-

Posts

60 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Smyrna388Z

-

http://forums.hybridz.org/topic/125801-repair-solution-for-bad-turn-signal-switch/

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

Update: Rear exit open; improves 1/8 mile ET by about .04 seconds and sounds very cool. Exhaust is working well. Recommend doing your next exhaust yourself!- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

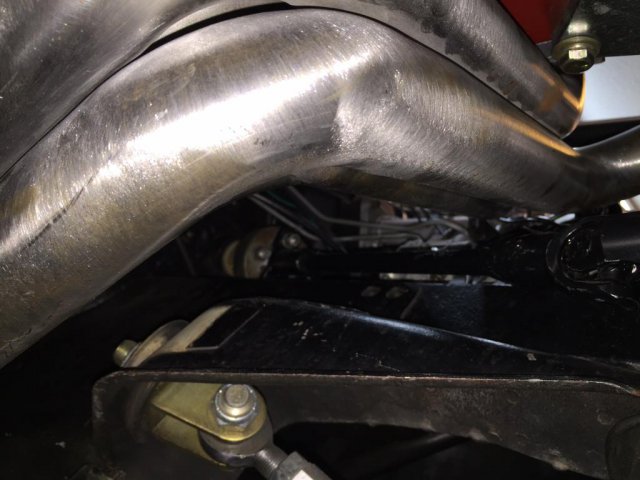

Sanderson long tube c33-ap are now installed on my 1976 280z with a Chevy in the JTR position. Minor clearancing at the frame rail on the passenger side, but this could be eliminated with manufacturing differences between the headers. My steering shaft has been relocated, but suspect the stock location would be very close to working. Ground clearance has not been an issue. Works great when you want a 1-3/4 long tube header.

