ckrell

Members-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ckrell

-

Well, thank you all for your advice and tips. I will use 2"/2.5" roll centers and 250# springs as a baseline.

-

-

Best swap for mid-engine balance

ckrell replied to MazerRackham's topic in S30 Series - 240z, 260z, 280z

-

The rockers are the lowest part of this car. The floors have been replaced level with the bottom of the rockers and also the crossmember has been removed and replaced level with the rockers/floor and will all be panned in to the nose. If 4" was lowest part of the underside (besides the outter part of the A arms) wouldnt that be resonable? sorry dont have more pics. rite now.

-

Brakes! Who is running what?

ckrell replied to SUNNY Z's topic in Brakes, Wheels, Suspension, and Chassis

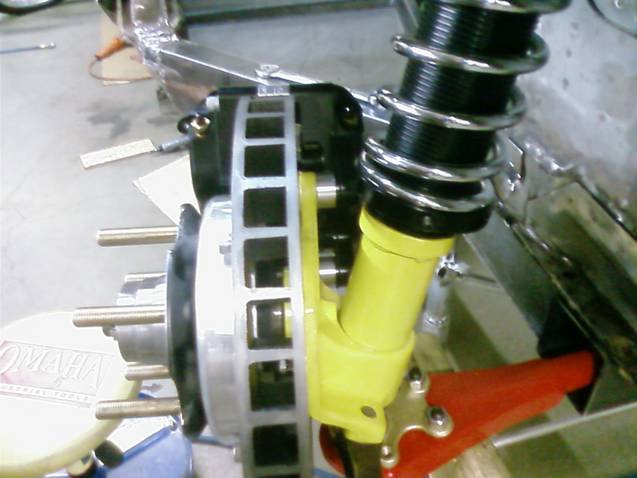

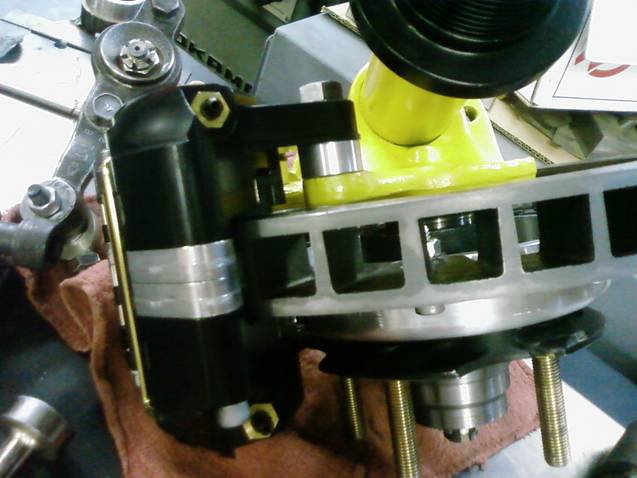

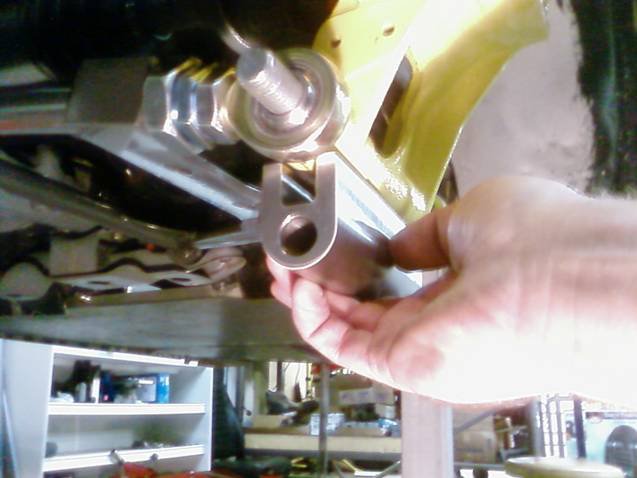

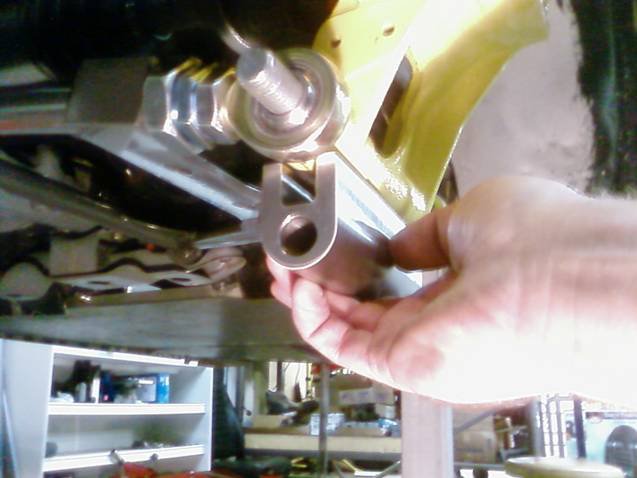

wilwood 4 piston (1.75" diameter) front rotor adp. I made rears are 1.71" offset wilwood rotors are 11.25" diameter 1.25" wide all in side 14" wheel -

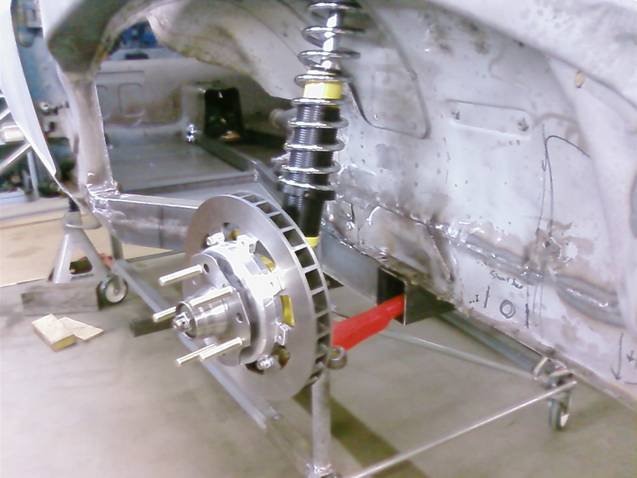

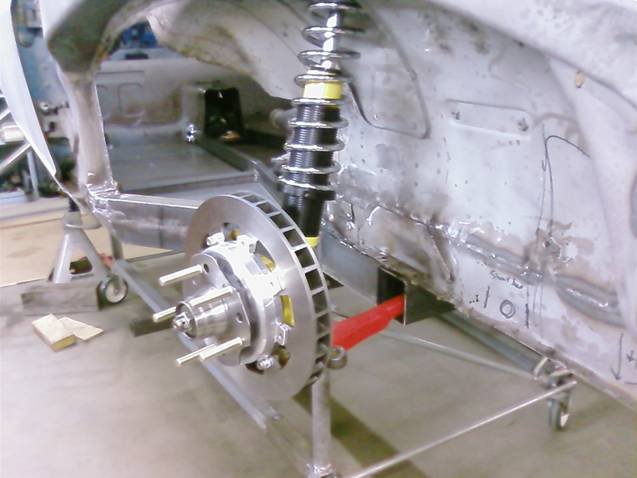

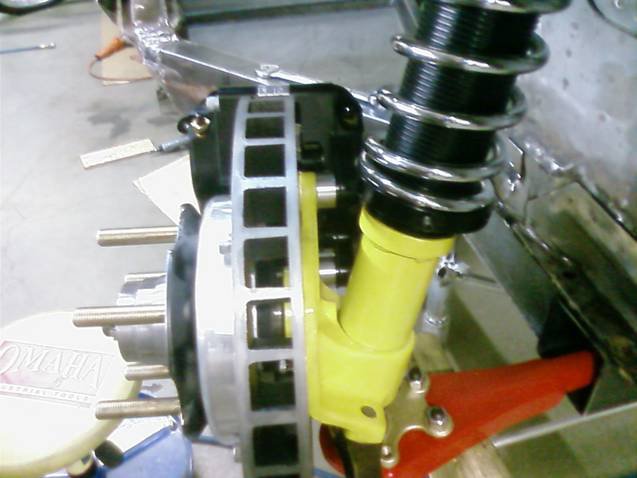

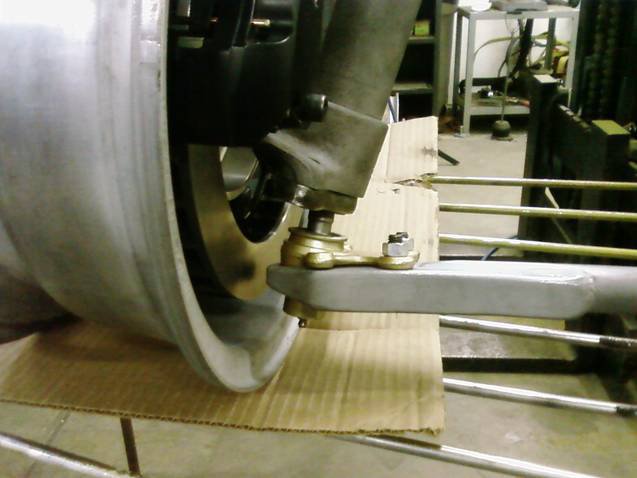

The strut housings are sectioned 2.5" and I found both front and rear KYB GR2 struts from various vehicals so at 4" hide height I have 2.5" suspetion compression and 3.5" droop with OEM rubber isolaters. Im starting with 140# front springs and 185# rears so I will have good suspention travel, very sprited street driving and the local drag strip will be most of the cars activity with maybe getting to the road coruse once a year. So with the softer springs and more suspension travel would you raise the roll center a bit in the rear? And the front roll center should be 2/3 of the front? Tires will be 205/55-14 NITTO NT 01 and I'm up in air on swaybars

