-

Posts

9963 -

Joined

-

Last visited

-

Days Won

74

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Tony D

-

Cutting my firewall to improve cooling??

Tony D replied to datsun_dom's topic in S30 Series - 240z, 260z, 280z

The Z really only needs a properly ducted 4x28” slit across the front to cool it. Keeping excess air getting in helps stability and aerodynamics. cutting three inch holes under the battery and brake master cylinder has been proven to be extremely effective venting position (low pressure area opposed to high pressure area at cowl) people put thermostatic controlled fans on the exhaust side to force flow through / out in stop and go traffic. no need to go through the upper firewall except to duct inlet air to your intake… you would be surprised what kind of static pressure exists there even at highway speeds… especially compared to behind the wheels in the left and right fender area! vent high pressure to low, and you use/require less open area to accomplish the same exhaust flow… -

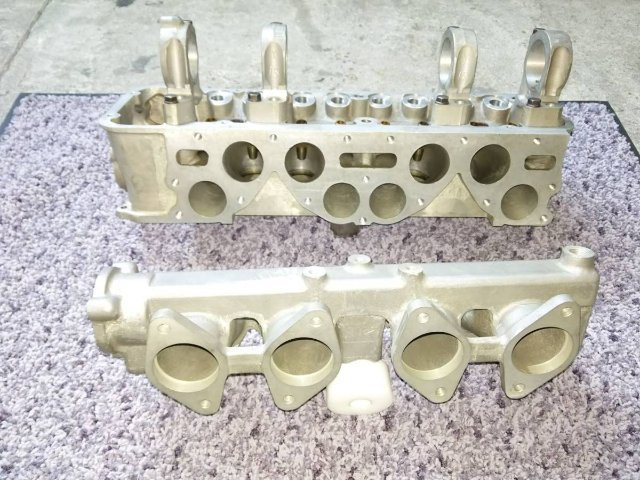

OK, now let’s mirror-image this Beyatch, size it for 50mm’s and hang it on the Right Side of the Datsunworks DOHC (which since it’s CrossFlow can use plastic additive machining to knock it up and prevent heat soak…) Thank God the bore spacing remained the same! My Necropost for 2022…

-

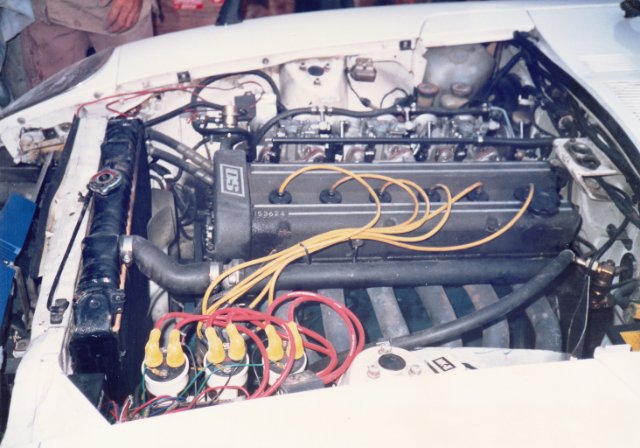

Parts bought out of the Nissan "Yellow Book"! Ahhhh, the good old days! I remember when Nismo was birthed. Long after the S30 was out of production, that's for sure!

-

As I said, this is mischaracterization of poor engineering on the builder's side, and anybody reproducing it with the intent of using it for 'high performance usage'. The characterization of the stock head having "a problem" is incorrect. The characterization of the JMC having the same identical problem WOULD be a 'design flaw' as the issue is known, as is the solution! The L-Head as was on the cars stock was not intended for more than around 220bhp, and even then they blanked internal bypasses and ran 2bar radiator caps. They ran those heads in production car categories. Where the rules permitted, they ran the LY head, or FIA head which was intended for sustained 220bhp+ production. It's like the breakpoint for applying the R200 in a chassis compared with the R180. It's curious Subaru who also uses the Fuji produced differential seems to follow the exact same application for intended horsepower and torque that Datsun/Nissan did back 45 years ago.

-

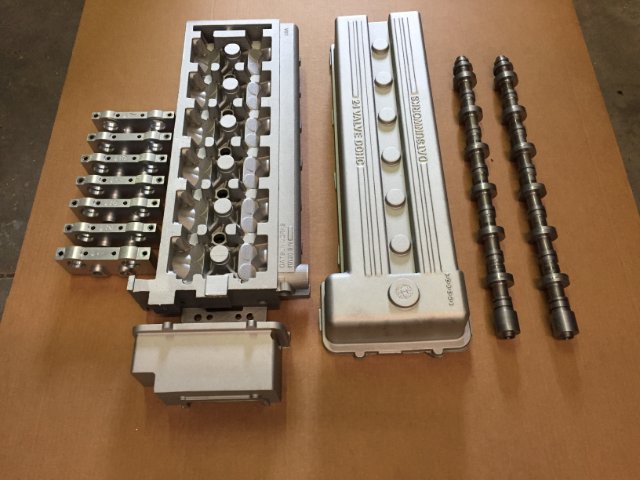

Twin cam head for the L6 from Derek at Datsunworks

Tony D replied to Derek's topic in Nissan L6 Forum

"One?" -

No, really it's logical. The head is altered and likely is just as illegal to run in any sanctioned events as the DW head. If I'm plunking down $10 Large + for a head to be done up... I'm not getting one limited to maybe 250 cfm. On a good day. With huge lift and all the buggery that entails. Truthfully the DOHC would be easier and is the logically-minded next step in the engine evolution. Now, if they reproduced the FIA L6 Head.... THEN we might have some competition. The L6 FIA head already HAD 'equal exhaust ports' but then people would whine about their existing headers not fitting, or that they couldn't buy and fit $149.95 Thunderbird Headers on it and had to pay money for custom speed parts... The "Rent, Baby Milk and Daipers Crowd" as John Coffey used to say! And besides, the Datsunworks head is a brilliant adaptation of modern port theory and combustion chamber design mated with modern production techniques that make previously impossible things possible at an affordable price! Whomever thought up that whole scheme and put it into production is absolutely Enstein-ly Brilliant! True L-Godz! All should supplicate themselves at their feet and pay homage...

