much you'll get a loss of traction.

The hub is below the strut tube, so adding length to it doesn't change the roll center. If you want the roll center higher then you have to raise the inner pivot of the LCA, or lower it on the outboard end, or both.

You will then need to fix the bumpsteer, as changing just the LCA angle will screw up bumpsteer. To change the bumpsteer you can raise the rack or lower the outer tie rod, or both. -

Welcome Joe!

If you're going to modify the 72, this is a good place to ask questions before buying parts.

My first Z was an orange 72 auto. I'm still not over getting rear ended in that car, which I bought from the original owner in '93 or '94. Loved that car and had all the parts to do a manual swap ready to go.

-

Leaving a gap on super thin sheet sounds like a recipe for blowing holes to me.

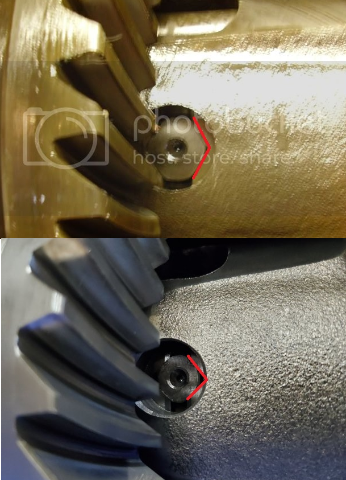

I butt them up tight and then use low heat and let the weld pool sit there a little longer. Usually get a little bit of protrusion on the backside, so I have no fears about penetration. The brake duct might not be a perfect comparison as the tube is a little thicker, but in the second one you can see the side that was welded (around the tube) and the backside where I welded a stiffening flange around the edge of the backing plate. -

Not sure why you felt the need to repost the same question in the FAQ area, but nobody can answer it there. Answers have to be approved by moderators. Plus it's not exactly a frequently asked question.

-

I don't believe they made a 2 pinion LSD for the R200. Only one I know of that isn't 4 pinion off the top of my head is R160, and that's a 3 pinion IIRC. Pull the cover off and count the cross pins to be sure. Would be interesting anyway just to see if it has the more aggressive ramps or the less aggressive ones. The bottom is the less aggressive.

-

Laguna Seca has nasty noise restrictions and walls just about all the way around the track. If you look up "muffler Laguna Seca" you'll find a bunch of weird shit like this, which I've heard people refer to as "donkey dicks." Apparently the idea is to get more muffler on the car, and then point the exhaust away from the sound meter. The corkscrew looks fun, but after doing it a ton on sims I don't think I'd bother with the hassles to get out there, YMMV.

Way further south (just north of LA), but your car would KICK ASS at Streets of Willow, which is a very tight road course. I think top speed I ever saw there going down the hill was 105 mph or so. It is so twisty you wouldn't feel like the lack of power was that big a hindrance. Would also be interesting to see how a well set up Prepared autoxer would relate to Coffey's ROD with sequential gearbox and all of that. IIRC he ran a 1:28 at Willow Springs. Big Willow and Streets are two tracks at the same site. The big track is much faster.

-

Looking good!

IMSA GTU vintage racer build

in S30 Series - 240z, 260z, 280z

Posted

Got that one from Coffey back in the day...