MastersMechanic

Members-

Posts

58 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by MastersMechanic

-

Hey I was just thinking about the car and was wondering how you were doing on it. I picked that tank for ease of fuel delivery you can get a intake sender/pump for that tank out of any 88-98 k2500 or use the sender and an external pump. Anyways good luck. And if you ever want to get rid of it let me know ) Josh

- 1 reply

-

- 1

-

-

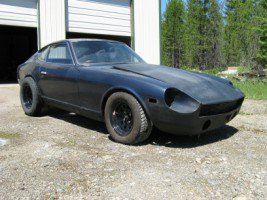

Here is an update I just finished the mounts for the 454 and 2004r. The driveshaft is going to the shop tomorrow. flares should be here this week. I'm playing with the head lights and the grill to see what I want to do any suggestions would be great or photochops. The fuel tank is in. I Reinforced the fiberglass with stainless and have tons of work left. The hood will most likely be pinned for now(that reminds me I need to start working on the hood. UGH

-

definitely needed to talk to you before I started this project. lots of learning curve. thanks

-

I can't believe 3 applications of wax wasn't enough, I pulled the fiberglass off after 2 layers of light weight cloth and 2 of heavy cloth, the paint and the foam came off with it. a scraper and a screwdriver and a hour later I got it all off except for some paint. I know you guys don't want me to use it as a skin but I think that is the way I am going to have to go as I don't think I can get the Inside as clean as I need to use it as a mold. I hope it turns out, lots of work left. Thanks for the support It is what has kept me going this long. Josh

-

Wow I wish I new of them ahead of time. Thanks for the help.

-

I apologize for not keeping up with the build I have rebuilt the front many times because of flaws and now I am finally fiberglassing. This project is way more work then I thought it was going to be almost gave up many times and went back to the original z front end, but luckily I threw It all away( to keep me from going back). with the work it has taken and how hard it is for me to work with this fast drying resin I decided to just build a over lay piece. The piece I pull off will actually be the front end. The only bad thing is I won't be making anymore so I can't break this one. I just bought 12 new paint brushes and 24 cups for resin, and an airplane building manufacture gave me 20 rolls of fiberglass in different thicknesses I only have 4 rolls left with all my friends who wanted some. now if I could only find cheaper resin (50 bucks a gallon) I have used two so far with only 1 1/2 layers(lots of 1/2 to 3/4 filled cups of dry resin Ugh! ) need two put a couple more layers on to be strong enough to hold form. I started a new project on the z ( big blocks fit in a z better then the small block, but still looks small ).

-

Can't you just use a satin clear to paint over your base coat and get the same result as not having a clear coat all together?

-

All the cars I know about have different plates, the plates and time of the day are what you need. then call dispatch and ask to talk to a Sgt. The Sgt. will stick up for there team but rest assured they do have to document it(at least in Washington they do). Tips on getting pulled over; 1: Pull over into a safe spot(but don't go over board) 2: Roll down your window and put your hands on the top of the steering wheel(if you have dark tinted windows put both hands on the door so the officer can see them when walking up) 3: Don't go looking for everything untill the officer says to.(really nice to have everything tidy and in an easy to get location) 4: do not get out of your car unless the officer asks you to(good way to look at the barrel of their sidearm).extreme officer saftey issue. 5: try to be curtious(most likely they will be) On the blue hair I parked in her neighbor's driveway and walked to the location about two houses down. and while searching the house I saw a lady out the window with a pad of paper and a pen writing down the cars information. I wondered what she was doing I found out the next day. Did you know that every time you get stopped the officer has to write a report on the contact if he gives you a ticket or not. I average about 70% of my time writting reports and entering evidence. Sorry if I sound one sided. I used to hate cops. I used to get pulled over once or twice a week. only 3 tickets though. then I became a mechanic for the county.(ever want to put a remote controll shut off on a cops fuel pump relay. hee hee). then one day a detective asked if I would like to go on a ride along. and then the ball started rolling riding along once a week, going to practice shoots. They got sick of me riding and not doing anything and sent me to reserve academy, what a blast I recomend going on a ride along to everyone, sorta get to see their side of it.

-

Sounds like a jerk, if you can get his plates you can always put-in a complaint with his superior. It has happened to me. going on a code run to an alarm call in my charger to a possible burg. A few blocks before I arrive at the location of the alarm. I shut off all lights and sirens to be incognito to try to catch the burg. In the act. I catch up to a little ol blue hair driving the speed limit like every outstanding citizen should. I was trying to get to the house,and I might have been a little close, So when I arrive and while checking out the house, she wrote my patrol unit down and called my sgt. and complained about me following to close. In my Dept. all complaints go in your personel file for a year before you can put in a repeal. It sucks. I actually called her up and apoligized.

