-

Posts

104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by vantage

-

Do you suspect the balancer mark not to be in sync with the actual piston TDC position? Might explain the startup issues you see. Could you do the test with only the first spark wire attached to cyl #1? I am quite curious if you get a carb or exhaust backfire with the current setup when testing cyl #1.

-

Do you have a timing light at hand? Connect it to spark wire #1 and point it at the balancer wheel. Have a friend then turn the starter and check if you see the mark on the balancer lining up with the degree indicator on the engine, e.g. cylinder #1 at TDC. Also, when you manually turn your engine so that the mark on the balancer wheel and degree indicator line up, does the rotor now point exactly to the vertical line on the distributor cap? (cylinder #1)

-

Looks like the rotor is turned 180º. Your distributor is at ignition phase cylinder 1 (as can be seen on the balancer mark), so the rotor must point above the distributor clamp on the left side. Of course you can always swap the spark wires 180º to make this work. Here is a picture from the factory manual: http://www.atlanticz.ca/zclub/techtips/distributor/distributor_clock.gif Pop & smoke: i am quite sure you experienced a backfire through the carbs (e.g. spark in the intake phase of the cylinder). That would result in a loud popping sound and a bit of smoke coming from the engine department (from the air box/carbs). Try this, remove all spark wires from the dist cap, mark each with the cylinder number, then start by plugging in the spark wire for cylinder #1 in the correct HV terminal (on the left side above the clamp, the side of the terminal is marked with a vertical line). Now try to start for just 2-3 seconds (so you dont flood the other cylinders) and listen what the engine says: - Do you get a backfire through the carbs? -> Spark wire goes to wrong cylinder, ignition in the intake phase. - Backfire through the exhaust? -> Rotor or wires are 180º wrong, ignition on the exhaust phase, igniting unburned gas. - Does the engine kicks back? -> Wire is probably correct but timing much too advanced, retard timing by turning the distributor a bit and try again. - Does the engine seem willing to turn, maybe even turns a bit faster? -> Then the spark wire is correct, add the next spark wire (cylinder #4 in the next HV terminal clockwise). If the the wire for cylinder #4 also works, insert the rest of the spark wires one by one and try to start. Keep the tests brief so you dont flood the remaining cylinders. If the engine and/or carbs have not been run for a long time, it might help to apply starter spray (or brake cleaner, the cheaper variant to the carb after making sure that the wiring is correct and you dont get backfires anymore.

-

Indicator lights use a different flashing unit than the hazard light, so a difference in speed should not be a concern. If you have a problem with the TS flasher, then none of the bulbs would work. I guess that your indicator (instrument) lights are blown or there is a ground issue.

-

Keep in mind that you need to connect the B/W wire to the regulators IG input, or your alternator won't charge the battery. A posting on zhome (http://www.zhome.com/ZCMnL/tech/280Alt.html) indicates that the terminal 'L' on the new alternator is the one to connect the B/W wire to (see also special note about engine run on at the end of the article): 4. Connect the black with a white stripe wire to the white with black stripe wire. This connects the "L" terminal to a switched 12V. The indicator (dashboard) lights are part of the turn signal circuit, if they don't work they are either blown or there is a ground problem. Slow turn signals indicate that the flash unit has not enough current to work properly (its a simple bimetal switch so it will blink faster the more current flows). Check your battery voltage and the turn signal bulbs to see if they are broken or the connections or sockets are corroded. Let us now how starting the car works out, good luck!

-

I am still waiting for the coil mount being finished by a CNC workshop, its currently installed using cable ties. After the coilpack is mounted securely, i'll have a dyno session

-

The fuse to the right (Ign/Flasher) covers the side indicator and the +12V feed to the IG terminal of the alternator. When you switch on the Hazard switch, the side indicator circuit is disconnected from the fuse, and only the B/W wire is connected to the fuse. So if the fuse still blows with the Hazard switch set to on, B/W is apparently wired to ground somewhere. Try removing B/W from where it is connected currently and check if the fuse still blows.