-

I'm at the point of picking my rear roll center height. With the weld on the R.C.A. I made at full height, my roll center would be 4.6" at 4" ride height. I can cut them down to whatever height to adj. the roll center. With no rear R.C.A.(spindle pin in stock location), I'm at about 1.3" high roll center. On the front at 4" hide height, the front roll center is 1.1", (because I've moved the front L.C.A. pivot up about 2"). With a 3/4" R.C.A., it gives me a roll center of about 3.5" and of course the RCA could also be cut down to adj. the roll center. High speed stability (140+mph) is my #1 priority. Comments, advice, and opinions are welcome!

-

Using the rocker rail seam as a the main reference point, how much lower is the floor pan and how much lower is the crossmember than the bottom of the rocker seam?

-

8351209737 wilwood billet dynapro 4 /1.750' piston slightly open mounting holes add .5" spacer and machine down rotor to 11.250" I got this all stuffed into a 14" wheel

-

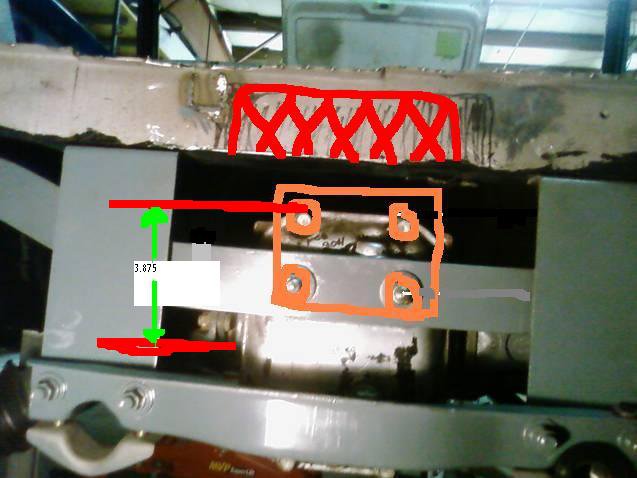

I'll be making a spacer (orange) to move the diff up the Mbar stays in its original place. The number I need is the diff top to diff axel output center (red) r180 is 3 7/8" thanks for your input, sorry for any confution

-

The car is being lowered 3". The Front LCA pivot is moved up 2" and rear out control arm pivot is lowered 1 3/4" (thats all I could go 14" wheels) help roll centers, The car will be flat bottomed the lowest part will be the rocker seams theres some pics at members projects under S30 4G63/240z I will have more later. Im trying to get the driveshaft angles beter buy rasing the diff and just want room to install R200 if needed.

-

Do you think the from mounting stud to stub axel centers are the same? I should be asking what the stub axel center to diff housing top is. My 180 is 3 7/8" (red lines)

-

-

My 180 is 2 5/8"

-

Kinda will post pics later

-

Rear RCA (weld on) The car is being lowered 3". The Front LCA pivot is moved up 2" and rear out control arm pivot is lowered 1 3/4" (thats all I could go with 14" wheels) to help roll centers, The car will be flat bottomed the lowest part will be the rocker seams

-

Can anyone tell me what the differances is I height from a 180 to A 200 at the white lines in the pic?

-

If i raise my diff (R180) to the unibody frame then later switch to a R200 will it clear? How much differance is A R180 vs. A R200 from the 2 mustache/diff cover bolts to the case top

-

-

-

-

In 2009, I felt the need for a street/strip/and track car build. I wanted something light, powerful and good handling. It would also be nice for it to be a cool classic. I went to the local import repair place and told the owner what I was up to. He said he had just the thing for me. He took me to the corner of the shop and showed me a 1972 240z rolling chassis he said, "$420 and you borrow my trailer to get it home." I said SOLD!!! The car was a started project partially sand blasted and a really bad floor replacement job, but it had a few goodies with it. Well, for the next year or so I just couldn't get started on it the car went from storage place to storage place and to the street for multiple times for sale. The car's was nickname was "The Orphan." Then at the end of 2010, I was finally able to use a corner of the shop that I work for to work on the car. It was just what i needed to get going on the project. (more to post later)

-

Under $400 and it comes with all the other stuff you need like crank adp. bolts, starter adp its great.

-

http://www.billsautofab.com/ This guy make lots of differant RWD tranny adps. for the 4G63 very reasonable prices.