mainboyd

Members-

Posts

83 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by mainboyd

-

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Well as of right now the car does not start. So I'm going to try to turn the shaft 180 and see if that will work. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

I was just trying to shoot for any number on the scale because it wasn't even hitting the scale, past the 30 mark when using the timing gun. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

To clarify why I decided to try to get the shaft "perfect" before having the car sit was because I used a timing gun (not sure if it was a good idea) to see where I was at in my timing and it was off. I was not able to just simply turn the distributor from the top to correct it so that's when I dropped the oil pump to turn the shaft one tooth to see if I can perfect the timing. Note to self: if there is nothing wrong with it then leave it alone!!!! Thanks again everyone. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

Yes I believe that might be it but man I swear I thought I had the shaft placed in the same way before but just slightly turned by one tooth... oh well I'll just turn it 180 now. Thanks everyone. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

I'll set the shaft 180° from where it should be. I did not know if that would be OK to do or not. I was just going to have the #1 sparkplug wire start where the rotor is currently at but I'll just turn the shaft. Thanks wolfapl1592 and z240. Kind of afraid to ask because I don't want to get flamed for it but I am interested to know how it is 180 off. I'm not the type of person that just fix the problem and don't care why or how it happened. -

Why is distributor rotor facing wrong direction?

mainboyd replied to mainboyd's topic in S130 Series - 280ZX

I understand that I can do that but I'm wondering why I'm having to do that when everything was installed correctly? Are the distributor shafts installed differently for a 1981 L28ET compared to an 82 or 83? (I believe I have an 81 motor) -

Ok so I been searching for a few days now on why my distributor rotor is facing the complete opposite direction then where it should be. Long story short, I have a 240z with a L28ET motor and it was running perfectly 2 weeks ago, had it sit for a week then tried starting it again and all I got was back firing through the exhausts pipe and it did not want to start. Before having it sit for a week I was working on getting the distributor shaft perfect by dropping the oil pump and placing the shaft in the right position. This was done just before I had the z sit for a week. Anyways I decided to take the distributor cap off and noticed the rotor is facing completely the wrong way. I have no idea how it happened or if it was always that way. So I followed the manual and everything online that I can find to properly place the shaft correctly and I am positive that I have done that correctly. The only thing is that when I put the distributor back on the rotor is still facing the wrong way. Why?? And why would all of a sudden it won’t start? I verified that the motor is at TDC by looking at the two front camshaft lobes to see if they are pointing upwards and the notch on the crank pulley is at 0. Either way, I set the distributor shaft in the correct position so that is what should determine where the distributor rotor is facing/starting before even trying to start or run the car. Also, there is only one way the rotor can be bolted on to the shaft because there is only one tapped hole on one side of the shaft, the hole does not go through the shaft. I have attached pictures of how everything is set. sorry for the pictured coming out sideways. I dont know why they came out like that.

-

ktm's 1972 240z - The ongoing saga.....

mainboyd replied to ktm's topic in S30 Series - 240z, 260z, 280z

So what was the reason for you deciding to ditch the L28ET and go with a LS engine? -

HELP On My Own 1973 Body Harness Near Completion

mainboyd replied to mainboyd's topic in S30 Series - 240z, 260z, 280z

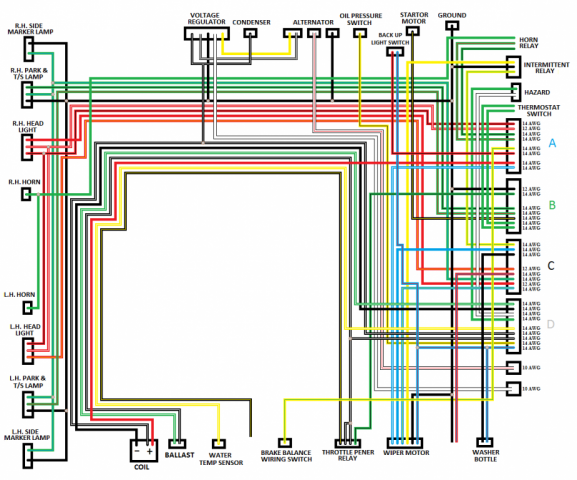

At the time I was putting this together I didn’t have any program/software in my computer to simply create the diagram so I just went with the good old paint program. It wasn't hard to do. I ended up buying a wiring harness in really good condition online for just $50. All the connectors were still there but the alternator one (which I already have) and none of them were brittle. No cut or additional spliced wires. And to confirm that my diagram was accurate I used the harness I bought online and traced the wiring with the diagram and it was all correct. However, I noticed that one of the white wires in the diagram needs to be changed. I'll change it and update the drawing later this week when I have time. I am still planning on restoring the old one after I get the Z running. -

HELP On My Own 1973 Body Harness Near Completion

mainboyd replied to mainboyd's topic in S30 Series - 240z, 260z, 280z

Here is the Wiring Harness Diagram I put together with all the wires sized from the Black, Blue, Green, and White connectors. Hope this helps. -

HELP On My Own 1973 Body Harness Near Completion

mainboyd replied to mainboyd's topic in S30 Series - 240z, 260z, 280z

Found out what AWG wires are used for the harness. I will post up before and after pics when its done. Looks easy. -

HELP On My Own 1973 Body Harness Near Completion

mainboyd replied to mainboyd's topic in S30 Series - 240z, 260z, 280z

Ok...? Thanks for the response Tony, i think. -

HELP On My Own 1973 Body Harness Near Completion

mainboyd replied to mainboyd's topic in S30 Series - 240z, 260z, 280z

Does anyone know what gauge/AWG wire the harness uses? -

Everyone's Z's looks amazing! Here is my 72 from when I first got it: First started to work on it: To now: Should have engine put together this weekend.

