-

Posts

726 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by NZeder

-

-

I found this pic on a 240sx forum - shows the Birfield 5x1 not the tri-pod like you guys have - so might be an after market thing I am thinking

-

Were they OEM? If yes then maybe I found something different of the JDM WD21 I got my axles from. I see in the CV catalogues that Pathfinder and Z32 share the same aftermarket replacement partnumber so I think it might be time for me to hit my copy of fast and see what I can find out with regards to the OEM stuff.They came off a z32 n/a 1/2 shaft... -

I think it might be an aftermarket vs OEM thing. What size is the shaft/spline this tripod goes on ie is it the same size as the wheel end of the shaft - on the OEM axles I have it is.Just a quick update. Got a photo of the internals of the EMPI 5x1 side. Off to work...I wonder if the issue is US vs NZ or OEM vs Aftermarket. If I bump into a 4x4 pathfinder at a junkyard I'll be sure to grab the axles.

-

Ok Pete S have found some thing different that I did not know. Looks like there are different axles for you guys in the US vs what I got secondhand here in New Zealand.

See here for the thread Pete S started

-

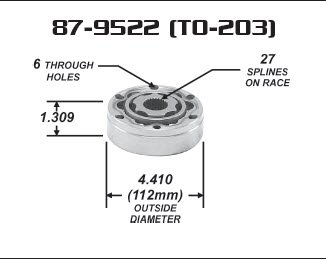

I found this on the EMPI catalogue - not sure if the 27 spline is on the same size diameter but might be worth a look given looks the US axles are different to this part of the world aka JDM sourced.

This is EMPI number 87-9522 and is used on the following models

Toyota Camry 4cyl AWD 1988 Front inboard

Toyota Camry 6cyl 88-93 inboard

Toyota Celica All Trac 88-93, Front inboard

Lexus E250 90-91 inboard

Lexus E300 92-93 inboard

See pic attached - you can see this would be easy to make an adaptor to whatever companion flange you have - assuming it will go on the other end of the alxes you have with the 5x1 (tripod - that has thrown me for sure) at the diff end.

-

Wow that is different. Inside my 5x1 axles from my JDM Terrano (WD21 pathfinder) is a race and cage setup with 6 ball bearing not a tri-pod like you have shown. I will get some pics for you.....just found this on my harddrive (must have taken it when I pulled them apart)Hmm... on the EMPI axles I've got the joint inside the 5x1 side looks like the attached image... (Apologies to whomever I stole this image from)I thought that this is what is referred to as a tripod joint. Do I have my jargon mixed up? Or are the factory parts different than these EMPI replacements?

I had the same issues trying to obtain the 80-9096. I wound up ordering two of the 80-4703 to play with (only $55US each IIRC).

-

No they are same inside as the 5x1 ie they use the same race, cage and ball bearing sizing ie 6 of the suckers. So the 4x1 Z31T is a birfield CV like the 5x1 inboard of the pathfinderThe pathfinder inboard w/z31t outboard could be a workable option. But isn't the z31t another tripod? The tripods are the 3x2 setups.

The tripods are the 3x2 setups.I hope to have my axles modified in the coming days, I have new CV boots so I will be assembling these shafts in the coming weeks (this weekend is a race weekend so no time in the garage) and I will post pics etc.

I have tried to source the 5x1 EMPI 87-9096 joints new locally here in NZ but no-one has them or can get them so I have to use my secondhand units and just rebuild them with new boots etc. I would consider building 5x1 at each end if I could get new 5x1 parts locally - I would just have the companion flange redrilled to the 5x1 (same PCD as the Z31T 4x1 so one hole is already there)

-

Has anyone other than myself thought of the possibility of wacking off the long stub shaft on the wheel side of those new CV's shown in pic below, and having a steel plate adaptor (to what ever companion flange bolt pattern you may be using) properly welded onto the large left over portion of said new CV shaft?

click

Thought about it - think about it often. Ever since my hunt for a setup that could use a stock axle that was a little shorter than the total Z31T axles. For now I am building a hybrid Pathfinder 5x1 with 4x1 300zxt at the wheel end so I can use the MMS billet companion flanges I already have. But I was thinking it might be possible to do as you state - use the pathfinder 5x1 at one end (the diff end - I have collected 3 sets of the 5x1 diff inputs from open shortnose R200 from R32 RB20DE powered cars, and one set of the 5x1 VLSD) then as you suggest a custom/modified pathfinder wheel end so it bolts to the stock flange. Might get to this one day....maybe.

-

Not sure about running tripods on both ends though. Doesn't seem to be something people do much and I suspect there's a reason for that...

I believe this is due to the lower angles that the tripods support so having tripods at both ends would not allow much movement.

tripods typically have around 15-18 degrees of movement were as the Birfield setups (typical 6 ball bearing CV joint) has 40 degrees. A Double Offset (used on the wheel side of the Z31 300ZXT axles) is around 23-25 degrees.

