-

Posts

840 -

Joined

-

Last visited

-

Days Won

29

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by clarkspeed

-

-

I have been 3d printing my velocity stacks in ABS plastic. Pretty cheap and you can do any length you want. Also 3d printed my prototype for a cold air box.

-

Google is your friend. There are things called emissions, economy, driveability, that factor in.

-

Easy peasy. Do you need to run on pump gas? You can do a lot better with some serious compression and different head.

Otherwise the N47 is fine for pump gas. Build engine like the book and verify every single tolerance. Stock flat top pistons are fine. Shoot for a little over 10:1 compression. The higher you go, the more octane boost you will need to keep the N47 from pinging on 93. Pocket port clean up the head so there is a smooth blend into the valve seat. Good valve job. Balance out the rockers/lash pads. Use the most open intake/throttle body set up you can afford and port match manifold to gasket to head. Run 2.5 or 3 open exhaust with a good header. If 2.5 use mandrel bends, if 3 muffler shop bends are fine. Personally I would go with a milder cam to keep from moving the power band up and try to keep the rev limit around 6500-6700.

-

Yep, put R compound tires on any car and it suddenly becomes a race car. Other than that, poly bushings all around, decent street shocks, and all fresh brake components with a track friendly pad/shoes. Good alignment. That would get you started.

-

Safety, Reliability, Driver Skill, Speed. Modify/Improve in that order.

-

1

1

-

-

As long as the tight side stays tight, no problem.

-

All good advice here. On the race car I had a combination of about 1/8" adjustment slot on the cross member, the big 1"+ TTT strut spacers, stock LCA, modified tie rods with 5/8" rod ends, and I reamed out the steering knuckle to fit a Pinto style 5/8" bumpsteer adjustment bolt. The tapers are cheap from Speedway Motors and ;you can get the pin and shim kits from any circle track store. The pin was a little long for my 16" 4.5" backspace wheels, but a little grinding did the trick. I made the tie rods out of tubing, 5/8 threaded tube end, and cutting the inner few inches off a stock tie rod. It is detailed on Hybrid somewhere. On the next car I will try to do a lighter version of all that.

Also agree with higher spring rates for your speeds. The car should really feel planted and solid at speed, not floaty at all. You should be able to drive it with 1 hand.

-

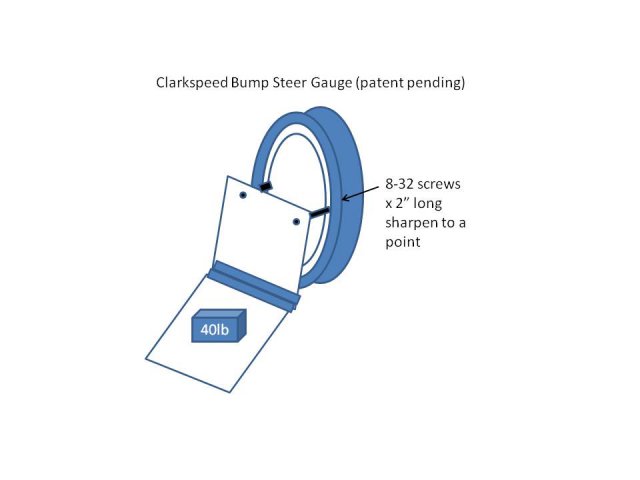

Here's a drawing of a similar gauge:

Jon, that is not fair. You beat me to the post with a better drawing!

-

Please send the royalty payments to my paypal account.

The answer to the camber question is it depends. If you are running a high roll center then technically it would pull out some camber that might be noticed. If your control arms are closer to parallel, then not so much. A 1/4" is not so much movement and most (all?) people who would attempt this already have some form of camber adjustment device to compensate. If you slant the slot to raise inner pivot and increase camber, you will end up with a nice roll center location, increased camber, and very poor bump steer curve. Everything is a compromise.

