-

Posts

870 -

Joined

-

Last visited

-

Days Won

19

Zetsaz last won the day on August 6

Zetsaz had the most liked content!

About Zetsaz

- Birthday September 25

Profile Information

-

Gender

Male

-

Location

Guadalajara/Utah/Seattle

Recent Profile Visitors

Zetsaz's Achievements

-

Those rear control arms are works of art

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Car show and parade was a blast. Went really well! Drove to Washington to visit old friends - trip went really well. Engine is working great, I'm really happy with how things are running other than some oil leaks that gunk up the underside of the car on long drives like that. When it comes time to rebuild with flat tops I want to really clean up and degrease everthing and do my best to avoid future leaks for a long time to come. End of the trip and the way back were slightly less successful. Looks like the bolts on my right CV axle backed out and last one stripped while on a drive with a friend. Fortunately he has a 912 and a well equipped garage. He let me use his space and stay at his house until my friend in Bellingham with a Z got back from Vancouver the next day who was nice enough to let me borrow his CV to get on the road while he waited for the new one I bought him. Unfortunately... the kindness didn't stop more things from slowing down the trip home. Almost exactly halfway near La Grande OR my front right wheel bearing seems to have seized up and started cooking things. Seemed okay at first thought something from the road made a belt squeak at first or something, then things got progressively worse until eventually my brake rotor was rubbing against the caliper. Tried hard to somehow get it fixed, but no one would touch it and I didn't have everything I needed to get it back on the road, so I rented a UHAUL to finish the trip instead of paying for hotels and rush shipping New parts are on the way. I suspect the wheel bearing was overtightened or the hub was already not quite in good shape when I first replaced the bearings and eventually those small changes in acceptable tolerances from all the miles I've driven caught up with it. The outer bearing race had partially friction welded itself to the spindle. This would have been my third round trip to washington, plus the pacific coast trip, plus any other miles you want to add from cruising around as often as I can when the weather is nice. Here's to 50 more years out of the new hubs and spindles. -

The ZX 5 speed is definitely much weaker than the "71C" The later 5 speed was in the 240sx/Silvia/D21. I think maybe the truck transmission had slightly different ratios? If your goal is 450 I'm not sure it'll handle the power. Probably fine if you're not launching it or abusing it regularly, but that's kind of on the upper extreme for it.

-

I had that same block on a jeep stepper. Worked quite well to be honest. I moved to the GM valve to clean up the engine bay more and because the protunerz throttle has the provision for it.

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

It's cleaned things up considerably! Extra nice now that I got a little bracket for the Deutsch connector. It's not just dangling around behind the head. Here's a handful of pictures after cleaning up the ride for this weekend's show. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Have spent probably 20 hours in the last few days working on details before this weekend's parade Easy stuff first, got the new dizzy cap on and it fits beautifully. I love the look on this thing New valve cover is a super nice piece too. I was slightly hesitant about the bronze but it ties in with the brown interior even better than j expected Next the interior vinyl was very long overdue for an update. The strut tower vinyl was ugly and tearing a bit, and had the holes on top since it was from a 76 when they started mounting the top of the seat belts there. The pieces that goes over the wheel arches were also splitting and I had never bothered to glue them so it was always annoying looking through the window at exposed sound deadening. Took a long time and put speakers in the stock locations while I was at it, but it was worth it. Also cleaned the flat piece behind the seats that goes up to the deck floor and installed that instead of the carpet that came with my carpet kit. Lastly I finally got the bumper back on. After looking through a variety of tests by independent YouTubers, I decided regular old high strength JB weld would be more than good enough for the job. I can't remember which specific metric they tested that convinced me, maybe it was against sheer forces? I went ahead and put some on the other bracket in the rear as a precaution. I don't trust the 6 tack welds holding the bent plate with the studs on the bumper by themselves anymore Regardless, I cut more of the bottom of the skillard grill and used different brackets. Older and simpler design that only required two bolts to the body, but didn't slit through the grill. I think it's a better design for serviceability anyway. The skillard grill combined with the front splitter made it nearly impossible to service anything up front - because the skillard brackets go through two of the grill pieces, there was no way to pull it off without also taking off the bumper. You could only access it from the side which gets annoying leaning over things and hoping your hands fit. Now I just remove 4 small bolts and the grill comes right off over the top of the bumper. EDIT: Oh yeah, also finally put the rear sway bar on and it's a noticeable difference! I was sent the wrong bolts (again). T3 was right that they used to use a 3/8 thread back when I bought the drop mounts and have since switched to M10 (smart), but they sent me 3/8-24 instead of the regular thread 3/8-16. For those who are a little slow with car stuff like me I did the math - a 3/8 bolt is 1/64" smaller diameter than an M10 and the -16 thread is nearly identical to an M10x1.25 - so a 3/8 bolt happily and comfortably goes into an M10 thread with hardly any play when you're using the thread checker at a hardware store, but an M10 bolt will frustratingly not go into a 3/8 thread despite seeming correct at first glance. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Friend in Washington printed the new distributor cover for me yesterday. Way bigger than he expected haha. The turbo dizzy was a much bigger diameter than the NA one. Here's hoping it fits! A mutual friend up there has a turbo Z we were hoping to test fit a cheap print with, but apparently he sold the turbo dizzy when he went with a OneSix CAS. If this doesn't fit we'll be reprinting when I'm up in Washington this summer. Still undecided if I want to do red or white enamel in the Z logo and smooth out the print -