-

The reason the cop was following you might have been because, when he ran your plates you weren't in locals(meaning that you are not in that county's computer system). So then they have to look you up on a state wide database that takes more time to get a hit. How it works is they run your plate; the number comes back with the vehicle information it tells if plates are expired or the car is stolen or if it has unpaid tickets, and it'll have the owner(s) of the vehicle's OLN(operators license number). then you can take the OLN and enter it into a local search which checks that county's records, for warrants and driving record. if you do not have a record in that county, you have to run a statewide check. Try doing this while driving takes some time. Yea some cops are jerks. but they have to deal with the worst of society. you have to remember that cops don't make the laws they just have to enforce them. Remember they are not donuts they are pastries

-

Yep, I think, I just got to figure out how even tried to figure out how to put 02 wrx fog lights in

-

-

Oh, and about the brick part, think of it as a 1850lbs brick with a 13.2:1 500+hp power plant, with a 200 horse nitrous backup. I think it will push the wind back. remember the highest speed limit I know of is 70 mph and I am a cop so you know i wouldn't exceed the speed limit by to much (hehehe)

-

Well I haven't worked on it alot, the spakle mud doesn't work very well I had to sand it off and start over with glazing putty But It is amazing how hard it is to perfect one side to be the same as the other.(time consuming) anyway I am not making any to sell I will make two and if any one wants the mold (if it holds up) they can have it and make their own. Don't want to bother with any "It doesn't fit right" or "It broke During shipping problems", anyway sorry It is taking so long, my wife bought my bmw back for me and I have been spending sometime making it right

-

Well I put my first layer of filler over everything, I am using my brothers advise and using spackle mud. It sands fast be easy to remove after I am done with the template, but is slow drying. here are some pics.

-

Well I took a few weeks off to catch up on some other projects(and being sick stupid flu bugs anyway). I went out today and finished up the right side of the foam so hopfully no more foam work I'll start the bondo work and glazing later this week(I hope :-!) then it'll be time for fiber glass work. Had my yearly tazer training maybe the 5 second ride on the white buffalo will jump start me to finishing this project

-

The Piece I pull off will be the mold or negative mold as you said. I have watched alot of you tube videos and looked at alot of fiberglass sites witch scare me more then help but I still want to try. If it doesn't turn out try, try again

-

What kind of mold? Well since I am new to this stuff I plan on finishing the front end just the way I want it, and then use that ASX (I think it is like spray on plastic wrap and makes the fiberglass pull right off) and then fiberglass over the top of the spray and when I pull it I hope it will be good enough for a mold. Just me thinking, never done it before hopefully it works?

-

240Z Doors - Weight reduction mod's

MastersMechanic replied to S15 200sx owner's topic in Body Kits & Paint

I just gutted my 280 door, and that piece you said was easy to get out of the 240 door was a real pain in the butt to get out. I left the door handle in its place and it still works after cutting all the inside metal away. anyways I'll weight the next door before I cut it all up for a weight difference but I bet it's more like a 30-40 lbs different with a 280 door. The lighter the better. -

My goal was to have 295 60 15 all the way around with zg flares. still might I just hope someday I'll quit changing everything and just finish it. I would rather have small winter projects and drive it in the summer, then keep changing my mind and never being able to drive it. It has been 4 years since it was last road worthy, and it was perfectly fine then.

-

that is a good question. I looked at Darius car and thought I need the same exhaust outlets. I thought long and hard (I don't know if I really want to answer any questions on how I did it, as there will be lots of structual debates on what I came up with) anyway; I cut the panel in front of the storage compartments, drilled a 3+ inch hole in the quarter panel and welded a piece of 3/16"x 3" stainless tubing thru the quarter panel. I then rivited a piece of stainless to the quarter panel and welded the tubing to it for a clean look. still needs finished and the new floor finished but what is starting a new project before you finish the other 100 you started and never finished. p.s. I am planing on putting baddog rails on and stiffing up the chasiss with tubing. so please don't flame to bad;-)

-

-

Dan5138 Kind of irrelevant... but what type of glue did you use to stick the layers of foam together? That is a relevent question. I used contact spray glue. You just spray it on both pieces and wait a minute, stick them together and they are locked, no need to wait along time for the glue to dry either. I don't think I will make side skirts, since I cut out the rear panel for the exhaust exit.

-