NewZed

-

Posts

6625 -

Joined

-

Last visited

-

Days Won

60

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by NewZed

-

-

-

A new MC has it attached. Motor Sport Auto has the pin.

-

That's a good idea, in principle, and you made it work. It would be interesting to hear the engine spinning with the ignition disabled, spark plugs in. To see how the starter handles those missing tooth ends. Hard to imagine that the tooth ends don't matter at all, but who knows.

-

It could just be that a valve guide was tight. People have had them pop off for no apparent reason. Usually after revving. The gasket should be reusable. I used the same gasket for many removals in the past. A 300 mile gasket should be fine.

Beside the noise, it's a good idea to check valve lash on a new engine after it gets some miles on it. Beware though, today's camshafts have been known to flatten a lobe easily, soon after installation. It just happens. Hopefully it's not that but be ready. Post some pictures.

Good luck.

-

Didn't listen to the video and don't know anything about the history of the vehicle but the simplest thing to do, if it's an L series engine, is to pop the valve cover and look around. They are known to throw a rocker arm occasionally, especially after sitting a long time. Sometimes a valve keeper too.

More details about what you're working on will help.

-

No offense, but it's highly unlikely that you have the same ignition set-up. But maybe you do. Do you?

"Electromotive XDi crank trigger setup V1.8."

http://electromotive.com/wp-content/uploads/2017/04/XDI-v1.8.pdf

-

-

-

On 9/24/2023 at 1:00 PM, zboi said:

Crank sensor. 58x (60-2 teeth). The flywheel is 120 tooth, so remove 2 teeth every 58 teeth. Missing teeth should be 81 degrees before TDC. Drill hole into transmission and grind away ~1.5mm to achieve proper clearance.

You're saying that the starter ring gear teeth are to be ground off? What happens when the starter gear hits those two empty spots?

-

The headlight low and high beams are controlled on the ground end of the circuits. Sounds like you have a short circuit to ground on the high beam circuit. That would also cause the high beam indicator to glow. Both circuits get power as soon as you turn on the headlight switch. The switch at the base of the turn signal stalk determines which circuit, low or high beam (short or long), gets grounded.

-

Those odd things. Forgot about those. I've seen it proposed that they are meant to stop engine movement if the car gets hit from behind or hits something. Seems more like they might be meant for ease of engine removal and replacement.

Here's a place that might have some pictures. You'll have to browse.

-

Imagine the engine in the car with its tilt and choose accordingly. The vertical side will be the short one.

-

On 9/10/2023 at 2:52 PM, zboi said:

1/4" difference in the the space between the crank pulley and the timing indicator as I rotate the engine.

Beside the fact that it's a sign that the damper rubber has been damaged and/or is failing, 1/4" will almost certainly throw belts at higher RPM. I damaged a damper pulley on an old muscle car and it used to throw the power steering pump belt when doing typical high school kid stuff in the rain. Pretty exciting, but it was a good arm workout when it happened.

-

If you pulled on the rim of the pulley you pulled on the rubber. Might have damaged it.

10 thousandths is not 250 thousandths. Not clear what your first post meant, with the 1/4 inch.. Anyway, if your timing marks seem off that's a sign of a failing damper also. Good luck.

-

Both of those are not right, but the damper is most wrong. Damper rubber failure is not uncommon on these old engines. The crank pulley is mounted on the damper, aka harmonic balancer.

https://www.rockauto.com/en/catalog/nissan,1976,280z,2.8l+l6,1209226,engine,harmonic+balancer,5512

-

1976 is different so my first comment might be off the mark.

Here is 1976 -

-

There's a connector on the way to the gauge. If whoever cut the harness has been inside the car you might want to check there. C-1, it's blue. Also, it might be that in 78 they ran that wire up from the passenger side. My comment above is about a car like my 76.

-

Might help if you showed a picture of what you're dealing with. If the engine was in the car and the harness intact it would be in the bundle that runs along the top of the intake manifold. A yellow wire, according to the wiring diagram in the Service Manual.

Here's a web site with pictures. And what I think is the main bundle that then splits up. p.s. I don't think it's part of the EFI harness. The two wire water temperature sensor is but the one wire temperature sender, for the gauge, is not.

https://bringatrailer.com/search/?s=1978+280z

-

Download a Factory Service Manual and wiring diagram from the site below. The headlight low and high beam are controlled by the ground circuit at the turn signal stalk. Both circuits have power when the switch is turned on but only the one that is grounded will light. Seems like you might have a short to ground on your high beam circuit.

https://www.classiczcars.com/files/

-

On 8/18/2023 at 7:40 AM, 72turboz said:

Looking back at your first post I see that you do have an aftermarket cam of some sort. Is the cam timing adjustable? Might be too advanced. Of course, the Isky cam will probably be correct, but you might have possibilities already there.

On 7/23/2023 at 3:33 PM, 72turboz said:The cam specs are as follows; @015 TDC, Intake opens 33, Exhaust closes 33, Overlap 66. Intake Closes 77, Exhaust opens 77. Intake Duration 290, Exhaust Duration 290. Intake lift 540, exhaust lift 540. 112 LSA.

https://help.summitracing.com/app/answers/detail/a_id/4706/~/advancing-%2F-retarding-a-camshaft

-

The basic subject of this thread was covered pretty well years ago. The thread is kind of buried in the L series sub-section under Powertrain FAQ's.

-

3 hours ago, zboi said:

People really need to stop with the whole build the bottom end up crap

Kind of extreme from a guy who has no apparent experience building engines. I assume that you read something on the internet and absorbed it as your own. You were asking how to install a turbo just a few days ago.

Nothing wrong with questioning somebody's comment but if you're going to fake expertise try to do a better job. Better yet, just don't. And there's no need for the insulting tone.

-

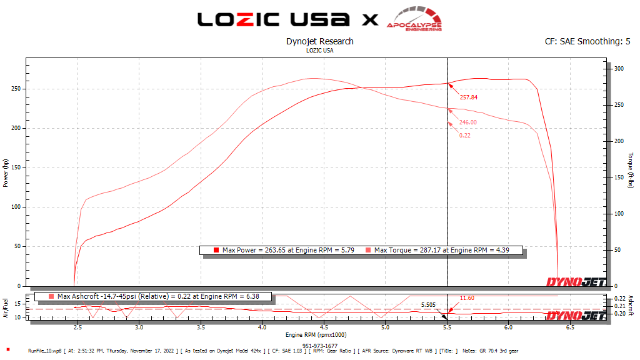

BRAAP did a lot of studying on the NA engines. He summarized his knowledge in the thread below. The third post and more might be relevant to your problem. I assume that your boost gauge is in the plenum. "Boost" is caused by restriction to flow. He also has quite a bit about port work. If the runners and ports are restricting flow a different cam won't help much.

Not an expert.

p.s. 270 HP from a 168 cubic inch engine is a lot. 1.6 HP per cubic inch. At the rear wheels. Have you thought about the bottom end, and durability? Solving your problem might be the end of the engine. Good luck.

-

Let it load upside down. People can manipulate it.

L28 + Vortec 4200 frankenstein

in Nissan L6 Forum

Posted

Here's an old thread, food for thought.