-

Posts

13742 -

Joined

-

Last visited

-

Days Won

67

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by JMortensen

-

-

That first Setrab cooler looks like what bjhines used, small and easy to package, but he reported 350* temps after installation, behind a 6 cyl.

I was thinking about going quite a bit bigger, more like the second one. If I ran a flat panel between the frame rails and 2 NACA ducts to feed that carbon duct, I think that would work nicely. Then I thought I should put one or two more in the panel further forward, just to blow on the trans. It's taken me so long to get to this I've forgotten some of what I read about it, but I do remember a Miata guy who had to install NACAs to blow air on the trans and diff without coolers. I think the same guy tried a plastic panel and it melted from the heat.

Did DM Gira about this, he seemed to think what I was doing was huge overkill, but I guess that's sort of a theme for me. It really does seem like these diffs get HOT though, and if you're going to do it, might as well do it right.

-

Pattern looks about right for vinyl top: https://www.classiczcars.com/forums/topic/58323-vinyl-top-as-an-option-240z/

-

This has been a back burner idea for me since bjhines installed one 17 years ago. Last year I installed an oil cooler thinking about doing track days (LS engines get the oil HOT) and so now I think is the time to get the diff ready for track duty as well. Here's John's thread:

I'm finally getting around to doing one for myself. I am not a fan of the Tilton pumps, they're expensive and so I started asking around and I got some good info on pumps, so thought I'd share my findings.

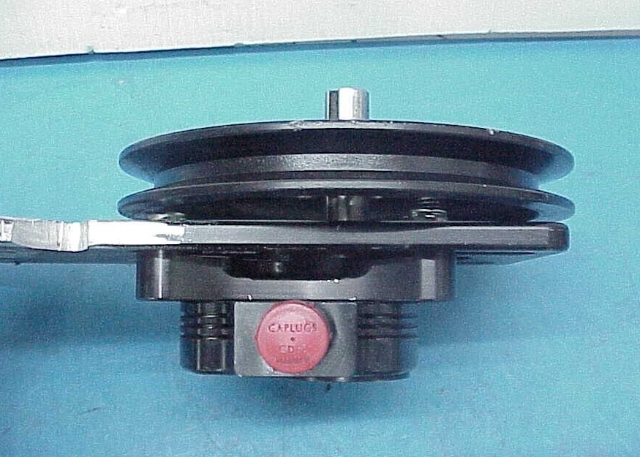

NASCAR runs mechanical pumps off of the pinion, using essentially a single stage dry sump pump. These are run with a V belt, and then you put some sort of pulley on the driveshaft or the pinion flange. This has a couple advantages, mechanical pumps are gear driven not electric motor with a diaphragm, so should be more reliable. Don't have to remember to turn it on. If you buy the pump used, it's pretty cheap.

I bought a pump with a 6.25" pulley and bracket that bolts to a 9" Ford diff for $100. No fittings, no lines, no cooler, but it's a start.

When I had my driveshaft built I screwed up my measurements and it came out a bit long. It fits, but just barely. Plan is to take the driveshaft back out, have it shortened, and then either modify a pulley to bolt in between the pinion and the shaft, or weld the pulley either the shaft or the pinion flange, depending on which works out better in the space.

I'm still considering how to mount the cooler, how to feed it air, and how big to go. I definitely want to go bigger than John did, as he measured 350* AFTER installing the cooler, at the end of a 20 min session with the 6 cyl working to build the heat. Katman had described breaking the needle off of a 325* gauge in a session with a 6. I want to install, and not worry about cooking the diff again.

I have the fuel cell and Accusump offset to the right side to move weight. Thinking I have room to put the pump to the right of the diff, then can run the oil lines to the left side and have the cooler placement somewhere in the stock muffler area. Feeding air thru it effectively might be a challenge. Preliminary thoughts on cooler feeding/exhausting:

1. Put a NACA duct in the quarter window and run a 3" hose down to the floor (can go through the fuel cell cover, and then feed the cooler which sits horizontally. I have doubts that the cooler will flow a lot of air in this position. I don't have pressure readings, but I'm thinking that right behind the open window is not a high pressure zone, and the air will be exiting near the gas tank, which I am hoping might be sucked out by the wake under the car, but I don't anticipate a huge pressure difference.

2. Finally get off my ass and put a flat bottom on the car, at least between the frame rails, which is legal in XP. Plan here was to use thin aluminum, maybe .040" thick. I worry about leaks onto fiberglass or cf that is flammable. If I did the aluminum panel between the frame rails, then I could run some NACA ducts in the floor and maybe a pair of 3" hoses to the cooler, possibly making a fan shroud type of setup so that all the air goes from the hose through the cooler. I think this might be a better way to feed the cooler, but I'm still not sure about getting the air out the other end.

