We Bad

Members-

Posts

45 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by We Bad

-

What is the weight?

-

Mine came from John Washington at reactionresearch. http://www.reactionresearch.com/doors.html Seven lbs. each as I recall.

- 9 replies

-

- door

- fiberglass

-

(and 2 more)

Tagged with:

-

Both the Davis and MSD units limit wheelspin by pulling timing from the engine. They look for a sudden increase or spike in rpm's that would occur when the tires break loose. The Davis unit sends a 12 volt signal to the engine's ignition box when a loss of traction is sensed (when the driveshaft rpm spikes). The ignition box handles the retard function. Most high-end ignition boxes have one or more retard circuits built in. These circuits are commonly used for backing off the timing when Nitrous Oxide is engaged or as a high speed retard when the car goes into high gear. The MSD unit senses a spike in engine rpm's. Since the engine acceleration is different depending on which gear the car is in, it has user adjustable settings for five different acceleration rates. The amount of timing retard is also user adjustable, as is the rate at which the timing is ramped back in.

-

If you haven't purchased the Davis box yet, you might want to look at the MSD ignition box #7531. It has traction control without the driveshaft pickup. (Of course it is illegal in most places as is the Davis box.)

-

Very nice!

-

reference post #152: I'm confused. Does the throttle body restrict the amount of air entering the supercharger?

-

"Oh, you're goin' straight to hell for that one!" Robin Williams in Good Morning Vietnam.

-

Dry Sumpin' it... What worked for you?

We Bad replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

I use this book, as does the engine shop I work at. http://rehermorrison.com/engine-book/ -

Dry Sumpin' it... What worked for you?

We Bad replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

Lots of good information here, (even if you are not running a gen I small block), including a chapter on lubrication (both wet and dry sumps). -

Dry Sumpin' it... What worked for you?

We Bad replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

Very nice! For the benefit of those who have never seen the inside of one of these pumps, this is a photo of the lobed rotors in the scavenge section (this from a Barnes pump). . -

Dry Sumpin' it... What worked for you?

We Bad replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

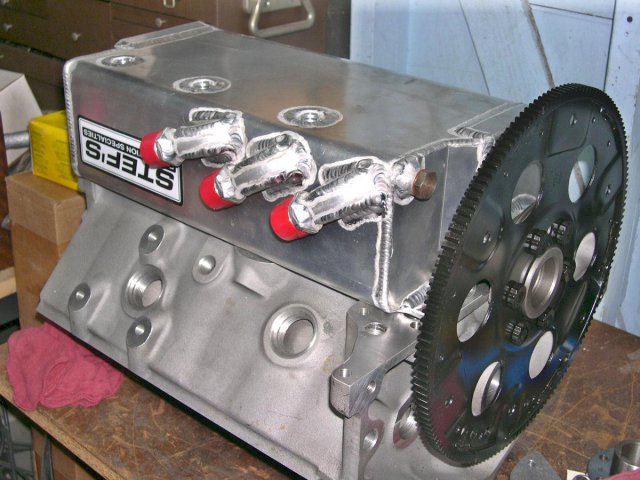

The Peterson tank shown is 18" tall (exclusive of fittings) and 6" in diameter. It is mounted on an aluminum plate (along with the oil filter and vacuum pump breather tank) and hung on a hand truck for use in a dyno room. Note the sight gage (complete with decorative tropical drink umbrella). It is extremely important to have a sight gage in place during dyno tests. It is the only way to monitor how well the engine drains back internally. It doesn't matter how many thousands of dollars the dry sump system cost, if too much oil is being pumped to the valvetrain and it is collecting in the valve covers, the tank can still run dry with catastrophic results. The site gage is the only sure way to measure how much oil remains in the engine while running. Of course, the site gage is removed before installation in the race car. -

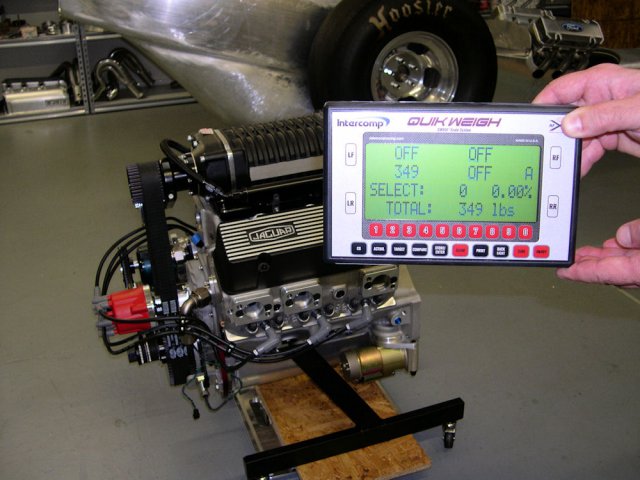

While getting the engine ready for the Dyno I weighed it. The scale was zero'ed with the wood in place. The engine stand shown is included in the total.