-

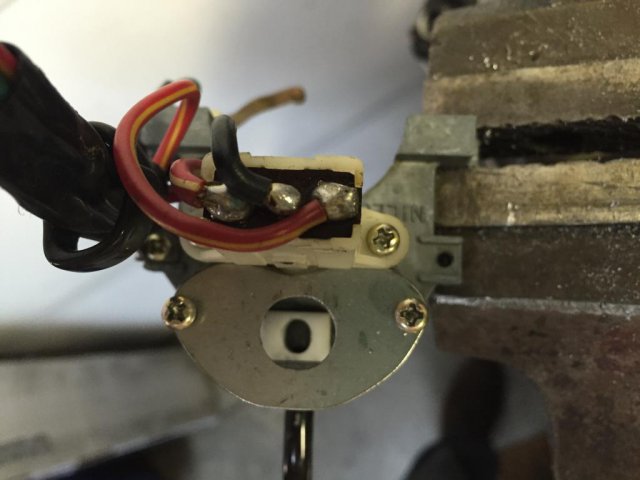

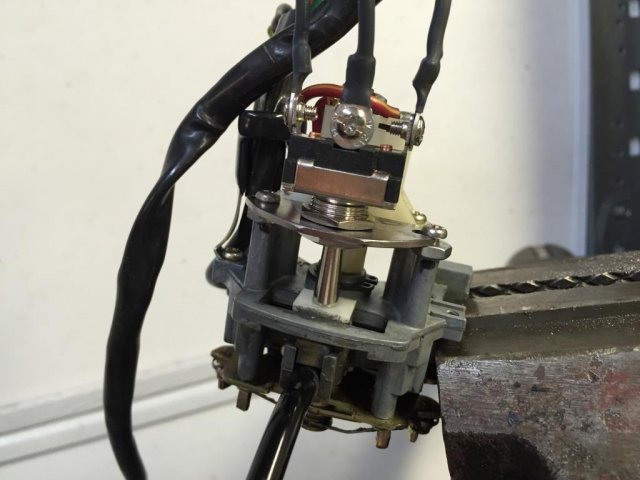

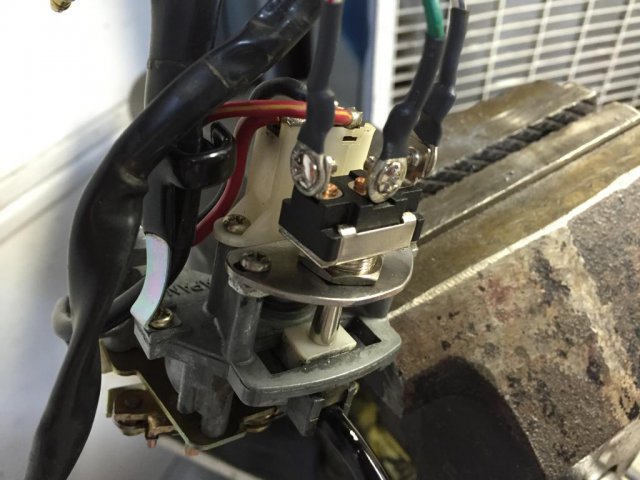

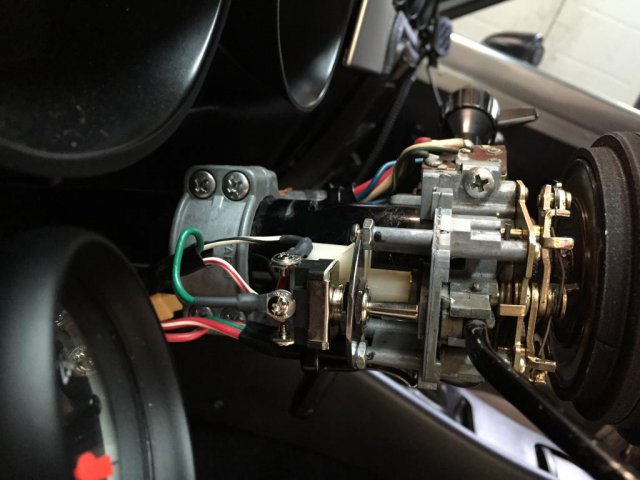

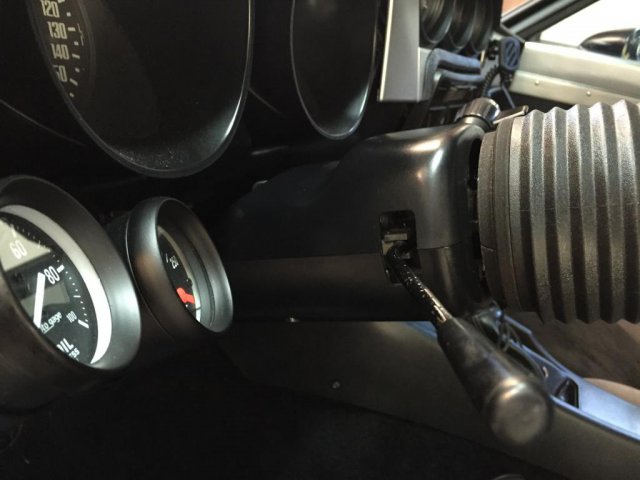

3 position switch. Center position is off - normal state Signaling simply moves the switch into one of two 'on' positions. The switch is designed to work like I am using it. Only difference is that the signal arm is actuating it instead of my finger tips. If and when the switch fails, a simple $5 replacement can be screwed into place. This conversion will help anyone struggling with a turn signal switch. The price of an OEM replacement rebuilt or new is crazy! Hope this helps someone.

- 21 replies

-

- 1

-

-

- Indicator

- turn signal

-

(and 2 more)

Tagged with:

-

Operation of the switch is better than original; glides easily into position and easily returns to off position with steering actuators. The original switch always seemed to drag and function was hit and miss. Brakes lights work as designed, no issues. Switch used was Dorman part #85905. I picked it up at Autozone. Note the two nuts used as spacers under the mounting plate. The spacers were required with this switch to set the switch arm at the right position.

- 21 replies

-

- Indicator

- turn signal

-

(and 2 more)

Tagged with:

-

Got tired of fighting with the turn signal lever to get the blinkers to activate. Worked on the OEM switch so many times that the circuit board finally broke. Here is an awesome repair solution.

