BQR280Z

Members-

Posts

113 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by BQR280Z

-

Oldhemi is spot on. They do weigh a considerable amount. Best case, remove them and fab up some aluminum mounts for your 240 bumpers. I removed all four of my mounts for this year, along with a fair amount of other things. Came up with a gross savings of 141# for this year. Pounds per horsepower is the name of the game. Bill

-

If you have all the mounting hardware for your 240 bumpers, you can remove them. If you need the mounting point you can drain and compress the shocks, then drill and cross pin them so they stay compressed. Bill

-

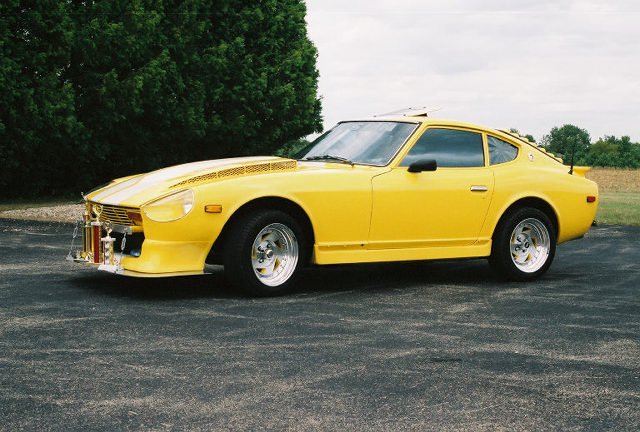

Here's mine. Bill

-

Anyone have shaved door handles and lights

BQR280Z replied to Scott_M67's topic in Fabrication / Welding

When I shaved my handles I ran a manual cable for the passenger side through into the engine compartment. The cable termminates with a loop pull in the area where the battery originally sat. I run a fiberglass hood and use a single hood pin in place of the original latch. Access to the engine compartment is available if the battery does dead so then I can open the passenger door. Bill -

My passenger window has been a problem since I bought the Z. Took the door apart for the handle shave and found this broken roller. It is the one that rides on the inside of the door towards the interior. It would roll a half turn then pop out. So I made up new parts on the lathe, with the roller in aluminum instead of plastic. We shall see if that takes care of it. Bill

-

Yes you can weld aluminum just fine with your Miller 185. Add a Miller spool gun kit and a tank of argon and you are good to go. The soft aluminum wire will not push through the standard wire feed hand torch. The spool gun only pushes 4" or so and works fine for up to .25 alum. (multiple passes) Bill

-

Chartoo, I really don't know who made them. They came with the car when I bought it, but I would bet they are old like late 70's ish. Bill

-

No, those are earlier pics of the car. Still has door handles, steel hood, no diffuser, side vent emblems, leaking gas tank. It was on the road for 6 years, been down for 1.5 years with current face lift. Still working on a few things, new smaller aluminum radiator, block-off panel, splitter turnbuckle mounts. So far this year weight is down 104 pounds. Should shoot the new paint in a week or two, and be ready for car shows in June. Bill

-

The diffuser is from a Ford GT, not a Mustang but the $175,000.00 Ford GT40 replicas. I used to work for a company that cut the roofs off Gt's and made open roadsters out of them X1's. The GT's are considerably wider than our Z's so I cut material from the center and narrowed it. Bill

-

The wheels are Enkei "Blades" I still have the 15" with tires if you are interested. The Enkei's are aluminum modular wheels, there are some pressed steel knock-offs that have the same basic shape. Since I do my own painting, a face lift was not that big a deal, although a gallon of Viper Race Yellow cost $246.00 yesterday. The first time I painted it the same gallon was $130.00. Bill

-

This time around I'm going bumperless. And yes wheels are getting changed. From 15x7, zero offset to 17x8, 40mm offset w/R compund rubber. You are right about the pics of my car, it was just showing its age a little and the hood was starting to bubble bad. So it was time for a face lift, but I still like my color/stripe package. Bill

-

Yes they are truck/trailer lights, and they are LED. I took the lenses from the incandescent ones and bonded them to the LED bases. I liked the convex better than the flat lenses. Bill

-

Well done! Bill

-

-

Hey guys, Tell me what you think of my new mods for the Z. Shaved door handles, welded up and smoothed cowl panel, fiberglass hood, reshaped front end, side vent scoops, narrowed Ford GT rear difuser. Paint will be Viper Race Yellow with white stripes.

-

I think I have a dual point Mallory distributor for our l-series motor. Let me know if you are interested and I will hunt it up. Bill

-

I have a Syncrowave 200 and also love the machine. I weld mostly .25 and under aluminum and it works just fine. Check around on the prices though, my shop is 17 miles from the Miller factory and when I bought the best price was from a company in New Jersey. So my welder was shipped from Wisconsin to New Jersey and then back for a cheaper price than the local dealer would sell it for. And we wonder why business needs bailout money. Idiots!!!! Bill

-

Drill press recommendations? Either cheap/used!

BQR280Z replied to Evan Purple240zt's topic in Fabrication / Welding

What ever you decide on, brand wise be sure it has enough speeds to get the chuck speed at or below 200 RPM for large bits. Classically the 5 speed models spin too fast and just burn bits. My .02 worth. Bill -

I had the same problem, and because Z's have the high underhood heat reputation, I added a 1" phenolic spacer and a .5" NOS spraybar. I looked at everything I could think of in the way of hood scoops. They all offered clearance down the middle of the hood but nothing where I really needed it. My fix was to cut the original hood 4" from both sides and the rear and lift the center section 2.5" at the rear. I welded 1/8" rod around the raw edges and grated the openings. This fix kept the Z lines and actually completely solved the Z overheating concerns. Airflow through the hood is amazing and really helped to stabilize the car at speed. My .02 worth. Bill

-

Here's a couple of shots of the scoops glassed on. The new diffuser is nearly ready so it is almost time to paint. Bill

-

On my 76Z the vents are already ducted up into the cabin from the factory. Water should not be an issue, especially for me because I don't drive the Z in the rain. Bill

-

Any fellow Z people going to the Iola Car Show this weekend. Show is Thursday - Sunday. Awesome swap meet with tons of everything. Bill

-

I needed clearance for my 4bbl carb and since with the L28 it sits off center there were really no cowls or scoops that provided the clearance I needed. My fix was to cut the stock hood across the back and down each side, then raise the center section 3". I welded 1/8 rod around both openings and installed expanded mesh. Air flow is good, the car runs under it's 180 degree thermostat, and shows no front end float at 100MPH+ speeds. Basic Datsun lines were also maintained. The stock steel hood lasted 5 years but is now showing some bubbles, so a fiberglass version is in the works.

-

Narrowed Ford GT diffuser

BQR280Z replied to BQR280Z's topic in Windtunnel Test Results and Analysis

Here is a shot of it in place, once tucked up into the final mounting place the sheet metal between the strakes will be flush with the bottom of the valance. Matching my stripes through the curved strakes will be a job for my line lasers. Bill -

Narrowed Ford GT diffuser

BQR280Z replied to BQR280Z's topic in Windtunnel Test Results and Analysis

The color is actually Viper Race Yellow, with white stripes. I put gold pearl in the clear and now for the new paint job it will get diamond dust in the clear also. The new 15 gallon aluminum fuel cell lets me mount things tighter under body than the original tank would have. Thanks for all your comments, I think it is going to look great. I'll post some pics as soon as I get it hung and more when the paint and everything is finished up. Bill