-

Posts

101 -

Joined

-

Last visited

Profile Information

-

Gender

Not Telling

-

Location

Bellevue, Washington

Recent Profile Visitors

5028 profile views

Boog's Achievements

Newbie (1/14)

0

Reputation

-

Hi all, I am in the process of switching to electric fans on my 76 280z and I am planning on threading the temp switch for the fans into the thermostat. The hole I am planning on using is the one where the small elbow comes out of to feed the intake manifold. I am running megasquirt now, so I have no need for this hole. Does anyone know what the thread pitch and size is? I have read so much conflicting information, whether it is BSPT or a standard metric thread. The one I am talking about is the one in the picture below with the rubber cap and hose clamp on it. I believe it previously fed the cold start injector? Anyways, thanks in advance all.

-

rossman, I ordered Apex Engineering A Arms, I will let you know if they provide the needed clearance. I am also going to go to the auto parts store and see what options they have, the slimmest boot is what I will buy.

-

Thanks for the input Brian. I'm thinking I'll do new boots, and I will try and get my hands on a few at the parts store to see if I can get a slim one. I'm also thinking the aftermarket arms will give me clearance. I have camber plates with some play left, so I can add half an inch at the bottom and keep my camber fine. I also have the tire clearance. I feel the same way about T3 vs Apex, I think they both have the same adjustability, and price, and clearance, but as for track record Apex doesn't really have one yet. I guess my final question is do you think those shorter axles work with the tripod ends? I wasn't sure if they were meant for OEM style axles. Its basically the same price for control arms or the axles for the same fix.

-

So in an effort to fix my rear end vibration I decided to upgrade to 300zx axles. Looking back now, I should have just put new u joints in the stock axles, but I liked the idea of CVs. Anyways, Not only do they *barely* squeeze in to the car with the adapters welded to the outer flanges, but apparently the inner boots also rub on the control arms. They both split open, and there is now grease all over the underside of my car (that I just cleaned while doing the axle swap in the first place). I am using CJ Cave weld on adapters and rock auto axles (that I believe are tripod style). What is the cheapest solution here? Should I just buy new boots, swap those out, and take an angle grinder to the control arms where they hit? Should I buy some T3 rear control arms that I believe have more axle clearance? Is there a such thing as a low profile CV boot? I'm sure everyone reading this knows that I just want to drive the car, and that I am looking for the fastest way back on the road. I was thinking about the T3 arms already in order to space the rear track width half an inch on each side, hopefully giving the axles more wiggle room. Now with my ripped boots, I have another reason to go T3. I guess I am just looking for suggestions, input, and maybe someone else who has been through the same thing to chime in. Below are some pictures of my "super fun" situation.....thanks for looking all.

-

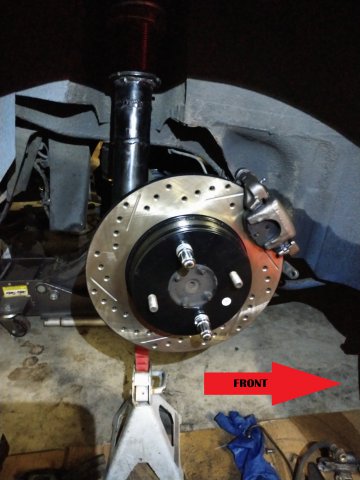

280z Rear Disc Conversion, Sport Kit from ZCarDepot

Boog replied to Boog's topic in Brakes, Wheels, Suspension and Chassis

I can definitely tell you like Z's! I've had mine 5 years and have loved every bit of it. As for the update, drove it just a few minutes ago. Going to CV axles eliminated the driveline vibration. I'll probably still do my front diff mount, but I'm not frantically ordering parts now. As for the brakes, there is as expected more pedal travel. I knew this because I didn't upgrade master cylinders yet. There is only maybe another inch or two, definitely nothing bad. The brakes make a whirring sound when I get on them, but I assume the pads are still bedding. I've been accelerating and braking +/- 30 mph as I've read, never coming to a stop. In sure they'll only get better with time. I did my CV axle swap at the same time, and I have a new topic to post regarding that. I still need to crawl under and give everything a little tighten for my conscience sake.- 5 replies

-

- brake conversion

- rear disc

-

(and 2 more)

Tagged with:

-

280z Rear Disc Conversion, Sport Kit from ZCarDepot

Boog replied to Boog's topic in Brakes, Wheels, Suspension and Chassis

Thanks for the input both of you. I got them bled tonight. The hand brake cables work great, i just swapped their sides over the diff which shortens them a little bit. I zip tied them up out of the way. Brake lines all have correct fittings, no leaks, no kinks. There is one tight turn, but it seems ok. I used brass washers on both sides of the banjo. Unfortunately in the bleeding process I was topping off the wrong master cylinder reservoir. So I actually ran the rear dry, so I ended up using a ton more than expected to make sure I didn't have any bubbles. I'll update on performance when I drive it tomorrow!- 5 replies

-

- brake conversion

- rear disc

-

(and 2 more)

Tagged with:

