-

Posts

196 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JCan

-

Interesting topic. Ive been reading about tractive effort and tractive resistance at: http://www.thecartech.com/subjects/auto_eng/Tractive%20Effort.htm . It is going to take me a couple days to absorb what I am reading. Basically we are optimizing the amount of Force (N) applied to the wheels and picking the optimum gear ratios to deliver this force on a level road taking into account rolling resistance air friction, and effective wheel diameter (rubber tires are lossy as compared to steel wheels). You know, I have always thought of the 240z as a variable displacement engine. IT seems to me that one could design an optimum gear ratios for fuel economy AND also take account the cars max performance. Therefore we could have one set of curves with the optimum RPM being low (2500 rpm) optimizing for economy and a traditional set of curves with higher RPM say 6000 RPM optimizing Force applied to the wheels, (tractive effort) Regarding Brian (my son). I think he has a level head and is rather deliberate with his actions. As he has completely reassembled each part of the car (with help from me of course) he has a lot of pride in it and doesn't want to damage it. Brian will only drive the car for the next two years, as when he goes away to college, the car will stay here (we do not allow our children automobiles at college). Once he graduates, I will put the car in his name and he will be free to upgrade it as he sees fit... Thanks for the introduction to great resources (Books) and this topic of Tractive effort. I am sure (over the next couple of months) to add this newfound information to my understanding of the car.

-

Vehicle dynamics prof? Leon, you are a sleeper! Send me your spreadsheet, maybe I could learn from it! Also, if you have a good book on vehicle dynamics I would appreciate the name as I might be able to thumb through it and get a better understanding of automobile engines etc. ( I did measure in general engineering in college and took the basic engineering courses, thermo, statics and strengths of materials etc). In the mean time, tractive effort curves... I'll look them up! My spreadsheets are rudimentary as I made them up in an effort to ensure the car I am building does NOT have tremendous HP from 0-60 (as after all I am handing it to my 16 year old son) yet allows me to add a few tweaks once he gets older to increase the fun factor! (notice the gear ratios are really high, I used SU carbs, the cam is a mild cam which destroys low end torque - yes the bad side is that after the engine hits 35mph, the car should be a rocket however brian's primary driving will be below 50 mpg (mostly streets). Jim

