-

Posts

536 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by zredbaron

-

Weber jets??All who live for their triples please read this

zredbaron replied to datfreak's topic in Nissan L6 Forum

Sorry about the delay! Carbs can receive too much fuel pressure, in which case performance degrades. Installing a return line acts like a shunt, or a relief valve, in that it would relieve overpressure (to a degree; it isn't a pressure regulator) via providing a path of lesser resistance for fluid flow. If memory serves, the Webers don't like much pressure... 3.5 to 4 psi. I don't have my book handy. In my mind, pressure surges up to 6 psi would likely degrade performance, and a return line might alleviate that symptom. -

Weber jets??All who live for their triples please read this

zredbaron replied to datfreak's topic in Nissan L6 Forum

Interesting... what type of fuel pump + regulator solution are you running? PSI? Sounds to me like the return line is serving as a patch to your fuel delivery symptoms. I run a high-volume, low-pressure, centrifugal, electric fuel pump that outputs 3.5psi for all flow rates. No return line needed. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Nice shop, Chickenman! Very cool. Just barely past the Canadian border, too. The shop isn't able to accept any new cars/projects until late summer (I didn't inquire about engine dyno services -- no longer interested, I'm proud to say). So that's out. Too bad, as I would have been happy to commission some of my other projects. Going to look into roll cage fabricators this week... hoping to find a shop that can do both my exhaust and strut braces. Fascinating powerplant! They have a 3.5L and 4.0L version that make about 650-700 bhp @ 11k! Radical. Would need an updated ECU solution and a transmission. Thanks for sharing! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

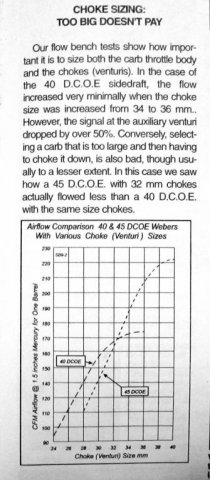

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Hah! Fat chance. I don't agree with their assessment of "negligible," and even if I did, I am not parting with my only headers. Can't knock you for trying! LOL No, the ignition settings are corrected/actual -- "two teeth off" was for my previous build, not my present build. I do not recall the detail of why Joe chose the timing settings he did, only that the engine seemed to idle better with the advance. The 3k and 8k knobs were experimentally derived from dyno plots. Thanks Cary! Question.... you had a 40mm venturi in a 40DCOE body? How? (no venturi?) Vizard's formula's ring a bell, but it's been awhile. I do know that from all of my previous homework on paper, I believe the 38mm is the likely choice. Looking forward to the chassis dyno results. I also suspect that there's a decent chance I might choke it down to the 36mm for autocross driveability. Too many variables to predict, at present. You're welcome! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Minor update. At the end of last week, I more or less woke up with the epiphany that I wanted to re-perform the engine dyno. The data and R&D experience was really, really important to me and I was really down about it. So I decided it was totally worth revisiting! I felt liberated from my disappointment, and reminded myself that this is my project and I can spend my time or money however I choose. This was priceless to me, so I should respond as such. I was excited! I called all around the Pacific Northwest. Portland, Seattle, Spokane, even in Idaho. Turns out our L6s are a real pain. Shops expect one to bring their bellhousing, which is impractical and incompatible for us. Some shops refused to accommodate, some lacked confidence in their ability to accommodate. One shop was confident in their ability to fabricate a mount, but it was a full day's labor at $500. That, and zero shops left me with any confidence that my headers would work. The headers hug tightly and even curl back under the transmission area. After doing my homework, I determined that this really wasn't a good option. I could force it and spend a lot of money and time only to find out nothing mounts up. This resulted in me accepting once and for all that this experience is behind me. Still liberating. The dyno that inspired the most confidence for R&D was in Seattle, if anyone ever searches for such a service. http://rpmdyno.com/dyno.html. Lastly, after reviewing my experience with Loyning's Engine Service, with reminders from Joe, the real value of Arnie's legacy experience is in the "art" of operating the dyno. That is, having a true instinct for the vitality of an engine. That truly is priceless, and after two failed builds, I remain very greatful knowing that my engine was broken in correctly. Lessons learned, as always. If I had it to do over again... I'd still go to Arnie Loyning for his experience and the fact that he has a known mounting solution for L6s. I simply would have more realistic expectations next time! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