Eventually will do a diffuser, and if I leave space between the diffuser and the body I think that the increased low pressure from the flat bottom and diffuser would help to exhaust the air out of the cooler. Might even be able to make an exhaust duct from the cooler to the slot between the diffuser and the rear valance, but I don't think I have the time/funds to do a diffuser and all of that ducting right now.

Leaning towards #2, but any thoughts on ducting, the panel, mounting the cooler etc are welcome. -

Gotta do what is comfortable. The adapter adds some thickness too, so if you got a wheel with the same dish as stock and then put a 1" adapter behind it, it's going to be closer than you want. I don't expect there are that many Z people you can ask to sit in their car in MN, but that would be the best option. Quick check shows spacers available, so maybe err on the side of too far away if you're in doubt and then use spacers to bring it back in if needed.

-

Just get an adapter for an S30 that fits the wheel you like. People without power steering commonly go 14". I found myself hitting the door panel when autocrossing, eventually went 13 and liked that better. Had aftermarket gauges, but didn't have any problem seeing them with the 13. It's been a while since I've shopped wheels, but Grant GT wheels have 5 bolts holding the wheel on, MOMO and most other aftermarket wheels have 6 bolts. But find the wheel first, that way you won't be exchanging the adapter.

-

Thanks. Found one last week.

-

If you've got How to Make Your Car Handle, p3 (first page of actual writing) has a Z on 13s next to a stock one. Always wanted to do it, eventually ended up with brakes too big to make 13s work.

-

I ASSumed it would be a carriage bolt type of setup installed from below, with the stud sticking out of the top. Looks like a plate goes underneath. My bad.

-

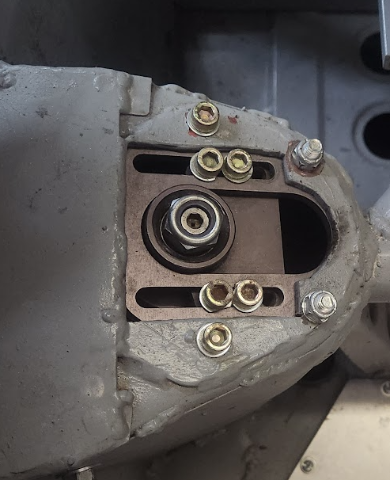

Nothing missing. The slots fit under the stock strut tower. Loosen the bolts and you can slide the plate in or out to adjust camber.

-

Just what the post says. If you have one for sale, DM me.

-

Don't have a diff for you, but if you're still looking it might help to know that you can take the threaded buttons out of an R180 with bolt in shafts and use in an R180 that had clip in shafts.

-

Check the biscuit style camber plates, second and third listings on this page: https://www.dpracing.co/datsun-z-front-suspension-1

Design Products has been making Z race parts for 3 decades, maybe 4, not sure.

I never used these, but suspension guru John Coffey used them and always talked them up. -

The problem is that there is a transition from the strut top to the area between the wall of the cabin. I'd be putting my camber plate right in that spot. I suppose I could cut out the entire strut top, lay a new piece of .120 sheet in there and put a gigantic slot in it and have 5 degrees of movement or something like that, and then just weld it to the plate on top of strut area and the regular strut area. That'd be weird, but I think doable. Might be a lot of cutting on the underside of the plate that is in there now. I seem to remember a little pocket in that spot that I plated over.

-

I thought about welding a clevis to the rear of the upright and then being able to adjust roll center with spacers. I think you had brought that up years ago. I like the "fix it at the top" idea though, I think that's going to be simpler, won't have to mess with the CVs, etc, so that's the plan for now. Just need to disassemble so that I can get the camber plate shape and then work backwards to make an offset spacer. Was thinking of drilling and tapping the spacer so that I could move the camber plate to the stock position and then 1" back, and running studs in the top to bolt to the chassis and bolting the camber plate to the bottom. Might be a little tricky getting the plate to move far enough without the strut top hitting anything, but I suppose I've reinforced enough in there that I can hack some metal away without affecting things too greatly.

It sounds easy from the office chair... -

I don't know how much I'll need to shorten the arms by, but I was thinking exactly the same thing this morning while at my kid's dentist appt. My rear struts are nearly topped out. I could make a spacer that bolts to the existing camber plate and lowers the top of the strut to clear the bottom of the plate, then just slide the top of the strut farther than it is now and maybe get the pos camber I need that way. I do have Ground Control plates, so they're not like the shitty ones that have 3/4" of adjustment that you get with BC coilovers or something like that.

