ckrell

Members-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ckrell

-

Bow, bow to the carbon GOD

-

I was hopeing to steel the air that causes lift from the lamminate airflow down the hatch lid and put it to better use

-

Sealed nose to reduce lift, lessen drag, better rear weight percentages,....

-

Heres some pics I hope you get the Idea. I'm looking for some Ideas on were the best place would be for the inlet. As you can see the outlet will be between the tail lights.

-

My obsessiveness sometimes gets the best of me. I couldn't help myself, the axel flanges had a few thousands (.003"-.004") face run out so I make this tooling to true them in the car. Also trued the wilwood hats (inside and out) to the rotor.

-

-

I really wanted the D bolts for my driveshaft but it seems there no longer available so this was my Idea. These are grade 8 bolts (5/16th very close in size) from Menards the body length is just right, grind A flat on the flang parallel with A flat and cut to right length. I also had to chamfer the yoke a little more for the radius under the flanged head

-

The engine should be able to achevie 450 Ft/LBS (@ flywheel) at the line with the 8" converter I have x 1.76 low gear = 792 FT/LBS at the pinion x 3.36 rearend ratio = 2661 FT/LBS at the rear axels /2 = 1330 at each diff stubshafts, I don't think these numbers will be devastating to a welded r180 especially with the low shock of the auto trans. I'm thinking and hoping my tires are the fusable link. I guess we will all find out.

-

-

The rear tires are M/T drag radial 2s 205/50/14 I may not have the traction to brake anything we'll see. Right now I'm rasing the diff 2.5" to strighten the halfshafts. I do have the 27 spline wheel axels, 240 halfshafts with neapco bruteforce ujoints and yes the r180 (3.36) I'll have some pics soon the the diff raising and I left room for a r200 up grade.

-

I don't know what stock angles are. The car has a whole differant crossmember and rack mounting position

-

I bought this power steering elc.rack motor off ebay its for a 07 cobalt ($57) I plan on coupling it to the BMW pump with a reservoir and then I can mount it anywhere.

-

-

Squirter are not needed with forged pistons especially with coatings. Besides the parasitic drag of the extra oil cost HP. Alot of guys eliminate them on the 4G63T

-

Its a 30" sprintcar torsionbar I bought my used off ebay $28 shipped new there around $90. I bought used bar stops and thats what I welded the arms to

-

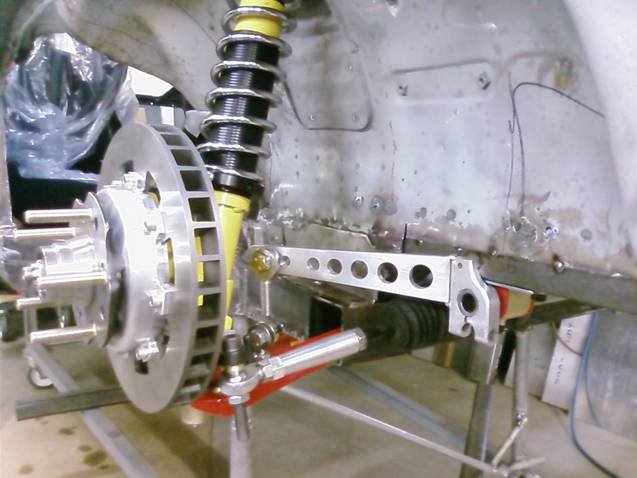

Today making sure theres no bumpsteer, binding, rubbing or interferance of front suspension. From ride heigth 2" of compresstion and 3" of extention

-

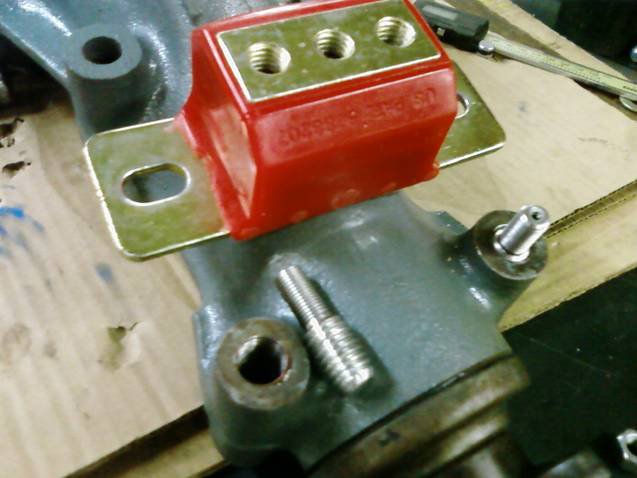

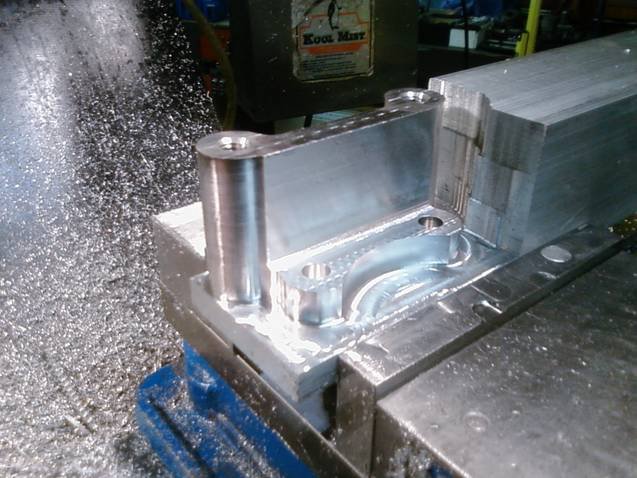

New rear caliper brackets finshed, designing, one prototype, two finshed brackets 25hrs. I'm never going to get this car done making parts like this

-

-

-

Looking for pictures of custom tie-rods

ckrell replied to egzlilgituarboy9's topic in Brakes, Wheels, Suspension and Chassis

There not done yet. I have to tapper the small end, 6061 T6, 14MM x 1.5 for rack end 1/2" 20 for rod eye end. -

First the rack needs to be a front steer type. The inner tierod distance on the M3 rack is about 24 1/2" and the S30(72 240z)LCA pivots are about 23 3/4 These two number need the same or close. Some would say there close enough but I moved the LCA pivots out .300" pre side and then shortend the control arms .300" per side(there adjustable)to reduce the chance of bumpsteer I belive there are 3 types from the mid 90s two from sedans 3.5 & 3 turns lock to lock and the Z3 rack is 2.5 lock to lock they will interchange mine is the 3 turn. Also mine is a 1995 variable rack

-

BMW M3 rack mounted (3turns lock to lock stock). The steering knuckels are shortened 3/4" lock to lock is about 2 1/4 turns now. The LCAs are proped at 4" ride hieght.

-

I'm going welded (done it before) its not as safe as open but to each his own comfort zone.

-

Need advice on favorite oils/antifreeze, etc.

ckrell replied to RebekahsZ's topic in Gen III & IV Chevy V8Z Tech Board

If your not using catilatic converter I like this oil www.penngrade1.com but on first startup I would just run it for 20 mins on cheap stuff. -