-

Posts

265 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ukcats07

-

Thanks!

-

I know this thread is old as dirt, but I could really use the pics that are no longer linked if anyone happened to save them. Thanks.

-

Yeah tuning is definitely going to happen when I get back. I'm not too worried about the car just sitting around, my uncle will have no problem driving it and keeping fresh gas in the tank. Wish we were neighbors as well, you have a sweet ride and I'd love to be able to pick your brain and just have another swap close-by. It's going to be a long 2-3 years of not having the Z--it's my outlet from pilot training, etc.

-

Thanks, we're super excited. I wanted to fly the Air-to-Air role and go overseas, so it's a win-win! I think I read somewhere that you flew choppers in the Army? Oh man, I would take you up on your offer in a heartbeat, especially if I feed you checks to make mine more like yours . My uncle offered to take my trailer and Z to Florida with him where he has a really good body guy who owes him a lot of favors. He's going to do all the body work that's needed and paint the Z for only the cost of the paint! I can't turn down that offer. I'm starting to wonder if Brendan at LT1swap.com forgot to change my injectors to the LS1 injectors in the PCM flash(I have a 5.3). I've checked them and they don't leak and I cleaned them using the battery/carb cleaner technique. They could still be flowing incorrectly, so I'm not going to rule that out. Interesting about the cold air intake, as I've read a lot about how restrictions before the MAF, not just after, can cause fuel trim issues. I just ordered JTR's cold air intake yesterday because my filter setup is a straight shot from the throttle body. I think my stock 5.3 tune doesn't like this setup and I'm hoping that some straighter sections before the MAF with the filter away from the hot radiator will help the fuel trims. If it doesn't work then I'm going to buy new injectors. Have you checked for leaks within 12 inches of the O2 sensors? I had some with my homemade exhaust that caused the O2 sensors to tell the computer to dump a lot fuel as it was seeing a lean condition. Mine was the collector flange that was causing the issues.

-

Update: First, and nobody probably really cares but I do , I just found out I was selected to fly F-15Cs. The Z will go into storage due to the fact that both active duty bases are overseas. I swapped the knock sensors with OEM ones and that code has cleared up. I drove the car around the block, about three times as long as I had before, with ZERO issues. I even got it up to 70ish on the access road by my house. I normally would have the fuel pump whine halfway through, followed closely by the knock sensor going off and the car going into limp mode. I used Torque Pro to watch the LTFT and STFTs during the run and I'm still seeing negatives for both banks. I think my fuel injector spray might be off or something, allowing too much fuel into the combustion chamber. I might buy new injectors or have these ones cleaned professionally. The car runs great and pulls hard through all the gears and doesn't smell super rich.

-

This will be long-winded, but hopefully it helps someone else. First, the knock sensors. I'll say right up front--do not buy the cheap ebay sensors. There are plenty of threads out there that bitch about them, and rightfully so. I've purchased a set of AC-Delco OEM sensors that should be here tomorrow. I did the ohm test on the wires and tap test on the sensor itself and had good ohms and no response from the sensor when tapped. My first indication that something wasn't right was when I went to unscrew them from the valley the inner section that the hex drive is formed on was spinning independently of the body of the sensor. I don't believe I overtightened them, as I recall this issue at the time of install. I didn't know much then and thought it was normal. For reference, 15ft/lbs is needed torque the sensors and there was no way I got to that number in the install due to the spinning housing. My harness was good with no pinches and continuity checked throughout. I'm banking on the OEM parts to fix the knock sensor code problem as I am not getting a misfire code and the motor sounds strong with no audible indication of knock. Second, unrelated to the knock sensors were my O2 sensors. I built my own exhaust for this swap (something I do not recommend unless you have a lift and the appropriate tube benders etc. and/or you're just better than me) and I had a few exhaust leaks around the O2 sensors. This was causing my sensors to see a lean situation and dump a ton of fuel to counter, making it impossible for me to run in closed loop. I've been doing my runs around the neighborhood with the O2 sensors disconnected while I sorted out other things. I finally broke down and had a full exhaust built for me with a much better collector, y-pipe and bigger exhaust tubing all around. After this, I came home from the muffler shop and hooked the O2 sensors up to find that they work and are switching voltages correctly. The kicker is that I had to swap the banks, i.e. bank 1 from the PCM had to be connected to bank 2 sensor and vice versa. I triple checked the connector wires at the PCM and ran continuity checks to make sure everything was hooked up correctly, and it was. Clue #1 that something else was wrong. If you're still with me, I'll switch gears and wrap this up with a conclusion to the O2 issue by talking about the injectors. So after I had the car running pretty well in closed loop, I was able to use my bluetooth OBD2 logger to read STFT and LTFT for both banks. I noticed that bank 1 LTFT was a solid negative 9-10 with short term fuel trims going even more negative around 3-4 at idle. Anything above idle would put both banks STFT and LTFT at or around 0. So the PCM is seeing a rich stream and is trying to take fuel away. My fuel pressure is constant around 60 psi and I have cleaned my injectors. I pulled the fuel rail and pressurized the system and verified that none of my injectors were leaking...hmmm. Clue #2. And here's where double-checking all your work and doing continuity checks back to the PCM for all connectors would have saved me this headache. I built my harness from the original truck harness. When I did that, I swapped the banks because the lengths of the wires were ideal for where I put my PCM. I went through all the work to do this AND I EVEN DOCUMENTED IT IN MY OWN PCM PINOUT EXCEL SHEET. I remember actually swapping the pins in the PCM before my first start, but because of other issues when trying to start, I attributed some of those problems to the wiring. So I swapped it back to the stock pinout and kept it that way because I fixed the other issues at the same time and thought this was part of those problems (if that makes sense). Fast forward to yesterday and the fuel trim issues and both clues come together and it clicks why the O2 sensors only worked decent when swapped. My injector wiring was like this---PCM #1 was going to injector 2, PCM #2 to injector 7, PCM #3 was going to injector 4, PCM #4 to injector 5, PCM #5 to injector 6, PCM #6 to injector 3, PCM #7 to injector 8 and PCM #8 to injector 1. The fact that it ran at all is surprising and the fact that it was running rich is not surprising. This also explains why pulling plugs to injectors while the motor was running made no audible change in RPM. I swapped the wires around and swapped the O2 sensors to the correct sides and my STFT and LTFTs actually started to make sense with both banks LTFT around negative 6-7 with positive STFTs to counter it. I'll get the new knock sensors installed tomorrow and hopefully after a short drive I'll be able to tell if all is well.

