Spdrcr

Members-

Posts

100 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Spdrcr

-

280z Suspension KYBS and Eibachs

Spdrcr replied to cruceno21's topic in Brakes, Wheels, Suspension and Chassis

I am so glad you posted this. I have the same question. When I look through threads most of the stuff isn’t available just like you said. I was also looking at the kyb. I am finishing up my ls swap and am looking for some wide tires and better suspension. Sorry I can’t help with the answer but I’ll tag along for some info. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

OHMYGHERD! tranny woes continue. Checked the level and it was low so I added some more. Still was getting some air out of the dipstick but I thought it might have been from being low on fluid. What do I know about auto tranny? Nada. anyway, took it out for another drive. Shifting much better.. and when I stopped at the end of the street... poof! fluid goes everywhere. And I mean everywhere. All over the whole car, the paint all the way to the trunk, the window, the entire engine. The dipstick popped out from the pressure and the fluid hit the rubber stopper and then bounced back. What a mess! get the car home and park and after I shut down I can hear the pressure coming out of the tube. I pulled the stick out a bit and a bunch of air came out. Spent about 2 hours wiping everything down. Figured it was one of these things 1. Overfilled - I am struggling with reading level but seems low still 2. Vent clogged 3. Filter loose in pan - car was crashed after all 4. Trans is just broke Figured I’d start with vent. Had to drop the tranny down to get to it. Pulled the hose off and it seemed fine. Little tube seemed fine. I ran some wire through to make sure. Then rerouted the line. Put everything back. started it up and everything seems to work fine now. No more pressure out of the tube. So either the hose was kinked or the tube blocked. We have a bunch of snow here so no test drive till later. Please no more fluid everywhere! -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

A few problems. first the new radiator is leaking when under pressure. eBay... then coolant was shooting out of the little air hole in the overflow tank. Like 3 feet up. That was fun. I believe it was just air since I’ve run it up and down in temp since then and it’s been OK. I may get a different style radiator with the in/out on the same side so the upper hose doesn’t have to cross over. second is transmission. level was fine when I put it in. Go to drive and nothing. No drivey drive. Check fluid and it was all gone. Figure it all ran into the converter and whatnot. I don’t know how long it’s been sitting. Ended up needing 6 quarts and is still a touch low. (I ran out) after the first drive fluid poured out of the dipstick after I parked. Like a lot. Everywhere. Had to start the car to empty the tube. Fluid level was the same maybe a touch lower seeing as how much was now on the engine. I drove it again yesterday and after parking I could hear air squeezing out of the dipstick. I pulled it and got a little puff of air. Lucky no fountain this time. I have to check the vent. Maybe I squished it during install. I just went around the block a couple of times but the transmission is slipping and mushy. Could be broke or could be the slightly low fluid. third is shifter is still not here. Ordered one last month and about to cancel if it doesn’t ship soon. I have a rig set up to get me moving. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Here we go!!! IMG_2221.MOV -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Throttle cable time. using the old hinge yes I know....terrible it’s too long. I may get a 24” so it’s not so sloppy. I only get 2/3 throttle but haven’t done any adjusting. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Driveshaft is in and fits perfect now. Just enough room to slip it in. the factory bolts were too small they did not go all the way through the nut. Grabbed some 5/16 x 1 1/2” bolts and washers that work great. here is spicy of the fuel line, power, and brake line. -

JCI 4l60e driveshaft fitment question

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

New shaft came back and fits perfect. 3/4 inch gap. Any smaller and squeezing the thing in there would be harder. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Need to get the cooling system hooked up so I can run it up to temp. upper hose Lower hose Steam port cut into the upper hose needed to mount an overflow tank so I grabbed a universal job. gonna try and get it on the existing bracket it came with a bracket that the holes lined up perfectly with the holes on the car gonna chop it warned you my fabrication is subpar -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

I love wire loom so much! I wish I could do it for a living... bleh! plug wire is hitting the battery tray. I don’t know if I’m going to fix the plug or the tray. new driveshaft has arrived. still have to test it. picked up some plugs for all the extra ports my pcv is going to be the factory line from the throttle body to the front passenger valve cover rear passenger side plugged rear driver side has pcv valve in the cover itself pcv valve to old evap selonoid port -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Let’s get this party started! Get it? ... started. FullSizeRender.mov -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

