-

Posts

196 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JCan

-

-

Hi Jim,

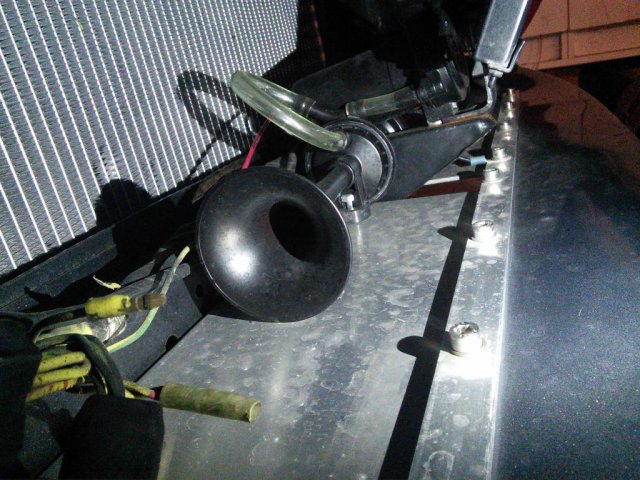

I'm running the stock pan at the moment. I don't plan on tracking the car and also run fairly low-grip all-seasons on my 15's (only reasonable option besides R-comps) so haven't felt a need to baffle the pan. I've long considered the Arizona Z/Kameari baffled aluminum pan (as you have pictured) but haven't been able to justify it as an immediate need.

I've not done research on making a custom pan but implementation shouldn't be too difficult once you have a design in mind. I'd recommend drawing inspiration from the old Datsun comp pans as those have been well-proven.

-

-

-