-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

As I hinted at in a previous post, I was getting E-Throttle errors that kept me from having control of the throttle. After working with Vi-PEC, they provided updated firmware & software and this appears to have cleared up my issues. Thursday evening was the first time I had proper control of both the throttle and idle speed. Friday night my Wife and I both drove the Bus for the first time... on our long driveway. Put big smiles on our faces. It showed all the signs of being lively and responsive with almost no tuning time. Even left four foot long 'scratches' with very little effort.

Now the bad news. I started up my laptop to make some adjustments and... no screen. Black. plugged in an external monitor and it's black as well. It was booting up and allowing me to log in, but wouldn't run a monitor. My assumption is that the video card has gone belly up. Anyhow, I ordered a new laptop yesterday, but it's a custom build and will probably be about two weeks before it arrives. There's plenty to do in the meantime though. I still need to wrap up the rest of the wiring... lights, gauges, etc., as well as see to a few mechanical items like CV joints, brakes, and so on. Guessing 4 to 6 weeks before I take it out on the road.

-

Pretty functional I would guess.

-

Video as promised. Sounds a lot like an air-cooled V-dub

It’s idling fast in the video – about 1600 RPM. I’m still sorting out the E-Throttle, which doubles as my fast idle control.

-

1

1

-

-

This is inspiring me. We just picked up a 1980 Westifalia for cheap from a friend who did not have the time to mess with it.

Its actually in really good shape but that air cooled 65hp motor HAS GOT TO GO.

Biggest issue I see is trying to get a radiator in it without having to cut the front up and install a grill, runs coolant hoses etc.

In my opinion the cooling is the most difficult part of the conversion and I actually like the looks of the factory grille in the Vanagon, so I’d be really tempted to put in the effort to retro-fit the later model stock stuff. I’m sure you already know this, but there are literally hundreds of Vanagans with Subarus. It looks like a pretty straight forward swap for those that came water cooled.

-

Can hardly wait to see a vid of it purr-n

Soon.

-

I've completed a number of smaller tasks since my last update, such as installing a DBW Infiniti G37 throttle pedal, completing the Vi-PEC wiring, and so on, but the real news is that she started up for the first time tonight

-

OK, i'm convinced that electric fans are better now. Thx

is an expansion tank going on the left side where the radiator cap is?

Yup, around the corner behind the tail-light along with a carbon canister.

-

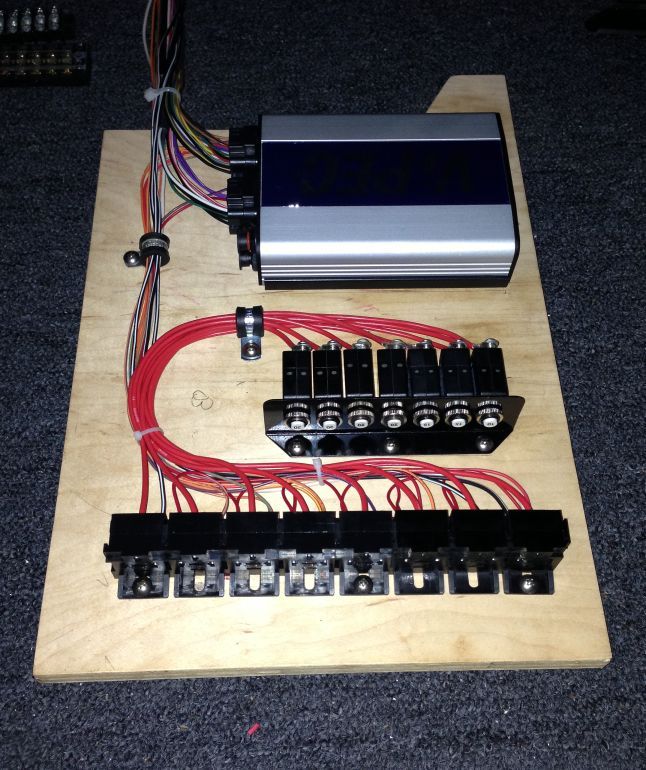

The engine is finally wired. The only wiring left at the rear is the battery and starter.

I have about a dozen or so wires left to run to the front. The only remaining challenge are the foot position sensors.

-

Today is a good day. I have not found time for rt260 for more than a year and I didn't see that changing in the foreseeable future. I felt that it was time for a new owner to breath some life into this Z.

I have passed this car on to good friend Tube80z and I'm looking very forward to seeing his plans unfold! -

That's an amazingly clean job.

