-

Posts

1471 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Six_Shooter

-

-

I find it absolutely hilarious how people in North America speak as an authoritative source on why the L-Series is this or that, and have the arrogant attitude that "If it didn't happen in 'Murrica (Canada apparently as well...) then no lil yallar fella coulda come up with nuthin' worth speak in' bout!"

I mean, talk about boorish and xenophobic.

It's actually quite offensive to me, in particular, since I still travel to Japan regularly and have many close friends in the automotive high-performance arena there.

I mean people are speaking as to why it's so hard to do this as of it's some mystical number and sooooo few, far between, rare. It's simply a matter of lack of exposure, ignorance of history, and of other arenas of opportunity or endeavour. If it upsets you that your ignorance is exposed when you speak about it, a reasonable proposition would be not to speak of it so as not to be corrected.

If someone's choice to use an engine other than an L-series in their car for their own reasons is offensive to you, then you have some serious issues.

For the amount of money it takes to build an L-series to the power levels I want to build my engine of choice to, I could build at least two of non L-series engine. FWIW, the engine I will be building is an orphan, and not generally considered for performance applications, so not all of us are taking the "easy way", but a different way. An engine that is 30 years newer will have maintenance parts available at the parts store, usually in stock, if not only a few hours away. Every time I have needed a gasket or part for my L-series, other than belts, or spark plugs has been days away, and usually only through the local Nissan dealer (where the parts manager is also a Z-car owner and enthusiast). I daily drive my 240, and I plan to keep it that way, so waiting for parts is a show stopper and not a position I want to put myself in. This is also the reason why I'm very selective of what aftermarket parts I actually use. Most wear items I use are not aftermarket, such as brakes, I use OEM from some vehicle that will give me the performance I desire with the serviceability I need.

It's about the dollars and sense.

Also why not, instead of stating over and over again in your own cryptic way that "Hey In Japan they do things differently and it works", why not show some examples, with some details about how they achieved what they did, so that people that might want to go that route will have some direction.

On that note a sticker I have comes to mind, that pretty much explains how I will be building MY car:

-

-

I like it. I'm trying to not need flares or widening of the wheel wells, but if I do go that route, I would be using this idea to get there.

-

Many of us realize that a lot has been and can be done with L-series engines, but there is also the fact that there are cheaper ways and ways that require less work to achieve our power goals.

If one of the criteria to our build is not "to keep an L-series engine between the front strut towers", then the obvious choice is to use something newer, that has been developed to be more efficient.Call it "sloth", call it "ignorance" if you want, I call it being efficient with time and money.

Personally I'd rather spend my time behind the wheel, and my money on the dead dinosaurs going into the tank under the hatch floor.The only way I'd keep an L-series between my strut towers would be if I had a cross flow head of whatever design (I.E. OS Giken, or an RB head swap) fall into my lap along with many maintenance parts, but at that point the only thing that would still be L-series would be the block and crank ... I can also think of much better ways to spend $40K+ than on a single head... For $40K I could have my car running 9's in the 1320, drive circles around people on a road course and win (custom) car shows.

That being said, the L-series has remained between my strut towers for about 4 years longer than I had planned, simply because it works and is reliable. I have even bought a couple parts recently to do some thing that people say is "pointless" and maybe even "impossible" to do with an L-series, simply to experiment, if I even go through with those plans.

-

You don't need to change the bulbs, just make sure the gasket is good to isolate the housing.

-

Both old and new sensors produce a voltage, otherwise there would be no signal. With the exception of sensors that modify (a reference) voltage, which are usually resistance based.

This is easily measured with a DMM, but the waveform can be seen with a O-scope. The type of signal depends on the type of sensor. Most sensors themselves produce a sinusoidal signal, unless there is some conditioning of the signal, which has nothing to do with the age of the vehicle, since you can find sensors in new vehicles that produce a sinusoidal output.

-

I think you mean 40000 PPM (Pulse Per Mile). The frequency at which the pulses occur will be directly proportional to the rate at which the tone wheel (reluctor wheel) is rotating. In other words, the frequency of the pulses is dependent on vehicle speed.

There is usually a control box involved, in many new cars this would be along the lines of the BCM and/or the PCM, to send a proper signal to the EPS. From what I have been able to find is that the signals that go to the actual EPS unit are usually a square wave PWM signal to vary the amount of assist, and in some cases is inversely proportional to what a VSS signal would be.

