-

Posts

818 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by dat240zg

-

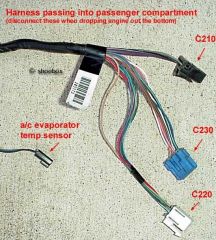

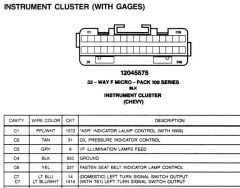

I'm still having the issue of the fuel pump not turning back on after priming. In previous posts, people have stated that the problem was that the harness had been changed so that the wire from the oil pressure sending unit was being used for a oil pressure gauge rather than to the PCM. (If I hardwire the pump, it turns on and the car will run). I checked the harness diagram and the tan wire from the sending unit actually goes directly to the oil pressure gauge (stock) and not to the pcm. Is there something that I'm missing? I sent the pcm back to Speartech get a few mods done and they believe that the oil pressure sending unit at the back of the intake manifold doesn't need to be connected to the PCM inorder for the fuel circuit to be complete. If it does need to be connected, which pin on the PCM does it go to? It wasn't originally wired to it (that I can tell) - or - was there a wire from the gauge back to the PCM to complete the circuit? Here are pics of the instrument panel connector and pin description: The oil pressure sending unit is the tan wire: The harness as it goes in to the passenger compartment (number C220) Thanks for helping me understand. Bryan Dat240zg

-

Every 240z fan will OMG when u see this

dat240zg replied to czecho's topic in S30 Series - 240z, 260z, 280z

Looks like rust under the bumper as well. -

It Runs!!!!! It Really Freakin Runs!!!!

dat240zg posted a topic in Gen III & IV Chevy V8Z Tech Board

Finally got it to run! After talking with Jon at Speartech (and with the input of several of you here on the site) I hardwired the fuel pump just to test it and ..... It started and ran! Pig rich, rough, idle was too high...but it ran! I actually let it go for a minute or so before shutting it off. I'll be sending the PCM back to Jon for him to dig through and test to see if there are any damaged parts, etc. Man, it sounded strong! At this point I'm so happy I'm shaking! Bryan -

Question about LT1 Oil Pressure Sensor / No Start...

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

Grumpy: Thanks for the post - I read through it - very good info. Jody: I'm going to run a setup similar to yours. Problem is, Jon over at speartech disconnected the wire for the oil pressure sensor from the PCM, so I'll have to go back and try to trace it to its origin. Hopefully I'll find the wire is snipped somewhere in between. Thanks again for the help. Bryan -

Guys: I'm still working on getting the LT1 to run for longer than a couple of seconds. I've tested everything (according to the LT1 no start document) and have power to the places I should. What I believe is happening is that I'm not getting the signal needed from the oil pressure sensor at the back of the manifold that triggers the fuel pump to kick back on - thus the car runs out of fuel almost immediately. The car has a speartech harness, and on the harness, the one wire coming off of the oil pressure sensor (tan) is designated by speartech for an oil pressure gauge. I have the wire going to my autometer gauge, but due to the fact that the dash is out getting restored, the gauge is not hooked up. What I'm wondering is, should the gauge be hooked up this way? If so, how is the PCM getting the signal to kick the fuel pump back on? Any thoughts? Thanks in advance. Bryan

-

I bought a passenger fender and hood from them. The hood fit fairly well, but was approx. 1/2" too long. The fender was rediculous, not fitting well at all, too long, not shaped well, the opening for the inspection panels is too small, etc. Problem for me was that the body shop had already welded the headlight bezels to the fender and I was stuck with having to pay them a pretty penny to fix what didn't fit well in the first place. I think that you'd be better off buying a factory hood and fender from some place like arizona z car and then having a body shop blast them and zinc coat them. Bryan Dat240zg

-

My (simple) Solution for mounting extra gauges...

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

Davy: It's a black vinyl that I purchased on ebay to redo the vinyl below the door. I had enough left over to cover this as well. It does emulate the glove box, using the screws on the edge of the glove box rim to bolt up. then again, maybe I have blurred vision. Ha! That's not your eyes...that's my blood sugar dropping and making me shake....took me 5 minutes to get a few good shots...Time for some orange juice! Bryan -

My (simple) Solution for mounting extra gauges...

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

Dave: Man, I really like that megaview. I can't go back and spend more money, but that looks like the ultimate. I've seen some of the guys who have removed their HVAC and radio controls on the 240. I'm going to be keeping both - my A/C is controlled by the stock looking panel (datsun cable control on the Hotrod Air system) and the radio is a flip face cd/mp3 so it shouldn't stand out too much. All that said, I really like your solution. Bryan -

My (simple) Solution for mounting extra gauges...

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

Mario: The gauges that I put in there are, for the most part, not going to be quick glance gauges - the exception is the AFR gauge. The bottom right is a D-pic, almost like a g-meter; the nitrous and volts shouldn't be spiking and the window switch is a set it and forget it thing. My dash should be back from the upholstery shop in a week or so, so I can actually mount it up in the correct position. I've been using an old dash that I had laying around to mock it up. Thanks for the comments. Bryan -

Just thought I'd share this with you guys. I've been testing the different A-pillar gauge mounts that are supposed to work in a S30 (with modification) and just wasn't pleased with the fit. Instead, I came up with a simple panel that I mounted in place of the glovebox. Total cost on it is somewhere around $7.00. Took me about an hour to measure, cut and drill and then overnight for the vinyl glue to set up. Allows me to have 4 2 1/16 gauges that aren't regularly needed to be mounted where I can still see them from the drivers seat with the glove box door open. Also still had enough room to mount my MSD window switch. The plan is to locate my nitrous switches below the window switch, so everything can be buttoned up and out of sight. Thoughts/criticisms? Front: Back:

-

-

Thanks guys. I've got a few days to iron out these kinks and then try to road test it some time this weekend, weather permitting. Dale: you hit it exactly - I was beginning to think that the car was never gonna fire...BTW, didn't end up using the opti, but just keep the engine cover pieces. I'll be shooting the opti back to you this weekend. Ended up that my electrical problem was tied to the ignition switch. Had power in the key on/engine off position, but during cranking, no power. Once I figured that out, things became a little more clear. Bryan

-

Scared the crap out of me too!!! I finally figured out the issues that were keeping it from starting and after a quick turnover, it started up! Unbelievable!!!! It's pig rich and will only stay running for a couple of seconds, but holy shnikes! Louder than all get out too. Man, I'm still shaking....can't believe it started... sorry....just a little excited. Bryan

-

Leadership Development It's a middle school principal position. My wife and I have always loved the NW, and have been looking for the chance to move that way. We'll see.... Bryan Dat240zg

-

Just like the title says, I'm considering applying for a job in Canby and am looking for any info that someone could add. Thanks. Bryan Dat240zg

-

Yeah. After having bought the product, I'd have to agree. The only "caution" would be making certain that you have the correct fittings (correct thread pitch, tip shape, etc). From what I'm gathering, the flare fittings used by Datsun are different enough from others with the same thread pitch that if you used them, they would still leak (Does that make sense?). Maybe some of the guys that are more familiar with stock parts can chime in. Bryan

-

I can tell you about this setup, as I was one of the first to purchase them. At that time, I had to wait for several months while they "ramped up" production. When they came, they were loosely crammed in a box, with the longer pieces bent to fit inside. The construction is nice, but the bends were not exactly the same, so you may have to tweak them to fit. The pieces definitely look good. That said, I have had persistent leaks at some of the fittings. I've worked at them, contacted Mike (owner of NOS motorsports) about the leaks and he basically blew me off. So, all that said, just be careful. Hope this helps. Bryan dat240zg

-

LT1 Fuel Pump Wiring Question

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

Guys: I know that there is a thread somewhere titled dumbest automotive screwups and this is probably going to need to be added to it. After all of the testing and checking and such it came down to me being an idiot. Last summer when I pulled the motor from the firehawk, I went ahead and switched out the coil and opti cover. I told the people at Jegs that it was a late '94 LT1 and so they sent me a vented cover. I didn't think anything of it until this afternoon. I had pulled the waterpump off of the car and was getting ready to swap in my new vented opti (Dale, you're totally correct - I now know that I need the timing cover, cam, harness, etc for the swap, not just the opti) and tested the optispark connection at the distributor for power and ground. Had both. It was then that it dawned on me about swapping out the cover and the fact that the connector for the early opti is different that the one for the later. Bottom line: the connector was just "sitting" in the plug, but not connected to anything. So to make a long story short, I'm an idiot. Sheez. So, until I can pull together the rest of the parts needed for the swap, I've purchased an early style opti cover to get the car running and I'll swap the other in when I do the hot cam kit. Live and learn. And kick myself. Bryan -

LT1 Fuel Pump Wiring Question

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

alright. Pulled the waterpump and the opti connector and have power at the yellow wire (No start document said red, but I don't have one). I'm guessing that I have a bad opti due to the fact that if I touch the first "pin" on the opti plug, my fuel pump continues to stay on. Hmm... Getting ready to replace the opti with a later vented style. Bryan -

LT1 Fuel Pump Wiring Question

dat240zg replied to dat240zg's topic in Gen I & II Chevy V8 Tech Board

Well, in doing more testing, with the key on, I have power at the injectors (positive side). However, under cranking, I should be getting a pulsing signal through the negative side - which I'm not. Sends me back to the optispark. Maybe more to come. Bryan -

Guys: I'm feeling like I should be really close to getting the Z started but am stumped as to what is not functioning correctly. Here's the situation: I now have power to all the correct areas: coil, icm, and injectors. The fuel pump primes and shoots a ton of fuel out, but then when it's done priming, it shuts off (0 fuel pressure) and the computer doesn't continue sending power to the pump - during cranking there is no power at the pump. The harness is a speartech harness and the fuel pump is wired using the relay from the stock ECU. Have I wired it wrong? BTW, thank you for the pm's regarding tips; I read the LT1 no start document and others that several of you sent. It could be that I'm missing something really basic. If so, sorry! Bryan Dat240zg