-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

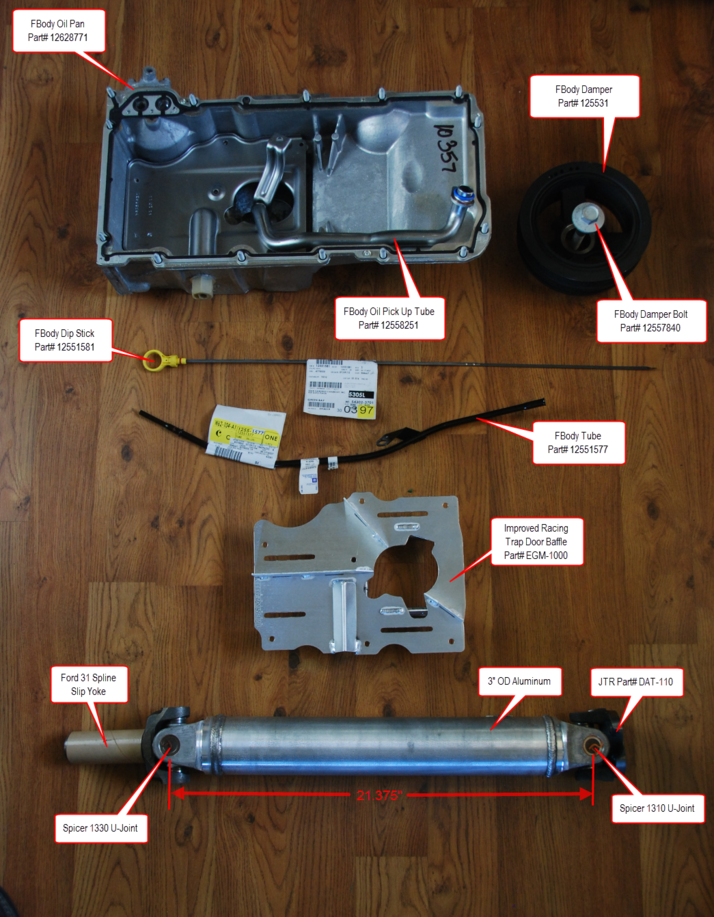

Been working a lot lately. Out of town, weekends, long hours, etc. Not much has been accomplished. Night shift is failing miserably. The only thing I seem to fit in is ordering parts. So, here’s the next batch…

The aluminum driveshaft was built by Driveline Service of Portland. I have had a number of shafts built by them and they’ve always been a pleasure to work with.

The remainder was ordered from Improved Racing. I really need to put a plug in for them. This is the first time I’ve ordered from Improved and I mistakenly missed the free shipping on orders this size. That evening I received an email from the President, informing me that the free shipping option should have been available to me. Cliff notes – On their own accord, they refunded my shipping costs and asked me to do some testing to make sure there were no problems with the site. The effort extended made it clear that they value customer satisfaction, and understand the importance it carries. I suspect they’ll be around a long time.

I was invited to co-drive the Locost at Packwood this Sunday, so the Wife and I have carved that one into the calendar. And it’s looking like I’ll escape work Saturday as well, so I will attempt to poke the Magnum T56 into the car to see how things land.

-

1

1

-

-

Maybe not what you want to hear but... you've gone so far and done so much with your car that I think it wouldn't be difficult to justify some custom built long tubes. Heck, you might even be able to con JohnC into the job.

-

Posts deleted. The thread starter asked for SBC's and picture sizes need to be kept down to something reasonable.

-

They were both asked to work out their problem offline, but chose to dispute publicly instead.

-

The good clamps are designed so that one exhaust tube in the joint projects beyond the clamp face by .1" and fits into a recess in the other clamp face. This significantly improves the seal and makes alignment a lot easier.

I think you lost me, John. I recently picked up these V-Bands from ATP. They’re on the lower end of the price scale and I see nothing special about them. But I see no issue with running one pipe through and letting it pilot into the other flange. Am I missing something?