-

Don't know what it's tuned for. I'll keep this in mind after I start digging into more specifics with the scanner. I researched this while I had the motor on the stand. I replaced both sensors and harness and put the recommended RTV dam around the rubber boot. When I pulled the intake off, I verified that the wires were not pinched. I looked closer today at my exhaust and found a few leaks at the collector flange to downpipe weld. I'm going to fix this and see if it clears up my slightly rich idle. My guess is I had compounding problems with the vacuum leak at the EGR and the air leak before the o2 sensors. Again, I'm looking forward to seeing what the scanner says when it comes in today.

-

It's saying that the car is knocking. Only does it under load when I'm about halfway through my little neighborhood circuit. My knock sensors and harness are new and are not pinched by the intake. I pulled the intake off to make sure I didn't rip an intake gasket and after cleaning everything I found the egr tube seal gasket floating around in the intake. I'm lucky it hadn't been sucked into the combustion chamber yet. I have an EGR delete plate on my intake and after inspecting it, I found that the rubber gasket (that came with the plate) was pulling off and was barely held on (when looking at it through the throttle body opening). I believe I missed the egr tube seal gasket when I put the block-off plate on and this didn't allow the egr block-off plate gasket to seal correctly. I haven't put it back together yet, but at least I have found something related to a lean condition, etc. I'm flying nights this week so I'll be able to put it back together in the morning and test it out.

-

5.3/T56 swap with original truck PCM and wiring harness. PCM was flashed by Brendan at lt1swap.com for the usual things (emissions, etc.). The engine starts nice and seems to idle great (by ear anyway) with an occasional audible miss. No codes are being thrown at idle, but the motor does stumble slightly when the throttle is blipped. Full disclosure: I do not have hptuners, efi live or any other tuning software and the car has not been tuned yet. I have ordered a bluetooth OBD2 for live scanning and should get it on thursday. Right now I only have a friend's actron OBD2 code reader. I was having, what I think was, a fuel starvation issue with a 90 degree pre-filter I had before the walbro 255 that was causing the pump to whine and subsequently throw the knock codes P0332 and P0337. I changed the setup to a less restrictive filter and now the pump doesn't whine and it seems like I am not starving for fuel now, however I still throw the codes. I have driven the car no more than a mile at a time and no faster than 30-40mph. It has happened both times under load and about halfway through my mile or so circuit I have around the neighborhood. I tried disconnecting the spark plug wires (bank 1) while running and there was no audible change in RPM. I did however get a pretty good shock from the coils (even with big leather welding gloves on). The wires and coil packs are from the original vehicle, the plugs are new AC Delcos. I checked each header tube with an IR gun and found most of them to be around 500-550 and a few in the 400-450 range. I've checked fuel pressure at the rails in idle (haven't checked under load) and I get 60psi. I guess my question is, should I replace the spark plug wires while I wait for my scanner and see if that clears things up, or should I just wait and see what information I get from the better scanner before throwing parts at this problem? Anything else I should check while I wait? I appreciate the help, Doug

