flatout

Members-

Posts

31 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by flatout

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

I have been way to damn busy last two weeks so haven't gotten much done. I did get to borrow a set of seats I thought I wanted, but they just really don't fit. being a full containment seat they basically stick out the window. I was also pretty disappointed with the quality. My buddy had these for one season in a drift car that lives mostly in a trailer or garage and they were already real faded from the sun and had plenty of little rips and tears after just one season. I ended up buying a set of kirkey intermediate road race seats. I have one of these in my other car and have put 100k street miles on it so figured id be happy with another set. I may add some head support pieces but for now I'm happy with them. Also think I got my wheel picked out. little teaser for now until I can get some tires and sit this thing on the ground -

this is very cool, I will be following along. Love the custom work. I am doing a 1jz swap myself at the moment so nice to see another with another person fab ideas

-

I agree with Mitchel. You need to decide what end setup will make you happy and build towards that. With that being said you don't need to go all out and put yourself in debt to do it. If the purist in you says you need it to be nissan powered than that seems like it should be a priority. Do some research on the VQ. There are a couple good versions and a couple that you should avoid. I'm personally not a huge VQ fan but power, weight, balance, etc, should be great in a older Z. Modern electronics make a lot of these swaps easier. companies like wiring specialties or similar, should make generic "swap" harnesses for these engines and will require little integration into the chassis wiring if your not that comfortable with wiring. ApexEngineered makes engine mounts. Transmission options aren't ideal. CD009 are strong but gearing and shifter location isn't ideal in my opinion. I got one for my 1jz swap and didn't like it so went a different route.

-

Some modern cars run CV joints but the transmission usually has a fixed output flange. I've never seen a CV joint slip yoke. What angle is the engine sitting out? can you get away with tipping it back a couple degrees?

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

This isn't just a track only build, just track focused, it will see plenty of street time. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

Thank you. a bit overkill but im happy with how it came out. I hadn't planned on making them but no reason i can't. I can get some material and when i get some down time i could make another one. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

up here in the north east we get some great fall scenery for cruising but can get a bit chilly so the heater will be used for that aswell. but the defroster on a raining track day will be important. Thank you. love being creative during a build. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

Got a few more things done last week. Made a driveshaft adapter to switch from the 1310 ujoint to a 1330 ujoint flange. now to order a custom driveshaft. The technotoys rear parts allow for some placement adjustment of the SN R200 so I made a spacer to slightly move it forward to align the axles better with the hubs. For some reason the diff itself is slightly crooked with their front mount so i'll be remaking that at some point but not a priority at the moment. havent ordered yet but got a good idea what seats im going to run so took some measurements and got the most of the cage tacked in. Harness bar height "should" be good but I wont fully weld anything until i have seats incase it needs to move up or down. -

I sat in those tillet seats at PRI this year and was very impressed with the hold and comfort despite not looking like it would be either.

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

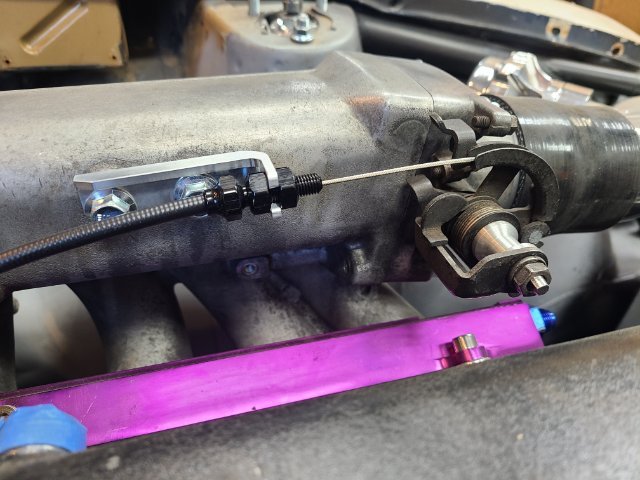

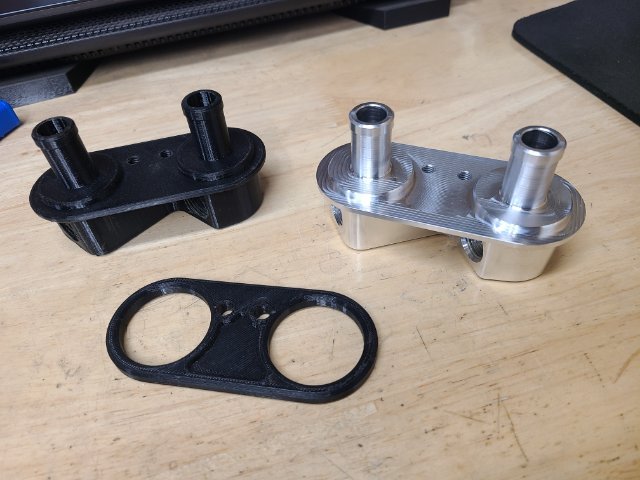

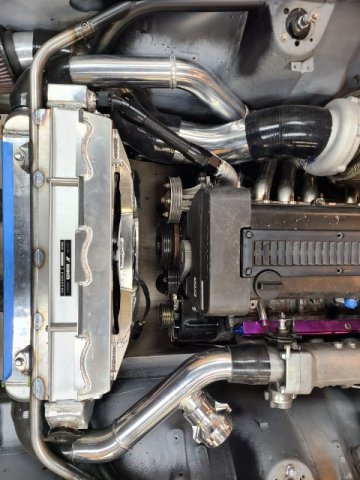

Got a few things done and checked off the list. made some modifications to the throttlebody and an adapter on the firewall to run a motion raceworks throttle cable. Made the firewall adapter have a 17mm hex to get it good and snug. This may be mostly a race car but decided to go with a small heater to make sure if inclement weather came up id atleast have a defroster. bought a maradyne universal heater to stuff under the dash. The JZ has the coolant lines on the driver side so decided to make this fancy billet firewall bulkhead. I have a couple aluminum fittings ordered and then i'll try and find some pre molded 90º hoses to fit up. The fuel rail that came with the engine appears to just be a cheapo ebay piece and the ends are cross threaded so i'll replace it. I went with a high flow 90 but may need to go with a banjo style as its close to my adapter. Started on the cage. but have been doing seat research before i go any further to make sure i can get the harness bar in a good spot. I am friends with a local youtuber so i took a ride down to his shop and sat in a bunch of his drift cars to get an idea of what seats i liked. now just to commit and hope i can make it fit in this tiny cabin. -

I don't know the RB that well but it looks like a coolant block drain fitting. its possible it oil but id guess coolant drain.

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

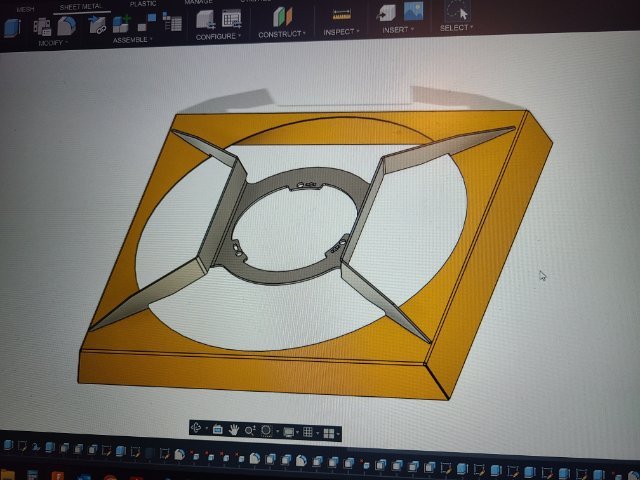

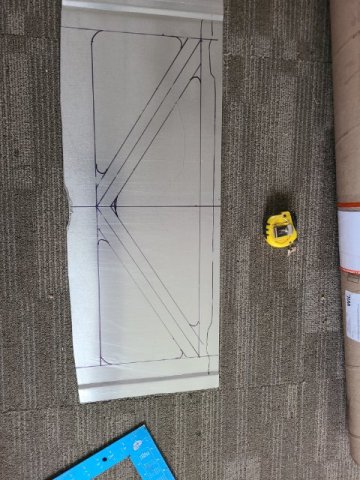

Next order of business was electric fan and shroud, and radiator hoses. I chose the 2016-2019 Camaro single SPAL 18" fan. it will be PWM controlled and is a very popular choice according to the internet as it can flow 5000CFM. Although I cut up the factory shroud to "work" I felt like I needed something fancier. modeled up a base to start working from and had my friends at laserbros in NC laser cut and bend it up. Should have gone one or two AWG thicker so added some bracing as well as some mounts and very happy with the final product. Cut down the radiator and inlets and outlets on the engine and welded on some -16an bungs, made up a couple hoses. in the last photo of the "hose installed" you can see the end of the pipe for the intake I welded into the chassis I mentioned in the previous post. Also decided to move the alternator to the other side of the engine to get it away from the heat. When i pull the engine to paint the bay i'll design and make a bracket to permanently mount it over there. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