-

Stumbled across a unique hybrid at this year’s Mckinnon fly-in/cruise-in…

-

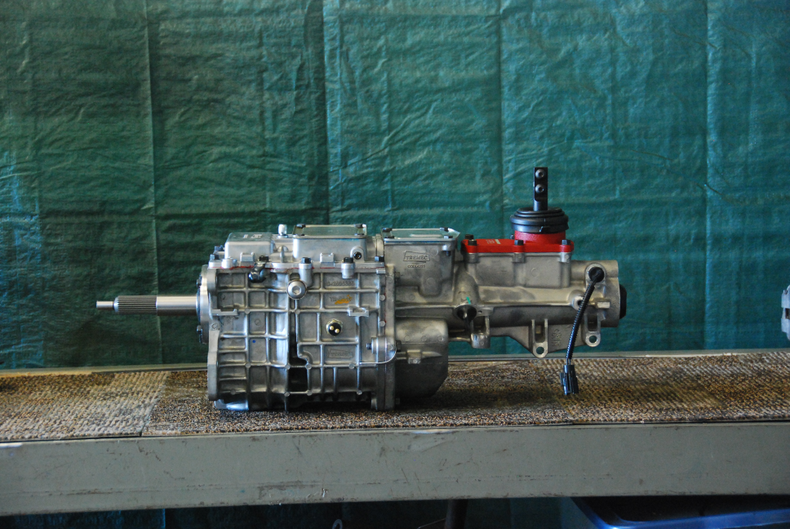

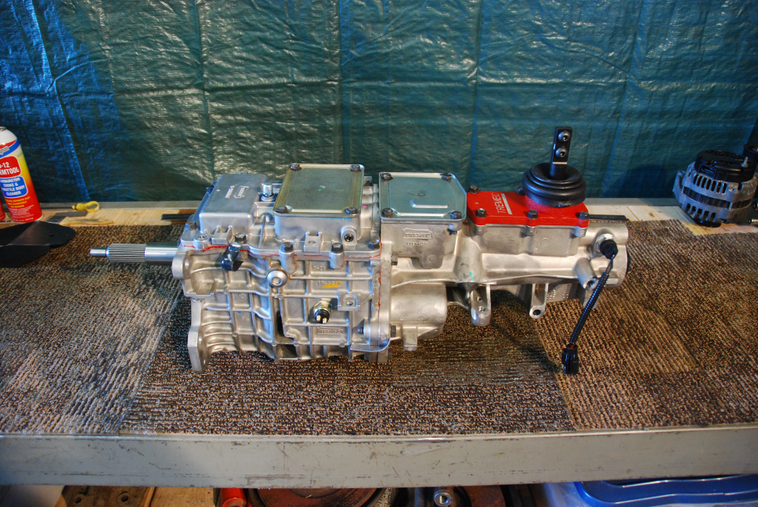

BrianV8Z was kind enough to offer his new Magnum T56 for test fitting. It's slightly different than a production T56 (rated for 700ft/lbs!), but very similar dimensionally. I'm out of town for the next three day's and I've got a busy weekend planned, but I'll make a dry run as soon as I get a chance.

-

1

1

-

-

Thanks guy's. I would consider making a small run of motor mounts if there was some interest. They work well with the TKO, but I'm not certain how they would work out with a T56. I have a T56 bell floating around the shop, so I could give that a look, but without a complete trans, fitment would be purely guesswork.