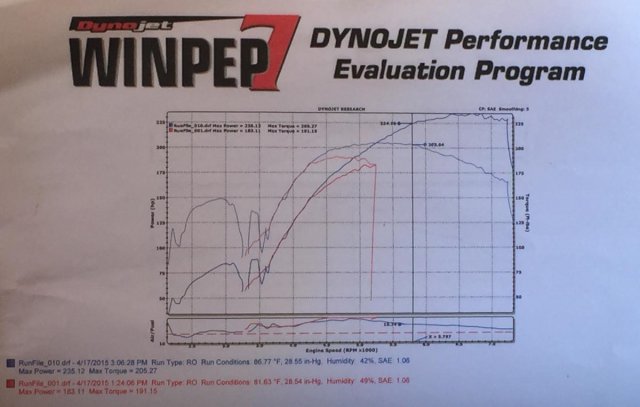

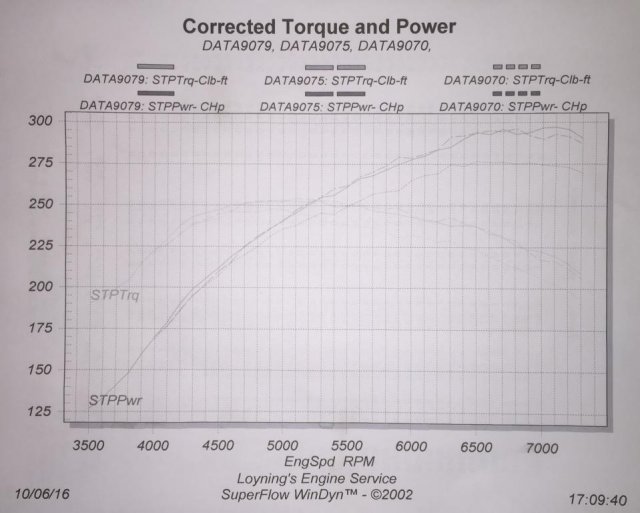

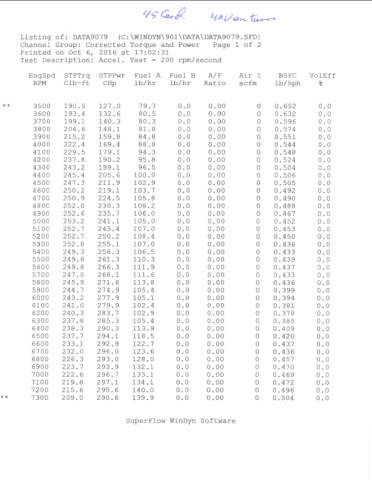

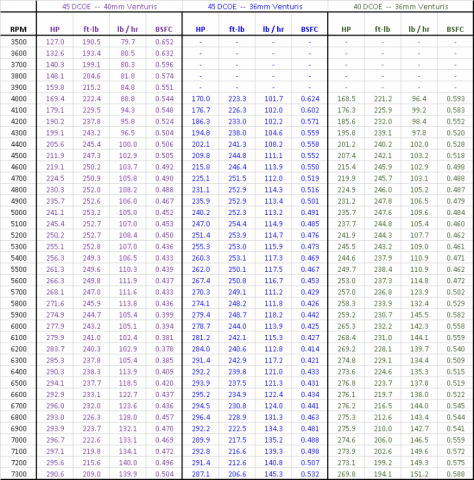

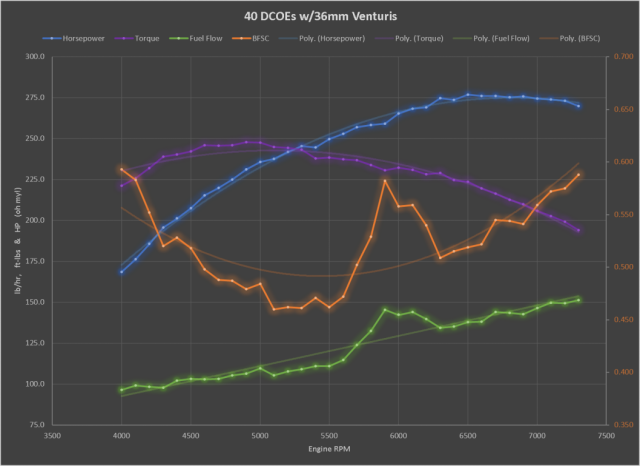

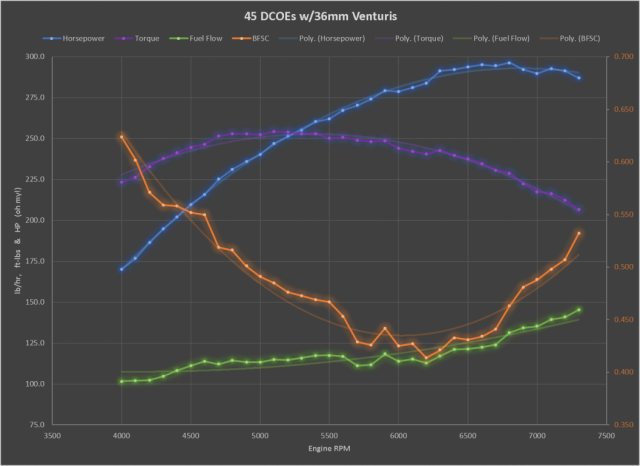

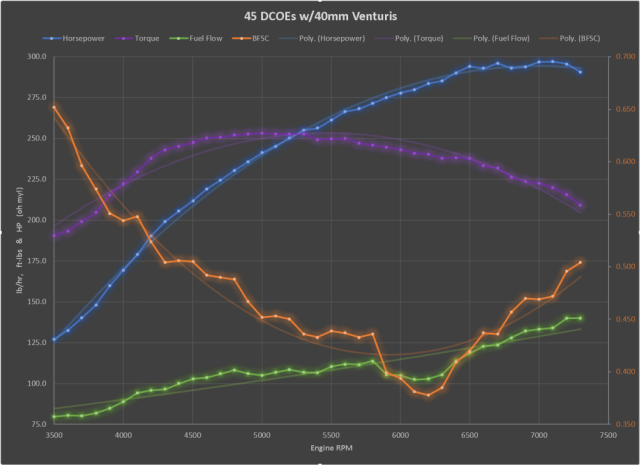

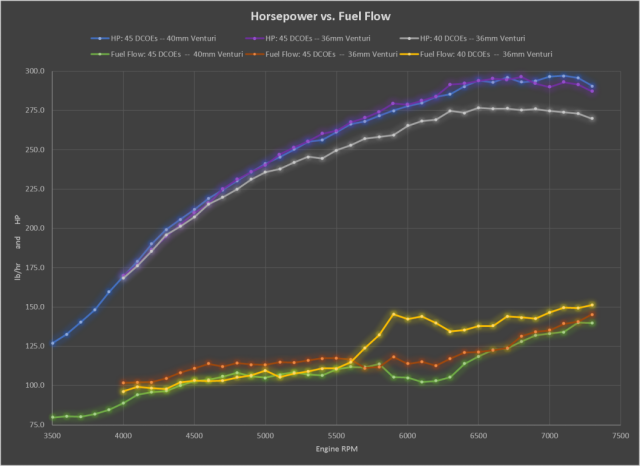

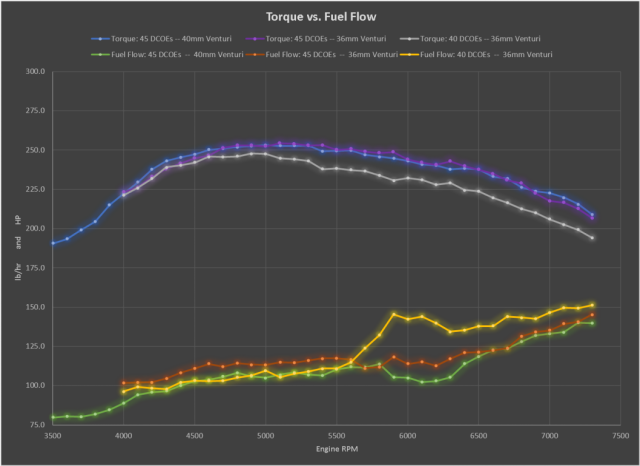

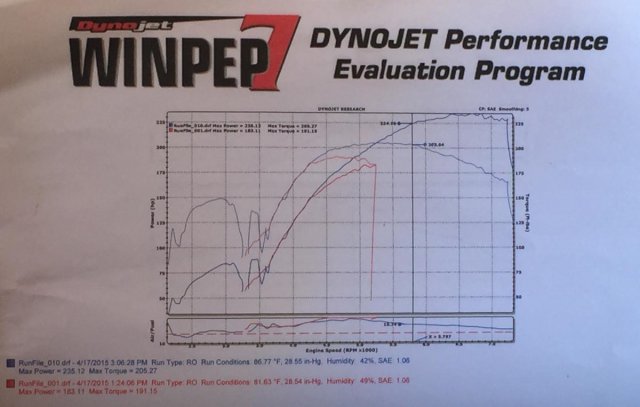

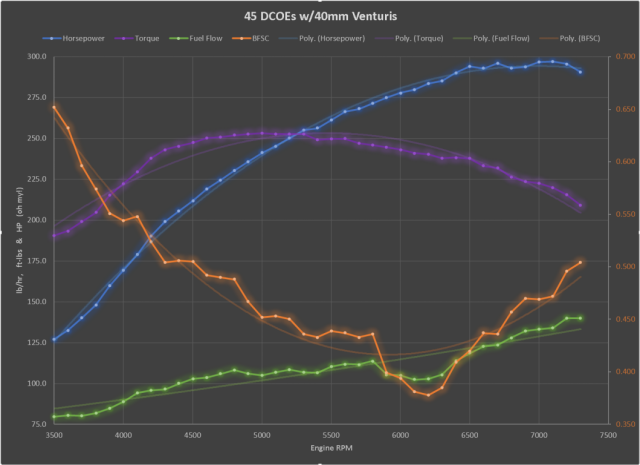

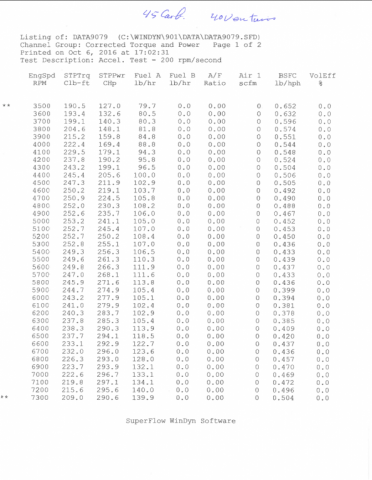

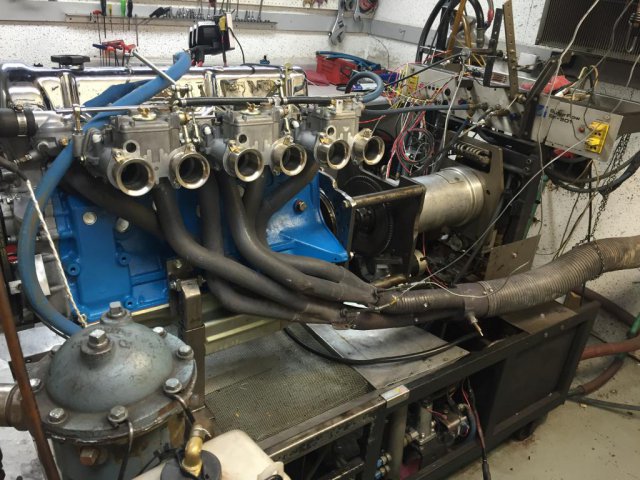

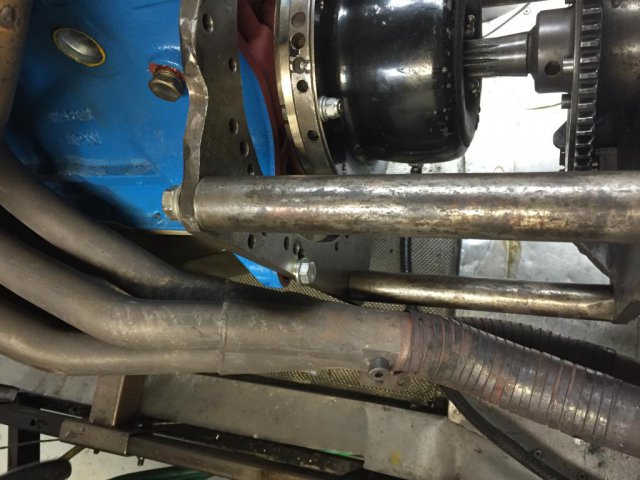

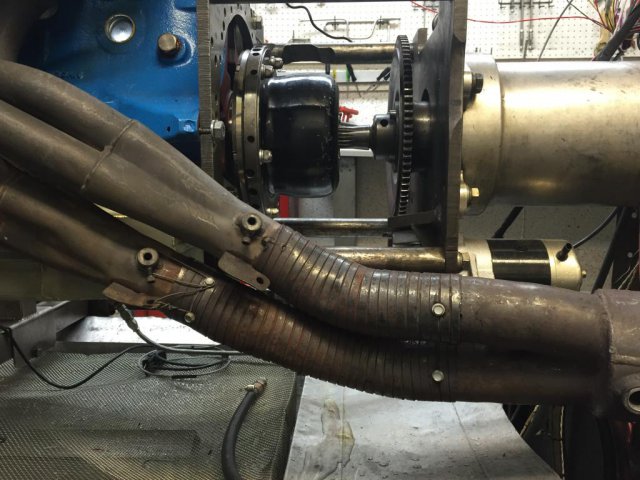

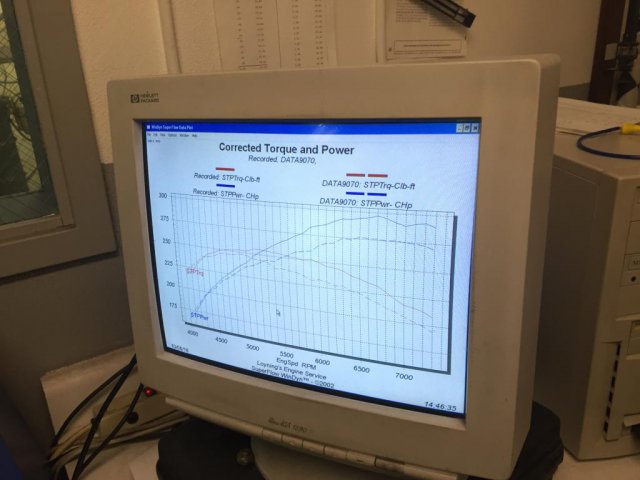

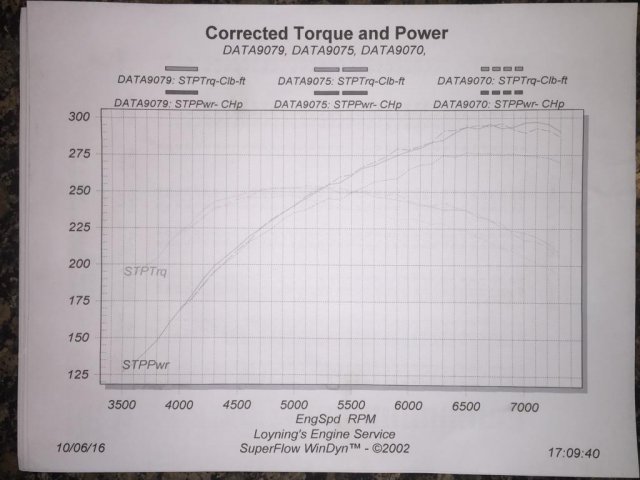

3 of 3, Part 2: Data Analysis Data Analysis: Torque and Power Plots 40 DCOE (w/36mm venturis), analysis relative to 2015 plot My gut reaction when I saw the first plots was that the shop headers + commercial muffler (and associated head loss, i.e. resistance to flow) capped torque around the 240 ft-lb range. The plateau ended early. On the “poor” dyno plot from April 2015 (with my headers), the torque plot is flat from 4500 to 6000 RPM. This dyno’s torque plot is flat from 4500 to 5500 RPM. 500rpm may not sound like much, but that’s a 33% difference in width of flat, peak-torque RPM. That’s huge! That indicates to me that the dyno exhaust is noticeably restricted. It also appears to peak approximately 300 RPM earlier than the previous run (5000, down from 5300). Additionally, the plateaued shape of the torque curve made it “obvious to my mind” and seems slightly capped in magnitude but I have insufficient data to support my intuition. 45 DCOE (w/36mm venturis), analysis relative to 40DCOEs w/36mm venturis Adds about 5 ft-lbs before plateau RPM and about 15 ft-lbs after plateau RPM Adds about 10-15 hp before plateau RPM and about 15-20 hp after plateau RPM 245 ft-lbs torque (or more) from 4400-6000 RPM… more than 3x the width of the same plateau on the same day with different carbs. Huge increase in intake capability… but only marginally increases peak magnitude in torque plot? Again, to me this indicates a restricted exhaust. Torque gain is in width, which now has peak plateau range of 1600 RPM. > 300% is huge! In my mind, the peak benefits to the WOT horsepower plot will be unveiled once we uncap the exhaust. 