-

Posts

1096 -

Joined

-

Last visited

-

Days Won

8

jeffer949 last won the day on January 4

jeffer949 had the most liked content!

About jeffer949

- Birthday 09/24/1982

Contact Methods

-

AIM

boosted260zed

Profile Information

-

Gender

Male

-

Location

Newton, KS

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

jeffer949's Achievements

-

@Derek I just found your 85d thread on speedtalk forums!!!. Just glad there are people on there sharing knowledge still!

-

Hey Derek. Good to hear from ya. Yeah input a vfd on it. And it already has the variable speed feed. It also has the indexable cutters on the head. Which will be fine to start but im looking at switching over to a single pcd/cbn cutter. I might have to do a pulley change to get the sfm where it needs to be. But currently im waiting on a box to put the vfd and other electrical components in. Im putting it on the machine where the motor start switch ans box was.

-

jeffer949 started following Keas Jatco 4n71b automatic transmission build info. , Something new and L28 Front sump conversion

-

I just wanted to share something pretty exciting in my world. 5 weeks ago I overheard a friend talking about how hard it was to get any machine work done. And it hit me..... I know how to rebuild heads I just need equipment. Did some research and found that 4 of the main shops in the area have sold out or retired. Told the idea to my father in law. And was just spit balling with him. I dont have the cash to start anything and it was just an idea.. well he gave me and my wife a rather large gift and I have now bought a storm vulcan 85b blockmaster and a winona van norman Ph-2000L valve ane seat machine. Still need a valve grinder and obviously tons of tooling. But im excited to see where God takes this. Been 25 years since ive done and work but am excited to get back into it. Plan to get the surfacer going and try to drum up some buisness to make some income to buy more tooling. I onoe they are not the best machines bit they are functional. Just wanted to share

-

Next I need to pull my current engine as I need the oil pan from it along with the new timing chain guilds and oil pump and everything else. Thats new from when i built it a year or so ago. With it being a front sump I'm going to look into adding some oil baffling of some sort. I cant remember if there is any. Need to button up my 4n71b Jatco from the 84 300zx turbo and finish the inner hub for my adjustable cam gear. But I cant finish that till I pull the old trans as I need the bellhousing. Then I go down the rabbit hole of needing a new driveshaft but also wanting to swap in a 8.8 out of an ford explorer... ..

-

Slowly been chipping away at building this engine. Got all the oil pickup tube mods done. Then used my cnc router to plot out where to drill my block for the cooling mods for JeffP's head gasket. I'm cheap and not using his gasket but modifying a felpro to have all the cooling passages. My router isnt ridged enough to actually machine the holes but it allowed me to do a spot drill for the hole centers. Then came back and use the correct sized drill bits in a hand drill. Then used a die grinder to connect the 2 holes on the oblong holes. Worked well. Some time after that i was working on m wife"s car but wanted to keep going on the engine so I took my heavily carboned up pistons and soaked them in Superclean. DO NOT do this!!!! It eroded my pistons and made them unusable. Talk about a gut punch. The pistons where within spec and perfectly usable. Well I didnt know what I wanted for Christmas But I did after this. My mom and Aunt said they would go in together and get some new ITM's for it and where nice enough to let me have them now. Pressed the old ones off. New ones on. Gapped the rings. And install.

-

Sold everything to a guy on zcar.

-

I'm not complaining to anybody specific. Ive been around this site for close to 20 years and back in the day it was so helpful. Now its dead. Is what it is.

-

Well. The above mod worked and its now front jumped. Had to make a new dip stick tube and then I started on making an adjustable cam gear. Turned the inner bore out and faced the rest so ill have a good flat surface for the aluminum inner hub to bolt to. I realizing noone answers questions on here anymore and people just use it for documenting their builds. Its really sad.

-

Im building a l28et and im converting it to front sump. I've already drilled everything and I know what im doing there. Wanted to run how im sealing the oil galley off. I the picture you can see my new pickup hole and dipstick hole. I have already put a Welch plug to the left of the small hole and plugged the old pickup. Next im going to put the aluminum plug i made that has a npt plug inside of it between the new pickup and dipstick hole. When I tighten down the npt plug it will spread the outer wall of the aluminum plug and seal it off. I will theb back that up with another Welch plug. Im almost sure it will work but I wanted to get some more eyes on it to make aure. Because if it doesnt work. Ill suck air and take out the bearings. Any recommendations on a sealer I should use if any?

-

Very nice. will be cool to see how tight it is in the engine bay!

