-

Posts

9963 -

Joined

-

Last visited

-

Days Won

74

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Tony D

-

-

Speak for yourself, Loy.

I feel it....he resides beneath me in a societal, figurative...and not literal...position!

-

$30 Cheaper as in $69.99?

Heck, last I looked in Eastwood I thought...nice tool.

Now I'm just pissing off Julia who will wonder "what the hell is in THIS box?"

-

NFS....

They are around €176 in Holland from Nissan. Last check in late 2013 they were still a part that could be ordered in.

If you get the P/N, any Nissan Agent can order it into their Parts Shipment.

Same as Suzuki.

<EDIT>

HOLY NECROPOSTERS BATMAN!!!!

-

Or set reserve high enough it will never sell then relist near the top bidding position with a reserve in that range.

MBA's rule these days, everybody must not 'leave money on the table' no matter how much you wanted to unload the thing, it must be unloaded for maximum cash possible...

-

interesting....

-

Your information is in error. There is no 'notching of the block' to put an E31 on anything.

That's applicable when you use the L28 sized valves, or larger REGARDLESS what head they are installed.

-

Keep in mind on a 3.0 a 53cc pent roof chamber is only 9.4:1 CR, and likely the optimal in this configuration is 10:1 minimum, allowing for advance in the 17-22 degree range due to superior flame characteristics.

I'm thinking even JeffP will be putting a pop some on a 3.0 to being it to 10:1 even for Turbo Use!

-

In Dutch, "Vette" translates to "Fat"!

-

What I have to add would get me banned at this point...

-

Looks like the 260 BTR Special after the cross-country tear in '01!

-

There was a system being niche marketed and private branded out of Corona CA called "boss EFI" it was based around a self tuning ECU, with PWM controlled fuel pump good to 500 hp.

The delivery and what engine it's on is really irrelevant. GM TBI was used on Turbo VW's for years. Same goes for Holley Commanders ... If the manifold flanges to the air door, the EFI works.

EFI doesn't care what engine it's on.

Going forced induction later on negates using SU's.... And a bonnet Four Batrel? Well that's surely been done to death.

If you limit your searches to L-Specific installs you limit your knowledge. Period.

The reason most of these projects fail is precisely because people put blinders on thinking a Chevy Blow Through reacts differently than a Datsun Blow Through.

You need to decide on the project you want to do. If you do all this long range bench racing "what if" contingency planning it never gets started.i know guys talking about their ideal build since 1985. To this day their rattle trap pos sits with Bondo zits and a bunch of half-assed attempts at interim steps, but never clarity of vision and focus to complete anything. Always holding up waiting for the next magic bullet.

Pick a route, see it through. Then see where you're at and see if it's a place you like. If not, change it.

At least you will have done something!

As for "discussing to death" four barrel EFI on an L-Series, there really isn't much to discuss. People wanting EFI generally go for port injection, not TBI. Those that are TBI satiated generally are of the "it works I'm happy" mindset and that's the end of it.

It's not a combination that shines in any particular way. It's just something you do to get a roller rolling. There are better alternatives for high performance and for near-stock performance. I mean, Patton's adapters are less than a new Holley, fit in the SUs most have on the car, and the rest of the EFI can be Bodged from stock nissan cast off parts and a Megasquirt.

-

In the old days of cheapness, be would take the big jets out, heat them with a LPG torch and solder the jet hole solid. Then re drill with the smallest jet-drill you thought would work, and trial & error work it from there until optimized.

Then buy a set of proper Holley Jets.

Then move on to transition tip in on the vacuum secondaries and the metering rods...argh!

-

DAMN WORK GETTING IN THE WAY OF OUR PERSONAL SIDE JOBS!!!!

-

It's not "Guinea Pig", it's been done. It just predates the Civilian Internet. Retroactively dissecting a working system for the purpose of documentation is more work than its worth.

Guy goes and takes apart a perfectly functioning system that's been daily driven for 20+ years, only to have idiots on the internet pick apart the work (by people too stupid to acknowledge a functioning system, and bent on bench-racing in mommy's basement.)

There really is no upside for someone who's done it, to go back and explain it in public after the fact.

The least expensive EFI system you will have is a Megasquirt on the stock EFI manifold, or a Megasquirt driving Patton Machine TBI Drop-In Adapters. Hell, with the Patton Machine conversion, you keep all your stock air cleaners and linkages, no hack job crap with bad filtration and hood clearance issues.

-

4BT? I've got a 4JB1 and putting a 4BC2 into the chassis I have...no turbo as yet, but going from 2.8 to 4.3L will make the longer trips fully loaded easier! NPR Cast-Off Engines and Transmissions.

-

I'm using Forged rods... Stock. They're all forged.

