-

Posts

853 -

Joined

-

Last visited

-

Days Won

35

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by clarkspeed

-

-

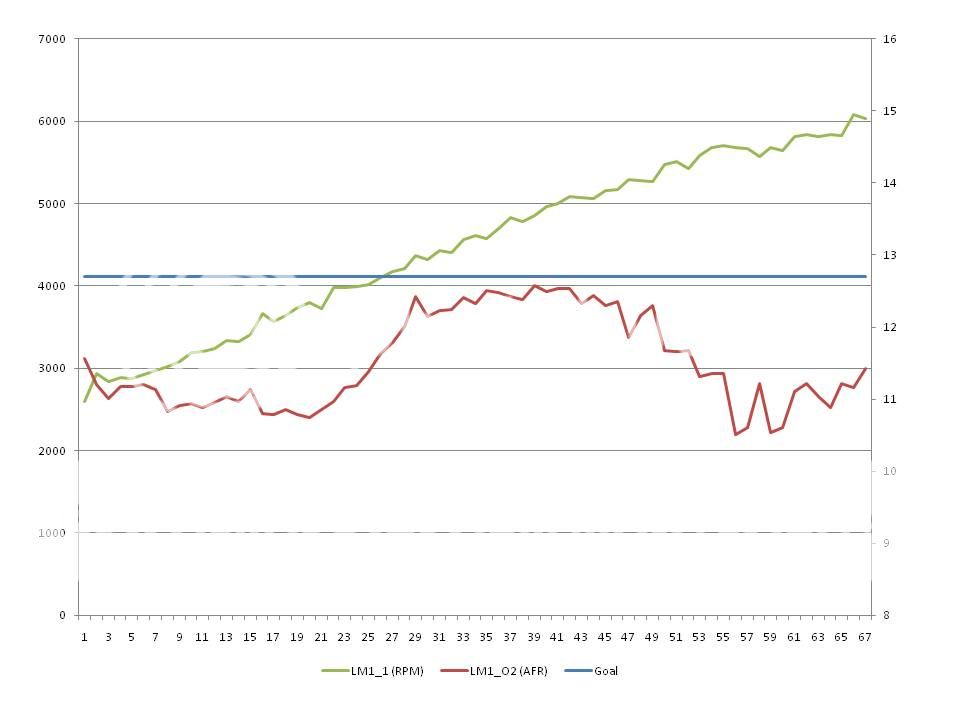

I agree, the AFR's are way off. Fix the rich condition.

-

Set up cam with degree wheel. It's the only way to know what you have and get close to cam specs. If its a new build, I will also check piston to valve clearance at multiple cam angles so I will have no fear of trying different cam settings on the dyno. Often you can get by with stock sproket so save your money unless your measurements say you need it.

-

Keep stock crank, ATI or BHJ damper, balance everything, then race it.

-

$3500 for a custom crank isn't so bad compared to those $1600 Carillo rods. EP isn't cheap.

-

Sam at LNA could help. Just south of greensboro. Knows much about L6's.

-

Better check valve/wall clearance. I'm not sure those will fit into l28 040 over.

-

Yes torquing of fasteners is so critical but still an approximation at best. These are some methods NASA uses to narrow the variability and prevent yield:

1. Measuring the stretch. Typically used on large critical fasteners that are reused.

2. Measuring the running torque with a dial torque wrench. This number is then added back to the tightening torque to calculate the final torque value. Typically used when fasteners have a locking feature or interference incorporated into the design.

3. All new hardware with specified lubricant.

I believe all flight fasteners are designed around one or more of these 3 methods.

-

Yes I agree with Tony here. I'm in Germany right now building engines of a different sort. Parts orders are specified clearly and inspected 100% upon receipt before "ownership". Rejects are responsibility of supplier. Nothing passes through. All of EU pretty much follows this practice.

I assumed in earlier post you had already reconditioned the rods. As stated before, it is typically a routine process for rebuilds. So is balancing as far as I am concerned. If you are going to spend the time and money on a rebuild.......?

So, if the rods are reconditioned you shouldn't have more than a few thou difference in piston heights. Especially after the pistons are cut. You can mix and match rods to get the final match. But that may be difficult if you are running press fit pins. I never said cut pistons to match.

Back to your problem. Machining all pistons to match #4 is a possibility. 0.035" is not excessive clearance and is what many books and builders will recommend. My machinist insists this is the number to shoot for and he builds many race engines, but I don't always listen to him. It's not what you wanted, and I don't suggest you accept this, and I'm not exactly sure you machinist is competent, but it is possible.

And to Tony's earlier post, I hardly think it's child's play to run 1:20's at Road Atlanta with a production based car. But you are entitled to your opinion.

-

Lazeum, I am in similar circumstance. I preassemble my engine, check a few clearances, then travel to Germany for a few weeks. Fly back, repeat. At this pace, I am shooting for a March completion even though I have all the parts sitting on the bench. As you said, CHECK EVERYTHING. I spent the last 2 days just measuring bearing clearances.

As far as head gaskets, I found the most economical solution to be the 0.6mm metal gasket from Nisson Motorsports. You can order from them directly and they are available. About $150. You will need to cut the piston top to match and yes the machinist will need to remove the rods to chuck them. I think we paid $15/ea last year for this service. Check each piston's clearance individually and try to get all of them to match in height. Sometimes you can get slight variations in the rod lengths.