45 DCOE (w/40mm venturis), analysis relative to 36mm venturis This shouldn’t be the case! Something is capping CFM. See Weber chart below.... 36 and 40mm are very different performing chokes. Since this is the case, this means the carburetors are NOT the choke point any longer. Have I mentioned it might be the exhaust? Not a significant change from 36mm venturis Drastically change air delivery? No change. Jets didn’t change performance much anymore, either. Seems odd at peak RPM in a race motor, doesn’t it? Really odd. At peak power you change a variable and… not much? Sounds restricted to me. Upper limits of Fuel delivery? Doesn’t seem to run out of fuel. In my mind, the equal performance of 36mm/40mm venturis within the 45 DCOE confirms my suspicion that the engine dyno plot is torque limited due to the shop headers. Pictures comparing Mark’s “Stahl headers” with the shop’s “Stahl headers” are below. The shop told me the header differences would be negligible Judge your own gut instinct for yourself! At the end of the day, I still have a really nice shape power and torque curve! At the end of the day, the tech was impressed and was happy to tell me “your Z motor did better than ours did!” Inquiring further, “the shop L6 motor” produced 270hp on their dyno with the same header. I know no further details. For what it’s worth. Pretty much a fridge sticker. Coming this Summer… on the Chassis Dyno 36mm vs. 38mm vs. 40mm venturis (45 DCOEs only) With A/F Data! Show us what is happening during peak RPMs and plateaued RPMs and other RPMs… confirmation of proper tune. Show us that chassis data A/F can be more flat with 45 DCOEs than yesteryear’s chassis data on 40 DCOEs… any conclusion with a big grain of salt, unfortunately. With different exhaust! Show us the difference in torque plots, the plateaus and the new peak RPMs Sing us an L6 lullaby How’s it drive? After writing down all of the venturi/jet combinations, practical driving will be very relevant for autocross selection. Again, the purpose of this engine is to have power / torque widely available at all pedal positions and not for WOT/high RPM numbers. With butt-dyno reports! Fin. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