This is where spending some time with a Oscilloscope and/or logic analyzer will help decipher the signals needed.

This is one of my main projects for this summer, but using different components.

-

I've been running my combination for 5 years...

-

I'm very familiar with live axles, I was raised on them, I just don't see what it has to do with the conversation, and didn't see any sort of "specific thinking" from the OP. All I see is that he doesn't know about diffs (he would have known it was an open diff if he did), and was asking for clarification.

-

I have no idea what being an IRS vs a live axle has to do with anything...

Also welding a diff does not turn it into an "LSD", It does however have the same effect as a spool. LSD still allows for each wheel to turn independently, such as when turning a corner. A spool does not, both wheels are locked together. You will usually feel one tire dragging and the car act a bit funny when turning a corner, with a spool.These are often referred to as "Lincoln Lockers".

I've seriously considered doing this to mine, since I refuse to pay the ridiculous prices for an R200 LSD. I haven't yet and will likely swap in a different diff, to get a cheaper (and possibly better suited) LSD and diff.

-

Umm you sure its ok to rotate that car like that with all that rust in the frame area?

No different than using a rotisserie.

-

I was having this same problem.

It seemed to effect threads that were less than about 20 hours old.

It appears fixed for me now. -

I'm running a Turbo L28 in my 240Z.

Other specs:

-3.90 R20, sadly open diff

-'81 280ZX trans (non-turbo)

-CV shafts

-225/55/R16 tires

First gear is almost useless, (when performing a drag launch) but the rest of the gears are decent for how I drive my car.

"Normal" driving the first gear is good, plenty of torque to get the car started off from a stop light without much effort.

As suggested you could swap to a different diff gear if you can't find a different trans.

AFAIK the T5 only came in the '83 Turbo (in an S130 chassis), N/A had the other trans (I don't recall the ID code off hand)

-

Modified OEM engine harness in most cases.

-

why not just get lower compression pistons? you could use the time to throw in new rings and clean up the cylinders as well. Its not simple to just "slap on a turbo" Its a fair amount of work, so if you are going to put the work in, you might as well get the benefits. For longevity of the motor and power, it would be better to do a low compression boosted engine vrs high compression boosted.

There are multiple people on here who have just "slapped on a turbo" to their NA engines, me being one of them, and it worked decently, could probably have done better with a real tune, but I was pushing stock boost, like 7psi.

I recall a thread where someone was doing this and using a 8:1 fmu and was at like 10 or 12psi. By no means is this the right way, but it will work.

Assuming your engine is stock, you should have 8.8 or 8.3 compression, which is not "high" compression at all, considering there are cars that come with 10+ stock from the factory.

I'll raise my hand as one of those that "just slapped a turbo on" my car. That was 5 years ago. I only planned to leave it this way for about a year or so, then swap out the engine, but the Turbo L28 has been a lot of fun.

Define "High Compression"

This is exactly what my first question/statement was when I read the the OP.

My combination starts with an F54 (with flat tops) and a P90 head (stock port). L28ET exhaust manifold, 6.5 diesel turbo (Mid '90s GM pick up), home made IC, N42 intake manifold, DIS, GM (Delco) EFI to control it all. Aeromotove FPR, 30 lbs/hr injectors, 3" exhaust, Walbro 255, etc, etc.

I'm currently running a max boost of 17 PSIG, but I have had it as high as 20 and plan to take it back there this summer with some larger injectors, and more tuning. I daily beat on my car too.

The 8.8:1 SCR is a "low compression" engine IMO, my next engine (not an L-series) will be at least 9.5:1 if not 10:1 with plenty of boost as well, but it's a different design.

The biggest problem I've found is intake temp control. The L-series with it's no cross-flow head tends to heat the intake manifold which can cause the intake temp to rise enough to be a detonation issue. Some creative fuel delivery can help reduce this effect.

Keep in mind I've done pretty extensive tuning on this to get it to live with 17 PSIG of boost, and have started over a few times with the tuning over the years. So you need to put time aside to tune it well. Start at low boost, get it tuned well, then move up to where you're comfortable.

YMMV.

-

Without the "halos" they will look great.

