mainboyd

Members-

Posts

83 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by mainboyd

-

I have an aluminum fuel rail extrusion that has an 11/16" ID that I would like to know if I can machine and use for my setup. The only question I have is if an 11/16" ID (1/2NPT) would be too large compared to the, I believe 3/8" ID or 1/4NPT, pallnet fuel rail? Some specs of my car: Megasquirt 2 L28ET (F54 block P90 head) 60mm TB Walbro 255lph Aeromotive fuel pump regulator 440cc injectors Stock turbo (larger turbo and an intercooler not installed yet) Sorry if this topic has been talked about already. I did try the search function here but I got thousand results about fuel rail but had a difficult time finding one out of the bunch about fuel rail sizing. Also, I accidentally posted this in another section that I shouldn’t of have… I can see how I can try to get rid of that one.

-

Anybody Know Anything About This Z-Car Design Drawing?

mainboyd replied to wrenchtech's topic in Body Kits & Paint

-

Has anyone heard of the TRZ body kit for the s30 and know where I can get more info on it? I can only find pictures of it on Pinterest.

-

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Wow thanks for the encouraging verse from Proverbs! I'm really glad you notice my determination on getting the car running and not just being lazy and giving up or having someone else fix it. It's good to know someone recognizes that, especially from you. Thanks Tony D However, if you think FSM is better than the Bible then all these verses from you are nothing but hypocrisy. Galatians 6:3 & Titus 1:16 Also, I assume you don't really know anything about the Bible and probably just search on the Web for something to your interest against me. How do I know? Because you lack to simply read and live by the verse before and after Proverbs 12:24..... BUT, just in case I'm wrong about you here is another verse that maybe you should also consider living by. Especially when trying to be the "tuff guy" in front of a computer. Proverbs 15:1 Jude 1:16 Thanks cgsheen. I think I'll keep it at the 20 mark for now. And since my original question has been resolved I think I'm done with this thread and don't need to add anymore to it, thanks everyone! -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Just an FYI so its more clear for you, when checking my TDC I also made sure to see if the actual piston #1 was at the top by taking the spark plug out and simply looking through the hole with a flashlight and turning the engine by hand. I didnt think I would have to go into so much detail for you about how I made sure I was in top TDC but whatever makes you happy inside... So yesterday morning I was able to work on the car a little. What I tried was kind of what you mentioned NewZed by removing the clamping screw so that I can move further. When I started the car and waited till it warm up I then checked the timing. The mark was on 30 and the car was running "ok" then turned the distributor to where the mark went to 20 and the car was running better. Then moved it to 10 and it was running "ok" again. Then moved to 0 and it got worse. So then I moved it back to 20 where I saw the best results and by surprise I was still able to use the holes to hold it in place. However, I am not sure where the timing mark should be on these engines if completely stock. What do you guys think? Tony D, I am super happy that I was able to get you to read a few verses from the bible and on top of that share it with all of us. If anything, thats probably the best thing that can come out of this topic I started . Just remeber though, you can't just share a few verse and "like" only a few verses if you dont live by all the versis (Holy Bible). So if quoting something from the bible I would assume you live by the bible. So please try acting like it in life and on the internet please. Patients, kindness, slow to anger, just a few examples. anyways I dont want to start preaching. Let me know what you guys think of leaving it at the 20 mark or messing around with it more?!?! Thanks, -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

I'll try to be the better person here by responding like a respectful adult and not get upset over silly things. I think you might be misunderstanding what I'm trying to say or maybe I'm just not being clear. I did start over last night by dropping the oil pump AND lining up the dot AND making sure the motor is at TDC (why wouldn't I start from the beginning when I just admitted a few posts back that taking shortcuts is where I went wrong?...). BUT, when I check the timing with the timing gun it still shows that the notch is way off. Just past the 30 mark like I have been saying. Now because it's off I would believe it would be safe to ask what would you suggest I do to "fix" the timing? Is that OK to ask? What I just SIMPLY asked/suggested in my last post is if turning the shaft one tooth a certain rotation would work. Or should I leave it alone because the motor seems to be running fine to me. Ecclesiastes 7:9 Thanks -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