As for the 200mph 510, that was an exaggeration in relation to the engineering, sophistication, and high level of build that the car displayed. It passed a lot of tube frame v8 monsters and had a multi-second lead within a few laps at Road Atlanta. My disclaimer to land speed record followers. It's high downforce aerodynamics would never allow over 150-160 I would guess, but it could get to that speed very quickly.

-

We race HSR since they stay mostly in the South East. They are much more about the show and full fields than picking on rules. They will allow just about anything to race and find a class for it. They now even have X classes for some of the stuff in between rules like EFI. I once saw a rotary turbo 510 that could run 200mph. Most all the classes seem to stretch the rules. The ex-Nascar guys are much faster than a Sprint Cup car, the Porsche's run $40,000 engines with titanium rods, and I'm not old enough to remember racing in the late 60's, but I doubt the front running Trans Am Mustangs and Camaro's sounded like Indy Cars going down the straight. I thought the tires were at least an equalizer, but lately I've seen slicks run in some of the production classes. I don't think there are many protests.

-

Yea Tony, but you can't snack on the modeling clay while you are working!

I usually swap out the MLS gaskets after 4-5 "cycles" of installing and running so I have a few shop queens laying around. I have found they don't last forever if you do a lot of teardowns. We had one spring a leak last year after building and testing the engine in in sunny Florida, towing it to Atlanta and cranking it in 30 degree weather.

-

Good thread. I am in the middle of setting up a very tight piston to head clearance also. I have a set of .6, 1, 2mm used MLS gaskets on the shelf I pull down for mock ups. This time around I will be using a new 0.6 mm metal gasket since my pistons are at deck height or just slightly below.

As far as measuring, I found Tootsie Rolls work well for piston to valve and piston to head. I let them sit in the Florida sun for a few minutes to get little soft. After molding, quickly take them to the freezer for about 5 minutes. They have a unique characteristic that they don't expand or contract from the heat cycle. You can then cut into pie slices with a sharp knife as needed and apply the calipers. You have about 5 minutes to work before they start to get gooey again.

-

-

What size are they? All the same? Did you measure them?

-

I need just (1) 0.230 Lash Pad to complete my head rebuild. I have many other sizes in my collection if you want to trade even for a different size.

-

Drive it like you stole it.

-

-

During my race weekend at Sebring in October I decided to strap the bullet camera under the fender to see what was happening. It was a little less dramatic than I thought it would be, but certainly useful. From the still shots I could determine the the compression maxed out around 1.75" and the droop or extension was about 0.75". I had been reading some threads on here about limiting droop, and by my best estimate, I should still have over 200# of weight on the outside wheel during cornering. My front springs are 400# and the roll bar is 1".

I was surprised how little steering input was required to drive the track. The hairpin turn only required a few more degrees of turn. I was also surprised by the limited suspension travel. Sebring is known as a bumpy track and I expected 2-3" of bump.

I may try some shots of the rear suspension next or some different angles.

The attached video starts with turn 17, a long sweeping fast right hand shift to 4th on exit. Followed by the "front straight", light brake, then a high speed 80+ mph sweeping left hander at Turn 1.

-

True, nothing is impossible. How about "much more difficult, risky, and not very practical". I'm a manager in manufacturing and if I say impossible, I would get fired.

Funny, I match-ported an installed head last week with a vacuum and lots of balled up paper towels. No problem.

-

I think it would be impossible to remove them with the head still on the engine. The valves need to be removed. And you would drop metal shavings all inside the chambers if you tried.

-

It's not too bad, I've done it before. A hammer and sharp chisel will take them out. Once you split them, they will fold in on themselves and can be removed. Light blending required on the scratches that are left. HOWEVER, most people on this board do not recommend this procedure. You can search for the reasons.

-

I'm not a carb guy, but it is definitely running rich.

-

The parts would make for a nice conversion. The car sounded awesome when he put the pedal down, I think the exhaust had been modified. If they try to repair it, I don't think anyone would want to own it again. I'm guessing repair parts + labor + depreciation = $100k

-

I was working in the front yard today. One block from my house I heard an engine rev, burnout from the stoplight, shift to 2nd gear, and them WHAM. I didn't see exactly what happened but this dude must have been showing off for his girlfriend and buddy sitting in the back seat, lost it, hit the curb, spun 180, side-slapped a block wall lined with trees, then spun another 180 back into the street. The guy in the back seat was shaken up and taken to the hospital but everyone was ok. Only the door air bags went off. There appeared to be heavy alcohol consumption involved. They made quite an effort trying to drive away before the cops came. The guy said "It just turned on it's own like something broke". As soon as it happened there was some guy at the stop light who saw the whole thing, screaming at the top of his lungs, "That's the stupidest f_ing a_hole thing ever!"

Video of Working Suspension

in Brakes, Wheels, Suspension and Chassis

Posted

Well I finally got around to shooting some video of my rear suspension during a hot lap at Road Atlanta. The camera was a little shaky but can still see what is going on. It was mounted left rear facing forward. Most of the turns are right so much of the footage shows the left rear loaded. Looks to max about 2" compression and 1.5" rebound at the wheel by my calculations off the freeze frames.