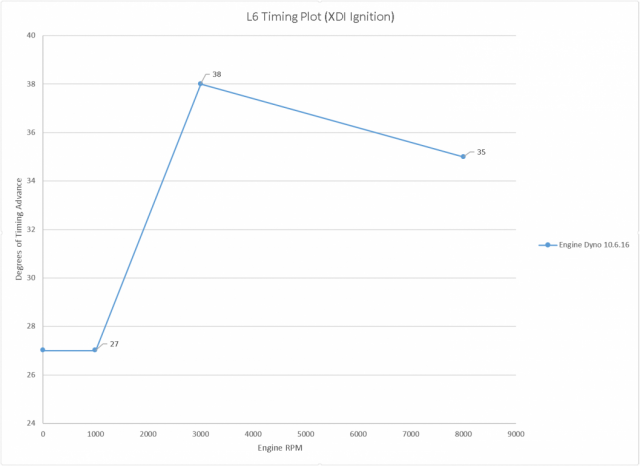

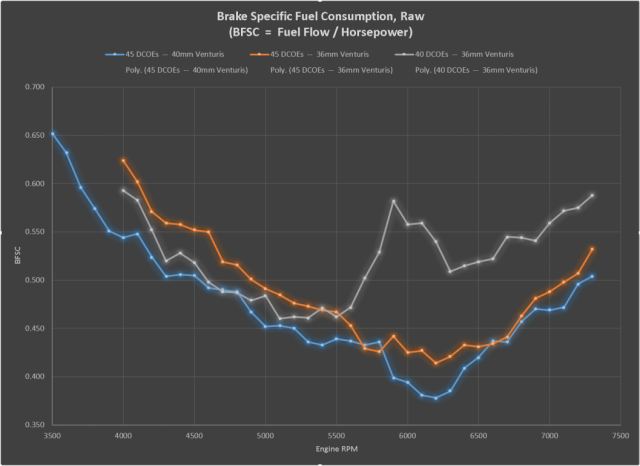

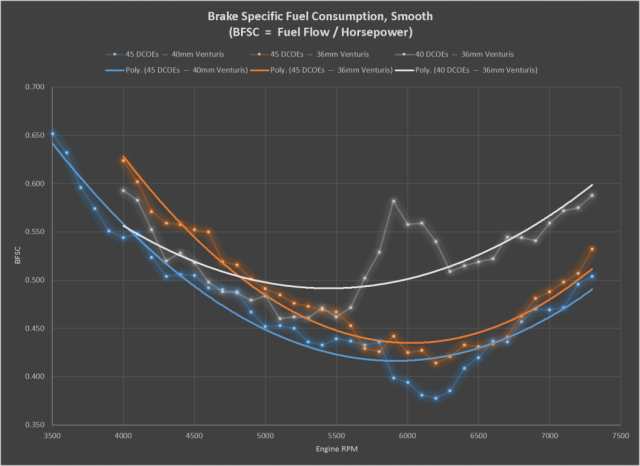

3 of 3, Part 1: The Data The Data: What I don't have, which really hampers our ability to draw emperical conclusions: A/F ratio graphs All theories on intake "stalls" / turbulence / reversion... dataless. Horsepower and Torque only. Better than zero, but doesn't address the whole point of my R&D…. A/F data. I’ll be able to theorize once all is said and done and I have a tuner’s feel for the 45 DCOEs, but that won’t be until this summer. Timing settings for 40 DCOEs The timing was already ball-parked from the chassis dyno in Arkansas from the last engine build. There were only a few pulls on the 40s. I do not recall if the timing was adjusted or not. I know the main jets were slightly adjusted, but not by much. Again, I withdrew interest in the details once I learned A/F wasn’t available Timing/Jet settings for 45 DCOEs w/36mm venturis I didn’t capture this either. Same reasons… hands off. Small space. Too many cooks in the kitchen. Not enough time. You get the idea. What I do have, which is still useful: Power and Torque Plots Easily compares result of upgrading intake CFM capability by way of larger DCOE body and intake manifold Pics below. Jetting (I think!?) 40 DCOEs (36mm venturi) 165 mains 195 air correctors 45 DCOEs (40mm venturi) 190 mains 195 air correctors All Combinations: F11 emulsion tubes 60F8 Idles Timing Final timing only. I didn’t capture what I walked in with, because the mounting bracket for the crank sensor was different. Joe caught that it wasn’t aligned to the correct tooth, which was essentially corrected by the knobs. It was off by 12 degrees since 1999! Credit to Electromotive for their design being able to easily “fix” it unknowingly with a knob. Electromotive timing varies linearly between points in the RPM band: Init: 27 degrees 3k: 38 degrees 8k: 35 degrees Note: I did not use a voltmeter to confirm accuracy of this part. Knob settings only. Pic and graph of final timing below. Custom, Recreated Power Plots! Taking the raw data tables such as the one shown in the post above, I manually typed the different runs into Microsoft Excel. I made the following graphs (all posted below) 40 DCOEs with 36mm Venturis 45 DCOEs with 36mm Venturis 45 DCOEs with 40mm Venturis BSFC (both raw and smooth) HP vs. fuel flow rate Torque vs. fuel flow rate They're pretty easy to ready visually, I think. Put a lot of time into them. Peace of Mind Engine is solid and ready for the next step! That’s priceless! So very glad that the engine was put on the engine dyno, despite the lack of desired data. Again, I would repeat this experience and recommend it, I simply have a few lessons learned. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Thanks Jon! Great input, thanks for sharing how you experienced Arnie as well. Thought we had captured the pressure surge detail in this thread... good catch! I still think about that mexican food we had for lunch! Holy crap that was good. Stress-relieving soul food, I say! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Thank you, Steve. My goals were to collect and compare A/F ratio, torque and power plots for the following on the same engine, same dyno, same day: 40DCOEs w/36mm venturis 45DCOEs w/36mm venturis 45DCOEs w/38mm venturis 45DCOEs w/40mm venturis My purpose was to confirm venturi selection, and my R&D desires were hopeful the data would back up my "stalled carburetor" theories (the 40DCOE). This is not possible to confirm or deny without an A/F graph. The BSFC was an unexpected bonus to aid this research, but it's useless by itself. For my application, anyway.... In short, because Arnie and I miscommunicated, the internet still does not possess such a comparison to the best of my knowledge. Upset me greatly. It's entirely possible I would not have found an alternate, in which case nothing was lost. I did not have such a choice, as I had already "confirmed" his shop met my needs. It didn't. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

2 of 3: The Dyno Shop and The Tuning The Dyno Shop: www.loyningsengineservice.com Arnie Loyning and his shop have a long racing history. Legacy, in fact, which is part of why I chose to step aside once I was there in person. I marveled at the age of this man (80?), his continued relevance in the sport and observing the arrival of his personal racer coming back to the shop (a 50-year-old Lotus that inspired the Mazda Miata). The techs joked that the boss man gets pretty grumpy if they don't get him on the track regularly. There were fancy heads and hi-tech intake manifolds and throttle assemblies (one piece, same function) everywhere. Clearly a ton of money coming into this place, and a ton of automotive pride going out. Respect aside... it's 2016, not 1986, not 1996, not 2006. I was very disappointed that he had a wide-band O2 sensor hooked up for instantaneous display purposes but he didn't pay for the add-on to his dyno software. The dyno and its controls were built in the 1980s (insert Weber book publication date comparison!) and the computer was easily over 10 years old. The black and white printout I received was printed from an ancient inkjet printer and it's hard to read in person, let alone the scanned image. I drive an old car! By definition I can appreciate old, IF it’s no slouch or is "kept original for vintage reasons." No one uses vintage PCs for modern use and says "they just don't make 'em like this anymore!" This might seem nitpicky, but it’s also attention to detail. If the attention to detail is only in the rearview mirror, who’s driving? Yesterday’s winner, says me. Granted, you might suggest the modern cars are fuel injected and the onboard computer is a part of the dyno tune. Correct. Except for the vintage racers like myself and the owner. The shop is named "Sidedraught City" for cryin' out loud, not "Fuel-Injection City!" He doesn’t have that for his own tune? Wow. At WOT only, he might not need it *as* much. I do. And every build benefits. Respectfully, I strongly feel he is riding out decades of success and doesn't care to evolve in this direction anymore. He displayed some stubborn traits and seemed to "tolerate" his job/role rather than enjoy it. That's ok, but I don't take my child to doctors that "tolerate" what they do for a living. He's earned his lot in life, again, full respect. Just so we're clear... his fee was well worth it and he provided a service. He simply won't be earning my dollars again for the same service. All chassis dyno experiences I've had (3 locations), by contrast, provided an A/F graph, provided a color printout that's readable, and offered the raw data files if you brought a USB stick. (You can download reader software from Dynojet, for example.) Even in rural Arkansas this is true, but here at the heart of racing in downtown Portland with multiple tracks in the region… here at “Sidedraught Central” evidently “what we’ve always done” trumps all. Jon noted that the printouts Arnie selected are not what Jon remembered seeing on screen at the end of the day. He just wasn't "present." Have I made my point about lack of attention-to-detail and disregard for the value of data? Curiously and enigmatically as far as I’m concerned, Arnie