-

When the hazard switch is set to the "on" position, and you then switch on the ignition, does the fuse blow? If so, it is very likely the BW wire originally going to the external regulator terminal IG. When you converted your Z to the 280ZX alternator with integrated regulator, do you remember what happened to the BW wire whih was connected to the external regulator terminal IG?

-

The '73 Service Manual, Section BE (Body Electric) show the connectors on the first two pages, might help a bit. There are two B/W wires for the ignition, one from the ignition key to the resistor, the other one from the coil to the tacho. I guess that the fuel pump was connected to B/W from the ignition key, so you might want to check the B/W coming out of the ignition key lock to the connector in the photo first.

-

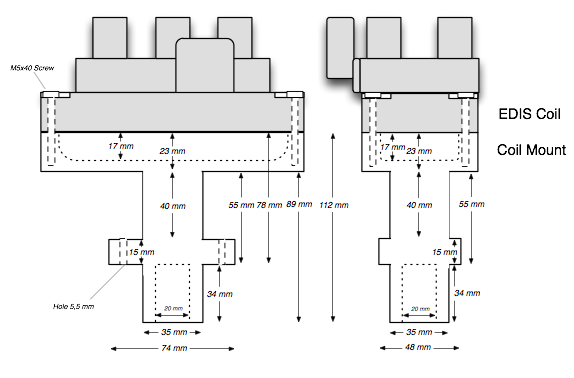

No photo as the CNC workshop has not delivered yet, but have attached a drawing so you get an idea how it will look like. The scope of my installation was to keep the 240Z as original looking as possible, the components are installed where they are not in plain sight and the distributor will be swapped against the EDIS coil. BTW, i build myself a tacho conversion circuit for the MJ installation, and after doing a recalibration my current controlled tacho is quite precise (less than 4% error), so these old beasts are not that bad after all

-

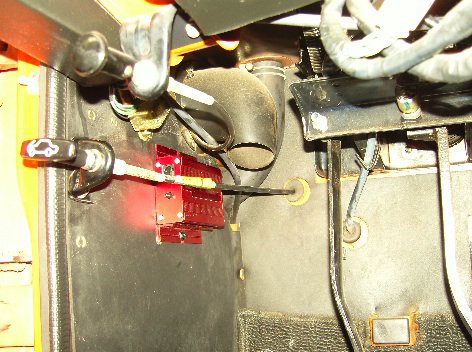

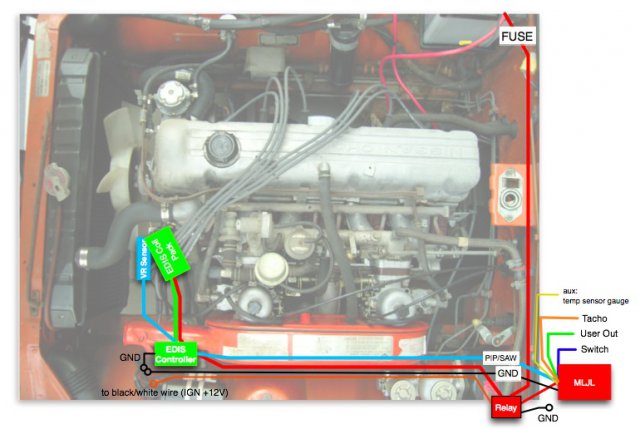

i have just finished the MJ installation in my '72 240Z last week. A 36-1 trigger wheel was machined to fit on the balancer and was then shrink fitted. The sensor was mounted on the original air pump bracket, next to the EDIS controller. The MJ unit is below the dashboard on the drivers side (keeping the wiring short and easy to install). EDIS Coilpack is mounted on an adapter in the original distributor position. Spark wires are sourced from NGK, they have the correct wires for EDIS to spark plug in black (NGK 593-nnn). I've added a quick chart what the layout looks like, and a wiring sheet for the installation. Wiring Megajolt Datsun 240Z.pdf

-

Megajolt is an ignition controller for carb engines. I like carbs but am happy with fuel injection setups too, i just dont think that a L24 gasonline with standard compression would benefit from a conversion to FI except if you aim for fuel economy. Good luck with the fuel pump and the carbs, looking forward to a running engine to continue our little tour of the Z's ignition and tacho setup.