I don't have any of the axles that I was having made back in the day, so I'd need to figure out the CVs. If I did something on the top end I wouldn't have to mess with that. Might have to cut back the plate on top that the roll cage is welded to.

-

1

1

-

-

I'm getting ready to rebuild my rear control arms. I need shorter. Too much camber for the slicks I'm running, and I have the camber plate tops flipped around to minimize, still not enough.

Question: I have some 1 1/8" x .120" DOM mild tubing. Looking around, most tubing ends are 1" so that works fine. Could also do some 1 1/8 x .058" wall chromoly. I'm not very proficient with my tig welder yet, but that would be another option. When I dyno'd the car they tied it down with the control arms and it didn't want to start spinning the drum, car was bouncing all over. Not sure I'd feel confident with .058 in that scenario.

Slight revisions I'm considering, would appreciate feedback:1. Using a monoball holder instead of an outer rod end in the rear

2. Welding in 5/8" studs into the strut upright rather than using a long bolt3. spacing the rod ends away from the strut a little bit. Monoball holder does this automatically, if I did a rod end again would probably use a rod end spacer like so:

-

I paid $2500 for a paint job in the 90s. That's like $60K now.

Actually ~$4600, just looked it up.

Actually ~$4600, just looked it up.

From experience, I would suggest that you will do it better than an inexpensive shop will, and a respray on a classic car is going to be the project in the back of the shop that they work on when they don't have fender benders coming through, so you'll be in paint jail for a while. My $2500 job had runs everywhere and crazy amounts of orange peel, you could see the original red creeping out from the silver that it was painted with, etc. I was really unahappy with it.

When I painted my car again after turning it into a race car I did a Rustoleum paint job and shot it with Harbor Freight spray gun. It turned out much better than the $2500 in terms of the paint itself. I didn't try to make it straight, so that did make it quite a bit easier.

Suggestion: do all the prep and then take it to MAACO or someplace like that, preferably with the fenders, cowl, headlight buckets removed. Have them shoot it and then reassemble. -

Thanks Ben.

NewZed, I'm looking for BASIC data. I don't really know what I'm looking for other than to capture data. I can do tire temps and pressures and that sort of thing manually, but I'd like to have video with g forces, speed, real basic stuff. Figure I can make changes and see if I see a difference in lateral or longitudinal gs. Was hoping to get friction circle data out of whatever I get.

I'm not interested in all the linear pots and all that, just too complicated. I do find it somewhat amusing that you can take a new Vette, or even my '07 GTI and plug a datalogger in and it will grab all of that info from the stock sensors. Reason number 487 to give up on the Z and get a new car to race. When I race the GTI it's just so... FWD. -

I need a new phone. Have been threatening to buy some sort of cheap DA setup for about 10 years, haven't made a purchase yet. Would like to go Apple on the phone because of the scanner feature. At one point there were a lot more apps for droids than iPhones.

What's the situation like now? Does it matter? -

My take on stock clutches is to use a stockish disk and a heavy duty PP. The puck clutches tend to chew up flywheels, and I had a friend with at CA18DET that chewed a groove in the flywheel and that took out the thrust bearings on the crank. My ACT pp and their "street" disk held up to my L28 with cam, 44s, etc.

-

You probably already know this but just FYI, "baby it" means DO NOT let it slip. I will let the clutch out part way, quickly, to kind of lurch the car forward when I'm sitting in line at an autox. Don't be gentle. Gentle = bad.

-

Mine is a standard dual 7.25 with the sintered iron disks. It's grabby, but it works great. Car shifts amazingly fast, and it's a T56 which are notorious for not shifting very well.

-

After talking about those trunnion bushings I went ahead and picked them up and installed. Did the CHE kit which has fully floating brass bushings, lots of the others are press in. Man, there really is something to be said for the simplicity of the LS. So easy.

-

Agree. 8.8 IRS is easier than stick axle swap.

FWIW, 9" isn't that great as they came on production cars and if you went that route you'd need all custom stuff. You'd have to replace the housing to take that much power and housing will be too wide, etc. Can buy the whole thing upgraded and built to fit, but the pinion is really low, which is another issue. I'd rather go custom 8.8 solid axle if you're going to a solid axle. Almost as strong, cheaper, just as many gear options, better pinion angle, etc. If you want REALLY strong, Dana 60.

R200 Differential cooler pump and plumbing

in Drivetrain

Posted · Edited by JMortensen

The quarter window right after an open window isn't the best for attached flow. I agree about the pressure at the rear of the car being really low though, so maybe NACAs, even in the quarter window, would work better to feed a cooler under the rear of the car than they would to push fresh air into a helmet in the cabin.

Still thinking two underneath in the bottom panel might be better, the flow would definitely be better attached.