-

Turbo oil feed line, block adapter, turbo drain. I really have no clue how much for this. I know they dont come up for sale much especially with the block adapter. It may be slightly tweaked but its really close to original shape. Will package on a bog enough box. $150 plus shipping?

-

Oil cooler assembly. Includes everything from the block adapte, all four oil lines and the oil cooler and banjo bolts. $250 obo plus shipping. I flushed it out in my parts washer. Hoses and adapter where dirty but i cleaned them up. Does not appear to have any leaks.

-

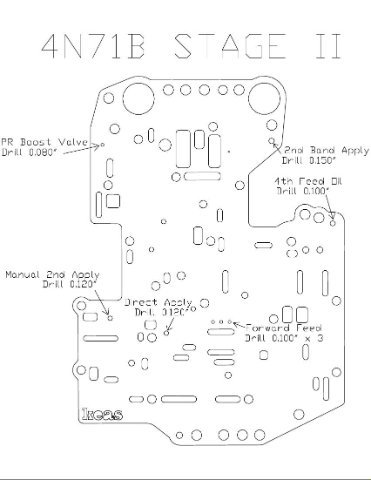

Adding info I was given from Keas on these transmissions. I was given permission to share. In an email I was told that only a slightly stronger spring could be used in the Pressure modifier valve. This goes against what other build info I have found online. I think the info on replacing the plastic thrust bearing and modifying the planetary to be very useful. I have seen alot of people in my searching having broken thrust bearings or planetary failures. I know this is an old thread but trying to put this info in places it can be found JATCO 4N71B Rebuild Modifications.pdf

-

Hello everyone. I am building a 1984 Maxima wagon (not a Z but has the same basic drivetrain.) I have turbo'ed the stock L24e and have a L28et sitting on the stand to put in. My car is auto and has the L4n71b transmission. I am in the process of rebuilding a 1984 300zx Turbo auto transmission for the car which is a 4n71b. Firstly there is very little info on the internet about these transmissions and half of it is wrong. In my searching for info on how to build the 300zx transmission up to handle power the name KEAS from Australia keeps popping up. They seem to have done alot with the jatco transmissions in the performance world. Well I emailed them and asked for pricing on a valve body This is where I was shocked. They sent me the instructions on where to drill the separator plate and then he sent me the info on building up the transmission itself and how to address the weak points. I asked if I could share and he said yes so putting the info on here to help future builders. What is interesting is that they don't modify any of the springs per the level 10 info and the shift kit the guy from austraila sells. See details in the thread below. Little hard to follow but i think you can understand. Jeff, The only Valve that could use a slightly Stronger Spring is the Pressure Modifier Valve. Over-do the strength of the Spring and extremely late or nil WOT Shifting will occur. The Weak Areas in order of Failure are: Intermediate Shaft Input Shaft Over Drive Sprag. We have Billet Piston/ Servo Sets but your not there yet. See attached PDF for transmission upgrades. Have fun. Paul. Wow thank you so much for that info. I have the stock modulator from the turbo 300zx. And I have ATP nx-2 modulator. Thats adjustable that is listed for the turbo cars. Not sure about the diaphragm thickness. With the separator plate do I need to do anything with the valves? The info I've seen online say to shim the pressure regulating valve 2.54mm and the pressure modifier valve the same or install a stiffer spring.(or pin it for very firm shifts. From the link below. https://www.mygen.com/users/dbruce/myz31/LevelTen_Performance_Automatic_Transmission_Install.htm At what point are the cast band pistons not viable and billet ones are needed? And yes the engine is a l28et from a 280zx turbo. Not sure if you ever got those in Australia but its the same l6 platform as the L24 from the 240zed etc. Jeff, I'll assume your Engine is Turbo Charged. The Valve Body (If it was from a Turbo Charged Vehicle) runs into Shifting issues around 13psi. And you cannot buy the Turbo Specific Modulator anymore. It contained a thicker diagram that lasted longer the NA items. I would fit a Full Manual Valve Body that has fixed Line Pressure. As a starting point- try modifying your Separator Plate as shown on the PDF Building a 1984 Maxima Wagon in the USA. Has a L28et from a 280zx turbo with a 4n71b from a 84 300zx turbo behind it. Planning on around 300 hp to the wheels Just replaced all the gaskets, seals, o-rings, clutches, steels, and bands set all clearances to factory spec. What valve body mods do you offer? Finding info in the states is hard and your name keeps popping up so I thought I would see what you offer and pricing. Thanks JATCO 4N71B Rebuild Modifications.pdf

-