-

In regards to side pipes: I used these http://www.classicchambered.com/index.html This post is inappropriate for this thread, sorry

-

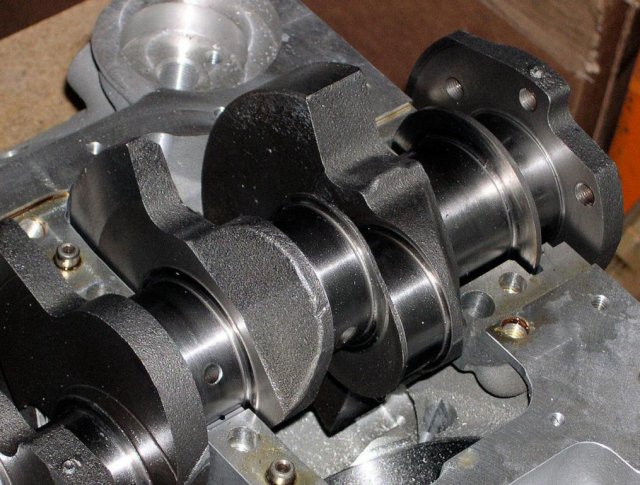

As Luigi mentioned in post #6 of this thread, most high RPM/high horsepower V6's run a common pin, odd-fire crankshaft. Such a crankshaft is shown below. The three crank throws are spaced 120 degrees apart. But since the cylinder banks are oriented 90 degrees to each other (like a V8) the cylinder firings alternate between 90 and 150 degree intervals. Hence the "odd-fire" designation. Jaguar used a 90 degree V6 with a common pin crankshaft in the XJ220. The 3.5L twin turbo produced 542bhp and made the XJ220 the fastest production car in the world in 1992. The production Chevy 4.3L crankshaft is shown below. The rod journals are offset 30 degrees to each other to give an even 120 degree interval between firings.

-

Autocross and oil pressure... impending doom??

We Bad replied to shuttlefever's topic in S130 Series - 280ZX

Just for fun, try this. Get a duplicate oil pan (just like the one under motor), fill it with 5 quarts of water, and hold it in your lap as you ride shotgun in an autocross while someone else drives. See how much water is left in the pan after the run. (Hot engine oil has viscosity approaching that of water and water is much easier to cleanup.) Of course the oil in your engine won't spill out like the water but there is the very real possibility that the pickup will be uncovered briefly and the oil pump will be pumping air bubbles to the bearings. As far as the Accusump goes, it is not a cure all. I've seen road race cars lose bearings because of them. If the oil pick up is uncovered during a long period of braking, like slowing for a turn after a high speed straight, the Accusump will provide the bearings with oil. The problem comes when the driver gets back on the throttle after the turn. The bearings need oil during hard acceleration but part of the oil pump output is then being used to refill the Accusump. It is not a cure all for an improperly baffled pan. Sound advice for autocrossing with a stock oil system: don't start the run a quart low. -

This is not really six cylinder tech, but it relates to possible heat issues with fenderwell headers. I saw this car at a local car show several years ago. I was quite impressed and told the owner so. Unfortunately I didn't retain his name so I can't give credit where credit is due. I think this is very tastefully done, kind of like the 1963 Corvette.

-

No, but heat soak may be a concern on a street car. I'll post some photos related to this as soon as I can find them.