-

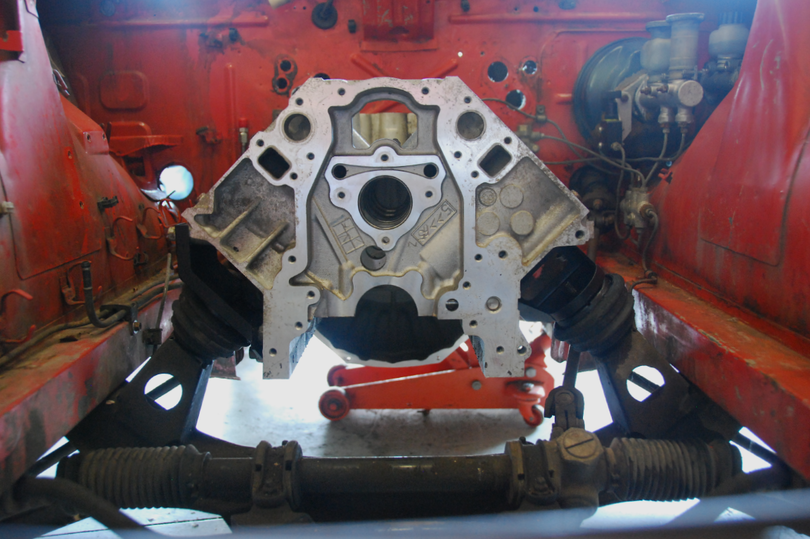

Ron, I may have missed it but you sold the car with the M3 motor and bought it back, but what happened to the M3 motor? Also, looks like you went with the aluminum block after all?

I kept the M3 motor for a while, but recently sold it to my son-in-law for his 240z.

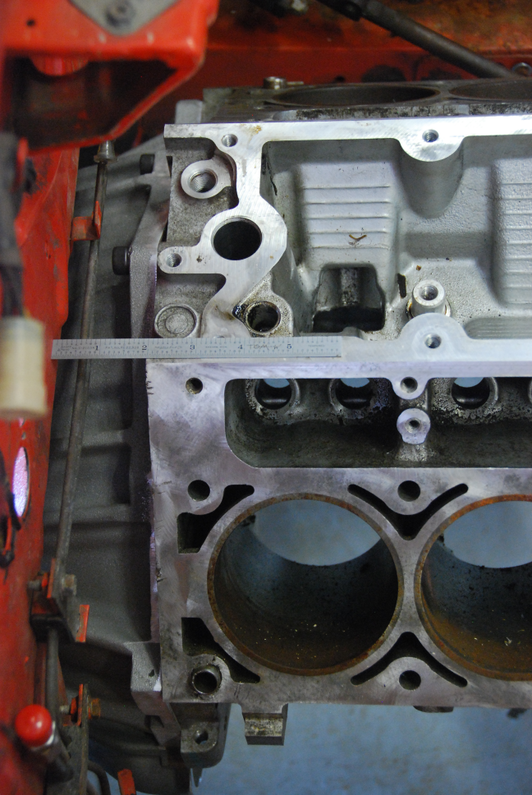

The aluminum block is only for mock up purposes. Being aluminum and gutted it's a lot easier to horse around than a fully assembled iron block.

-

I want a ride!!!

You'll be one of the first to take the keys.

Nice Ron! What are your plans for the EMS? Wolf V500?

I like GM EFI, so it'll get a factory 411 ECU with HP Tuners software.

