katman

Members-

Posts

611 -

Joined

-

Last visited

-

Days Won

6

katman last won the day on February 18 2021

katman had the most liked content!

About katman

- Birthday May 18

Profile Information

-

Gender

Male

-

Location

Acworth GA USA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

katman's Achievements

-

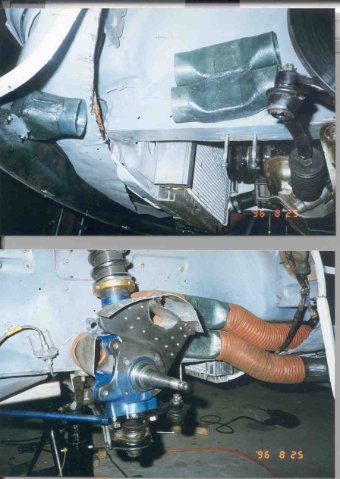

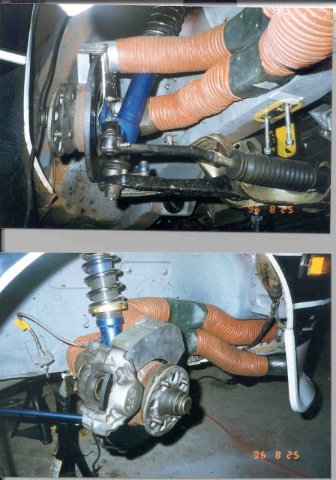

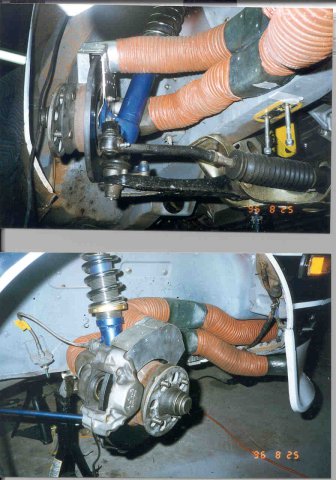

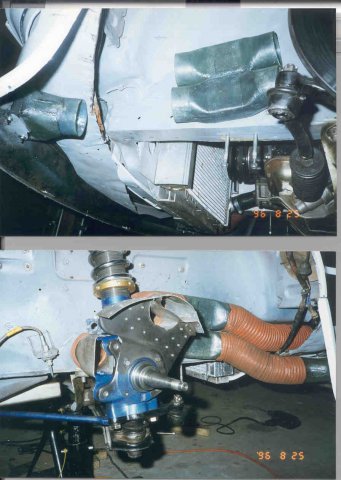

You could do this. It gets busy, but there's 2 intakes for ducts on either side of the air dam and one beside the grill, all ITS legal at the time. For Willow you probably don't need the third duct to the top of the brake pads blowing down, just the duct on the hub and the "can" splitting the air to both sides of the rotor.

-

Great memory Jon, yes after the SCCA outlawed my remote reservior shocks I built 2 E36's, won another ARRC, and then they slapped that Sonic Intake Restrictor on the E36's and killed the motors so we quit SCCA. Anyway, vented or not, I'd try to avoid as much of the standard backing plate as possible. It's there on a street car to keep mud and water off the rotor. AydinZ71 are you talking about an EP car? What tracks are you racing at? Example: Roebling Road no problem. Road Atlanta big problem. But if you're stuck with solid rotors and calipers, what we did for ducting is about all you can do. See pics above. I'll try to see if I have a picture of the duct overtop of the caliper.

-

Straight into the center of the rotor is what you want- a vented rotor is going to naturally expel the air out the periphery, also helps keep the wheel bearings cool. In our class we were limited to 14" wheels so there wasn't a lot of clearance between the rotor or caliper to the wheel. Is this for street? Autox? Track?

-

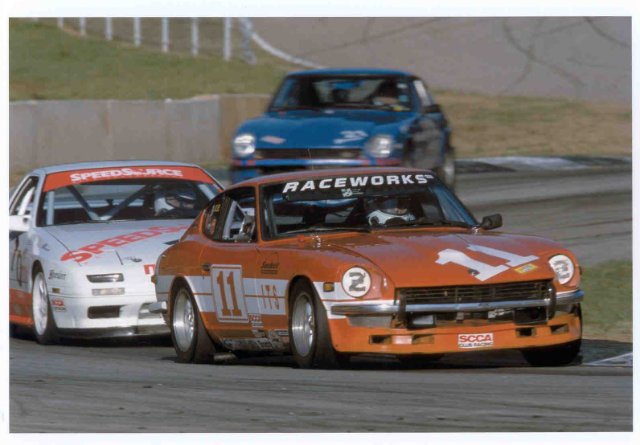

These are ITS 240Z, but same concept for a ZX. You have the advantage of vented rotors, so you don't really need the duct that blows down over the rotor, the one that blows at the hub area will supply your air to the vents to expel. I had to add the 3rd duct for Road Atlanta after Panoz took out the dip and turn 11 (and eliminated what separated the men from the boys) but I don't have a picture or the real parts handy.

-

Nope. Unless they've changed the rules since I left, you are not only limited to a 0.5 compression ratio increase, but you are also limited to 0.025 machined off the head to achieve that. If you exceed that the head gasket thickness won't matter. You also have to run stock type pistons. There are many things engine, suspension, cage et al that you can do in EP but cannot in ITS. If you're anywhere near competitive in EP you'll be illegal in ITS. Build one of the other, IMHO.

-

Drum brakes for a racing application

katman replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

Soup can? I'm insulted, lol. Custom fabricated air splitter! BTW your picture of the melted brake pad backing plate is how ours looked like after 7 laps at Road Atlanta after Mr. Panoz took out the dip and put in a downhill braking zone for turn 10a. Took a lot of duct work, Carbotech HT-9 pads, perfect rear brake bias, and cryo treating everything in order to get 20 laps at Pro-IT race pace out of an ITS 240Z. One duct splits to both sides of the rotor, one cools the hub and bearings. I eventually ran a 3rd that fit between the caliper and the wheel (not easy to do with rules mandated 14" tires) and blew directly over the pads from the top. And while it wasn't specifically allowed by the ITS rules, my caliper pucks might have had a series of 1/8 diameter hole drilled about the exposed periphery so that air could actually get behind the pads and into the puck cavity. And as somebody already mentioned, don't remove your parking brake to save weight- being able to adjust rear drum brake slop during a race is priceless. -

Historic/Vintage Race Standard Brakes

katman replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

katman? Where the hell has he been for the last 10+ years? Oh, that's me, back from the dead. That thread may have been on improvedtouring.com. Assuming your friend also has to run the stock drum brakes, here's how we made brakes last in an ITS car, which at the end of its development was probably as fast as any CP vintage car. I don't know what compound Carbotech has today, but back then the HT-9 was the only thing that would hold up to the heat on the front. The HT-10's that replaced them were not as good, but that was about the time that SCCA pissed me off by outlawing remote reservoir shocks so I quit thinking about Z brakes. I ran both the Nismo rear shoe, and the relined Carbotech shoe, I think. We cryo treated rotors and drums. We ran the parking brake so we could adjust the rears during the course of a race. That and having an adjustable prop valve so you can make the rears take their share of the load is critical. If you aren't turning the friction surface of the drums blue, then you ain't there yet. Scour the junk yards and find every Z drum you can find and have them turned and expect to rotate in a new set every weekend. Up front, don't fall into the trap of using a pad that maximizes the pad material, in other words instead of this | | , you want this \ /. The outer radius of the rotor runs hotter because its going faster (linearly) and wears the pad faster. Nothing worse than having to pump the brakes every corner to take up the slop from tapered front pads, maladjusted rear shoes, and expanded rear drums. We drilled holes in the backing plate on the rears for some cooling, but not much else you can do back there. Up front we ran three 3" ducts on each side, one to the hub area of the strut to cool the bearings, one to a custom "can" that blew air on either side of the rotor, and one that blew into the caliper overtop of the pads. That one was tricky to make as there isn't a lot of clearance between the caliper and a 14" wheel that we had to run. I also drilled a series of small holes around the periphery of the pistons just behind where they contact the back of the pads so air could circulate behind the pads from the aforementioned duct over the pads. PM me and I'll send you some pictures. -

Besides the rain issue another down side is a welded diff strains the stub axles more. Broke 2 on our first ITS race car (basically stock hp) while we owned it, and after we sold it the new owner broke another and totalled the car at Moroso (we told him it was time to replace them, doh!). Know of 2 other ITS guys that broke stub axles (and 1 more totalled car) before we all got smart and started running LSD's. Never heard of any stub axle failures with LSD's. Not to mention the fact that welded diffs were slower around a road course 'cause you're always dragging a tire around! I wouldn't do it on the street, but people get away with it.