-

Stock LS1 intake and injectors--bone stock otherwise. Brendan at lt1swap flashed the PCM with the appropriate changes. I don't have the ability to tune it and haven't been able to get it to a tuner. After grounding the wire for the IAT, the code went away and the motor is running much better. The truck harness was in great shape, I think I just missed that the white/black wire needed to be grounded. The only issue I'm having now is fuel starvation. My pre-filter to the walbro is too restrictive. I drove the car around the block and halfway around I threw both knock codes and the fuel pump was whining like my two year old. I can make the pump stop whining if I tap the 90 degree filter while it's whining. I'm going to put a less restrictive filter before the pump and see if it fixes the problem.

-

I swapped a 2002 5.3L into my 73 Datsun 240z and re-worked the original suburban harness using lt1swap.com. When I started it up I had a really rich condition and today I finally had the chance to wire the OBDII and run the codes and I only had the P0102. I checked all my wires to the MAF and found that my five wire sensor has a yellow, pink, black, tan and black white wire. My yellow wire had good continuity at the PCM, the pink wire had 12v, the tan wire had 5v and the black wire had a good ground. My black/white wire did not match lt1swap.com 2002 PCM pinout and did not have continuity at the PCM. I must have over-looked it during the re-work. It's only a ground wire for the IAT, so I cut it and ran it straight to a good ground. I had an issue before finding this bad ground where when I had the O2 sensors connected, the car would run extremely rich and barely idle. If I had the O2 sensors disconnected it would still run rich, but at least it wouldn't bog down or attempt to die. Now that I fixed the ground wire, I was able to start it up with the O2 sensors connected and it ran great (idle only) with no hints of running rich. Side note: I checked the headers with an IR gun and my passenger side is reading around 450-500 and my driver's side is more like 250-300. Any advice on where I should start with regards to this? Doug

-

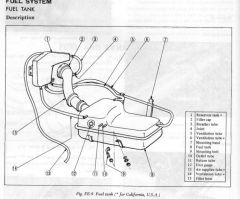

I have not eliminated the vapor tank, assuming you're speaking about the metal tank behind the panel. My setup looks exactly as you see it above. Any reason why the air in the tank would not just pass through the other two vent lines into the vapor tank?

-

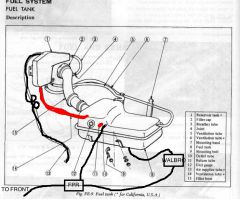

Just to be clear, this is my setup in a picture. The red lines are capped and the black squiggly line is the double loop I was referring to. Thanks

-

From the album: Fuel Vent Hose

-

My setup is a stock 73 tank with a Walbro 255 and corvette FPR feeding a 5.3L. I have tapped the drain plug for 6an feed line and I'm using the original feed line as the return from the FPR. I've had the classic garage stinks of gas smell overnight problem, so I have replaced the vent lines #5 and #6 and capped #14. My return line is going to #10 from the FPR and I have #11 capped. I've double-looped #13 and I have a filter to put on it if need be. Assuming no leaks elsewhere, should this fix my gas venting smell issue? Am I overlooking anything big/unsafe with how I have my fuel lines setup? Thanks

-

From the album: Fuel Vent Hose

-

lt1swap.com A goldmine of information is available on that site--to include step-by-step guides with pics. I was able to take a stock truck harness and build a standalone using only the information on that site, on my first try with no previous experience with computer controlled systems. The owner of the site also flashed my PCM for a good price and took less than a week. Edit: the website was missing the "1". should read lt1swap.com. Apologies.

-

5.3/T56 swap noise--video inside

ukcats07 replied to ukcats07's topic in Gen III & IV Chevy V8Z Tech Board

I've come across too many threads (not necessarily this site) that do not update to do such a thing. On a side note, I finished the exhaust last night and drove it around the block this morning. Great feeling, considering I had a perfectly running complete 302/T5 swap just under a year ago and I did it all during USAF pilot training. -

5.3/T56 swap noise--video inside

ukcats07 replied to ukcats07's topic in Gen III & IV Chevy V8Z Tech Board

Redwine automotive it looks like you were right. That broken dust shield was just getting beat up by the flywheel. I started it up today and the noise is gone and the motor runs great. Thanks for the help everyone. -

5.3/T56 swap noise--video inside

ukcats07 replied to ukcats07's topic in Gen III & IV Chevy V8Z Tech Board

Can't start it tonight, but I have a feeling that this is my noise culprit. I'll check tomorrow and update. I will definitely check all these tomorrow if the noise is still there.