-

Posts

5399 -

Joined

-

Last visited

-

Days Won

58

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by RebekahsZ

-

Mild steel cage or chrome moly? I love it; looks great.

-

Mine have been that way for ten years. I'm thinking about shimming the door hinge out a mm or two to see if it will help. Not an easy job. Will get help from a body shop if I do it.

-

Get rid of the car and spend as much time with your family as possible. A car can become such an idol-I know mine is for me. I think about it when I'm on dates with my wife, my thoughts drift to it during the sermon on Sunday, and when my wife asks me what the sermon is about, I have no idea because I was bench racing when I was supposed to be listening. Now, if you just can't part with the car, come visit me this summer for autocrossing and drag racing. You will sprint to your garage to get back on your car project!

-

Translation: take the flange off your Nissan diff and put it on the subi diff. Bolt up your driveshaft and go!

-

Yes, with an AutoPower adjustable brace.

-

Strut options for ground control coilovers?

RebekahsZ replied to Blf0005's topic in Brakes, Wheels, Suspension and Chassis

There's just such a big price difference between the cheap stuff and the expensive stuff. On a street car, you probably won't see a difference, heck, we haven't even talked spring rate (you will get a million opinions there).. Unless you are an experienced driver who races in sanctioned events every weekend, have a race team and have mega dollars for lots of private track time for trial and error testing, you likely won't see a difference between any of the shocks out there. The guys who really tune their suspensions for the most part are professional team with professional drivers and crew chiefs. Save your money for wheels, paint and tires. Just my suggestion. If you don't already have great tires, that's probably a better place to spend money. -

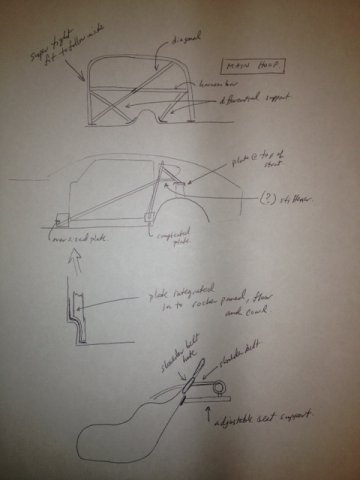

I am scheduled to drop the car off Saturday; the fabricator has ordered 1.75" DOM. I think my last issue is differential support-I've already torn the floor at the lap joint between the forward floor and the rear floor where the RT mount bolts up. I am building a cage that is primarily a NHRA 9.99 second "6-point" roll bar. The required 6 points are the main hoop, rear legs, and door bars. For lateral diagonal support of the main hoop, most NHRA cages I have seen as examples in the rule book also use two little semi-diagonal legs below the harness bar, and no diagonal above the harness bar. I'm really not a fan of that design and I really think the SCCA full diagonal is a better design, so I plan to include both a diagonal and the little diagonal legs below the harness bar. So my last question has to do with differential support. I can't just put a plate on the top of the tunnel due to placement of my fuel lines and brake lines high in the top of the tunnel, instead, I plan to put plates on either side of the trans tunnel near where the RT mount bolts up. Please take a look at these options for differential support and vote for your favorite option (or suggest something better). My car is way beneath the minimum weight for class which is 2800#, so a few extra bars don't scare me. Plus, I just finished my second day as a vegetarian (I'm starving).

-

I'll contact them. I'm trying to go lighter and smaller. The design payload of my trailer is 7000#, but I only put 2500# on it-its a trailer for anything from firewood to a John Deere tractor! I'm hauling around 4500# of excess capacity.

-

Strut options for ground control coilovers?

RebekahsZ replied to Blf0005's topic in Brakes, Wheels, Suspension and Chassis

Just go with an Autozone replacement insert. Put the 280z front insert in the rear and the MR2 strut in the front. Otherwise you are looking at Koni 8610-1437s, for which you need to budget $900. -

I know you guys were down on single-axle trailers, but what about this one? http://www.youtube.com/watch?feature=player_embedded&v=LeQHRK5qjRc http://youtu.be/bcgDTK4pjVY