-

I guess I would have to see video to see exactly how the intake pressure is rising. It sounded from your earlier description that it was a pretty immediate rise in pressure, which is over boost.

No, any leaking at the BOV would reduce potential boost, also know as a "boost leak"

Check that wastegate flapper for movement first and take the car for a drive with the wastegate actuator disconnected, so that the flapper is open all the time and report back.

-

Ok, go back to not having the boost control solenoid in the loop.

Go out to your car, pull the wastegate actuator off the wastegate flapper arm, and move the wastegate flapper. Can you move it? If so how far does it move. Take the car for a drive, does the over boost still happen.

BTW this is over boost by your description, not boost creep. Over boost happens quickly, like it sounds like you are experiencing, boost creep happens slowly and usually increases only with RPM.

-

The engine looks to be sitting correctly in the second picture, though it's difficult to really judge based on how little is there.

What it looks like is that the drivetrain is twisted about its vertical axis. In other wards the tail of the trans looks too close to the left side of the car which would make the front of the engine too close to the right side of the car.

You may have to loosen the 4 bolts off that mount the engine brackets to the rubber mounts and give the engine a twist to get it to line up correctly. IIRC I had lots of play about this axis when I had my engine out last time.

-

So did you ever try either wastegate actuator with the vacuum line connected directly from the compressor outlet to the wastegate actuator?

Some boost control solenoids block flow until power is applied to them.

-

A picture of the wastegate and vacuum hose to it would be more beneficial in this case.

The bypass valve looks to be connected fine.

Assuming you are using an internal wastegate and as a test you can disconnect the wastegate actuator from the wastegate flapper and wire it open, or just leave it, since exhaust pressure would push it open at that point.

There may be a tear in the wastegate actuator diaphram.

-

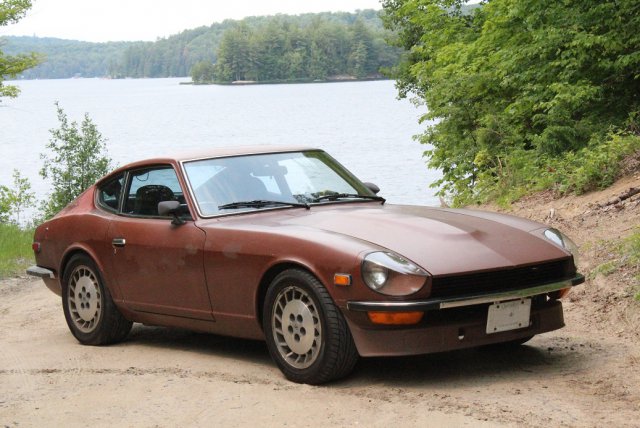

I agree, for the quality of this car that seems high. It looks like a good driver.

-

Yeah I need a perfectly bent pipe like yours hehe. I may just fashion up an air duct and ram some cooler air into the filter for a temporary thing.

I was playing around with some longer piping like that with my previous set-up and noticed the longer the piping got the more laggy it felt. You didn't notice any lag with that long pipe?

Maybe a slight increase in "lag", but nothing too noticeable. I'm using 3" for that inlet, and my turbo is on the large side (6.5L diesel turbo), so it's "laggy" to start with.

I know the set-up is not ideal, but I'd rather have the slight increase in lag, and cooler intake temps, where my IC doesn't have to pull as much heat out of the charge. My IC's working pretty hard as it is, before I put in the IC, intake temps at lower boost levels was upwards of 180*, now when in boost at higher levels it's damn near ambient, usually only a few degrees above I need to add a pre-IC temp sensor to see just how effective/efficient the IC is.

-

Block code will be on the opposite side from the head stamping(under the manifolds behind the PVC boss). If it says f54 you have an l28et

F54/P90 also came in an N/A version.

But I do agree that since one of the pictures looks like it has a turbo, it would likely be an L28ET. The thing is, if you said that about my car, you'd be wrong, It is an F54/P90 with a turbo, but it was originally an N/A engine that I added a turbo to.

You can pull the spark plugs and look into the cylinders pretty easily and determine whether the pistons are dished or flat top. Dished = L28ET, Flat Top = L28E

Air dam it!

in Body Kits & Paint

Posted

That's awesome to find an ad.

Unfortunately it seems that the company no longer produces these, or may not exist in the facet it did when they produced this air dam.