- 21 replies

-

- Indicator

- turn signal

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

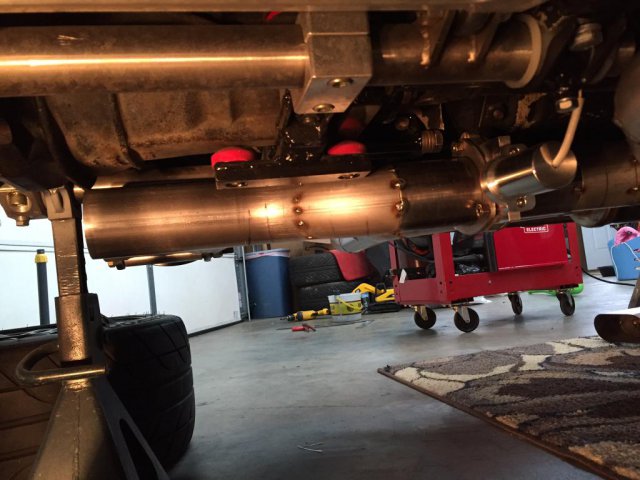

Exhaust complete The attached video clip is with rear exit cutout closed and with rear exit cutout open. The long tube headers were a challenge, but so far happy with the results. I did raise the front end 1/2" to increase ground clearance. trim.55A47C92-2E13-4190-8DCF-5AA8E7CF7EDB.MOV trim.357DCFD2-14DF-49DF-879F-10BD617A33DC.MOV- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

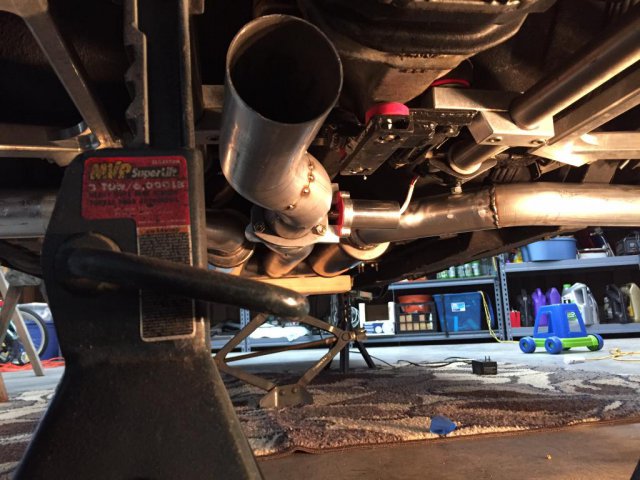

The Sanderson long tube 1-3/4" headers are installed along with a single 3" non-muffled pipe to the rear. This pipe can be sealed by means of an exhaust cutout valve. The exhaust would then flow through 3" collectors, pipe, and H-pipe to two side pipes muffled by two 2-1/2" Magnaflow mufflers. I painted the pipe black and therefore it is hard to see. But notice how well 3" pipe can fit under a 280Z. I am very happy with the figment of the Sanderson headers in this engine swap. I did pull the passenger side header toward the passenger side while heating the pipes to gain more clearance along the frame rail. I suspect this was due to jig figment at the manufacturer because they left more room than what was needed between the header and oil pan on that side.- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

Today I got all of the exhaust pipes in place and tacked. I have more ground clearance now than I had with the old crush tube 2-1/2" system I removed. Long tube headers and 3" exhaust is possible on a 280Z.- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

Update: Sanderson C33-AP, 1-3/4" primary, long tube headers fit great on a 280Z. I installed the headers today. Be prepared for variances in the manufacturing process. I had to clearance my oil pan a bit on the driver's side with a hammer. I bent the passenger side tubes in to the engine about 1/8" to gain clearance at the frame rail in the engine bay and the fuel lines that run alongside the frame rail under the body. This may not be necessary if your set is manufactured with slightly more bend in the tubes. Very happy with the fit. It is as if the headers were made for a 1976 Datsun 280Z with a Chevrolet LT1 350 and 700r4 transmission.- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