-

heavy85-of course I considered alignment right off the bat. I checked the wheel bearings myself, then I took the trailer right back to the local company that makes them. They checked the alignment and gave me a new tire for the one that was worn so preferentially over the other three (it was on bias ply trailer tires then). Certain it was bad alignment, I took it to a competitor's trailer shop and they said it was true too. I'm not sure how they checked it, but I think the second shop checked it by stringing it out. You are right, I have not checked it myself, but I sure will this Saturday. I will also check camber. We thought maybe it was a consequence of cheap bias ply tires, but it is doing it again with radials. tube80z-Is the speed argument justification for changing to car tires? Surely, I don't have to drive 50mph across the country as a Uhaul trailer is labeled? I mean, the whole setup only weighs 4000 pounds-not really heavy enough to need high load capacity tires... I have seen how the tires roll around on the rim when going around a corner-it is quite impressive; it is my suspicion that this is the cause of the excessive wear on the rear tires. Guys, the original purpose of this thread was to see if anybody was using a light-weight single axle trailer. Seems the answer is no. If I fail to find anything wrong with the kit I have, my plan is to just rotate the tires more frequently (like after every long tow) to avoid having one tire that is nearly worn to the cords while the other three look new.

-

It is little wonder there is so much debate and chatter over cages (there are lots of threads that have started innocently enough and devolve into pissing contests over who is a better welder than who). The guy who is a actually doing my 6-pt NHRA bar was happy to do CM, but I backed him down to DOM. I had a salad for lunch, and if I can discipline myself to only eat lettuce for the next six months, the extra weight in the chassis shouldn't matter-maybe I will get faster as the season progresses! Maybe hybridz will become a health and weight loss sight! 1.75 is required for NHRA in a 6-pt bar. Only 1.5 is required for a full 8 or 10-pt cage. My final plan is to really focus on the main hoop this year. Then next year when I pull the dash to do guages, I hope to do a shorter forward hoop at knee level below the dash, then finish out the foot well protection. As a rabid over-thinker, I really struggle to stay on task, and my goal this year is NHRA chassis inspection sticker. So, I best plan is to comply with the rulebook completely, then ask all my questions about gussets, extra bars etc to the guy who will actually be signing off on the car. What I wanted from this thread was help to avoid painting myself into a corner, and I think that has been achieved. The trip to Barber and all the time I spent roaming the pits looking at every bar and cage was super helpful. Learned a lot about fire systems too, which was a subject on which I was totally ignorant. And in the 8th day, God created zip-ties!

-

I was chatting yesterday with one of the MTI techs at Barber. He said that for them to change a non-dry sump LS to dry sump, it costs the customer 3-4k. Sounds like you are in that ball park, too. An accusump just went on my to-do list, but it has lots of company.

-

1973 240z 5.3 / ls1 microsquirt build

RebekahsZ replied to ECUAdam's topic in Gen III & IV Chevy V8Z Tech Board

Congrats on one of the fastest builds on here! At the risk of being a snob, we're gonna have to get you on some decent rubber. Plan a trip down here for a tire fitting session. I've got more shoes than Emelda Marcos. I'm not all anti-stretch, but keep those wheels and tires for shows. But, now that you have some power, you will want more tread and less sidewall on the pavement. If you can get some tire circumference, you won't miss 5th for now-heck overdrive transmissions are fairly new to the scene. I had a talk with a guy with a C5 vette yesterday who pushed his rev limiter to 7000 and ran 150 in the standing half mile using only 1-4 gears. At Barber yesterday, my instructor never got past 4th gear and we were flying in a C7. But that was with 345/35/18s. I'm buying the next set of used 315 A6s I come across. Figure out the local autocross club and I will plan on meeting you up there for an autocross and if they will put us in opposite run groups, I will share some race rubber with you. Stay 4-lug. -

Why are you against ZForce Production BAMF flares? I have purchased rears only, and they are much nicer than any other screw-on flares I have seen. I'm afraid you (as I) will be disappointed with the quality of ALL of these cheaply made flares-no one makes a set that looks very strong or fits very well. Perhaps one of our forum members who is capable with composites can make a new blank that actually fits are cars specifically. Then, we need them made of injection molded plastic, so the price can come down. They are priced ridiculously because of supply and demand. We are crazy to pay what we do for them, and one minor bump will total them out.

-

That's a great point, and I understand. In fact it has been bugging me all day. I decided not to do a full cage to protect my head, and now, I run the risk of smacking it on every dip or bump, much more so a roll-over! I think that even if I cut my seat mounts out of the floor, my head might still be above the bar. I really wanted to get my seat mounted in order to figure out my width limitations for my door bars. I may come back to the seat mounting before I'm satisfied-I really think my adapters need to be stronger. Although, I may not be satisfied with my Z until all the Z has been hacked out of it. I may delegate reworking the seat mounting to my fabricator, but I've got to give him an angle that works for me. Maybe he could put an angle finder on it somewhere and duplicate what I have now. It is super comfy, much more comfy than the well-driven, but stock seatbelt-equipped C7 'vette I rode in today at Barber. I was sitting on my hands to keep myself from helping the driver, and it was a bitc_ to stay in my seat even with the seat motored all the way forward and both seats firm on the floor. I'm gonna put some motorcycle pegs in my car for the driver and the passenger.