was very interested in a table printout which included BSFC (pic below). (https://en.wikipedia.org/wiki/Brake_specific_fuel_consumption) When I asked him about A/F ratio, he pointed at the BSFC he was so interested in and explained how I might calculate A/F ratio from the BSFC. I asked him several times, in disbelief of what I was hearing. Maybe I’m missing something, but in my opinion he has a gross conceptual error. One cannot possibly know how thoroughly fuel/air burned by watching the fuel consumption rate. You could have the ignition off, for example, and mechanically draw out this number with a reciprocating set of pistons. That said, the number is exceptionally useful when modifying port shapes, intake shapes, exhaust shapes, etc. and striving to maximize volumetric efficiency at every RPM. Less fuel for more horsepower is equally advantageous in a racecar and a Prius, albeit for different reasons and goals. To me, the efficiency or inefficiency is quite set in stone given my manifold and carburetor selection are a done deal, as is the head work and my camshaft. If I can’t adjust it and I have no intention to… it’s not worth much beyond “neato” and noting which RPMs the engine might vary efficiency… but my throttle pedal can tell you that range also. Like I said… “Neato.” (Anyone know what I’m missing?) I do intend to circle back to this after the build is complete. In the end, his shop has a reputation. He has repeat customers. Apparently they win on track, which is what matters. Some rent his dyno for a week. If I were experimenting with camshafts, port shapes, intake manifold or exhausts that fit, then I would value this facility for these purposes. This shop would be amazing for such experimentation IF AND ONLY IF fuel injection was used. None of these applied to me, so this shop did not meet my expectations or needs in terms of my expressed R&D intention and investment. In short, I would still do it all over again just for the engine break-in, especially if I had no other shop to choose from. I do not feel Arnie’s legacy experience offered my engine one single improvement detail -- this was my engine and Joe's engine; Arnie only participated in the break-in. In a way, I’m really glad I got to take my engine to a legacy shop so I can pat myself on the back for being there and giving my engine a royal break-in. That said, I'd like my money to be green AND understand when it is not. I'd like to be able to pay people to help me go the direction I want to go, not pay people to go the same direction they've gone for decades and convince me otherwise. I'd like vendors and service providers to be honest and speak up if goals and/or capabilities are not aligned. I told Arnie on the phone before any of this that I'm coming expressly to collect A/F data and I received the response of "oh sure, my dyno has that." No, actually, you have a gauge mounted near your controls but your dyno has no idea it’s there. (Pic below... the gauge is behind the glass -- red LEDs). In my opinion, good sir, you have a mentality that you know everything that is knowable and this mentality prevents new things from being discovered and prevents dialogue with sufficient understanding. I sincerely believe I told him what I wanted and he recalibrated my words silently into “you just want to come break in your engine and see what the gauges show.” Communication is a two way street, and I own up my half for not micromanaging the conversation and ensuring I spoke the correct lingo to interact with his mind. Trusting the expert and respecting my elder cost me two days of pay (I took time off during the week), plus the cost of the dyno day, plus the permanent loss of not attaining what I [believed I had] purchased -- a priceless and scientific R&D experience exploring new territory. Arrogant or not, my conclusion is that vintage racers might continue to expand the envelope in vintage ways, but not all vintage racers share the same idea of modern tools or sufficient communication. Full respect to men like Arnie, but my path is my own. Again, it was a really neat experience and I’m glad for it. Food for thought for all you enthusiasts out there The Tuning: Joe, maybe you'd like to chime in here, but the impression I received from observing you and Arnie is that you also were deferent to Arnie's experience and the fact that we were in Arnie's shop and Arnie's hands were on the controls -- It was The Arnie Loynings Show. It seemed to me that Joe was also reading Arnie to see what he might learn from Arnie’s decades of experience. Neither Joe nor I consider the engine tuned beyond "a decent start." Joe knows carbs very well also; I observed him ask questions of Arnie that I myself knew the answer to, so I figured he was probing Arnie to see if any unanticipated fruit would fall out of the tree. None did. Arnie did make an impression on me regarding orientation of the aux venturis, so I did reinforce a good habit, but it was more like "hey it's easy to mess this up" than performance insight. (I already knew how to orient a venturi.) I felt 50% like a guest and 50% like a customer. A welcome guest! …which is nice, but confusing when paying for services. I was in my right to ask them to swap parts and spend more time, but I feel that's the only thing that I as a paying customer had influence over. I felt I was wearing out my welcome just by being a customer with custom goals (same root word, even, go figure). Really odd! This is likely a common, upside-down result of supply and demand when supply (of comparable shops) decreases. The dollar just doesn't mean much after that, people get set in their ways, and eventually “it's my way or the highway because I have more customers and experience than I can shake a stick at.” I can list a few restaurants that meet that description but offer lousy food or service and the economy still inexplicably pays them. The people at the shop were in no way rude but rather very friendly; the owner’s mentality simply resulted in a closed door for this specific customer’s purpose. No disrespect, they treated my engine very very well and broke it in wonderfully. Worth every penny. I simply thought I was coming for a different reason. Since I took time off of work to accommodate *their* work preferences, it further cost me two days’ pay to come be surprised and disappointed with what I thought I was purchasing. Ouch is right. I sacrificed a lot. Again, I own my half and do not assert blame... but I do feel my money wasn't green at the shop. We humans affect each other’s lives more than we know. It would have been nice if the other parties joined me in the desire to communicate precisely or openly. It would have been nice if I was given the CHOICE to be ok with limited R&D... instead it "happened to me" against my knowledge. And Joe, just so you and I are clear... none of this reflects my opinion and trust of you, sir. Arnie and his business alone. I do not feel you mislead or ill-advised me in any way! To the contrary. It was fabulous advice to come break in the engine at this shop. That was your advice. It was my desire to conduct R&D. That's on me. As always, if I am missing something, I'd love to be wrong and retract my harsh perspectives... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

1 of 3: Engine Dyno Experience Overview Very overdue post... but then again this project has always been behind pace. Thanks for bearing with me! Preface: Now that the experience of the engine dyno is behind me, I understand much more about realistic or practical goals relative to expectations in this industry. In short, although it did not go according to my plan, in the end I have zero regrets and would still make the same choices again. The details and pros/cons are outlined below. My overall conclusion and message would be that of positive reinforcement: you get what you pay for, you can't rush a job being "done right" and, well, to quote Mario Andretti, "if everything seems under control, you just aren't going fast enough." In this case, my pursuit of pushing the envelope is, by definition, understood to “not be fully controllable.” The engine dyno day was not, as a whole, under my control by a long stretch. I recognized this early on and I quickly stood back to get out of the way throughout the experience. Would I have don't things differently? Oh hell yes. Was it worthwhile to see what would happen if I just watched? Oh hell yes. Did I confirm to myself that I can't wait to do it my way? Oh hell yes. Interestingly, I wouldn't know the last two points had I just arrogantly pressed forward and done things my way. Still might have been right, but I wouldn’t know. Preface Part 2: This post contains constructive observations and impressions regarding how it might have gone differently and how I intended it to go. This "criticism" is NOT intended to judge the shop, the owner, the techs or my engine builder. This feedback is intended as "lessons learned" for those who are considering R&D, i.e. herding cats. The "criticism" is essentially pointing back at ME -- it is constructive to other customers to ensure they ask the right questions and speak the same language as the shop. As a customer, I told my engine builder and the shop what I wanted to accomplish. I used my words. All verbally agreed. My engine builder later stated he "missed the memo that we wanted to test stuff" and the dyno shop made similar statements indicating non buy-in toward my goals of experimentation and data collection. Personally, I think the arrow points at ME. Evidently I did not use the right words or stand firmly enough. I also conclude I did not ask the right questions, and neither did the vendors. Thanks Jon, for your comment about me being zen throughout the experience. I was trying for that… admittedly part of me chose to be numb from the surprises, and, oh God!, the freeze plugs popping out so many times was quite intimidating and stressful. I chose to not “feel” the fearful what-ifs… I had enough going on in my head! LOL. Muted my excitement a bit, too, unfortunately. Overview: I did not get the data I wanted to get. As a result, the “experiment” and its results were significantly limited from an R&D perspective. Scientifically, what I set out to demonstrate or discover was not available. The environment had too many variables, not enough controls, and did NOT contain the most important data (to the R&D) -- a graph of the air/fuel ratio. As a result, I elected to skip the 38mm venturis altogether in the interest of practicality. I also placed no personal value in paying attention to the jetting and overall tuning, which was now moot in my mind. It became far more valuable to me at that point to observe tried-and- true racers and “performance carburetor practicality,” let’s say – literally to observe the industry standards that I as an amateur am questioning in 2017. The overall value of this choice was that I learned that I didn't learn anything new about tuning carburetors and was able to smile in confidence that all my time tinkering on triples since 1999 hasn't been fruitless in the slightest. In the end, the power/torque data we have is simply "food for thought" and the real value was primarily breaking-in the engine in a controlled manner and secondarily the experience itself. Worth every penny and I recommend others go for it, if able and inclined. Coming soon (this week, I'm not intentionally dragging this out)... 2. The Shop / The Tuning 3. The Data -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