-

Absolutely

-

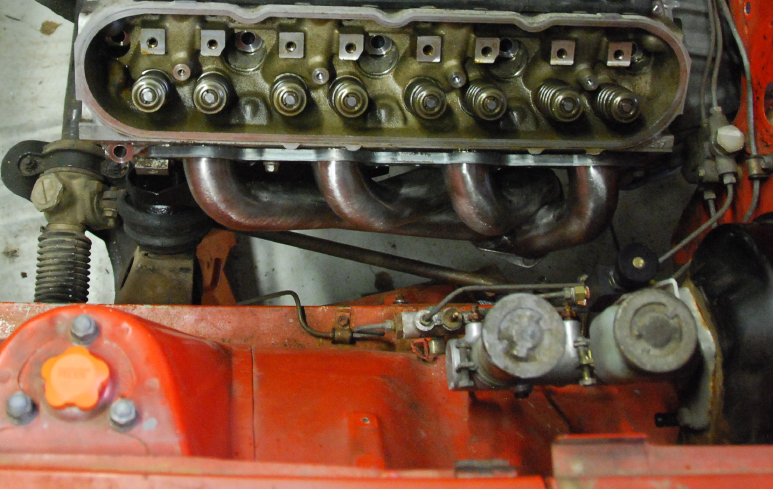

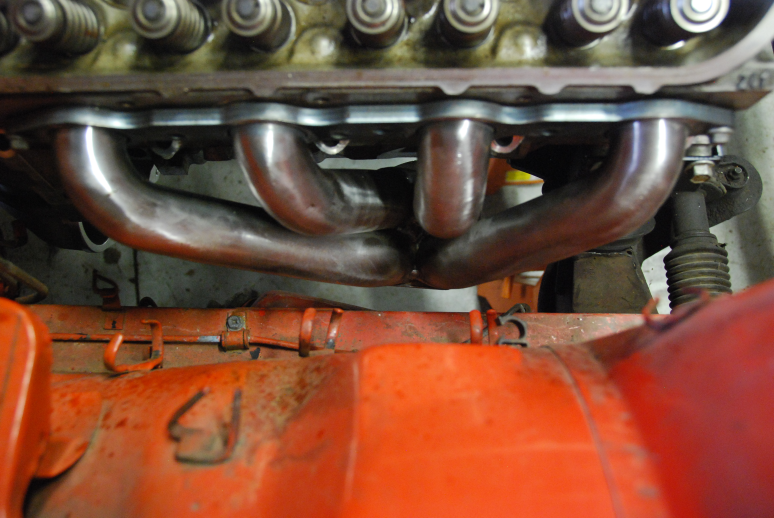

Header clearance...

-

Finished the motor mounts (w/BMW E36 isolators). Just eyeballing, it looks like the engine sits about a 1/2" higher and 3/4" more rearward than the JCI mounts...

-

Congrats. Doesn't look like the lack of an LSD is holding you back one bit!

...it has the welded diff in it.

Tire chatter at 25 seconds gives it away

-

Fiberglass

-

Christmas in July.

Sanderson headers arrived from JTR. Not my favorite design, but they'll get the job done for now...

New TKO600 showed up as well...

I had Liberty Gear perform thier typical massaging which includes:

- Bronze Shift Fork Pads

- Surface Enhancement/Processed Hubs & Sliders

- Internal Shift Linkage Upgrade

- Liberty's Exclusive Threaded Front Cluster Bearing Support

- Carbon Fiber Blocking Rings 2nd, 3rd & 4th Gear

Monster Stage 2 clutch: Kevlar disc, 18lb Chromoly flywheel, and ARP bolts also made thier way into the project...

- Bronze Shift Fork Pads

-

Calico, Please read #5... http://forums.hybridz.org/index.php?app=forums&module=extras§ion=boardrules

-

Sorry - didn't know the rules (should have). What donation level is required?

Thanks.

Dave

The minimum amount is all that is needed.

-

I edited out your for sale ad. You must be a donating member to advertise here.

-

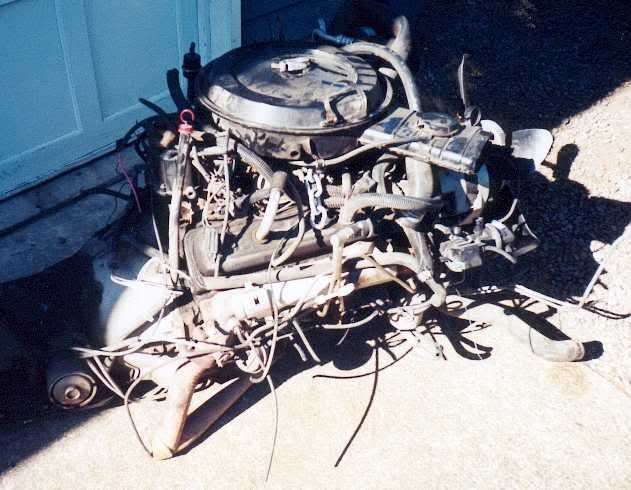

A long time ago in a galaxy far, far away....

First SBC swap:

Second SBC Swap:

Before...

After...

-

If your tach. is working correctly, and it's connected to the positive side of the coil, it's current triggered. If it's connected to the negative side, it is voltage triggered.

-

-

-

Don't forget about Beta Motorsports

Finally acquired one of the 7 wonders of the S130!

in S130 Series - 280ZX

Posted

Time for you to start following forum rules. Please make an effort to use proper punctuation, capitalization, and spelling.