-

This was Kirk Racing that made the comment about cracking. He sends made-to-order roll bars and ships all over the world. I have been in his shop, seen his tools, jigs, etc. I have no doubt about his fabrication skills. I wonder if maybe he's had a couple of pieces returned, and with high volume sales, I bet he just doesn't want any problems. And we all have problems. I think after hearing the various arguments, I'm down for DOM.

-

My Dream LS7GTZ.......project underway

RebekahsZ replied to cobramatt's topic in S30 Series - 240z, 260z, 280z

Thanks, Matt, for a great day hanging with Team MTI! I'm sorry I missed your big race; I don't know enough about road racing to realize that you weren't racing every time you went on the track-I just have to learn the protocol and order of business. I will post some video i took of some qualifying laps from the viewing stand early in the day. Thanks for getting me the seat with Reese-I'm thinking of a dog box in two years, he was selling me on it and it didn't take much to get me excited. It sucks that MTI is so far away..... Two videos: The first is of Matt Isbell in his C5 World Challenge car during qualifying. The second is of Reese (owner of MTI) in his C6 Z06 equipped with MTI's sequential T56 in the process of setting a lap record. The Porsche led until Reese got his tires warmed up, then he blasted past him like he was standing still. The Porsche driver was so dejected that he came off the track before the session was over. At only 25K for the kit, I'm thinking about selling a kidney. Matt Passing.MOV Reese passing.MOV -

Just got off phone with fabricator, he's ordering 1-3/4 DOM on Monday. Trying to get clarification from the area's NHRA chassis certification inspector to find out how far forward the door bar must contact the floor and if any additional bars are allowed for chassis stiffening. At the end of the day, he's the guy I gotta please. My local fabricator who will be building the setup indicated that he was fine with either material and that he is mostly building in CM these days, but that CM must be tigged. I'd rather have a material that can be migged for the addition of window nets and switch panels, etc in the future. I like how you guys have encouraged me to be PRACTICAL. Good advice. Went to a NASA track day as a spectator today. Lots of carnage. I'm thinking of my car more and more as a drag car and autocross car, and less as a track car. I saw more carnage in two hours today at Barber Motorsport Park than I have in two years of drag racing.

-

Upholstery arrived today. Looks nice. Feels GREAT. Put my helmet on = very close to headliner (can't squeeze a finger between helmet and ceiling), but it clears. Angle is comfy, good support everywhere, good reach to pedals, wheel, shifter, etc. Might smack it on some big bumps, but for now, it's a win.

-

Getting cage built by local builder next week. Was in Birmingham for business so I went by Kirk Racing, which is a cage builder who advertises in lots of racing magazines. The builder there discouraged me from chrome moly (CM). He described some issues with cracking during welding or during strapping cars down during transport, a requirement for tig welding with CM for any future brackets etc that you might want to add later. He also said that even though a cage might not be required for a DE track day, if you have one and it doesn't pass tech, they might not allow you to drive. Although a cage is not required, it could still be a cause for being excluded. Argh! He stated that SCCA does not allow CM cages to be thinner than their DOM steel counterparts, so that any real weight advantage in weight is gained at the cost of a greater chance of failing tech due to tubing thickness. For these reasons, he has stopped doing any CM cages or bars; he no longer has any CM tubing in stock. I do'nt want to do any wheel-to-wheel sanctioned racing, so i was really only concerned about the NHRA rulebook. But if an un-required device can become an inspection item merely by its presence, i guess i cant totally ignore the more conservative rulebook. I think I'm going to go with a DOM steel bar instead of CM. any thoughts/suggestions?

-

Thanks for helping, johnc. Would you continue to run 40psi even if you noticed your tires wearing a lot more in the center of the tread? I started high psi and have been dropping over the period that I have owned the trailer (bought it new, for what that's worth). The forward tired wear in the center of the tread. The rear tires wear very in evenly, but not consistently so. The rears may cup, they may feather on one edge, but they are never the same. I've had the tires balanced, but haven't had them true-ed. Ill post a photo of the wear patterns tomorrow.