-

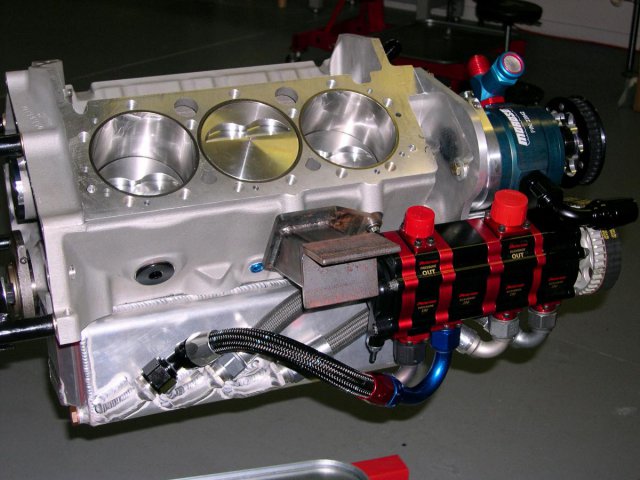

Motor mounts: The V6 block shares the same three-bolt mounting pad design as the 1st generation SBC V8, but the mounting pads are 4.4" closer to the rear of the motor. With the engine in the setback position (as close to the firewall as practical) the stock crossmember engine mount towers are too far forward to be used. Hence, they were removed. In my case it was a moot point: the towers interfered with the belt drive for the oil pump. Motor mounts were made from 1/4" thick plate, 2" square tubing (1/8" wall) and 2 1/2" X 2 1/2" angle (1/4" wall), TIG welded together. They fit between the engine and the top of a polyurethane vibration damper which bolts to the top of the Datsun frame rail. The polyurethane damper, one per side, is an Energy Suspension Transmission Mount, part #3-1108. It features an interlocking design that prevents the mount from separating even if the polyurethane fails. The right side mount is offset to the rear to clear the oil pump.

-

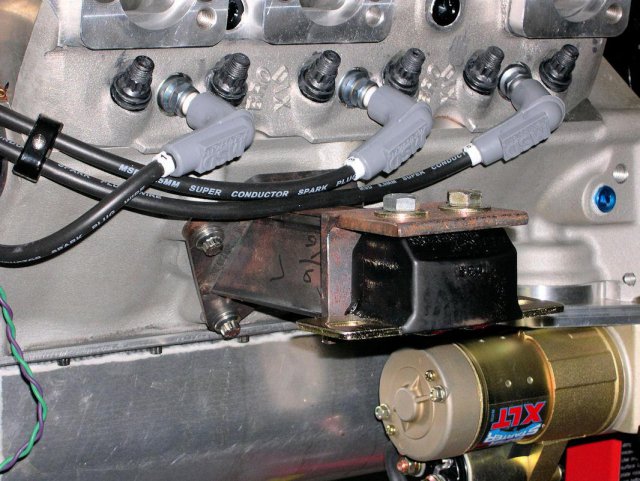

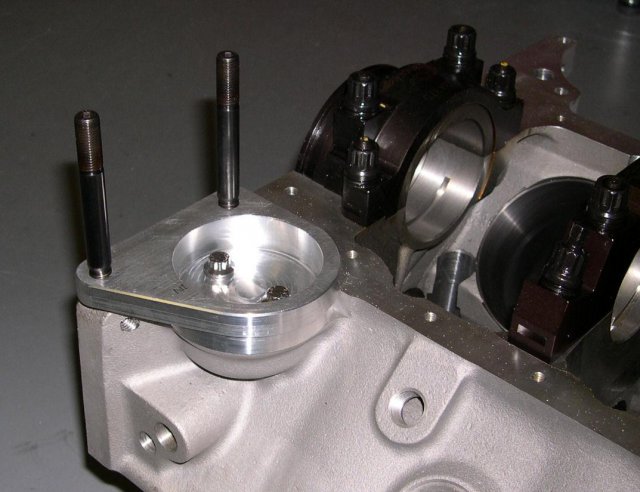

The 4.3 L Chevy V6 shares many features of the Gen I small block V8. The oil filter mounting pad is on the left side and the starter is on the right side of the block. The dry sump oil pan I'm using has a full length kick-out on the right side. That is, the right side of the pan is extended 2" outboard of the pan rail mounting holes in the block. This, combined with the scavenge oil line fittings being on the right side, prohibits the usual right hand side mounting of the starter. Since my external oil pump allows me to relocate the oil filter, I fabricated an adapter to mount the starter on the left side of the block. Being only six cylinders, and not high compression ( 10:1 CR, supercharged), I can get away with the lightest starter Tilton makes.

-

The 4 stage dry sump oil pump was located on the right side of the engine to avoid clearance issues with the steering shaft.

-

A discussion of master cylinder relocation would be off-topic for this thread. Incidentally, for those curious, the plastic engine block and transmission came from P-Ayer Products (http://www.payr.com/).

-

-

Headers on a V8 (or V6) Z car are problematic. Steering linkage issues on one side, starter heat soak issues on the other side and narrow spacing of frame rails requiring small diameter primary pipes with sharp, tight bends immediately out of the port. Once down in between the frame rails you are left with a tight transmission tunnel compromising either exhaust system size (diameter), ground clearance or both. I went with fender-well headers ( 1 7/8 " dia. primaries) that go outside of the frame rails and a side pipe exhaust system. The downside is that the battery must be relocated and the master cylinder moved to the driver's side of the firewall.