-

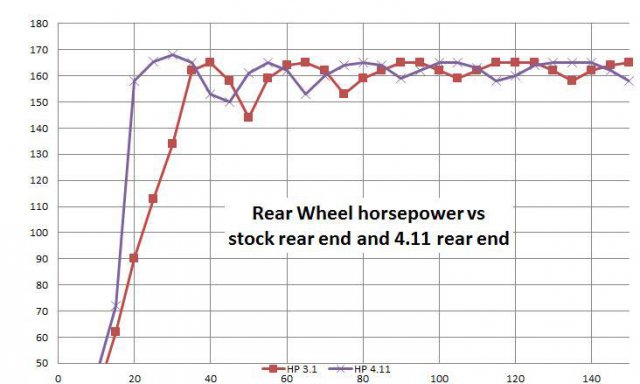

Leon, I am afraid I am going to be a bit long winded now... Apology in advance... Attached are two screen shots of an excel spreadsheet we assembled for the car we are building. Given torque as a function of RPM (what we expect to get out of our build) and the gear ratios w can assemble optimum shift points and can plot HP as a function of Speed (assuming I am racing the car). Please take a look at the spreadsheets --- Since I know my tire diameters, rear end gear ratio, and transmission ratio, and can look up what other people have measured (torque vs rpm) I can take a look at what the optimum shift points are for my car. The first spreadsheet shows (from right to left) RPM, Torque, HP, then left to right, the speed the car would be traveling if it were in 1st gear, 2nd gear, ... 5th gear by knowing the speed and Engine RPM then looking up the available HP (in the right). First thing, notice the knee in torque at 5500 RPM (I expect the engine I am building will not knee until 6000 rpm, but I am being conservative here). The loss in Torque causes a loss in horsepower at 6000 RPM. A wider torque curve would greatly improve overall HP. Your car has webbers ( a 6 pack right? ) Well your torque curve comes up much faster in the low end then mine does using SU carbs. You can model this here also.! Lastly, lets take a look at the last plot. In this plot I plotted the available HP as a function of RPM you can see the HP dips / each represents a shift point. In addition, I compared the car as is with a different rear end (one with 4.11:1 gear ratio). Notice the low end HP improvement! What happens if I swap out the stock rear end for one which has 4:11 gears. Notice we get 160HP at the tires at 20MPH in first gear (4:11 gears) instead of 35MPH at first gear (3.5:1). This little change should make a BIG difference to quarter mile and off the line times. Again, note your webbers have more torque at the low end then my SUs so your results may be difference. Which means, if I want my car go go faster, the easiest thing to do is to change gear ratios instead of farting around with trying to eek out another 5HP. This is a long winded way to say: - The L24/26/28 are magic motors and one thing they have is their ability to be perfectly balanced throughout all RPM. Take advantage of it! o balance your motor o understand how your modifications will effect torque - Take top down approach to building your car and understand how your car will respond to each modification you make o sometimes your best modification are gear ratios If you want a copy of my spreadsheet, send me an email and I'll forward it to you. James.Canyon@gmail.com

-

Leon. They are not going to balance your engine unless you ask for it. V8 engines can not be balanced throughout the rpm range and require a harmonic balancer, this pully sits on the front of the crankshaft and is offset and designed to make your engine run smooth at one RPM. on american engines I believe the RPM is maybe 4k? If you balance your L28 and they do a good job you will be amazed at how comfortable it is to run your engine to 7k+rpms (remember HP = torque * RPM, a flat torque curve out to 5k if you can get it yields what I consider to be as close to a variable displacement engine at 2krpm=x1HP The crank and flywheel assembly need to be done dynamically. Piston and rods are done statically. I checked the piston weights, rod weight (big side and small side) and they were accurate to 1 gram. (I have a digital cooking scale I "borrowed" from my wife when she was away Don't be afraid to assemble the bottom end yourself. It is easy and you can check clearances with plasti-gauge and some calipers (digital ones are really inexpensive now). If you want to talk, give me a call. 858 204 9422.

-

From the album: '73 240z HLS300135272

Engine finally assembled, Everything on this engine is 40 years old with the exception of a new exhaust manifold and replacable parts like sparkplugs/wires/etc. Black pieces are expxy coated, yellow metal has been nickel plated. -

From the album: '73 240z HLS300135272

Brian wanted a big before and after shot... However, the work required to restore this car... sigh... I believe we would have been better off finding a car in much better condition... -

From the album: '73 240z HLS300135272

Note, we polished the plastic lenses and had the plastic pieces in the middle re-chromed... it was a bit expensive but turned out pretty good! -

From the album: '73 240z HLS300135272

-

From the album: '73 240z HLS300135272

-

From the album: '73 240z HLS300135272

This is the car prior to fixing the valve lash. Today the engine has been reassembled and we are getting ready to work on the interior. -

Leon. You did not mention what I believe is the most important thing about the bottom end.... Balancing>!!@#$~!!!!!!! How good is this shop at balancing the crank/flywheel/rods/pistons/pressure plate??? My brother and I always focused on ensuring our engines could easily wrap to 8krpm without too much vibration. (of course you know that one of the great things about the L6 is that it can be perfectly balanced at all frequencies and does not need a "harmonic balancer"), Back in the day, my brothers car, L28/mild cam/webbers/11:1 compression, ran on 97 octane, and would smoke lots o cars just because we had such a wide and flat torque curve (leveraging RPM). Each time we rebuilt it, the car seemed to be smoother and smoother. I am sure you are doing this, but if not, you might forgo having the shop assemble your motor so you can spend your money having the shop balance the key components. Also... what compression are you looking for? what head / piston combinations are you planning?

