NewZed

-

Posts

6680 -

Joined

-

Last visited

-

Days Won

70

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by NewZed

-

-

Imagine how these tiny skirts would run. I think that they are coated to help with what you're seeing.

https://www.datsunspirit.com/product-page/super-lightweight-forged-pistons

-

Edit - sorry I probably didn't read what you were saying correctly. You meant that the oil film was breaking down and the skirts were scuffing the bore. Anyway, the following still applies. Short/small skirts have drawbacks. Good luck.

Not sure why the focus is on the skirt contacting the bore. Piston skirts do contact the bore during normal piston movement. The reason for the small skirts is to reduce friction for better performance. But it also allows more cocking of the piston in the bore so the wear patterns change.

Piston skirt design is a specific area of study. Lots of stuff out there. Performance improvements tend to have more expensive side effects. You can build for longevity or performance, but those two things tend to conflict.

https://auto.jepistons.com/blog/maximizing-horsepower-with-piston-skirt-shaping

https://www.sae.org/publications/technical-papers/content/970839/

-

I assume that you're not French. They hate that label.

Looks like I am one also. Merde!

-

1 hour ago, JMortensen said:

Does it matter?

That's my point.

I wonder if people see different things under their name than the general public sees. Or maybe tube80z changed a global parameter and everybody's subtitle changed. Your subtitle is "Donating Members" now.

-

Welcome back. Where'd you go?

-

1 hour ago, Miles said:

I have over 2000 posts. So not a newbie.

I could not respond to any posts.

Saw the same reply three times. So, it is possible.

Not sure you understood my point about the subtitle/name/label change. For whatever reason, after a name change it seems the forum software re-labels people as Newbies. I don't really get much from the labels anyway. Moderators can label you, or the forum software has default labels. I am, apparently, a "Members" now. Plural. What does that mean?

-

12 hours ago, Miles said:

Log in says I am a Newbie but have been here since July 28, 2001 and I cant respond to posts

Is it possible that you were trying to respond to an FAQ post? The FAQ reply problem has never been resolved. Your post count still shows.

I know that after I asked to have my subtitle changed from "Clandestine Moderator" ('cuase people were thinking I was a real moderator) that my new subtitle was Newbie. Weren't you a real moderator for a while? Maybe it's just the subtitle change.

-

I assume that you mean the inline resistor on the line from the ignition coil to the tachometer. I don't know what "POXY resistor" means.

It's in the wiring harness by the fuse panel under the glovebox. You can see the lump under the tape. It is rarely a problem. Shouldn't affect starting.

-

Seriously though, to the person posting the bot stuff - what are you learning? It is a fun game, but do you get paid if you fool people?

I n th e spi rit of A I I w ill p aste the sa me re ply in all A I pos ts/

A new AI bot! Welcome?

What kind of car do you have? Tell us about it. @hellersavana

F unny th is loo ks li ke o ne of my 7 th grade b ook repo rts. O pen up the E ncy clop e dia an d cha nge a fe w wor ds.

-

I n th e spi rit of A I I w ill p aste the sa me re ply in all A I pos ts/

A new AI bot! Welcome?

What kind of car do you have? Tell us about it. @hellersavana

F unny th is loo ks li ke o ne of my 7 th grade b ook repo rts. O pen up the E ncy clop e dia an d cha nge a fe w wor ds.

-

I n th e spi rit of A I I w ill p aste the sa me re ply in all A I pos ts/

A new AI bot! Welcome?

What kind of car do you have? Tell us about it. @hellersavana

F unny th is loo ks li ke o ne of my 7 th grade b ook repo rts. O pen up the E ncy clop e dia an d cha nge a fe w wor ds.

-

A new AI bot! Welcome?

What kind of car do you have? Tell us about it. @hellersavana

F unny th is loo ks li ke o ne of my 7 th grade b ook repo rts. O pen up the E ncy clop e dia an d cha nge a fe w wor ds.

-

People have reported odd results from aftermarket axles. Some appear to be longer than factory Nissan axles. You might call Silvermine and ask where they source the axles that they sell as an add-on in their ad. Aftermarket parts are generally sketchy. Take measurements or test-fit the axles while you can still return them.