-

KGC10, they're out there, talk to Elvin Wes in Pomona. I think there was a nice box skyline on his site for around $41K...

-

I wouldn't bother until you get them all three.

The LAST thing you want is one carb with cool fuel and different density fueling two cylinders and hot gas in the other four!

I'd put the fuel cooler on the return line (and the feed line for that matter.)

If you have A/C, you can wrap the cool line in copper coil and then put insulation foam over it and use that to cool the feed or return---caveat being it's only functional when the A/C is running...

-

Lotta work...

Not really up on the 4305 specifics.

Generally speaking the best way to get torque is get your boost threshold as low as possible, use a higher lift cam with the head match ported for the lift (if your ports flow 220 at 475", then stick with a 45 lift cam, etc...) Get the cam timing to bring the cam on after you hit full boost and pull. Uncork the exhaust.

Most people I see have an A/R far too large. JeffP thought he "needed" that .82 on the hot side...but in fact when tested his wheel cut and 0.63 had no more exhaust backpressure than inlet pressure (something Corky Bell says only happens in F1....) That smaller hot side brings the boost in lower, and gets you 2-3# right off. That in a cammed engine makes for a LOT of torque.

If you want to add methanol, and put your timing back to what an N/A normally runs, that gives you gobs of torque back as well. But there's that tank capacity issue.

There's only so much that's going to happen from injector placement. If you're starting from a clean sheet that may be one thing but retrofitting to an existing engine piece will always have it's payback limitations. I'm not really following the second plenum feeding secondarily into the injector ports...is that for some 'swirl' to tumble the mix and get a more homogeneous inlet charge? The injector angle is not optimal for that, you would want something tangential to the valve bowl area....and that may be pretty counterproductive for clean laminar flows acting like an "Air Knife" at a drive through window...effectively hurting ultimate flow into the cylinder rather than helping it with additional injected air at the valve pocket.

I guess the only way to know for sure is to try it!

-

Shed nominee, since searching is not his forte (everything asked is already copiously answered...)

Asks for "OPINIONS" and then gets butthurt when HE GETS THEM!

If money is tight, a performance sports car is not in your future.

G'bye!

-

My stock "Blue Turd" 260Z routinely turns in times at S30 AutoX events like MSA very close to top time of the day. The instructors seem to like competing in it.

Work on the handling until your funds are better. Get the chassis sorted and prepped first, and learn to drive the car first. Power is the last thing you need to add right now.

-

Most of those Home Depot Packaged IR's use the same pump head at different speeds for different capacities. Durability will always be better at the lower end of the frame size.

You can also get a 7.5hp compressor and put a smaller motor pulley (and 5hp motor if you're feeling ambitious!) Your compressor turns slower, you only use the 5HP of energy, and increase pump lifetime. If you need more capacity as you grow, you can always refit the original pulley for the original 7.5HP Capacity.

This works really well if your wiring or circuitry is limited. It really depends on what used unit you can find. There seems to be a lot of 7.5 hp recips out there...not as many 5's as there once was.

Turn the lower speed and cut out based on motor amperes verified by an amp clamp. Turning them slower than the direct ratio will allow them to pump up a bit higher in pressure before max load on the motor is experienced.

-

Right now, there is an Atlas Copco GX4FF on tank for $2,900 buy it now on eBay in the LA Area.

The GX series was the Single Phase Version of the "GA".... It's complete compressor, dryer, medium sized tank.

This would be a smokin' deal... And perfect to hook up to my 600 gallon tanks!

In fact, since I'm gonna be there in less than a week now... I may be replacing my dead Devilbiss Oil Free with an Atlas Copco! Killer deal.

Just be aware...most of these compressors are rated at "KW"---so yeah this is 5 HP. It's 4KW with a 0,3 KW dryer for package electrical costing. You turn this on and actually USE all the air it's making, that's 4 Kilowatt-Hours.... Know your power costs.

-

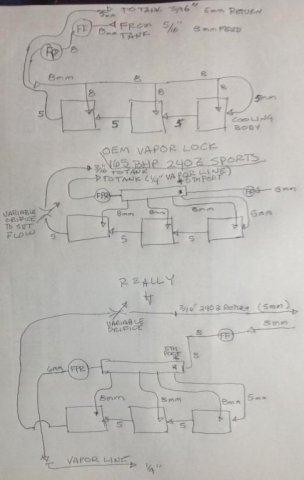

The fuel cooler could be in the feed line coming up to the engine bay, and then one on each return.

Return from the engine bay is hot, no matter what. I like to open loop the tank, and use the vapor line as it has far more flow capacity than the stock return. I also tended to use EFI pumps that flow like crazy so the two return circuits at 3.5 psi is not a big issue.

How much is my car worth?

in Non Tech Board

Posted

That was my sarcasm....

It's my sarcasm you miss...