Hope this helps

-

just noticed this post - but did you know you can use a RB torque plate on the L6 too

Same bore spacing and head bolt pattern

this has been covered on this site before (or did I post that on CZCC it was a few years back now)

this has been covered on this site before (or did I post that on CZCC it was a few years back now) -

What centre bore did you order these with? I had the same size on my 71 240z fitted with no issues at all. They make the RB-R with different centre bore sizing you need the 73mm version not the 67mm version

-

That is OZIsn't it also illegal to run wheels more than 1" wider than stock too, or is that Oz? Regardless, I'm glad we don't have such issues here... we and go wider here in NZ

we and go wider here in NZ

-

Depends on your location but here in NZ it is illegal to cut springs period.

-

yes but for you guys state side that have the steering wheel on the other side of the car - will these bad boys work?

-

I have not pulled apart my Zed rack but I have pulled a part a UK Mark II Escort rack and they are the same design and they have the spring in the end of the rack - then the bushing then the rack end. The Escort guys replace the plastic bush with a brass/metal unit as an upgrade.

So I would say yes the spring is needed and is missing from your rack - this would keep some tension on the bush and ensure it up against the rack ends ball.

-

you know what I just found another thread, and according to it I can use the stock 280z halfshafts, can somebody back me up ?

The OBX that I purchased what you have stated/found out above is true. So the stock inputs will work

and you will need to get some spacers for the M12 vs M10 this assumes your R200 is the early type that has the M10 - more common than the long nose M12 version (I have not found one yet and that includes getting long nose R200 from a number of late model JDM saloon cars ie 83-85 Nissan Laurel's etc)

and you will need to get some spacers for the M12 vs M10 this assumes your R200 is the early type that has the M10 - more common than the long nose M12 version (I have not found one yet and that includes getting long nose R200 from a number of late model JDM saloon cars ie 83-85 Nissan Laurel's etc) -

Ok using the same site I thought I would just to a quick search for the specs on the Sub leg racks that Tony has.

90-95 use a inner tie-rod (rack end) with the following specs.

Moog EV257 = M14x1.5 at both ends they are 11.47" long (291.34mm)

So looking at this looks like the Tercel EV165 or EV168 depending on the length required will work with these 90-95 racks.

If others have info on the racks they have I am sure I can do a quick search and get a solution for you too.

-

Ok using all the websites I have found for tie-rod ends over the past 12 months and a bit of quick search. I found this info.Sorry guys, it wasn't a Wide-Body Camry,The rack-end was from one of these things!

1982-1988 Toyota Tercel, Manual or PS Steering,

The fellow has ordered on in for me, so should be able to provide some pics - but from memory, it was 145-150mm, 14x1.25 on both ends and rack side was flush, so this part together with the stock Z tie-rod ends should give you a "bolt-together"!!!

First looking at the sites I find the Tercel had two rack ends - depending on the model.

80-82 = Moog EV165 = 161mm long with M14x1.5 at both ends (not the 1.25 as stated above)

and

83-88 = Moog EV168 = 139mm long with M14x1.5 at both ends (again not the 1.25 stated)

Also for info the stock 240/260/280z (s30) tie rod is Moog ES2109R for RI thread and ES2110R for the LI Thread. They have a M14x1.5 for the rack end connection and M12x1.25 for the nut on top of the tapper which has the following specs .604 to 520 and they are 8.14" Long or 206.7mm for those who use the metric system.

Hope this clears some info up

-

Excellent work - so what is the replacement for the zed given you have stated this engine will now move into a shell more suited to doing 7's (don't blame you one bit given the tracks here in NZ and the resent crashes 1/2 or last 1/2 of the track) It would be one hell of ride if it goes wrong with just a 6 point cage in there. So I assume the current cage does not tie to the front struts or even have a bar under the dash - I have seen this on many a zed here in NZ and having owned a race car with a cage setup like this I would want one that has a bar under the dash and that ties the into the front struts for a circuit car but a drag car doing 7's well tube the whole whole thing....

-

oops my bad sorry just spotted 300zx and missed the TTim speaking about the vg30dett axles not the vg30e or vg30et.thanks

-

Posted on this site a number of times before but this might help

see

-

For those down under I believe CastleMainRodShop do a rear sump for the RB20/25/30 bottom - not sure if it is just modified front sump (ie cut and move) or not.

-

cool thanks for putting me straight on the rods issue but everything else I thought you would have done you in fact had done

-

Well I think there are different pistons remember this is a RB30DET ie RB30 bottom end with RB26DETT head so a custom piston would be required for the correct CR. But all other parts are bone stock RB30e parts, crank (no mods), rods (no mods) I think it will have good bearings and assume the rotating mass has been balanced you know standard stuff when you build an engine.Damn, so the bottom end is stock??? WOWI am sure Rob could clear this up but I think I am correct. So this does go to show that the stock rods are good for the power

who needs $$ I or H beams when stock units are up to the task. Also those that say you can't rev a RB30 bottom end I think Rob has proved this wrong time and time again with his shops engines, he pulls this one to 9500rpm. However this is a drag car/engine so 9500rpm on a circuit might be a different story but then who would want to circuit race a car with over 1000hp that would be insane.

who needs $$ I or H beams when stock units are up to the task. Also those that say you can't rev a RB30 bottom end I think Rob has proved this wrong time and time again with his shops engines, he pulls this one to 9500rpm. However this is a drag car/engine so 9500rpm on a circuit might be a different story but then who would want to circuit race a car with over 1000hp that would be insane.

/toyota_1986_tercel.jpg)

Let's see your RB Z...

in Nissan RB Forum

Posted