-

If you want to minimize bump steer and are not bound by rules, a small 1/4" vertical slot, not slanted, in the cross member (combined with strut spacer if you have lowered the car) is usually all you need. Quick and easy adjustments. And it doesn't take a $150 gauge to get in the ball park. I use what amounts to 2 square pieces of wood connected with a piano hinge. I place weights on it to keep it from moving on the floor. The free side leans against a wheel with what amounts to 2 nails resting on the wheel outer shell about center height. Adjust it until you get both nails touching equally. Remove the springs and sway bars, jack the car up and down through normal range of movement, and watch how far one of the nails will move away from the wheel. It usually moves A LOT. Adjust inner pivot until you can keep both nails touching through the entire range.

I think I mentioned before, 0 toe in the rear of my car really added to high speed stability. But your speeds are another deal.

-

@ Clarkspeed,

"For the most part, materials, processes, and quality are on par with anyone else in the world, but you have to commit considerable resources to get it. Well defined specs are necessary. And companies like GE assign their engineers to stay there and work the technical problems."

You just said exactly what I did. Your observations are no different than mine, nor from the book mentioned above.

Unless you have considerable resources there to monitor EVERY facet of production, you will get a great batch initially to hook you into a contract and they will screw you with 'cost down' and argue specifications every step of the way.

2012 is within "the last 10 years". We have had a major manufacturing presence in China since 1990.

Hey, I only said a "little" different. Point being you can get parts from China manufactured to any quality level you desire. But a crank manufactured to the standards of Sichuan Andes may not meet your expectations and shipped in a box packed full of risks.

I have not experienced any bait and hook tactics with my suppliers. But again my products have detailed specifications. It is also a long path to qualification so suppliers that invest into that dont want to lose out due to quality problems.

-

Oh and the original subject, if Scat or Callies, or other reputable supplier put their name on it and stand behind the quality, then made in China is no big deal, maybe even better. But I don't think I would buy anything off Ali Baba with unknown quality standards.

-

I would say my observations are a little different. All of the OEM gas turbine manufacturers have significant Chinese content. Things have changed drastically there in the last 10 years. For the most part, materials, processes, and quality are on par with anyone else in the world, but you have to commit considerable resources to get it. Well defined specs are necessary. And companies like GE assign their engineers to stay there and work the technical problems. Like anywhere, there are good companies and bad ones, and definetly more risk of IP and trade secret loss. The suppliers I manage there are very impressive to say the least. BTW you can buy stuff from India for about 1/2 the price of China. But that is another story.....

-

"Made in China" is in no way a label for crap. You would be amazed at what OEM manufacturers export from China whith the highest grades of alloys and precision manufacturing capability. It's all in the specifications and what quality you desire. On the other hand, if the part was not designed by a reputable company with robust quality control, then you may well be buying crap no matter what the country of origin is. And yes, you usually get what you pay for.

-

Little tip. I installed a pair of tie down rings in the outer nutplates just behind the seats. You can easily reach under the car blind and hook on tie down straps in the trailer and allows the rear straps to run parallel.

-

-

No substitute for cubic inches!

-

Curious why you would be selling those.

-

Interesting. Is that Mustang II based?

-

Tragic indeed. Did not know John personally, but I can attest he was one of the few truly knowledgeable, helpful, and insightful contributors to this forum. Not many people "get it", but John did. A great great loss for the Hybrid community. I took for granted that his response was always there, with just a few hours delay, for so many years.

-

Good 2 know

-

Wish they would do some 3.3, 3.1, and 4.3 R&P sets

-

I tried to lower the best I could on the car I am building now. I used a different steering rack mounted slightly lower and dropped the engine until there was less than 1/4 inch clearance to oil pan. I dont think I gained much. I also moved the engine about 1" to passenger side for weight distribution.

-

That is interesting. Have any pictures of your pan?

Rebuilding engine and want to hear your opinion on rods.

in Nissan L6 Forum

Posted

A set of Pauter or Carillo are 1300-1600. Normally used in 10k+ race engines