-

Datsun_Z240: It looks like you have lots of options. I would like to suggest one additional! you can purchase a gas vent tank from the internet (ebay, craigslist) (here's one for $34 http://www.ebay.com/itm/70-78-DATSUN-240Z-260Z-280Z-FUEL-VAPOR-TANK-WITH-SCREWS-GAS-BOMBA-/321043465435?pt=Motors_Car_Truck_Parts_Accessories&hash=item4abfae84db&vxp=mtr ) and then purchase gas line (be sure it is rated for gasoline (go to napa (hose sizes above))) for another $60. When you run the lines, be sure there is no way for air to travel between the outside and inside cabin where the lines cross interior to exterior, rubber grommets maybe if you use the old ones you could add silicone to take up the slack between the hose and the rubber. It is a lot of work, but once it's complete, you should have no problems for the next 10-20 years! Good luck with which ever you decide to do! Jim

-

Are you sure you want to remove the evap tank? I know the hoses are a pain in the butt, however I was able to replace all of them with hoses from Napa. 1/4 " for the return hose, 3/8" for the fuel pick up and one vent hose, 1/2" from the far end of the gas tank to the vent tank, 5/8" - gas tank to the vent tank, and 3/4" from the gas tank filler tube. Here is what a fellow Z driver says.. "If you remove the vent tank and plug the outlets on your fuel tank, you'll never be able to fully fill your fuel tank. The air that gets displaced by fuel when you fill the tank has to go somewhere. With the vent lines plugged, that air gets trapped in the tank limiting the amount of fuel you can put in. You'd probably only be able to fill the tank about 3/4 full max. Also, even if you did manage to fill the tank, enough pressure could build up to force fuel out the filler neck and down the side of your car!!! I've seen it happen." If you still want to remove the evap tank, I'll try to find a copy of how to do it for you. ( I saw it somewhere on the web) Jim

-

Sounds like you have just about everything you need to complete the car... and because of it I do not have any suggestions to add. The car I am building is for my son, and because of it, I purposely didn't add a lot of horsepower. However, a 2.8L block with fuel injection and a turbocharger with waste gate set at 14-16 psi really has some get up and go. I look forward to reading about your progress! PS Congratulations on your wedding! However after I was married, I lost about 50% of what I call "peer pressure points" (having influence over your wife) so I say "get the car finished at all cost, prior to the wedding!!!" --- GRIN

-

Leon - WOW! Nice car. I noticed that the engine bay and I assume undercarriage looks AMAZING! What a find! The 260 you have, new interior (including dash!) and under carriage metal means you can spend time on the fun stuff (HP, Gear ratios, Suspension) What do you plan to do to it?

-

Z240 - It is true, chain wedges are cheap, but if you don't have one and need one right away, we now have a resource. Thnaks! Jim

-

But how much more pointy? and how much longer? I guess I should purchase a wedge and measure it for prosperity? I was hoping somebody would provide dimensions. Jim PS I understand the wedge I made is not optimum, however i have used this type of wedge many times as a kid and used the above wedge 4 times in since January and did not have any problems.

-

Bo We are not planning to cut or change anything until the car is fully assembled. We expect the car to be fully assembled by the end of march. Regarding the 280 springs, I believe they are probably the best option. We plan to set ride height (both front and rear) using the springs we currently own. This means cutting both the rear and front springs. Once we achieve the proper ride height ( I am looking for a ~0.35" inch difference with the rear height higher than the fronts assuming we are using the same tires front and rear (which we are not) (noting we are running 205 45 17 front and 225 45 17 rear, this setup should provide the same gap between the top of the tire to the edge of the fender on both front and rears) After driving for a couple months, we will review the following issues (in summer): - Cam (we have close to a medium cam in this car which is loud and is possibly a bit too much for my son (per my wife)) - Suspension (Review ride height and comment on front springs - We will blog our findings) - Cooling (I installed only one cooling fan with a custom made fan shroud. Will test it to see if we need to make a change) - Finish installing air conditioning Thanks for your inputs. This site is great!