-

I also would like to apologies to anyone else who's feelings have been hurt. I am simply looking for answers and not a pointless cat fight.

-

Chill out guy. You take things a little to serious... if this forum took you this far took talk so immaturely then that's just sad... All im doing is asking questions and here you are taking it personal. Im assuming im talking to an adult on here sense you have over 8000+ posts... unless you like to jab at everyone on here countless times about how your always right and everyone else is wrong or you just spend way to much time on the computer. Block this thread buddy, I don't mind. All I know is that it will show how much of a person you are by just blocking this thread because of your emotions or feelings getting hurt and want to just try to have the last say hahaha Don't worry though I forgive you. It takes more then just a macho guy behind a computer to make me go to an unnecessary level of emotions like what you have shown. I still thank you for the info you have provided me about the heads and will look into it more.

-

"It's not that Nissan wouldn't ever...it's THAT THEY NEVER DID!" Maybe because it was never worth it?..... just throwing that out there... not trying to cause trouble lol Nissan had to of made two different heads for a reason and dont say the liners of the P79 were because of emissions because the P90 and P90A turbo head had to go through the same emissions.

-

"Not only yours, some people are taking time to answer your questions. Don't ever forget that!" Hahaha all I can say is that thats on you. I didn't twist your arm to answer my questions or look into this forum. However, I do appreciate the time that people have put in to answering my questions. Don't ever forget that!! Also, I ran into this today which was insightful: http://forums.hybridz.org/topic/109877-cylinder-head-flow/ http://datsunzgarage.com/p79/ However, it seems like the only difference would be the amount of porting you can do to the P90 exhaust port compared to the P79. Might be wrong but ill be looking into it a lot more. Even though im not looking into performance gain for my personal use between the two heads, I would still like to know if there is any other difference between them when modded. FYI, I already have a complete L28ET with a P90 head so all this "work" I have been putting into the junkyard build is not stopping me from enjoying my car.

-

FYI, Junk yard build is probably the best title for what im doing because thats where im getting all my parts from and it might be a junk head once its all done...

-

Well first off I would like to say thank you Xnke and Tony for the info. I just started working with these engines so whatever info I get off the internet or from forums or even from this specific forum I take in and study or do more research on. Also, I would like to make clear that no where on any of my post did I say I was wanting to gain any performance on this head but just save it because I thought it was a better head to use. I dont mind the swapping of heads because this is the first time I have worked on the internals of a piston engine. I have way more experience with rotary engines because I have owned and rebuilt a twin turbo RX7. Also I have not paid a dime on this head because my friend is the manager of the wrecking yard that I have been going to for the P79 head. Only thing I have "waisted" would be time but I have for sure gained a lot of experience with these head (not as much as you guys for sure). Just be patient with me and my questions. I try to do all the research before posting. As of right now im going to use the P90a head sense I already took everything off the P79 head... yea it probably wasnt a good idea to pull all that out but it has already been done and there is probably no point to going back. Im going to pick up the P79 cam and do some measurements on it sense there is not much for this "k" stamp cam

-

If thats true then why do people choose the P90 over the P79? Also, why would nissan create two different types of head for the L28? Why didnt nissan then just use the same head on both the turbo and non turbo and have the only difference be that one had dish pistons for the turbo and the other flat? I mean they take the same F54 block...

-

The liners in the exhaust and its exhaust port are round for the P79. I thought that the square exhaust ports flowed better then the round... Would it be ok to basically put all the P79 internal parts, besides the valves, and put it in the P90a head? So it would be a P79 internals in a P90a head. Can this work? Tony, if your saying that the P79 head is the same in all respects to the P90 but the exhaust ports then this P90a/P79 head should work right?

-

So I found a 280zx that has a P79 head with an F54 block. I took the solid lifters, pad, and rocker arms. However im am still in need of a cam. The cam that is in the P79 head is stamped with a k. I cant find any positive answer to where its from or the specs on it. Some say its a maxima cam. If so can this be used on a P90 head?

-

Leon, Ill make sure of that. Thanks. I also forgot to mention that the head did not come with the sprocket. Are all sprockets the same on L28 motors?

-

Hello everyone, So I was given a free P90A head that only had the hydraulic lifters, valves, and valve springs. Nothing else is on the head. My goal is to try to save this head and use it on my F54 block as a turbo engine. I dont want to spend much money on it so ill be looking around in the junk yard for anything that I can find and of cores work. A couple weeks ago I found a 280zx in the junk yard but i forgot if it was a N42 or N47 head in it. Ill take a look at it tomorrow to know for sure. So now for the build. After doing some research (correct me if im wrong) I found out that all solid lifers are the same on the L28 heads but the P90A head that has the hydraulic ones. So I will be swapping out the hydraulic lifters with solid ones and I know its not a direct swap into the P90A and will be needing an adapter to fit the solid lifters in replacement of the hydraulic. Next would be the cam and cam towers. What are the possible cam and cam towers that i can use to put in the turbo P90A head? I read that the N47 cam could work on the P90/P90A head... is this true? I also read that some camshafts have internal and external oiling and that the P90 and P90A have the internal oiling. Is there any other cams that have the internal oiling that I can use? Next would be the rocker arms. If I find a cam in good condition then would it be safe to take the rocker arms too? Am I missing anything else? Any help would greatly be appreciated. Thanks