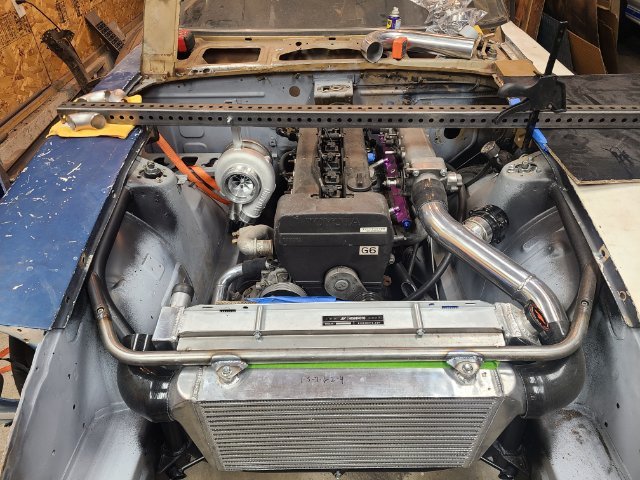

over the christmas break I got the rest of the turbo hot side plumbed. the manifold is like 3/4 welded up. My purge bottle was getting real low so instead of risking it i held off and started working on the rest. Notched a hole in the "wheel well" to go around the new added strut support bar I did that allowed me to run the 4" intake tube thru the front end and put the filter out in fresh air. Just made a piece out of 4" stainless exhaust, notched and welded it into the chassis. welded an elbow to the turbo. simple intercooler pipe made up. tial BOV on the throttle body side. have the downpipe fitted and tacked together back to about the bellhousing. Forgot to note. ditched the 350z trans for a tremec TKX. The size, weight, and gearing of the 350z transmission were all turnoffs to me. having run the tremecs in other cars i knew it was a good choice for this build. Much smaller. better gearing and options for a saftey blow shield made it my first choice. The car already had the factory trans mount cut out (poorly) so i cleaned it up and added a new mount system off the full frame rail pieces. that were also "added" They are so poorly welded that i used "added". I'll finish welding them in. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

Thanks, Im trying my best to build something fun, reliable and something I'm proud of. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

Its so much fun being in the pits and having the Porsche guys come over and be so surprised how fast an old car can be. "I expected to blow right past you and I did everything i could to even keep up". We get it all the time in my uncles GT40. Hopefully this year we can have both cars out there doing the same. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

got some more photos uploaded. Switching to manual brakes per the recommendation of wilwood. moved the pivot point for the pedals to give me a 6:1 ratio. Also added one for 5.5:1 and 5:1 incase i feel the need to. welded up a gusset to the "bend" on the pedal as well as machined bronze bushings for the clutch. Designed and 3d printed an adapter plate for the firewall to accept the wilwood balance bar adapter raised to match the 6:1 pedal ratio better. Made a few design changes and machined it out of anodized aluminum. Real happy with how it came out. Ignore the mismatched hardware. thatll get changed later at final assembly. Didn't take any photos but took the factory pedal box assembly out and added some stitch welds around all the spot welded areas to reassure myself that it would hold up to the added abuse of racing. I went to PRI and talked to wilwood and tilton and couldn't come up with a real good reason to spend the extra money on a aftermarket pedal box. so well see how this holds up. I can always change it later. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

started tackling the turbo system. designed and machined a stainless exhaust flange because I couldn't find one I liked. 304ss that seamlessly transitions the oval port to round so i can use sch 10 stainless. Went with a billet turbo flange from elmer racing. I make these kind of things but no way I could have made one for what they charge. beautiful piece. I ordered 321 sch10 stainless weld els to make the rest. after a little "writers block" i finally got a decent layout for a turbo manifold. The car came with a precision turbo but unknowing the condition and the size wasn't ideal i ended up going with a garrett gtx3076r with a v band inlet. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