-

Still here, no worries. I am doing well, thanks, my 240Z is back on the street since a week as the Megajolt ECU conversion has been finished. Now need to get on a rolling road to do the maps. I don't think that the dealer did install the updates, i would guess that you have a transitory model inbetween two series where manufacturing already changed/added options. How are your Webers, making progress with the seals? Its much easier to fix tach issues when you have a running engine

-

Thanks, you're welcome!

-

The diagram looks good to me. The product description mentions the following "This switch is suitable for single and small dual electric fans.", so it depends on the size of the two fans you have. If in doubt, add a car relay, which is activated via the fan control unit (instead of the fan), and switches +12V from the battery (via a fuse) to each fan.

-

Now looking at the chart again, i should have said #9, not #12, which makes no sense as #12 is keyed anyway. Good job! Its easier to start the engine with a bit of advance so set it to roughly 10º, then start the engine and use a timing light to set it around 10º. Keep in mind that the engines exact idle advance should be checked with a warm engine and slowly turning the distributor to advance/retard the idle timing until the idle feels solid, the 10º is merely a factory recommendation. Installing new gaskets and seals in your carbs does not really sound like a fun job, good luck!

-

You can still feel unlucky if you dont find out while the car is not running. Right now you are on track! 1. Swap the spark cables 180º to check that the engine starts now 2. Exchange the magnetic ring between the two distributors and see if the old one works now. Whatever you send back then, (accidentaly the new distributor with the old magnetic ring) is left to you I have never rebuild a 280ZX distributor but would assume that only #12 needs to be turned 180º to fix this.

-

Looks like he did! Check out what happens if you swap the spark cables by 180º, if the engine then starts you need to correct the rotor shaft position by 180º (check out distributor chart on previous page).

-

Ok, so the mystery is solved, there is something wrong with your original refurbished distributor, probably the stator (magnetic ring) or the coil or both. Since you have been through four coils, i would assume that the magnetic ring or assembly is at fault. Spark wires look good! I don't think you get that much more power out of your HEI module compared to the E12-80 but replacement modules are much cheaper. Webers (at least DCNF) would like to see 3-4 psi, could you try to lower the pressure in small steps and see what happens when you start? 1. Can you post some details what happens when you try to start the car, e.g. does it nearly catch on, just turns the engine, still backfiring (where? carbs and/or exhaust?), any kickback on the pistons (knocking)? 2. Do you have the factory choke lever connected to your carbs? Does the setting of the choke lever make a difference to the engine when trying to start? 3. How do the plugs look like immediately after you tried to start, bone dry or wet? With dry plugs you have either an issue with the carbs not delivering enough fuel (e.g. too lean mixture) or you might have a vacuum leak so your engine sucks in too much air with the same effect, a too lean mixture. Wet plugs indicate a much too rich carb setup, not enough air, or the spark is too weak. 4. When you hook up a multimeter to the battery + and -, what voltage do you have when you turn the starter? Its ok if the voltage goes down to 10 volts, but if you see 8-9 volts or less you spark might be very weak, so it fails to ignite the fuel/air mix. Its not unusual that an old battery is too tired to deliver enough current/voltage when trying to start, even though it would show a healthy 12-13 volts without load after charging.

-

Not sure about the '81 model but on previous models the ignition is handled by the transistor igniton unit, the ECU manages fuel only based on a trigger impulse from the ignition. So if there is a problem getting a spark, you need to check the output from the magnetic coil trigger unit in the distributor and the functionality transistor ignition itself. The attached wiring scheme might be useful. You won't see any activity on the tach while the starter is activted, as the RPM is well below 500 when turning the engine.

