-

Posts

606 -

Joined

-

Last visited

About Doug71zt

- Birthday 10/26/1970

Profile Information

-

Gender

Male

-

Location

Toronto, Canada

Recent Profile Visitors

5225 profile views

Doug71zt's Achievements

-

That yoke is junk. With an open center there is hardly any material there. Powertrain industries has a yoke that is solid in the center and is a fair bit beefier that that one.

-

CV half-shaft swaps in 2014 any less expensive alternatives?

Doug71zt replied to gvincent's topic in Drivetrain

I have built adapters in the past to install Z31T axles in the 240/280 without short axles and without binding. I have been running a set in my personal car for over 10 years with no problems and I have tubular lower control arms which are narrower than stock. The end of the stub axle needs to be trimmed, as does the CV axle. You need to flip the cage on the CV assy and run a 280zx lock nut on the stub axle. If you are able to accurately operate a hacksaw, you can install these adapters. To save cost on fabrication, they are constructed on factory adapter flanges. I think I have two or three sets left, but I am in Afghanistan right now so I can't check for a month. I'm not sure how many 240 and 280 sets I have left. Drop me a PM if interested. -

I ran a T3/TO4E for quite a while with a STG 3/.82 housing. Worked fine for me, 11.50's @ 126 mph in the quarter. I used both a .63 and the .82 housings. I preferred the .82 for the top end power. Less boost creep with the .82 housing. I was using a 60 trim compressor in a .60 A/R housing. I always wanted to try the STG 5/.82 combo, but I went to a GT35R instead.

-

Thanks John - I can wait.

-

Hey Uncle Joe - I'm interested in some of your spares - sent you an email with no response. Drop me an email or PM Thanks

-

I didn't use the Z31 pedal, just drilled out the ball end on the S30 pedal and mounted a cable swivel on it with a bolt. Similar to what Dave did on the arizonazcar.com website. I used the Z31 cable, firewall mount and the adjuster on the throttlebody end of the cable. Cheers Doug

-

Sorry - No pictures right now, I'm in Afghanistan. Pretty simple though, remove the grommet from the hole and the cable mount snaps in. You will need a universal cable or something, I reworked the Z31 cable to fit, but you are probably furthur ahead to get a universal one.

-

z32 brakes on s30? ? ?

Doug71zt replied to 73z_in_sc's topic in Brakes, Wheels, Suspension and Chassis

I run Z32 calipers the front and rear of my 240zt, but they are soon going to be replaced by a Wilwood setup. I ran the old (1990 vintage) Arizona Zcar 11.5" rotor setup previous to the Z32 brakes I have now and the Wilwoods were superior to the Z32 calipers. I have the 1990 TT calipers (alum) and they are quite flexible. My 92 Z32 has iron calipers and they are better, but still not worth the effort of adapting them to the S30. The caliper bolt spacing on the Z32 calipers is around 100mm, the S30 caliper bolt spacing is 90mm. I run Wilwood 12.2 x 1.25" rotors with custom hats to Z31 hubs in the front and 11.75 x .810" rear rotors with a custom hat/bolt-on wheel spacer setup. It was easy for me to do, as I can do the design of the custom bits and have a good buddy who is part owner of a machine shop. I had the caliper set sitting around, as well as the rotors, so I just worked up something that fit. I have no parking brake. We have done another S30 that runs Z32 NA calipers (26mm disc) with 88 Z31 rotors that have been machined and drilled to fit the rotor mount of a 86 Z31 hub. You have to make a simple bracket to mount the caliper, as well as cutting off a part of the caliper mount on the strut and drilling and tapping a new hole. Again, this was done because the parts were at hand and the system suited the daily-driver status of the car (350 hp L28et, high 11 second car). This car runs a Modern Motorsport 240SX rear setup, as will my car in the spring. Having done this, I wouldn't go through the trouble again, as there are better kits available from vendors. I will be moving the Z32 setup to my 280z/2jz that is in the building stage right now, as it is a low-cost, non daily-driver that is going to have a lot of personality and is going to need some decent brakes. -