The car came with s13 front knuckles. Apparently this was a thing a long time ago but the geometry is terrible. So I 3d scanned a knuckle and started designing a knuckle that will work. in the mean time I am modifying these with the corrected geometry I came up with for real word testing before I made a set from billet. My new design will use the 370 wheel bearing so I modified these to accept that as well to go 5 lug since I'll need that bearing eventually. They need more changes but I figured i needed to get moving on other projects like brakes, turbo stuff and body work so these will have to wait a bit before any more modifications. Went with a custom set of wilwoods. after talking with the reps a few times settles on a set of superlites front and rear. The piston volume front and rear meets the common spec of twice the front piston volume compared to the rear. designed and 3d printed calipers brackets that will get CNC machined when i have some spare time. Plan was to do 7075 for the front brackets but may get made from titanium because I have some in the right size, but rear will be an alloy steel because of the design I want the strength. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

the 1j factory throttle body is big is dumb looking so i decided to trim it down and remove all the unnecessary pieces. made up a little billet spacer to remove the cruise control pulley. I may go dbw eventually but this will do for now. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

spend some time planning out the front, bending up some tubes and getting the tubular front made up. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

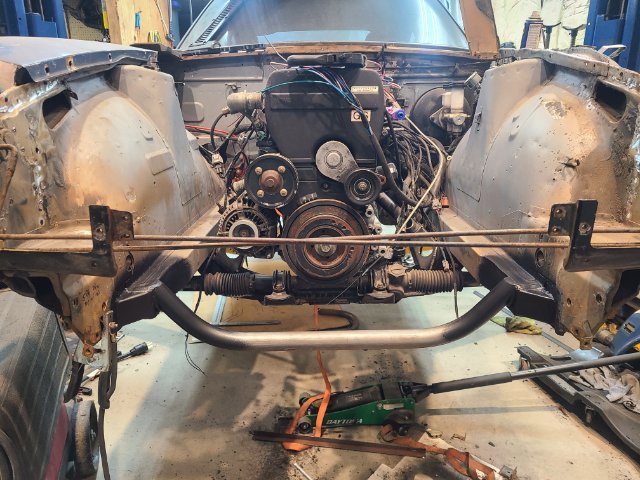

Next order of business was to get the 1j sitting in there. It came with some cx racing motor mount kit but I really didn't like them so decided to make my own to put the engine where i wanted it. Apparently i only took 1 photo. but just imagine a second one of these mounts. once the engine was sitting where i wanted it i decided to cut the factory radiator support out and make something removable to make service easier. -

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

first order of business was to add a fuel cell since i didn't have a fuel tank. Went with a radium 14 gallon unit. Cut the trunk out between the factory frame rails and built a basket. Cleaned it up with some bead rolled panels. plan to add a fill behind the license plate like an old muscle car. -

After about a decade of talking myself out of buying something as Ive spent a lot of time building and tuning a handful of other cars in road racing and drag racing disciplines, as well as starting and building a machining business 5 years ago, I finally started the search for something to build to race myself. I tossed the idea of a lot of different chassis options. S30, 240sx, Mustang, Corvette, MR2, ETC. The 240sx made the most sense considering I have a S13 240sx as a high performance street car, that I have also raced in a few different forms so I am very knowledgable in that chassis, but my search always ventured back to the S30 because I have always liked them and not to mention beating up on modern sports cars with a 50+ year old car just really sparks and interest for me. My main road race car i support and tune is a gt40 so going to the track with a couple old cars and beating up on Porsches sounds like a good time. I searched far and wide in the north east, USA looking for a quality candidate. Unfortunately rust made that a challenging feat. Randomly a friend of a friend posted a 1jz for sale and my friend had a suspicion that it meant he was giving up on the 280z he had been trying to build for 10 years. I reached out. showed "interest" in the engine. showed up and talked him into selling the whole deal. The chassis has some really "questionable" work done but overall the chassis is a super low mileage fairly clean car that i wont feel bad modifying and making a track oriented build. The deal ended up being a package deal with: 1jz-gte with 350z trans a pile of T3 suspension parts R200 short nose conversion fortune auto coilovers 300zx front and rear brakes Universal wiring harness bunch of misc parts. wheels not included, I planned on going 5 lug so they where not use to me.

-

A 2026 SEMA SHOW 260Z Build all the way from Great Britain

flatout replied to toolman's topic in Body Kits & Paint

love how European shops are so full. lots of nice tools and cars all stuffed in a small "shed" -

very cool, Nothing wrong with an old machine if its dialed in right and run by somebody that cares to make a good product. I run a small machine shop from my garage, just not engine related machining. Sure you could drum up some work for those machines.