Thank you.

Any reason you went with electric fans as opposed to one running of the crankshaft?Several:

- The Subaru is not set up for a mechanical fan so you would have to construct a fan drive

- As I see it the only practical orientation of the radiator and airflow would require pushing air through the radiator. Most engine driven fans are built as pullers, not pushers.

- Pulling air through a radiator is generally more effective than pushing

- It would require the radiator to be in the vertical position directly behind the engine. That equals crappy maintenance access to the engine

- You would still need to route the discharge air without a visual impact to the Bus

- Electric fans are generally quieter and more efficient

I can think of a few more reasons but I think we’re already past a solid ‘heck no’

Have you fired it up yet?

Have you fired it up yet?Still working on wiring. It’ll be a while yet before its running.

-

What car and what EFI system do you intend to use?

-

There's nothing better in the world than a wife that supports your insanities. Just remember to return the kindness.

Oh, and congratulations!

-

Started mocking up the board. It fits neatly into one of the cabinets in the rear of the Bus.

I've also spent quite a bit of time researching and testing the E-throttle over the last couple of weeks. I think I'm finally comfortable with what needs to happen and what to expect. Next is to finish up the board, install it, and tackle the remainder of the wiring.

-

Thank you, Sir. Maybe someday I'll actually get to drive it

-

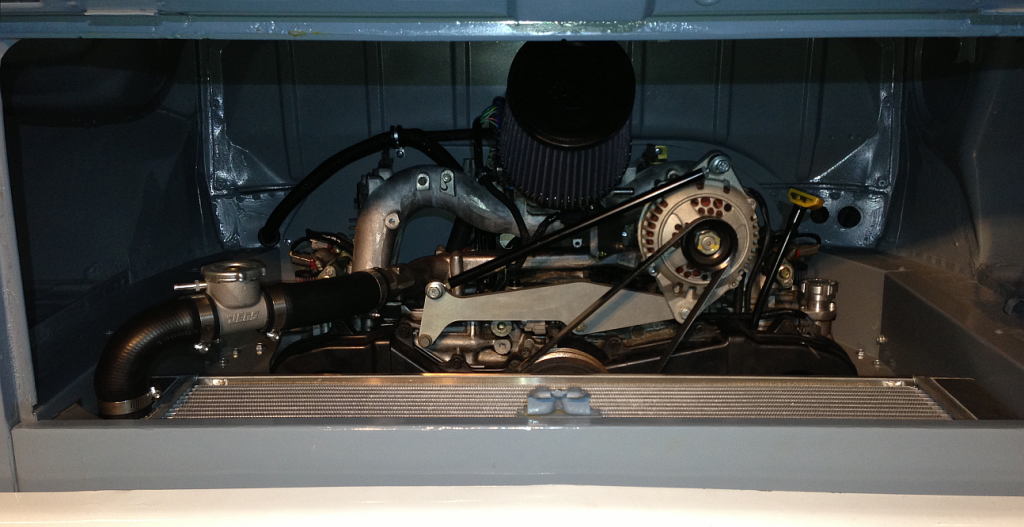

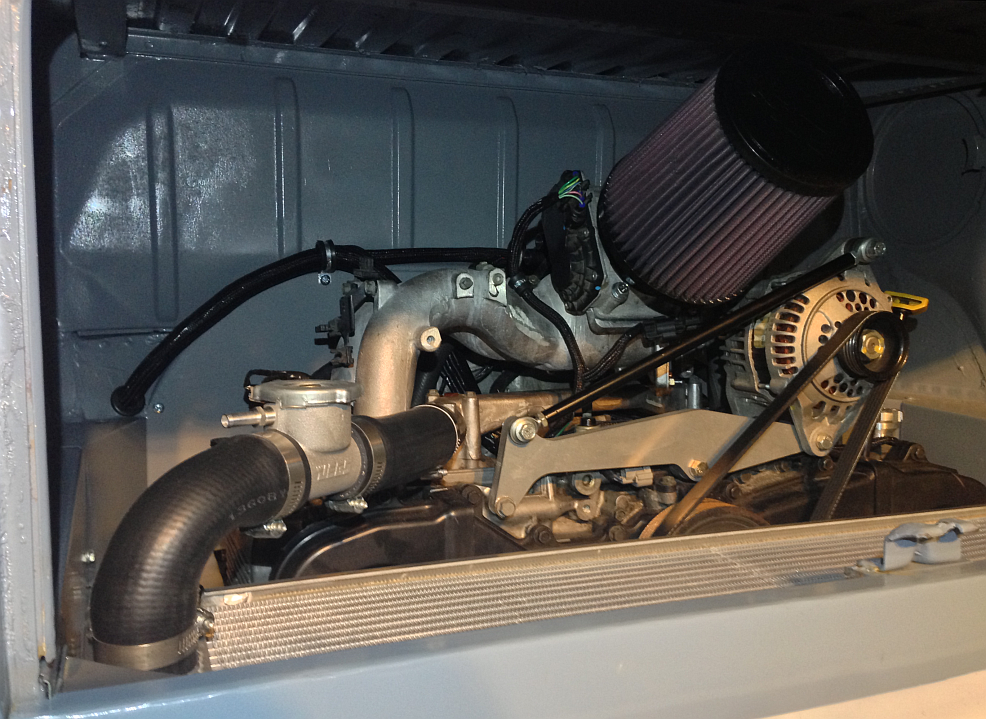

Removed the old spent wiring harness, neutralized a lot of surface rust underneath, repaired battery tray, repaired bumper mounts, modified the rear apron to accommodate the radiator, painted everything, and reassembled. It's pretty well complete mechanically. I've installed AN push-lock fittings in the fuel system, but I'm still waiting on 2 more to show up. Once those arrive I've have about an hour or so to wrap up the fuel system end all that's left is a coolant overflow bottle, carbon canister, and some tune up items (plugs, wires, PCV valve, oil, etc).

Then it's on to EMS and wiring.

-

Interesting about the tune. I have noticed it takes a lot longer to get back to idle than it takes to close the butterflies. You have any details of this clutch set-up like brand, part numbers, etc?

I assume you're asking about the button clutch? I took the lazy way and bought everything together as one package. Tilton part number 52-33130. It's a triple disc 5.5" for LSx. Includes everything in this picture...

Side by side of a stock sized flywheel...

-

Something else that may help speed up your shifts is reprogramming the ECU. The OE programming is intentionally designed to keep the RPM's up between shifts and these can be nulled with HPTuners, etc.

I think Ron Tyler found it was 38 pounds less weight than the Corvette flywheel and clutch combo.Yup. Sort of. 38lbs less than a Monster Stage II clutch with 18lb flywheel. But I believe that package is nearly identical in weight to the stock stuff.

-

That's impressive and kind of weird. Is this home-made cider vinegar or some special brand? How do we reproduce these results?

Pretty basic actually. The vinegar came from Safeway in gallon jugs. I would guess most of the supermarket apple cider vinegars are pretty close to the same thing. The natural acids in the vinegar are what is attacking the rust. All I did was completely submerge the part in the vinegar and be patient. That's all there is to it. The only 'magic' in that sentence is completely. What I found was that anything not submerged and exposed to the off-gassing of the vinegar would rust nearly as fast as the rust was being removed from the submerged portion. Aside from that, it's child's play.

-

I dropped the transmission mount in a bucket of apple cider vinegar for a few days. This time I snapped a before and after. The black areas are paint...

The fuel tank was far worse.

-

Been a while since my last update. Progress is happening, I promise. A few of the noteworthy items...