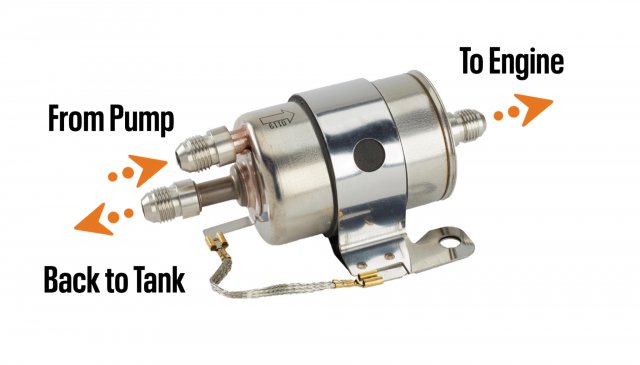

Um.... short story is make sure to review this diagram before connecting the fuel lines. And that’s all I have to say about that. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

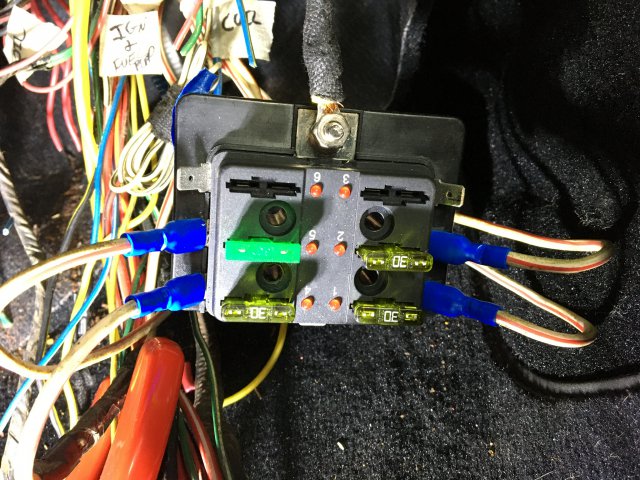

Got the fuel line ran. I used nylon braided line. I used the old fuel p clips and cut half the rubber out of it. That made a good spot to run the fuel line. I left 2 holes in the mount and that holds the brake line and power line. I forgot to take a pic of that. I’m going to get a 90 fitting on the fuel rail to change the angle a bit cuz the line sits on the battery. I’m going to be an electrician soon if I mess with wires anymore. Here is the harness laid out. I’m really glad I didn’t wrap it on the bench. I had to cut the 02 sensors out to get the where they made sense. I created a new wire pulling tool. I can make extras if anyone wants in on a group buy or something. this is an absolute mess rights now but I really wanted the ecm in the car to keep the bay cleaner. I was able to pull the factory wiring through the firewall and strip all the old wires I don’t need anymore. The I slid the ecm connectors one at a time through the hole. here is my fusible link replacement. Just plain blade fuses that are powered directly from the starter line. I put on the 4 red and white wires that came from the links. then I made up a relay box. Using 5 relays and 6 fuses. fan relay and fuse fuel relay and fuse starter relay and fuse ignition relay and 2 fuses split pass and driver side coils, inj, etc brake signal relay which will receive power from the brake light and ground the ecm tcc signal -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Drilled some holes for the trans mount. Rivnuts are fun. mount in. It’s a tight fit. unfortunately I ran into into clearance issues. Not totally unexpected. The fittings for the trans cooler lines were squished on the tunnel wall. I tried to hammer it after dropping the trans down but couldn’t get the leverage. Then shenanigans ensued when I dropped the trans too much and the engine slid back so the intake was stuck in the firewall. Took me a minute to figure that mess out. Good times. Ended up having to pull everything most of the way out and mashed the passenger side tunnel right on the crease about 1” in. added some paint after all the banging. Then put it back in. Test fit the driveshaft and it was short. After conferring with you guys decided it was too much and contacted JCI. They are taking care of me. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Yeah. I’ve never done a project like this so most of it I’m just doing whatever seems right. the headers are the JCI that come in the kit. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