This thread has been silent long enough. Life can be hard... and depression is a mother lover. The engine still rests on the floor of my storage unit, the rear of my car is still in the air. I've made significant progress, but I'm still working on the Wolf Creek CV axles and T3 rear LCAs. I've completed my differential mounts, diff crossmember repair (cracked) and upgrade (thanks Joe! Fine work.), and all parts powder-coated (including moustache bar, etc). I pulled up my word document from November... and I just don't have the desire to create a presentation at this time. I don't even want to edit the writeup. A video is unlikely but possible. Better to share what I do have than sit on what I might have one day. For now, I will post my write-up in three installments: Overview The Shop / The Tuning The Data As always, thank you gentlemen and ladies, as this community is very, very much appreciated on my end. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Thanks fellas. I appreciate the feedback and encouragement very much. After yesterday's post, having slept on it, I think I'll share one piece at a time rather than trying to tie it all together. I was trying to bite off more than ought to be chewed. As for my project... I haven't accomplished much, sadly. I had the rear of the car in the air when I received the engine in October. I'm upgrading to the T3 LCAs and Wolf Creek CV axles. Found a huge crack in the differential crossmember. Shipped it for repair, shipped it back a 2nd time, etc. Will powder coat the crossmember, moustache bar and a few other pieces while I'm at it. Have had a heck of a time with the spindle pins -- I had a machine shop fabricate a tool for me, but in the end I still had to have a shop press it out. Much ado about nothing, basically! Haha! So it goes... Once the car is on it's own wheels, I can then wheel it out of the storage unit and back it in so I can access the engine bay. I still have a long ways to go. Being ready for spring autocross is looking really, really tight and less likely each week. I have no doubt I will be waiting in line for a tig welder when I get that far along... (mandrel exhaust and strut braces) So as far as the engine is concerned... turning it by hand periodically is the only action it's getting at present.... Hey, that's better action than the 2011 motor got right about meow! Now that's progress...! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Hey gang. I'm still here... my apologies for never getting back to this thread with the "details to come." I created a lot of gorgeous, all-original graphs and typed up a long post back in November. Then I stalled. It wasn't complete. A media supplement, an option. I wanted to make a video, no wait, a PowerPoint... Through December, I remained stymied. I've put a lot of time, energy and money into this R&D experience.... how to share my data? How to share my lessons learned? How to share the experience itself? Overthinking it, no doubt... but then again I can think of a lot of presentations that would have been a lot more helpful had the author focused his content with his purpose. That's why I'm hung up. Is my purpose to share lessons learned? To share carburetor theory? To chronicle my journey? Sigh. Those are three different audiences. Three different presentations. Three sets of data. This isn't supposed to be a book, it's supposed to be a single post on a long thread. That's a lot for a small audience. So I do nothing instead. Good job, Mark! Making real strides this year! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Thanks Joe... now *I'm* not clear! LOL. By "fully ported from head side to carb side" you mean both ends of the new Cannon manifold were port matched, correct? And the full length of the runners were therefore conically ground out to match, removing a ton of material, correct? The Cannon manifold isn't junk once it's been opened up... Clearly, we're all speaking *slightly* different English. I feel for the texting-Generations Y and Z behind us! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Haha, I forgot about your understeer comment at the dyno, Joe! And thanks for entertaining my desire to collect and share data. I didn't know it going in to the engine dyno, but I now agree that the real value is breaking the motor in and having a nice and safe general tune before digging in for the real deal. My original purpose was primarily to collect data, but that only partially worked out. Worth every penny for unexpected reasons! Yes, Leon. There are two complete triple weber assemblies with their own throttle linkage, their own air horns, and their own Cannon intake manifolds. Both are port matched, otherwise it wouldn't be much of a comparison. Previously, the 40mm Cannon manifold was port matched to the head and to the 40mm DCOEs. Joe received a brand new Cannon manifold. All Cannon manifolds are 40mm and are very crude and rough. Joe opened up the 40mm to 45mm on the carb side and port matched the intake to the head side. So in the comparison of 36mm venturis in 40DCOEs to 45mm DCOEs we are really comparing two main differences, the air horns and the exit diameter of the carb and the long intake runners' nozzles: The 40mm short air horns and the 40 DCOE's 40mm exit, which nozzles to 36mm via the Cannon manifold. The 45mm long air horns and the 45 DCOE's 45mm exit, which nozzles to 36mm via the Cannon manifold. I would have preferred that both carb sets utilized the short air horns, but alas, only half of my data collection went according to plan. Again, more on that to come. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Thanks Garrett! Joe, please feel free to add comments or correct me if I'm off base! 1. Yes, valves were contacting pistons. This is primarily due to incorrect rocker ratio of CNC rocker arms not noticed by my previous builder, combined with a very intolerant camshaft duration. Joe had issues achieving the desired seat pressure map with the above springs from Wolf Creek Racing. He ended up selecting the outer-springs he uses in his own race motor, as they were closest specs to desired. He'll have to comment beyond that. I still don't speak valve geometry. 2. Reversion falls into the "carb theory" category and that post and all its details are still to come. 3. I use ARP stud bolts. 4. Yes, pure race gas. 105 octane unleaded. 5. The rocker arm ratio is the presumed culprit of the engine failure. Undue fatigue caused by contact of valve / piston. Spring able to absorb impact, rocker moves with impact. Failure imminent. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Wow, lot's of parallel topics! Thanks Joe! I think we've successfully honored and even pushed the envelope of the head and cam's intent (displacement!). "Optimized for my sport" -- music to my ears! Thanks Leon, 300hp *is* stout! I have to keep reminding myself... It's easy to get caught in the pursuit of big numbers, but flat curves and mid-throttle driveability are worth more to a driver in autocross than peak hp numbers. Steve-- The E31 head has had extensive port work, yes. All references to Jim Thompson, Sunbelt and John Coffey's R&D dollars are crediting their achievement. The first page this thread shows JohnC offering a phone number to a very young and naive version of myself. Most of us recognize that true power is made in the head... and in 2004 I was very fortunate to have landed a head and camshaft that were both optimized for one another's flow characteristics. JohnC wanted a wide torque band 3.0L engine with minimal drivetrain loss. This resulted in an outer-springs only profile (less seat pressure -> friction) with a rev limit of 7700 rpm. He chose an N42 head and ran Megasquirt. I believe in the end he had 285hp and 250 ft-lbs to the wheels. Anyone remember? I had Jim Thompson apply what he learned to my E31. Initially I chose his less aggressive camshaft with .525" lift and nominal high performance duration since I was running flat top pistons and a 3.1L stroke. Once I started using forged pistons with reliefs I was able to upgrade to the full head-profiled .565" lift with super-wide duration of 326/315 in/ex. Again, this was designed for a 3.0L bottom end. The 3.1L kit has a positive deck height of .025". Not sure about 3.0 setups. It should be highlighted and credited that Jim Thompson / John C.... and now Joe / Mark were able to achieve 300hp without the use of adding more RPM to create power, without exceeding .600" lift, and without full race compression. The exhaust that I'm so proud of was also what JohnC ran, with extra emphasis on exhaust scavenging. He helped me further optimize the merge collector angle to aid low and midrange torque at the cost of peak hp. I also made the same compromise with header primaries, which Stahl helped me select. There's a lot that goes into the big picture, and when I recall all of that... 297 hp is a great start before an optimized tune! Ryan, I agree about seeking different air horns. The 40s had the short air horns which I like inside an air box. I'll have to look into the T3 horns, thanks for the tip! I'll get back to you guys on my jet settings and final timing in a few days. Unless Joe remembers off hand? My MAP sensor was not installed at the dyno, either. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

