manimal

Members-

Posts

14 -

Joined

-

Last visited

-

Days Won

1

manimal last won the day on April 30 2020

manimal had the most liked content!

Profile Information

-

Location

Bay Area

Recent Profile Visitors

1883 profile views

manimal's Achievements

-

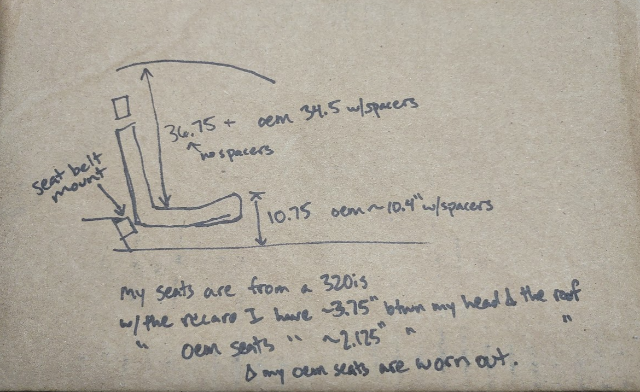

Yep, the portion most of your weight rests on is lower in the Recaros. My recaros were rebuilt, so the webbing is still taught. I'll get some measurement with myself sitting in the recaro vs the factory seat this weekend. Mind you, this is with the plastic seat spacers in place(2 iirc, can't recall the thickness) with the factory seat and none with the recaro. The only downside to the seats is they're deeper so you can't get them quite as far back. I'll measure that distance this weekend too.

-

I'm going to be producing them shortly. Here's a few shots of the "prototypes" with the seat in the car. They're tilted forward slightly to compensate for the higher thigh bolsters compared to the Z factory seats. They bolt to the factory seat adjuster rails

-

With the S2000 trans you can and you can get the shifter to pop out in almost the OEM position. It still requires a curved shift lever like the Z to get the shifter in a better position. Late to the party, but a free engine is great for mockup. You could get the car to a running state on the free engine, then swap in a JDM import engine with the USDM engine accessories pulled from the free engine. As for cost, $10k+ to do it right. Some may have done it for a bit less, many don't remember to add up all the little incidentals. If your goal is more roadkill style and you can wait for deals, you can probably do it for $5-6k not including turbo stuff. /end hijack OP, nice to see it running after all the common non-standard engine swap headaches!

-

It needs to be mounted vertical, but the overall height is less than the 260z external pump + filter. You can't mount one sideways unless the product is designed for it with alternative locations for the overflow line to enter so air can purge. I'm going to run a clear plastic low pressure fuel filter(like oem) before the LP fuel pump then a 10 micron post surge tank. It's definitely going to be a bit of a rats nest even though I attempted to minimize fittings and I'm using radium swivel banjo fittings to reduce the line loops. I'm hoping it's not too loud, being inside the rather thick surge tank should help.

-

Another option since you're planning on running a surge tank would be the FiTech Force Fuel Systems 50006. It's a mini surge tank with a built in fuel pump. I also have a 260z so I can confirm it fits where the OEM external fuel pump resides, though I've only held it in place as of yet. You'll have to make custom brackets to mount it and use a low pressure electric pump to feed it. With the return line plumbed to it and a branch going back to the tank, it won't run dry and you won't need to worry about an in-tank baffle system.

-

Looking at his pics he only has the necessities, water pump and alternator. I'm doing the same and I made my mounts to clear the stock steering shaft. I'm running the stock oil pan and it's basically dead nuts even with the factory pan location/subframe. I'm using a S2000 trans and I had to notch the transmission tunnel "gusset" hoop for the S2000 transmission shift tube. The factory location for the AC compressor sits where the steering shaft lives unfortunately.

-

T3 Long Nose R180/R200 CV Axles for 240/260/280Z

manimal replied to FJOVA's topic in S30 Series - 240z, 260z, 280z

Zcardepot sells them for $560 as well(no affiliation). TTT doesn't build them, they buy them from a supplier based on their specs(or quite possibly one they acquired from Fritz and sent to a supplier to duplicate). All you need are the specs and you can get them made in small batches overseas. IIRC Fritz said "250hp" because that appeared to be the highest verified hp on a set which were used. TTT is likely saying 350hp for the same reason, though no one has been driving on them for that long and vehicle weight, tire treadwear, and driving style matter a lot. The real bummer is Fritz was selling a set which plugged into the Subaru R180. I asked Zcar if they planned on doing that and they said "no". Hopefully TTT decides to offer that configuration. Futofab has more options and a higher quality parts if you're concerned about the hp rating. -

Cool build, I plan on doing a full writeup of my k swap in a month or two once it is on the ground and running. It's the perfect engine for the car, turbo if you want reliable hp or NA(what I did) for a light weight high rpm screamer.