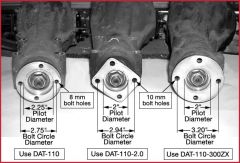

The Z31 flange could be used in an S30 if you run a Ron Tyler diff mount without the factory mount. There is not too much difference between the two diff flanges with the 10mm bolts. Here is a picture stolen from the JTR site that shows the three different R200 flanges. http://album.hybridz.org/showphoto.php?photo=22826&cat=500 I am going to use the center one, it fits the S30 with the stock diff mount. The Powertrain Industries part number for the mating yoke flange is #3102-20. The Z31 diff flange (right hand side of the picture) mating yoke is part number #3102-21. I see no need to go with the Z31 flange if it won't fit your application. I agree with the OP that the 8mm bolts in the left hand one are probably not the best choice for 3 times the stock torque. Cheers Doug

-

Have you bought the flange from JTR yet? I have both the differential flange and the correct yoke flange for the 300ZX. It will bolt on the the R200 and the yoke flange takes a standard 1310 ujoint. I was using both in my 240Z for about 300 miles. In the S30, the larger diameter flange interferes with the diff mount, so I am changing back to the other 10mm bolt style. Are you putting this in a 510, S30 or an S130? The large style will work in an S130 or Z31 but not in an S30 with the stock diff mount in there. Not sure if it will work in an 510 though. You will have to measure to see if you have enough clearance around the current flange... Cheers Doug

-

Transmission wont come apart... whats the problem

Doug71zt replied to bigjohnsonzc's topic in Drivetrain

There is a pin that prevents the shifter from over-travelling from side to side on some of the early transmissions. It is near the top of the tail housing. You have to pull this pin to allow the shift striker to move out of the way of the shift rods in the transmission. That is what you are hung up on. If you go to the NICO site, there are downloadable original factory service manuals for the 280Z that will have a good rebuild procedure for this transmission. http://www.nicoclub.com/FSM/ Sorry if I'm being a bit simple in the explanation, but I'm nowhere near the z car right now. -

You're on the right track. It is harder to balance the damper and flywheel without the crank to mount them on. So, you zero out the crank to have a starting point, then add and balance the flywheel, then the damper. Everything can then be replaced down the road without having to worry that you are throwing the balance. If you mounted up all the components at once, would you drill the crank, flywheel or damper to zero the assy out? The process I use to balance a new build is: Match the piston/pin weight Match the rod total weight/small end weight/big end weight. Now the recip. components are done, on to the rotating components: Zero balance the crank Zero balance the flywheel Zero balance the clutch housing Zero balance the damper. If you are rebuilding a factory-built Nissan motor with all the original parts, I have found that it is not really critical to balance the assy as they are very close from the factory. Worst I have seen is around 4 grams. They were correctly balanced from the factory, not thrown together like a GM V6..... If you are building something from scratch or a Frankenstein motor, then it is a good idea to balance it. I didn't do the clutch housing on this last engine because it was custom-built and balanced by the shop. They are internally balanced - to answer your first question. No external weights are required and the assy is at zero balance without damper or flywheel installed

-

I would recommend a 3.54 if you are running a tire under 26 inch diameter. I have run both 3.7 and 3.54 in my car and the 3.54 is quicker and faster on the strip.

-

There has been some discussion about RB oil pump damage due to holding the engine on a rev-limiter. Either way through ignition cut or ignition retard limiting, you will still have fuel burning in the exhaust. Neither is particularly good for stuff downstream of the exhaust valve. You generally want a soft limiter for the situations that you are describing, as a hard limiter is pretty violent. I have boost-cut hard-limiter as a safety on my car and when it cuts, it's harsh. I would doubt that the stock RB rev limiter leans the mixture - most of them are a fuel-cut, which doesn't lean it out. It cuts the fuel off, period. It re-introduces injection after the engine rpm has dropped to a lower threshold. Doug