-

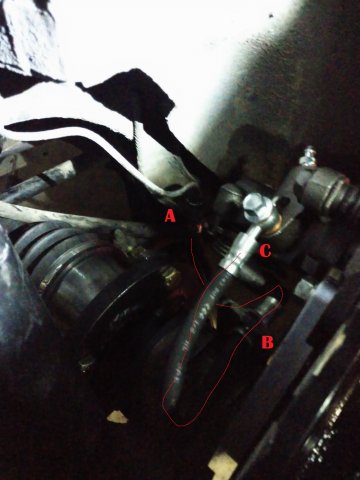

Hey guys, Sorry about posting this in the FAQs first, didn't see what category I was in. I recently got the Zcardepot.com Rear disc brake conversion kit, the sport one with the drilled and slotted discs. It uses a maxima caliper. They didn't send me any install information, just a box of parts. I have searched around and haven't found anyone who has documented the install. I did my best to install it how it makes sense, but I want to make sure that it is correct before I bleed the system and drive the car. I've posted some pictures below of my install, sorry for the lighting. I usually do all my work with a headlamp on, so pictures are either too bright or too dark..... I posted a picture of the brake line included, as well as letters showing where they are located on the installed caliper. I used the factory bracket to hold the middle of the brake line fitting. I also used the caliper with the R for right side on the right side of the car. I literally couldn't even find info on how the pads are supposed to be installed. They seem to be left/right specific, as the pad touching the caliper piston has a large tab off the back of it that sticks out. Mostly I am wondering: 1. Is the caliper even in the right position? 2. Is the brake line routed correctly? 3. I read that to make the hand brake cables work, i should swap them across the car so they are short enough to use them on the front of the disc. That is my plan, but have yet to do it. Is it correct? 4.Is there anything I am missing documentation-wise? I can't even find a maxima caliper swap guide. The one I found has broken picture links, so it isn't much use. Thanks in advance!

- 5 replies

-

- brake conversion

- rear disc

-

(and 2 more)

Tagged with:

-

Question about injector impedance, specifically supra ones

Boog replied to Boog's topic in Nissan L6 Forum

Thanks for all your input. As an update, the car runs perfect with nothing changed as far as resistors or anything. All I did was tell Megasquirt that I have 440cc injectors now. -

Hey guys, quick question. I have an L28ET in my car (with MS) and I am upgrading to supra injectors, the 7mgte ones. From what i have researched, they are 440cc and work with a pallnet 11mm rail, which I just ordered from him. I am confused as to what impedance I need. Here's what I currently believe to be true: L28ET injectors are low impedance, and require the resistor pack to make them work. 7M-GTE injectors are also low impedance, and should be used in my system with my current resistor pack. However, all the 7m-gte injectors on eBay (don't worry, not ordering from there) are listed as high impedance. I just don't want to order the wrong injectors, is there anyone who is running the 440cc injectors on an L28ET who can chime in to what their wiring system is? I don't want to order them before I at least have some answer.....There is so much weird and confusing information out there about this stuff. Thanks in advance!

-

Compression numbers (1-6): 130, 160, 150, 140, 160, 140. Cold engine, 55 degrees out. I had just enough oil in the bottom of a quart to do a wet test on the #1 cylinder, which brought it up to 160. Couldn't get the pictures on here, but I got them in an album at this link: http://imgur.com/a/fxeX5 Sorry that the plug numbers are out of order in the album.

-

I'll take pictures and pull a plug tomorrow, I might have time to go out and collect a log. Compression test on Friday. Thanks for the help so far Brian.

-

They didn't give me any paperwork. I guess that's what I get for going with the cheap guys. They said my block just needed a hone, as it was in good shape. I'm still planning on using the compression tester this weekend, any other information I should gather to come to a conclusion?

-

I bought ITM pistons with the rings they came with. I used NAPA's machine shop, which is a separate location from their normal chain stores. I assembled everything myself, with proper oiling, lubing, torquing, and ring alignment. I can guarantee you that the gaps are within spec and lined up properly.

-

So really big update. I tried three things to fix the problem. Firstly I tightened my manifold bolts. Then I went to napa, bought a pcv valve and hooked back up my crank case vent. I also stuck a hose from the valve cover to the throttle body. The smoking stopped completely, I went and drove it around and it was great. However, the idle got all weird. It stumbles between 1500 and 1000 rpm and drives worse. I took the valve cover hose off and capped the throttle body, which made the idle much smoother and it ran way better again. However, with the valve cover hose disconnected and venting to atmosphere, the smoke from the exhaust came back. I love that the smoke is gone, but I can't drive it with that hose connected. Which port on the throttle body should it be connected to? Does this point to valve seals? It doesn't smoke until warm, but it also doesn't smoke when there is vacuum to the valve cover. Help!

-

I also just had a break through that I hope comes to fruition. My crank case vent is basically the oem hose turned down with a filter, wedged near the motor mount. Based on my symptoms I have told you guys, plus what I assume is my leaking main seal and my leaking capped turbo return bung, I think that my hose might be kinked and that there is no crank case venting. All that pressure is causing the the seal to leak in the rear (apparently this is common on mustang 5.0's). I am going to go check it right now and I'll report back. I am also going to hook back up the valve cover vent to the intake. EDIT: My vent hose was not kinked. I tried re positioning it, but no fix. I also paid close attention to when the engine started smoking. I started the car up, and there was no smoke. I gave it a very light rev, no smoke. I was starting to think it was fixed until the tail pipe started wisping smoke around the 2-3 minute mark. It then got worse and worse as the engine warmed up. After it was decently warm, I gave it a rev up to about 4k, and smoke blew out. I also noticed the wall behind the tail pipe had a black soot circle on it. 2 feet away, and it left a black circle probably 8 inches around. Is it possible I have oil in my exhaust that is burning off?