-

OEM Brake hose to Wilwood Caliper

manimal replied to nikk94's topic in Brakes, Wheels, Suspension and Chassis

Brakequip BQ187 is the line adapter you're looking for. If you end up using a wilwood master cylinder, BQ50 is the brake line adapter for those 3/8-24 inverted flare male to M10x1 IF female. ~$5/ea direct, I was able to find some locally at MFCP which is a west coast Parker affiliated chain. Midwest/East coasters likely have a similar chain. https://brakequipproducts.com/product-category/thread-changers/?filter_thread-type=standard-and-metric -

I made a custom T with 1" & 5/8" tubing + some custom "washers" to close the gap. Doing that would take a lot of time by hand + some semi specialized tools like a die grinder w/carbide burr, step drill, drill press + vise. The easier option is a 1" NPT brass "T" with 1" NPT 5/8" hose barb. If you have a local supply place you can probably get the parts for ~$20. The fabric coated hose I used in the pictures was ~ $4/foot iirc. I mounted mine to the block since I think it looks cleaner, though it would be better to have the block outlet hose dumping slightly below it's outlet so anything condensing drips down into the can. Generic $35 ebay catch can. Motoiq.com put out a video on the "IAG Air Oil Separator" which is a step up from the catch can. It uses the coolant loop to heat the can directs the mist to the wall of the can in an effort to evaporate any moisture with the oil draining back into the block. Definitely overkill for a street car, but worth a mention if someone finds this thread and is looking for a better track option.

-

Engine Blow-By. Catch Can hose routing

manimal replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

I bought a $35 ebay special and added some steel wool to the "filter" it has for the inlet. I can't say whether or not that really helps, but some of the more expensive catch cans do that. I plan on running a line from the out to carb filter baseplate eventually. The hose sizing is odd, from memory the valve cover is 16mm and block is 25mm. I cut some 1" 049 tube for the T body and some 5/8 035 for the catch can/valve cover ends to make a custom T. You could do the same with parts from a store specializing in hoses. Idk if this is common, but I have a local store which does custom hydraulic, water, air, etc lines and has adapters out the wazoo. I bought the fabric coated hose there as well. Leak down test is a good idea, but something even easier you might want to try is UV coolant dye + a black light if you are concerned about a coolant leak. The UV dye survives the combustion process and is visible at the tailpipe if there is a coolant leaking into the combustion chamber. If it's leaking into your oil you'll find there. -

help identifying wiper switch wires

manimal replied to alternaklaus's topic in S30 Series - 240z, 260z, 280z

Why are you looking at the wiring on the combi switch? Unless you're replacing all the wiring, factory relays and all with an aftermarket setup, you only need to look at the engine bay connector wiring. I've got an early 74 260z and just wired up the honda motor, I believe the wire colors are the same. I won't be able to test it for a week or two because I'm still working on other wiring updates, but I'll report back when I do test it. I recommend adding a SPST relay to the circuit and lubricating the wiper linkage before swapping the wiper motor. I have very little experience with the Z, most of my car work has been old BMWs and Volvos, but I did take a multi-meter to a number of locations on the car and the voltage drop is pretty significant all around. I probably would not have done the swap as my wiring plans evolved and instead started with adding a SPST relay. You can quickly add the relay and possibly solve your slow wiper issues(also lube the two main wiper posts!). If it doesn't solve your issue, the relay won't have harmed anything or taken much time to install. If you unwrap the wiring harness where the wiper motor wires meet the main wiring harness about two feet from the engine bay connector there will be a LR (blue/red) single 18ga(16ga?) which splits into three and feeds the reverse light switch on the trans + washer pump motor. This wire is hot when the key is in and switched to Acc or Run. Cut this at the joint and the single becomes the trigger (85), the triple (87) receives +12v from a fused wire to the battery (30), and 86 is ground to the chassis. I found the new aftermarket honda motors don't use the wiring colors mentioned in all of the writeups, likely due to the generic vs OEM unit. Also, it's NOT a '91 honda wiper motor. '91 was the last year of one generation and the motor you want is from a '92 to '96 civic or '94 to '01 integra, part #76505-SR3-A01. I ordered a $40 generic unit off ebay and it came with the hardware needed and the shaft was notched like the OEM wiper so no grinding to it was needed. The wiper mount still needed grinding, approximately where my squiggly line is. The heat shrink colors match the generic wiper wiring colors and the connector pic is from zcardepot with a slight enhancement to the colors. '74 early ----- Generic 92-96 civic 260z 94-91 integra wires Black ------------ Black Blue/Red ------ Red Blue -------------- Green Blue/Yellow -- Yellow Yellow ----------- White Blue/white ---- Not used TL;DR - install a relay and lube wiper pivots first, easier, quicker, cheaper. -

I'm disassembling mine right now and had a remove a broken stud from the intake side recently, so top of the head knowledge. Looks like a welder is your best bet at this point.

-

Welding a nut on is the best solution, it's a M8x1.25 bolt. Use a M10 nut so you get better penetration and leave the nut partially off the stud so there is a bit of a pocket you can fill with weld. Before welding the nut on, fill the oil pump hole with one of those blue "shop towel" paper towels and tape over it so you can't get anything inside the engine. Another idea I just thought of for those with out a welder. You may be able to get the stud out by continually soaking it in PB blaster over a day. Then clean the stud really well with acetone and a small wire brush. Cover it with red loctite 271, thread a nut on, and let it cure over night. I would try that before filing flats into it, because you can do one before the other, but not vise versa. I've also found channellock GL-6 pliers to work better than vise grips(though I haven't used the V-jaw vise grips yet) and they would work better with out filing flats on the stud.