If you are still just running a hot L28 the CD009 is probably overkill, and will require drilling into your floorboards or heavy modification. The FS5W71C transmission is probably enough to handle the power, but if you're set on a 6 speed, the BRZ/FRS engine is becoming more available now as well. A lot has changed since you last posted. https://www.godzillaraceworks.com/drivetraintl70/tl70swap

-

A musician's therapist (The $300 Z)

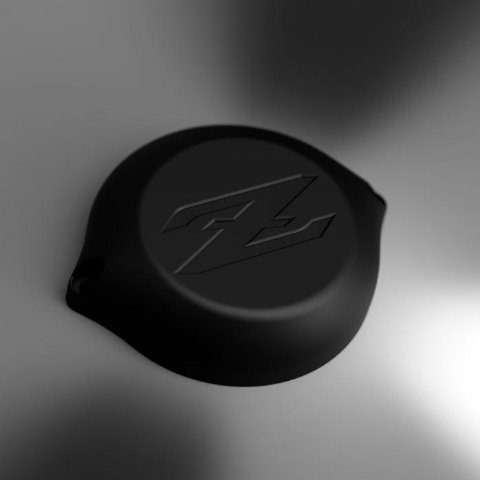

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Small extra purchases recently to be installed before the annual Cache Cruise-In -Lonely Driver Co. "Juliet" Oil cap -New OEM dome lamp - these are unreasonably expensive from US vendors, managed to get one at nearly half price from a Japanese eBay vendor -Reproduction 5 speed shift knob - I love wood shift knobs, and wanted something original but the datsun thread is smaller than the 240sx shifter, meaning it can't be adapted easily. Bought a reproduction that looks to be decent quality from a woodworker that makes them with your choice of thread. We'll see how it turns out. Last thing I'm hoping to do before I head home for summer is get the original shifter bag remade in leather. Hopefully this weekend I finally have the mental capacity and energy to go out to the downtown area and get some materials to hand over to an interior specialist at a customs shop near my apartment. -

stock suspension with custom wheel and tire size

Zetsaz replied to Flippy's topic in S30 Series - 240z, 260z, 280z

0 offset if you're going 8 in wide. Not totally positive that will clear with stock spring perches, but if you go any more negative offset you'll definitely end up rubbing unless you have more aggressive negative camber which isn't ideal. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I honestly haven't done too much. Most of what I've printed so far have been things others have made and made freely available. Usually my cousin or a friend have printed things for me. T3 parts ARE nice. Fitment has occasionally been JUUUUST a bit off but it's almost always when I have to chase some threads or because I have mismatched parts from such a broad range of dates on my stuff. That rear brace on the driver side is unfortunately gonna hit my exhaust so I have a guy that does stainless work checking out the car at some point soon and hopefully redoing some of it to correct things and get better clearances everywhere. I think we're about at the point with 3D printers, in terms of reliability, as home inkjet printers were when I was a kid. Still not quite as mainstream but getting there. I remember inkjet printers being good for getting my homework done when I was still using floppy disks to take my work between home and school, but they were pretty slow, and the ink ran out pretty fast. I think within the next 10 years we'll be approaching where laser jet printers are now and we'll have reliability and speed in a mainstream consumer level printer. -

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Couple of small things coming up as I prep the car for summer -Still super unhappy with the fitment on the exhaust, especially after the rear bracing was added. Have gotten in touch with some folks that do stainless about some adjustments. -New vinyl trim for the rear arrived. Won't be tearing anymore and won't have the holes on top of the strut towers. Should finally be able to start buttoning up the interior. -Purchased a new valve cover. This one came up and seller accepted my offer. Red might have been better, but it was sold. The bronze will sort of match the interior and right now I think it's a good homage to the original brown paint on the first shell I had that was unfortunately beyond saving. I think I'll eventually modify mine to relocate the breather, and shave some of the bits with threaded holes are for the old spark plug cable holders and make it red with polished lettering like the one on the right. - Also had a friend help with a better design on the distributor cover. The original was just a very plain 3d printed cover. Friend has a nicer printer that can do much smoother work with carbon and started making a better design when I sent him the old one and he didn't like it haha. Should be a fun change. The plan is to print it in black and maybe fill the Z logo with enamel -

Here's your Jeep Stepper And a GM Stepper If it's any help this is the one I'm actually running, which looks closer to what Protunerz lists on their site. The one with the black housing I took a screenshot of technically only shows compatibility with V6 engines but I'm pretty sure it's functionally identical, just has the pins facing a different direction?

-

I've compared them side by side and it's important to note that the Jeep stepper won't open as far as the GM one based on its design. On cold starts it won't bypass nearly as much air. I have a GM stepper on my protunerz manifold and after re-pinning for it everything has been much better.