When I got it running last night the timing mark was where it was before I screwed it up, which was past the 30 mark (using timing gun). Now if it's that far off and I want to move it towards the zero mark which way would I turn the shaft? Clockwise? -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Yes now I remember the whole dot on the oil pump and the shaft. I think where I messed up was when I took it apart and was then just relying on setting the top end of the shaft. I don't remember but I bet when I tried to fix the timing, by turning it one tooth, the shaft probably dropped and I then tried to push it back in place when underneath, causing it to be placed 180 off (maybe and a good possibility). Basically what I needed to do was not just follow one part of the instructions but the whole thing from start to finish on setting the distributor. That would of helped clear things up about the whole end of the shaft deal. Thanks Tony D for pointing out those key points about "The raised part is not half the existing diameter." I never realized that when seeing it in person and in the book. Good to know. Thanks NewZed for not giving up on my foolish thinking and sorry to lead you into thinking there was something wrong with the distributor when it was just my human error. I thought that I would be able to get away by just making sure the top part of the shaft was correct. Anyways, the car is running again. Thanks again everyone! -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Awesome! Thanks everyone!!! I'll set it up right now and see whats up. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

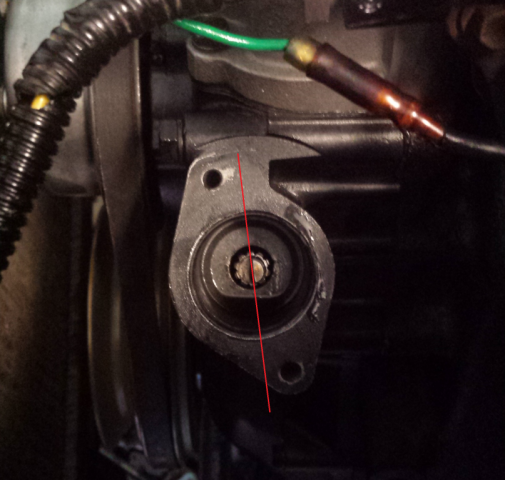

So basically I was misinterpreting the picture in the manual? The half moon part that I thought was machined down was actually the other side? So is what I am pointing out in the two pics below correct? -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

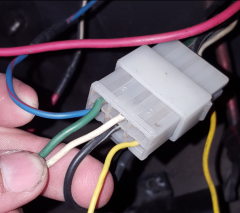

NewZed, The part of the rotor that sticks out is on the same side of the machined down half moon (see pic for clarification). And yes it is the correct rotor with just one hole for the screw. Tony D, hmmm I have been searching for a while and never seen a post that had the same problem and figured out what the cause was. If it has been covered before then please would you be able to provide a simple link to what you believe has been covered, if its true? I think I might just go to autozone and see how theirs looks compared to mine. They show that they have one in stock. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Cgsheen, I was looking at that when I took it apart and the roll pin is still there and looks like there is nothing wrong with it. I even tried to see if maybe the roll pin sheared, causing it to spin freely, but no. Does anyone know what that "1" is referring to on the cover plate under the rotor? Is that where the rotor should start at? maybe indicating spark #1? Well I am almost certain that the previous owner did something to the distributor if everyone else does not look like mine. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

I don't know what I am looking at... On the first picture I am pointing out what seems like something that would allow that top peace to go on one way which is on the direct opposite side of the tapped hole. Can anyone confirm that theirs is also that same way? Should I try to unscrew the phillips screw in the shaft? -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

hahaha I'm sorry if I am coming off as being defensive I really didn't mean to. I haven't had time to look into anything yet. All day today I have been out and about doing some daughter and father time, the Zoo and Civil War reenactment. So I'll look into it tonight after 11pm ish when my family is all sleeping and I finally get some time alone. I am not sure what I am looking for when taking the distributor apart because I don't have one to compare to or know how one should look like but I"ll take some pics and post them up here. Oh and I have taken the actual rotor off hoping that there was a tapped hole on both sides of the shaft so I can just turn the rotor completely 180 and call it a day. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Well that would be because the motor is not exactly at TDC. Either way its facing the opposite direction. I'll take the distributor apart and see whats going on in there. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Well lets take a step back and think about this here. First what I am trying to figure out is why my distributor rotor is off 180 degrees. Lets leave "TDC" out of the equation for now because, and correct me if I'm wrong, the motor does not need to be at TDC if I'm trying to determine why my rotor is off. If you think about it, the placement of the rotor is determined by the placement of the shaft. Technically the shaft can be placed in any position (but there is only one correct position if wanting the car to start). So by taking "TDC" out of the equation it makes it a little easier to find out why the rotor is facing the wrong direction because we are not having to worry about if we are at TDC any more. So by looking at the three pictures I put together on this specific post I have made it a little easier to see where my shaft is placed by making the important things to realize in RED. Now when looking at the pics I believe that the shaft is in the correct position according to the manual and what I have searched for online. However, when I place the distributor on, the rotor is then pointing in the wrong direction (keeping in mind that the distributor can only fit one way due to the machined end of the shaft and of the distributor). AND THIS IS WHAT LEADS ME TO WHY I STARTED THIS TOPIC.