-

What sort of distributor is this? How do i hook it up to a 240Z?

vantage replied to d3c0y's topic in Ignition and Electrical

You should be able to trigger your MSD6A with the optical Crane pickup. I havent installed this particular setup yet, but similar setups based on the Lumenition OS50 pickup, but don't see a reason why your setup should not work. You can't use an optical trigger setup to directly drive a coil, you need a transistor or CDI ignition inbetween the optical pickup and the coil. I have found a wiring setup in a MegaSquirt thread which uses the optical pickup as a trigger, so for the MSD 6A it could look like this: Grey: Connect to white wire of the MSD 6A unit (points input) White: Connect to Ground Black: Connect to +12V via a 510 Ohm Resistor Reference: http://www.msextra.com/doc/ms1extra/Dizzy_Ignition/DistrCrane_v3.htm -

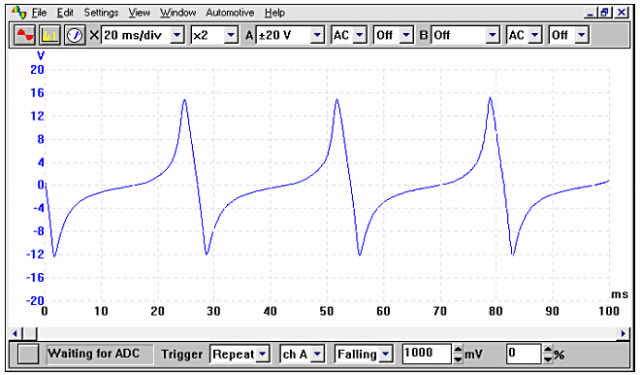

Hmm, not sure why you would get a backfire through the carbs if the wiring is correct, hard to say if you don't stand in front of the engine. The Proform is compatible with vehicles that use a 4 pin HEI but not necessarily with your 280ZX distributor coil. But even if the HEI module is not compatible with your pickup coil. the E12-80 should be! Could you ask your electronics store if they have a scope? If so, give them a visit with your distributor and the installed pickup coil and connect the two output wires to the scope. Watch the screen as you turn the distributor by hand, the picture should look somewhat like the one i have attached. If you just get a flat line instead, then there is indeed something wrong with your pickup coil and magnetic ring. This is the best test for a coil pickup so you will know for sure what the condition is.

-

Backfire through a carb sounds like the spark happens in the intake phase, are you sure the spark wires are connected in the correct order to the distributor cap? The ignition won't work at all if the four wire tacho is removed, as one of the coil wires goes through the tacho connector. So if you pull the tacho connector, you disconnect one side of the coil too. You can get quite a decent multimeter for $20-$40, this one looks good as example: http://www.amazon.com/Mastech-Ranging-Digital-Multimeter-MS8221/dp/B0006GD9Z6/ref=sr_1_1 I would love to have a Fluke or even an Agilent but they are quite pricey, i use a Voltcraft AT-200 most of the time. There is a chance that your Proform module is not compatible with the distributor coil/magnets output signal, can you do the following tests: 1. Swap the coil wires from the distributor coil, e.g. connect red to HEI module 'G' and green to HEI module 'W'. 2. Could you wire in the E12-80 module to check if you get a spark before you order a a second 280ZX distributor. I don't have a 280ZX distributor/coil at hand so unfortunately cannot do a test with the Proform module.

-

You can have the pickup coil recoiled (rewired) but i doubt that this would be economic considering the low prices of a coil. Can you get a new pickup coil (and maybe a decent multimeter while you're at it)? Did you get the backfire through the carbs (air box coughing smoke) or through the exhaust? The later one would be an indicator that the distributor is installed 180º from the correct position, but as the axle is keyed that would be unlikely. Maybe the cap is installed 180º (no idea if thats possible or your spark wires? Just a thought. Check if the plugs are fouled with gas, might be the case after trying to start the engine several times. Have you tried to retard timing by turning the distributor?

-

Regarding the points setup, does it appear to nearly catch on? Then your timing is probably too retarded. Distributor finger and cap are ok? Thats really bad luck to catch three defective distributor pickups in a row. On the good side, if you can get the pickup replaced or fixed, you should be able to get your HEI or E12-80 setup working at last