All right time to stop playing around. Bad boy is going in! it was a lot harder than I thought. Took me all day. I couldn’t get enough length on the boom. (Thats’s what she...you know what) I had to remove everything off the front including bumper, grill, and even the hood mechanism. That still wasn’t enough. Had to modify the lift by drilling an extra hole. Then I had a problem with the lift which was vapor locked. Had to take take it off mid install to cycle. Then the chains were hitting the firewall before I was even close to the mounts. Had to unhook everything and lengthen the chains so I could push it back. Very fiddly. I eventually had to undo the drivers side mount and bolt it back to the block after it was in. I had to shave the top off that mount too since it was hitting the header. A small corner of the JCI mount also needed trimmed. the passenger side coil is very close to the battery tray. I think it’s going to be an issue later. had to trim a bracket off the passenger side for the header to fit. No big deal there. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

thanks for the heads up. I’m going to wait to get it on the engine before i wrap it up. I have some new loom too. I’m going to try and get the fuse box, relays, and ecm in the passenger side. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

I thought there were a lot of wires before. It’s pretty scary cutting all the wires out. LT1 Swap is the place to go. I also sent my ECM to Brandon to tune out VATS, emissions, etc. Easy peasy to work with. I thought about just snipping the old stuff and not getting too deep in the harness. I’m glad I did. Was able to easily identify all the stand alone connections. here’s what I ended up with. Fingers are crossed. hope I don’t need any of this! Wish I could go on a diet that easy. I’m not going to wrap it until it’s in the car-ish. In case I need to reconfigure anything. computer is back -

I’ve got a 280z. The angles look good. I’m using the JCI kit and they seem to have everything sorted out.

-

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Radiator time. I have a cheap eBay unit. The stock shroud holes don’t really line up. I drilled it a bit and added the fan. I ordered some hoses based on the search function. heater bypass hose New fittings for the trans. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

Finished with cleaning the bay. At least for now. You can see I still need to wet sand some more. there’s no going back now! transmission ears are gone. -

SPDRCR LS1 and 4l60e Build Thread

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

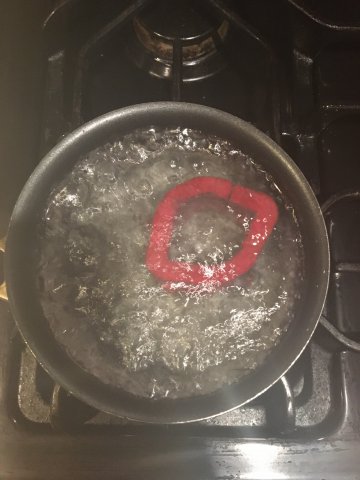

New steering coupler and rack bushings. the drivers side gave me some trouble. Seems like it’s a common people, followed some advice and boiled it for a bit. That helped a lot. don’t judge the crappy paint job. Still looks better than it was. -

I am doing a 4l60e and it’s tight! If the 4l80 is bigger I don’t envy you. do you know how you are going to run the exhaust? I’m worried it is going to be low.

-

JCI 4l60e driveshaft fitment question

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

I reached out to JCI and the service is great. I sent it back to get fixed. Very happy about that. -

JCI 4l60e driveshaft fitment question

Spdrcr replied to Spdrcr's topic in Gen III & IV Chevy V8Z Tech Board

bummer was really hoping for a yes that is normal answer! Here are some more measurements. The transmission shaft sticks out about a 1/4 to 1/2”. The yoke is about 3 3/4” and the splines go all the way to the edge I can’t math real gud but that leaves about 2 1/2” of spline contact. My gap is 1 1/2” If the normal gap is 3/4” would it be worth redoing the shaft to add 3/4” more contact? -

Hello. I tested the fit of the JCI driveshaft in my 280z with LS1 and 4l60e. The driveshaft slides all the way in the transmission and then pulls out a bit once you get the flange lined up. It seems to pull farther out than I would suspect. About an inch and 1/2. Does this look correct?