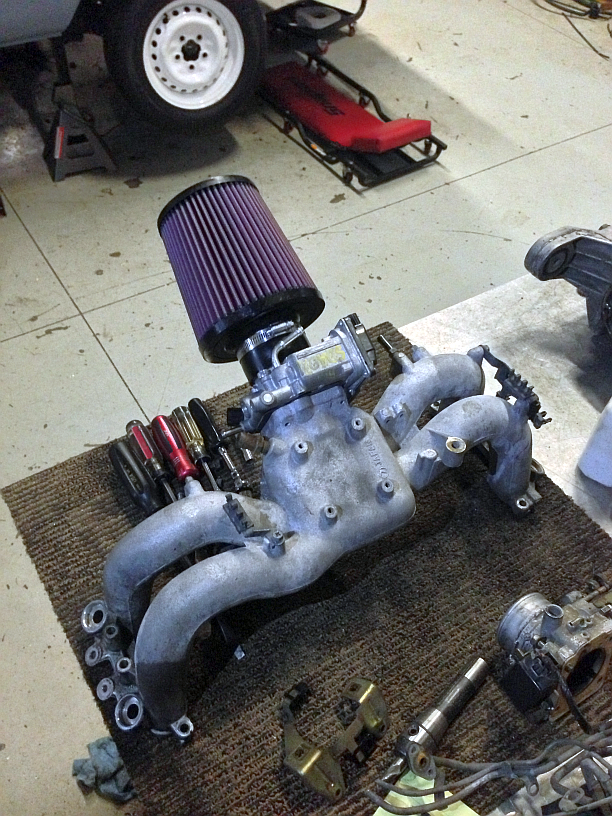

Exhaust is completed on both sides.I adapted the Bus throttle cable to the Subaru throttle body. Didn't like it. Not one bit. The combination of the 18 mile long cable, with two more bends, made for a snatchy throttle feel. Various springs in various places subdued the feel to heavy numbness. I considered modern cables and liners as well as hydraulic operation but ultimately settled on an electric throttle. This (and other wants) ultimately lead me to aftermarket EFI. Most of you know I've been fond of Wolf EMS for many years, but they don't offer a system that directly supports Drive by Wire (ViPEC calls it E-Throttle). Long story short, I settled on a ViPEC i88 purchased from Vic at Pauertuning.com. I'm looking forward to getting my feet wet with ViPEC. It's a bit harder on the pocket book and the learning curve is a little steeper, but has a lot to offer in return...

I picked up a used 2006 Legacy E-throttle and adapted it to the older manifold. The main hurdle is the bolt pattern is 'off' by about .070". I machined the throttle to fit but, in retrospect, I should have modified the manifold instead...

I disassembled everything in preparation for rust proofing, painting, and some rust repair at the bumper mounts. Once everything was out, pulling the fuel tank for inspection seemed obligatory. Glad I did. Aside from the hidden rubber hoses that were cracking, the interior of the tank was in a bad way. Rust had settled in deeply. I decide to try the apple cider vinegar trick and filled the tank with 15 gallons. It worked FAR better than I expected. I wish now that I had taken some before pictures, but believe me when I say it was BAD.

Here is the after pic. You can see the signs of the deepness of rust penetration. Very pleased with the results...

-

"seasonal affective disorder"

Would that be SAD?

-

The rear spring/shock arrangement is interesting. Any more pics you can share, particularly of the outboard end, and how it ties into the rear hub?

-

Happy New Year!!!

Happy New Year!!! -

…only to get showered with trash when the fans reversed.

But if you run a smaller set of fans with an alternating mechanism as one always runs those brushless DC fans can last a looooong time! And multiple fans mean partial cooling for limp-home.

Fair enough.

…plugging any internal bypasses, and incorporating them and the thermostat up at the radiator so no secondary hoses to run for heaters front and rear, just taps in the piping going up front, with those neat stepper motor heater control valves now available.

Not a bad idea.

Unless, of course you are indeed thinking of retaining exhaust heat recovery heating in this van....

No way Jose! She gets liquid heat. It was one of the bullet points for ditching air cooled.

VW Bay Window Bus - Subaru Powered

in Other vehicles

Posted

Wrapped up the rest of the chassis and instrument wiring, installed new retractable seatbelts (original belts were non-retractable and when I started installing them I was suddenly reminded of how often I cursed them in my other Bus’s. Life is too short to screw with fixed belts), repacked the CV joints/new boots, changed the transaxle fluid, adjusted & bled the brakes, and a handful of other miscellaneous maintenance items.

I put about 30 miles on the Bus. A couple issues have surfaced... the left front brake caliper is retracting the pads too much causing significant pulling to the right while braking. The alternator is looking to go belly up. It’s charging fine until it gets hot, then shuts down. When it cools down it starts charging again. And my WBO2 sensor is reading artificially lean. Need to get a new sensor coming. I’ve been tuning with my butt for now, just to get it drivable. I’m debating on picking up an NGK AFX controller. Anybody have experience with the NGK?

I suppose you want to know how it runs? It runs FANTASTIC. I’m very pleased with the power. Even with the hobo tuning its coming around nicely. It’s geared a little too low (it’ll take off from a standstill in 3rd) and goes through the gears rapidly. As far as cooling goes, it’s probably too early to tell. Ambient temps have been hovering around 90 degrees and the highest coolant temp I’ve seen is 201. That was when leaning on it HARD at low speeds and then stopping, idling, making some adjustments, and repeating. Most cars would struggle to keep temps down to the stat in this scenario. With more normal driving it typically wants to run around 190 degrees (thermostat is 173 degrees).

And I guess I should post a pic of the G37 electric pedal. It fits reasonably well. Stock vs G37…

I’ll post another video soon.