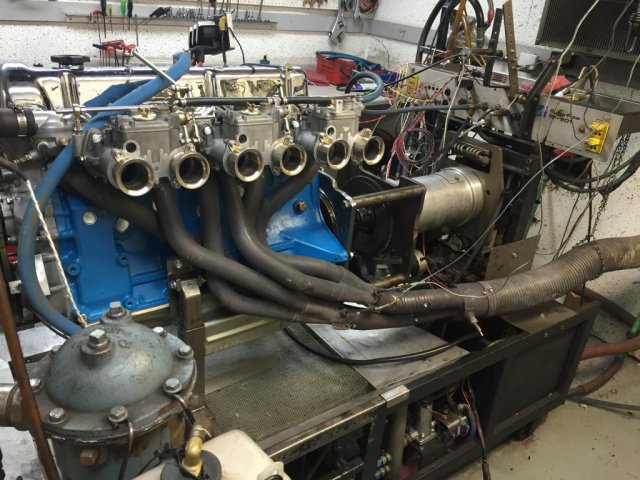

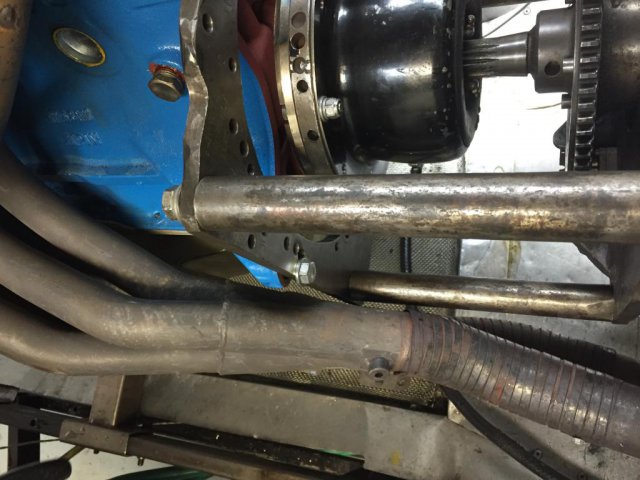

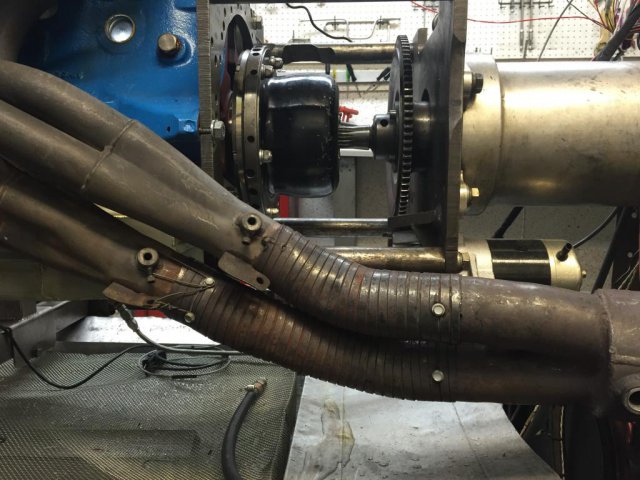

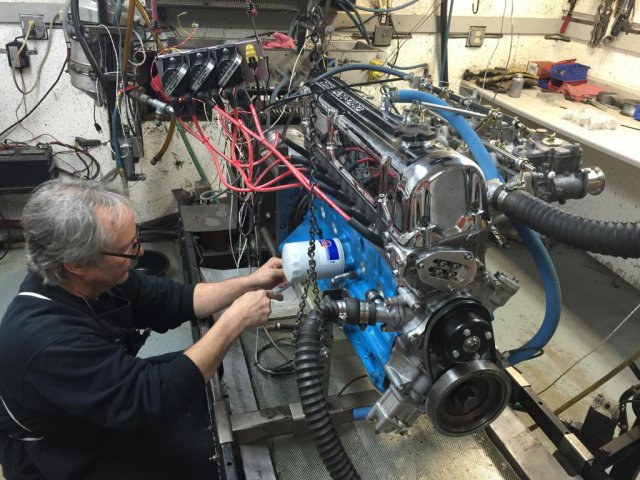

Thank you gentlemen! It's been a long road indeed... Thank you all for your collective input, enthusiasm and encouragement! Haha! Loved the surprise commentary at the end, Jon! Your YouTube channel then appropriately played your video of jet tuning with very satisfying V8 throttle blips. Can't wait to hear our cars on track! Well, gang, I sincerely apologize for the cliffhanger disappearance by yours truly. I thought I made a mid-day post at lunch via my phone with numbers and pictures, but evidently that didn't successfully post. Whoops. The final numbers were 297hp and 253 ft-lbs torque with a very nice set of torque and power curves. [insert restricted exhaust comments, here!] Haha. The three plots are comparative performances of 40 DCOE (36mm) and 45 DCOE (36, 40mm). Not a huge change between venturi plots in same DCOE. (More details to come.) Without further ado... here are some pics while I type up the details! Big congratulations and thank you to Joe for a fine engine assembly and catching a number of incompatible parts along the way! Thanks again for coming out for your support, Jon! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

At lunch with Jon. Slow progress. My headers and merge collector don't fit. The engine dyno's mounting setup just doesn't fit. The good thing is I can compare my L6 to others with the same header. The drawback is of course true tuning and comparison of engine to chassis dyno will be difficult. We've had 3 freeze plugs pop out. Suspecting the loose driving belt. Thus far showing 270hp / 250 ft lbs on the baseline. Their headers, the 40mm carbs, and all timing/jets untouched from the previous build. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Thanks guys! Yes, to be clear, I intend to share everything. The numbers, the graphs, the media. It's an open project. Figured I'd share this surprising find: type "Weber 45 dcoe venturi" into Amazon.com and voila! $17 each! Doesn't qualify for Prime shipping, but does allow for intelligent mass shipping. Wow, select DCOE parts fulfilled by Amazon? (Still stuck on wow....) -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

P.S. Very excited to have friend, competitor and comrade Jon Mortensen in attendance! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Dyno day is set for next Thursday, October 6th.... -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

Yes, both are identical Cannon manifolds (except for 40/45mm respective port matching). -

NA 3.1L=>head & camshaft questions. No shortcuts, max

zredbaron replied to zredbaron's topic in Nissan L6 Forum

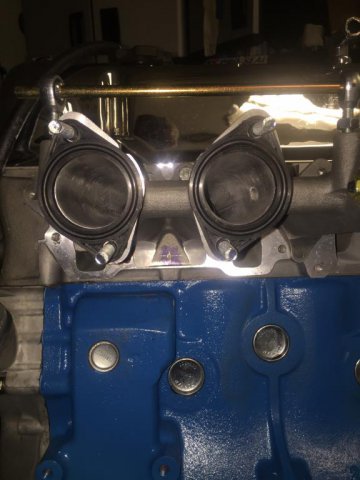

Final assembly pics before engine dyno. Getting close! The second pic shows that Joe "pinned" the intake manifold to the head to ensure the ports are aligned. (The purple marking.) Pretty slick. Perhaps that's a technique commonly found in comparable engines... but it's the first I've seen it?