-

Me thinks the RX-7 that won the ARRC in ITS this year was on A6's. That's 20 laps at Road Atlanta. We tried them on our 2 time ARRC winning 240Z once (with extremely well dialed in shocks before the SCCA banned them, bastards, but I digress, point is it was a well sorted car so if any Z could run an A6 it would have been us) and weren't happy with the longevity or grip but it's been several years and proly a few compound iterations ago. At the time we tried them on a Z the Speedsource guys were running A6's for qualifying only, they still raced on the R6's. But it appears now they may go 30+ minutes on a road course. With R6 Hoosiers the break in is everything for longevity so I would imagine same thing for A6's. Run them 2 laps until they warm up and them put them in a dark place until the next weekend. Don't even think about running them the same weekend you break them in. Used to make a huge difference for us in tire wear and grip longevity. YMMV.

-

Well this ranks right up there with a fellow racer who brought me his Rebello "rebuilt and recurved distributor" that he'd just had Fed Ex'd to the track. It wouldn't turn and he asked if that was normal. I told him it was normal for Rebello.

-

Don Potter (The Friendly Curmudgeon) Passed Away Last Week.

katman replied to RTz's topic in Non Tech Board

Proly been 9 years since I last saw him, and he wasn't the picture of health back then. He probably should have been dead 10 years ago but was just too stubborn I'm sure he's in hot rod heaven drinking a beer with Frank Leary and planning the next Giant Killer Z. RIP old buddy. -

help identifying coilover kit

katman replied to cockerstar's topic in Brakes, Wheels, Suspension and Chassis

The threaded collars are Carrera. They're designed to fit over a ring (missing from the picture) in a groove machined into the strut housing, but you can, and should, support them with a welded on collar. IIRC the Carrerra's used to come with two nuts (spring seat with the spring guide, as shown in the pic, but another nut just like the spring seat but without the spring guide) and an oring and you squished the oring between the two nuts to lock them together to keep the spring seat from moving. The jam nuts as it were, appear to be missing. The camber plates look like somebody copied Tilton, but not exactly. Seem to be missing the spherical bearings, although looks like you have the c clips that hold them in. Also appear to be missing the thrust washers and bearings that go between the upper spring seat and the sliding camber plate. -

What TonyD says is a good idea. If you're not up for that, or a dry sump, make sure you "blueprint" the oil system, i.e. remove all the sharp edges everywhere the oil has to turn to aid in eliminating cavitation and restriction. Bad spots are typically in the timing cover, and filter boss area- especially where the oil galley enters the boss area. Grind all that out smooth like you were porting a head. I think the crank probably wasn't heavy metal balanced properly, wasn't a straight as you thought it was, or wasn't a good choice to start with. Every engine builder has their secrets to determine if a crank is going to "be happy" and not move around alot. Some guys "ping" them. Torsional twisting turns into radial deflections because when torsionally displaced the balance is thrown off. Likely a harmonics problem IMHO. Like John says, the right ATI can go a long way. We may never know, especially without actually seeing the parts, but I think your shotgun approach is the right idea in this situation. Best of luck with it.

-

First, buy a factory service manual so you can tell what the TDC mark is on your crank pulley. The white mark may be something the PO painted on there to mark 12bdc or whatever. On a 71 there should be one nick that's slightly bigger than the others. It will be the leftmost as you look from the front. That's TDC. Each other mark is 5 degrees advanced from that. Second, go here http://www.ztherapy.com and buy the 240Z tune up video. If the timing is right, running too rich could just be jet position. Or, somebody has put the needle at the wrong height in the piston. Needles and/or jets could also be worn, but most likely its a matter of proper tune. Know that when everything is perfect, it will still smell like gas often. Carbs are just a semi metered fuel leak, and with 70's combustion chamber and metering tech we were never burning all the fuel we put in. Best of luck.

-

Share your favorite Math/Science/Engineering jokes.

katman replied to X64v's topic in Non Tech Board

Ok, a priest, an opthamologist, and an engineer are playing golf and they come up on a foursome that's just playing slow as molasses. Not only are the slow, but they seem oblivious to the threesome behind them. The priest, opthomologist, and engineer try their best to look impatient in hopes of catching the foursome's attention so they'll be invited to play thru, but no joy from the slow players. Finally, the opthamologist has had enough and flags down a Greenskeeper in a cart and say's to him- hey, what's the deal with that foursome in front of us? They are slow as hell and won't let us play thru. The Greenskeeper replies: "oh, that's a group of blind golfers. They have these cool golf balls that make a noise so they know where it is, and some sort of GPS thingies they carry to help them line up. I'll drive up there and tell them you want to play thru. The priest says: "Oh, I'm so sorry we were so impatient. I had no idea. I'll have my congregation pray for them this Sunday". The opthamologist says: "Yeah, I feel terrible. Get their phone numbers and I'll invite them to my clinic to see if there's something we can do about their sight". The engineer says: "Why don't they just play at night?" Snort....