Just curious, but why do you want to switch to CV axles? Edit - Looked back at your other posts. Part of the overall plan, I assume. The u-joint half shafts are pretty strong. Good luck.

-

18 hours ago, HusseinHolland said:

I need to figure out how speed signals, etc., are worked out for the given EMS - I also don't want to use standalone

If you buy an engine from one of the typical engine sources where are you going to get engine management? If you're planning to use factory stock EMS then the fact that the threads are over 20 years old doesn't really matter, right? It's the same stuff.

p.s. I get very few ads on the forum. But I'm on a computer. Are you on a phone? Good luck.

-

-

The crud could be from antifreeze that leaked in from a blown head gasket. The engine does look pretty beat up.

Aftermarket pistons and rings are getting harder to find, especially oversize. Better source parts before you have any machine work done. People are out there right now with freshly machined blocks and nothing to put in the bores. Can't find the parts.

Make a spreadsheet and fill it out, see what will work and how much it will cost. A used L28 might be the best route, as suggested. They were used all the way through the 280ZX years, 1975 through 1983.

-

6 hours ago, Dale280z said:

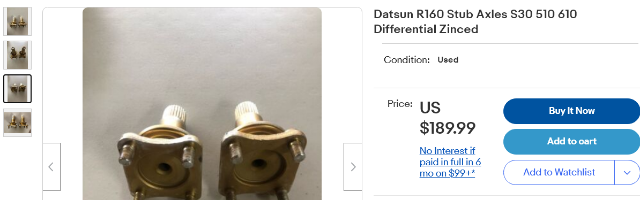

The indented portion of the flanges on these new ones are a few mm smaller and do not fit into the axel adapters I am using.

Sorry, I missed this part. Looks like you already compared.

No idea. There's a guy on classiczcars.com that has many spare parts. TerrapinZ. He probably has a set that will work.

Best guess would be an R160. They seem to be different, people don't call them R180 or R200 axles. Edit - except that they are bolt-in, not clip-in. There's a hole through the shaft.

No idea. Good luck.

https://www.ebay.com/itm/175411767044

-

I've not heard of any difference in that part of the axle. They're all the same, the half-shafts are swappable from 240Z to 280ZX. That locating ring is the same size across all of the Z's and ZX's, and R180's and R200's, I think.

It is supposed to be a very tight fit, like very close to zero tolerance. A few mm is huge. Are you sure it's not "almost there", maybe rust and crud are the problem? Old crusty paint? The parts look correct for the way they are supposed to work together. Make sure that they are the same temperature. Aluminum expands a lot more than steel.

Have you compared the dimension of the adapter ring to the raised ring of the half-shaft flange?

-

2 hours ago, Dale280z said:

The indented portion of the flanges on these new ones are a few mm smaller and do not fit into the axel adapters I am using. Any idea what these out of?

Which adapters? What "indented" portion? A picture would help.

-

Interesting that ZCD specifies them only for the R180. The 240Z's with R200 swaps is where people had binding problems in the past. Maybe ZCD knows something.

$9.99!

-

Best to be aware. Elon Musk co-founded ChatGPT.

It's a philosophical discussion.

-

-

Forgot to say, although I've mentioned it before, they are using us as beta testers. They are trying to get people to respond and interact. Fake us out.

On a different forum that I frequent I recognized the pattern and replied with a question that only a real person could answer, and ID'ed it as bot with words that character recognition shouldn't pick up. So far, no response. Somebody else had already responded with a "Like" to the comment. Kind of embarrassing.

"Big tech" will do whatever they can do to extract money from the masses.

-

Nobody really understands how Facebook and Google make money. But, apparently, they do.

Here's a decent review about the why and the latest. If you've ever used "Chat" when trying to get something from your cable or phone company then you can easily imagine a Chatbot taking the person's place.

Kameari street piston skirt /bore contact

in Nissan L6 Forum

Posted

Skirt coating stuff. There's a whole industry.

https://patterson-elite.com/piston-skirt-coating/

https://www.rosspistons.com/piston-coatings/

https://auto.jepistons.com/blog/je-s-patented-perfect-skirt-coating-is-a-breakthrough-in-piston-technology