LanceVance, the side exhaust pipes are 2 1/2" pipes and I know they will not have quite enough CFM to support my HP goals. Just need a bit more for 500hp. Beyond the header 3" collectors and the 3" H-pipe the goal is simply to have enough CFM. The flow direction (90 degree turns in the H-pipe) will not be a concern. Similar to a chambered muffler. The thought is to open the cutout valve at the race track to supplement the side exhaust CFM and keep it closed on the street for a tamer tone. Alternate reasons are to fill the exhaust body cut in the rear with a tip, more noise when I want, uniqueness in sound and layout. I'll be able to make passes down the drag strip with the 3" pipe open or closed. It may or may not benefit. I'll post the results on this thread. I appreciate the feedback. Not sure how it will work myself, but I think it will be cool. Thanks.- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

Weight went out the door for a reason for the new exhaust, but it is still lighter than the 2 1/2 duals all the way out the back. The dual out the back system had two Magnaflow mufflers (pictured) + two Cherry Bombs at the tips - great sound but a bit too restrictive for the new power levels. The side exhaust is complete and now waiting on the headers to make the last two tubes.- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

Aluminized Under the rocker panel. Ground clearance will not be an issue with 2 1/2" pipes. I welded the pipes with them touching the rocker panel bottom flange, then trimmed the flange for clearance. I will email tomorrow and try to get a ZAttack date. I have to get this exhaust done, the new AFR heads on, and the headers installed before the weather warms up and the race tracks open. More pictures of progress. I have decided to run the 3" exhaust dump out the back. Custom tip and mandrel bent 3" tubing.- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

Smyrna388Z replied to Smyrna388Z's topic in Exhaust

General location of the 3" exhaust cutout This could easily run to the back of the car and exit in the original location. I will install it as if it is going to exit in the rear (future addition).- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

In order to reduce weight, add simplicity, and improve exhaust performance, I decided to tackle an exhaust system myself. I've always paid to have a crush tube system installed and have never been particularly happy with the ones I've had. They have been functional, but I suspect restrictive. To build what I have so far, I purchased two 2 1/2" mandrel 180 degree J-bends and a stick of 3" tubing from Summit Racing. Tubing cuts have been made with a miter saw with cutoff wheel, sawzall, and hole saw. I will add a 3" dump where you see the hole in the H pipe. Prior to the Magnaflow mufflers, including the H pipe will all be 3" pipe. Time consuming but fairly simple to this point. I recommend anyone giving it a shot. Satisfaction of building your own exhaust will be worth it. I am running the 3" dump to the rear. I added to pictures to show the custom oval tip as I align it for welding. Picture after final welds is attached. System is ready for install. Once I get the headers installed, I can fabricate the header collector to H-pipe tubes.

- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

The hood was purchased from Robert through 280Zone@cox.net This was the same issue I had. I wanted to vent the engine compartment and get some fresh air to the carburetor.

- 15 replies

-

- ram air

- Cowl induction

-

(and 1 more)

Tagged with:

-

- 15 replies

-

- ram air

- Cowl induction

-

(and 1 more)

Tagged with:

-

Summit Racing Bearing: AAF-ALL52132 U-joint: SUM-770660 Shaft: AAF-ALL22190

-

- 15 replies

-

- ram air

- Cowl induction

-

(and 1 more)

Tagged with:

-

Good eye! It is a Dixie horn. No problems with high temps with the stock hood. I'll post if there are any differences with this setup. I found myself opening the stock hood in the staging lanes to let heat out. My plan is to relax in the car and keep this hood down. I will also post an ET improvements that I get from the cowl induction of fresh cool air. It will be a few months before the tracks open. Thanks.

- 15 replies

-

- ram air

- Cowl induction

-

(and 1 more)

Tagged with:

-

Sounds good. We can turn Friday night at Music City Raceway into 'Znight' Drags. I'll post when I have more information about ZAttack. Thanks for the compliments, that carbon fiber hood you have is hard to beat.

- 15 replies

-

- ram air

- Cowl induction

-

(and 1 more)

Tagged with: