-

Posts

216 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by SDgoods

-

-

JPNGarage, Are these wheels made in malaysia? Who makes them? Are they gravity cast?

-

Bumping this, there is so much misinformation going around, this should be stickied,

I am trying to figure out what gasket to use with my p90/F54. The gasket that came off and the Ishino/stone gasket I bought (p79 I believe) block off most of the ports on the spark plug side of the engine, being the "oem" gasket.

Other than the 2 sentences stated in this thread:

Question,

having the water holes on the exhaust side of the head ( less on the spark plug side), will this increase the amount of the water moving past that side of the head, and thus reducing the chance of spot boiling, and helping reduce heat faster ?

NigelI have not come across anything regarding those being blocked off. Is this side of the engine the feed or drain portion?, as mentioned by TonyD, which really matters where the restriction is. Understanding that the OEM is meant to block these ports off, the question is, will the older gasket benefit the head with opening up the spark plug side ports and will it seal with there being too many holes in the gasket? (as verified by looking at pictures of the gaskets in relation to my head.)

-

l28ET in 73 240z

I found very little information regarding this valve. It's the valve that connects the cyl head outlet (that goes to the heater core) to the Heater core outlet (that goes to the water pump), and it allows water to circulate upon the engine warming up as opposed to just sitting in the engine itself and potentially creating hot spots.

Now, This requires a fitting off the back of the head with 2 ports; one port going to the heater core, the other going to the Y pipe that connects into the heater core outlet (and back to the pump) The one that came with my car has one port, and when i got the car, the system was simply hooked up with lines going to the heater core and from the heater core.

So, is this setup with out the radiator bypass valve safe to run? (lines going straight to and from the heater core)

If not, is there a source for this radiator bypass valve (I cant seem to find one).

I'm really trying to get my stockish and relatively simple setup running as efficient as possible by doing things 'the right way', rather than simply modifying and hoping that it will work.

Any input would be great!

-

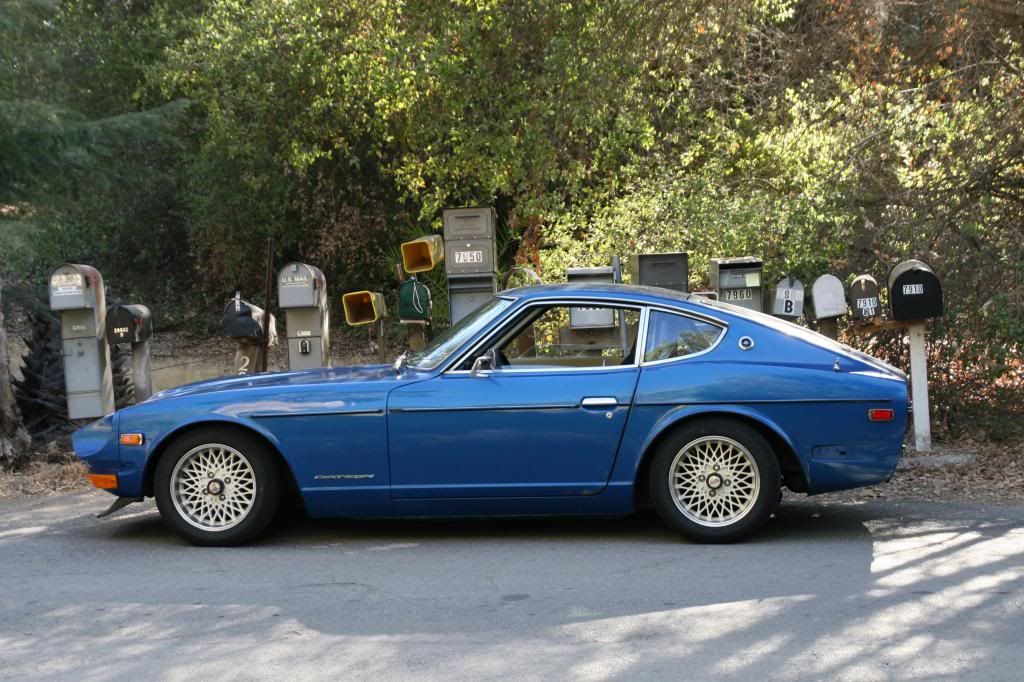

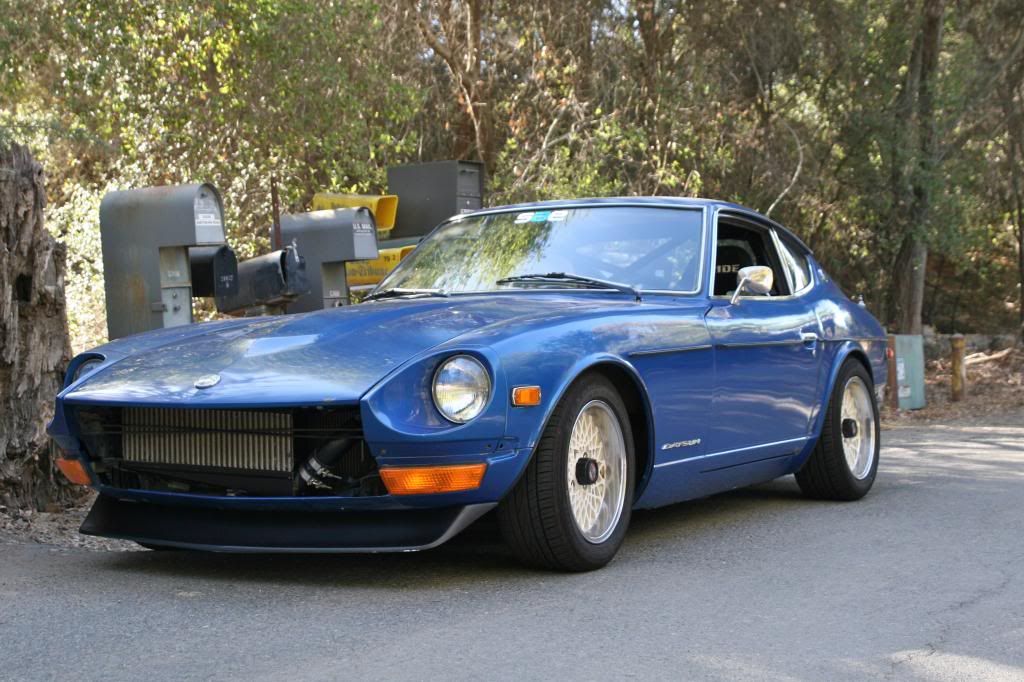

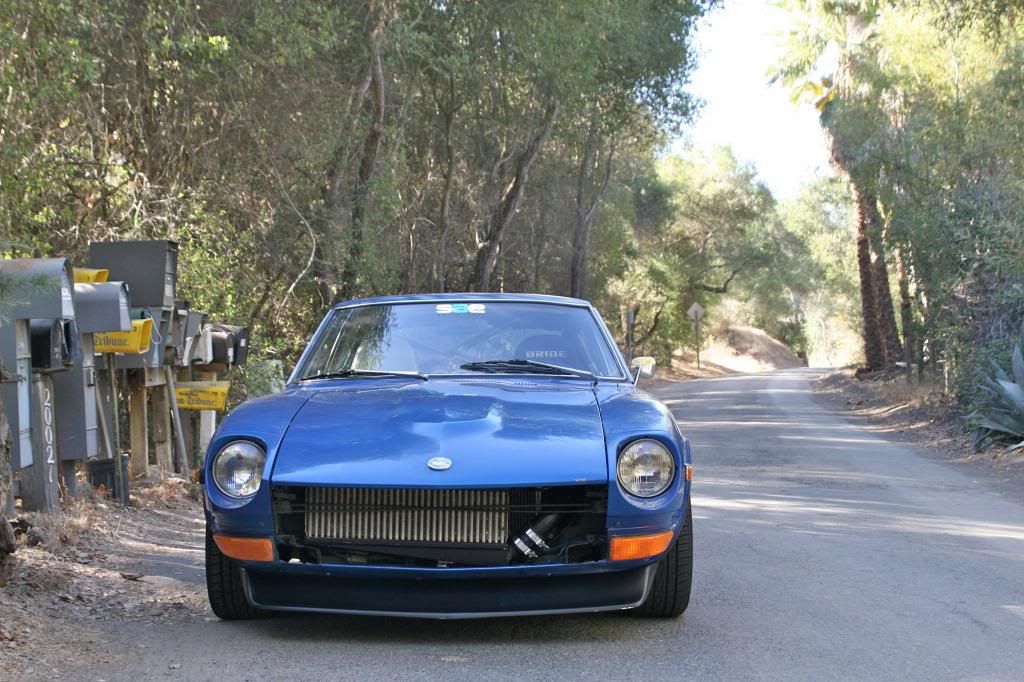

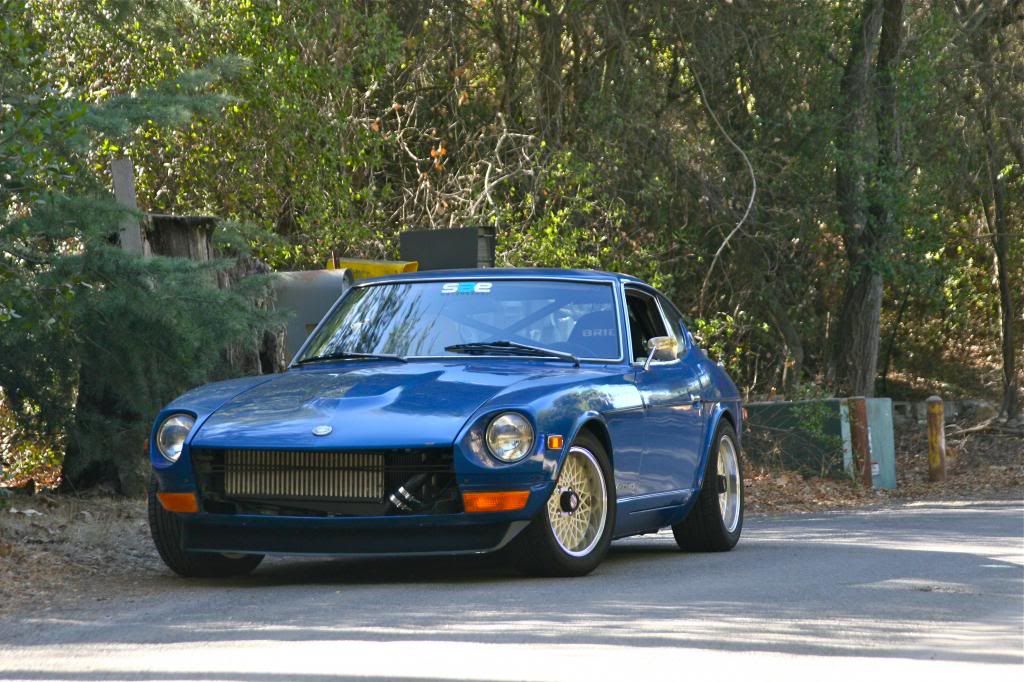

I believe this is Nissan Pacific blue

-

This is exactly what I want, but are harnesses still "safe" attached to a bolt-in cage?

Also, that looks like a Bride Zeta Type S, or an Exas III.

The bar isnt going anywhere. What is your concern with the harnesses? When the bar comes out again im getting a rod welded in right there to keep them sliding laterally.

-

What seat is this? Cost? Source?

As he said^^ , Bride exas III. I got it used off a miata forum for $600, new theyre around $1000

-

I'm going to forget about the cage idea. I'm just looking for a really nice street car anyways. I was thinking 10 years from now, when I finish the Z, I'll tear down my foxbody and turn that into the race car. I like the style of the car, just not all the Ford engineering in it so I think it's a prime candidate.

Why not get the best of both worlds and buy or build a quality roll bar? This is my Custom 100% bolt in bar. It does require 8 holes to be drilled through the rear fender wells, but it can come out at any time.

-

1

1

-

-

PMd you

-

I managed to get a free set of .015 shims from silverseal because of how long it took them to ship my other ones!

With .015, I'll be .005 raised from stock, which I think (hope) is marginal enough to be acceptable, compared to .010 below stock with out shimming.

Thoughts?

-

If you can find a shop or a friend with a smoke machine, they work great

-

Ill be able to afford to do it right along with the battery tray rust etc.. When i graduate in a couple years. I dont have room in my garage or a cherry picker, and the block and rotating assembly work fine for my current goals. Why tear it apart?

-

I think you missed the point---with all this time, you could have removed the block, stripped it, properly caustic dipped it, and reassembled it without ANY reservation about what was inside, outside, or left over!

Could have, but didnt, dont have the space, tools, or budget. Workin with what I got, and i didnt ask for speculation on what i could have done. Thanks for your help though

-

Head usually measured on granite or other surface plate with height vernier/height gauge.

Measured today on a granite surface with a height gauge, came in at 4.2380, so .010 variance from "stock". Should I even shim for .010??

-

tip the stripped block upside down and flush it all out the deck to head passages.

You missed the point, the block is in the car , hence my problem

-

The one I have is similar in that it also attaches to the wheel arch at a very similar position. I'm 6'4 and have some recaros installed with a very low profile slider. The bar doesn't impact my ability to move the seat back or recline. In fact, the back of my seat hits the wheel arch before it comes in contact with the bar.

I'd imagine it's possible to have a plate with slots in the top to have the camber plates being used, but I'd imagine they would need longer studs to clear the stock shock mount metal and the roll bar plate.

It would be a tricky and unique setup to that car, but it could probably be done, and would certainly look badass.

-

Located in San Diego

Looking to buy the wide heat shield for the n42 intake manifold. I'd prefer to pick it up but would pay shipping for the right price!

Let me see what ya got!

-

-

The shop measured 4.2345" with whatever they used.

-

excited to see the new build start. I knew from the day you sold the others that you'd eventually have another. This should be the best one yet. You know my input, stay with it and keep it simple

-

Well, I managed to find the user manual online. Old/hardened/porous source lines can cause problems. it also looks like 2 of the ports are supposed to have "vacuum filters". I'll get some new hose on there and try to source a "vacuum filter"

-

Back to your original dilemma, to trust the shop, or to trust your faulty measurements: probably best to get the right measurements before you do anything. You can't make a good decision until you know what you're dealing with.

I agree, my mic is not cutting it, I'm going to use a friends navy spec/calibrated tool. Ill post results when i get them

-

I would doubt they cut the top of the head, then. I would imagine they decked the bottom and didn't cut the top, and just told you what you wanted to hear to get you out and not have to fix the mistake of forgetting to cut the top.

What??? They cut the top. They removed the remaining studs (?) on the head that were able to stay on ffor the bottom to be surfaced

-

Don't have an answer but curious if you mean that .005" is the range that you get measuring the same spot (your measurement error range), or if you mean that the head thickness varies by .005", from side-to-side, end-to-end. They're both bad, one means you're not sure what your measurements really are, the other means the shop didn't keep things very parallel and/or flat.

It must be my outside mic, it is probably not ideal for measuring the head. it's difficult to get a perfect, flat reading the same everytime. They are an experienced shop, and I do trust that they machined it flat, however, i'm very confused as to how shaving ".022" from a head thats originally 4.248" ends up at anything more than 4.226". If it were less, it would mean the head was previous shaved, or they shaved more than they thought they did. In this case, either both of our tools are inaccurate or they didn't shave as much as they said.

-

I just got my p90 back from the machine shop, who apparently took off .012 off the bottom and .010 off the top for a total of .022. I bought .030 shims as I figured after .012 was taken off the bottom, about the same was off the top.

Now, in measuring the head height, im getting as low as 4.235" and as high as 4.240". According to a couple sources on this site, stock head height is 4.248. I'm using a matco outside mic that was calibrated in 2011, and measured my .030 shims at .034 (not sure if the mic is slightly off or the shims). 4.248- 4.235 = .013" (????) I was careless and didn't measure it before it went to the machine shop

SO, in order to shim the cam correctly, do I go off what the machine shop told me, and stretch the chain .008" with the .030 shim, or closer to what my head thickness is telling me and shim a lot less? The numbers don't add up to the actual thickness of the head according to my mic. The machine shop measured is at 4.2345" (so it is accurate to my lowest reading)

Any speculation would be great, as i'm lost at what to do!

Urethane Steering Coupler Bushing Difference

in S30 Series - 240z, 260z, 280z

Posted

I believe thr different hole patterns are for datsun roadsters