-

Run the stock build engine and spend your money on porting, polishing, camshaft and EMS along with a properly sized turbo. An all stock L28 at stock compression ratio of 8.5 will run 350hp without anything but be somewhat of a boring ride IMO (see end for why.) A bone stock L28 N42/N42 bottom end with a ported, polished, cammed and fuel injected (Now, was blow through mikunis) EMS can make upwards of 450HP at 17psi with a GT35R strapped to it.... And that's limited to under 7,000 rpms. Once you get all that sorted, and are satisfied with your build THEN buy your pistons and retune as you deem necessary. By that time you will know what you are doing, and breaking the pistons will not break your bank. I know someone who did not listen to this device and spent upwards of $6000 on engine 'refreshes' before he listened, put a stock bottom end under his head and bolt-ons and then blew those pistons three more times before getting it all right. But those pistons and rings only cost him $200-300 a set (ITM off eBay) and he learned that after the Fel Pro Gasket blows three times, likely the pistons are shot... All those failures on the stock bottom end didn't add up to the costs of ONE refresh of his forged piston built engine. He was mildly annoyed that a stock bottom end ended up besting his 'first generation forged piston' build by some 25 odd horsepower and at only 17psi instead of 30! Spend your time on fuel delivery and airflow, same as an N/A. Then worry about durability. You WILL blow up your engine tuning it if you're going after big numbers, and even if you're not clogged injectors can sink your setup at 8psi as spark knock at 30psi. I'd never put a MLS head gasket or Forged Pistons in a Boosted Build unless all major tuning is over and I was satisfied with the results to 7,000 and only had 7,000+ left to tune. Even then, I'd keep a Fel Pro Gasket in there for a 'safety valve' in case detonation occurred. Blowing a $50 head gasket is better than sinking the rings on 5 of your cylinders because a fuel filter decided to explode and clogged all your injectors! Identify your power goals in advance, and work to them. Don't get greedy and make components do something they aren't capable or suited to doing. Under 400HP cast pistons will do just fine unless you want the engine to ACT like an L-Series and pull to 8,000... then you will need forged pistons and woo wheee will it be fun to drive compared to a big boost low-flow setup which will basically be a Boring Big Block Corvette setup. Sell the Z in that case and buy the Vette...

-

Not really, until the valve head is away from the seat more than a given ratio to it's diameter, it represents a flow impediment. On a ported head capable of flowing more, the further away that valve head needs to be to not impeded the inward rush of airflow. Since the valves are relatively large, compared to a DOHC Valve and do not tilt inward away from the cylinder walls like a Pent-Roof DOHC again... it represents a "shrouding" of the valve. This is why people cut the heads combustion chamber in the area of the valves... it 'unshrouds' the valve at low lifts and represents a considerable amount of flow increase (ESPECIALLY on Turbocharged/Supercharged builds) given the assymetric nature of the cam profiles used on Nissans and their time spent 'just off seat'. If he's got large ports, it only stands to reason that higher lift gives more flow. If the porting is conservative, you will hit a wall and not flow more regardless. Even at that, you can still use a higher lift cam as it will spend more time "under the curve" at the peak flow number with no restriction at all than if you used a cam that only lifted to the max your head was capable of flowing.

-

Is it possible to bore a l24 to fit 89mm pistons

Tony D replied to Estoque grigio's topic in Nissan L6 Forum

Fitting Liners is the way it was always done for big engines. You can muck about trying to find a block that might take a boring (and that usually is an L28 Block) but overseas where block casting numbers as well as stamps are checked for compliance with national inspection criteria, people have been making 3.2 liter L20A's since the early 80's when I was in Japan. This obsession with boring on OE metal and aversion to Liners is just laughable to me. How many Keith Black Hemis are there that don't run Sleeves? Different animal altogether I understand, and different maintenance routine for sure... but if they'll handle over 1,000 HP per hole, I think a liner will be just fine in any L-Block... just mind the head stud clearance as that's the OD Max Limit... Or IS it? Mowhahahahhaha! -

When you call Ron at Isky and tell him you want an "all out performance cam" after all these years he realizes there are two kinds of people out there, and his first question is "do you mind cutting your pistons?" If the answer is yes... ohhhh the wonderful things he has for you!

-

Now, you want to discuss an SOHC head that SHOULD have been reproduced? For $6K? FIA Group 4 Six Cylinder SIGN ME UP NOW! For the money given the JMC current offering? I'd buy a Datsunworks.

-

Guys, this is not a "5/6 Problem"! You're trying to make a silk purse out of a sow's ear and blaming the OEM for incompetent and uninformed aftermarket engineering when increasing performance! Look at the Nissan L6 FIA Group 4 Head, the LY Head, and the S20 Head - all Nissan "HIGH SPECIFIC OUTPUT" heads and you will find they have a SIGNIFICANTLY different way of handling water flow through the head, and all of them handle it almost identically! And unfortunately without an external water manifold to remove the "flow knife" action of cylinders closer to the water pump obstructing flow back along the exhaust side to the front of the head to take it off to the radiator. The solution to this is simple: take water off the top of the cylinder to an external manifold which can be designed like an exhaust header with subsequent cylinders creating a pulling effect on the downstream cylinder to promote flow out of the head. The knowledge of this "issue" has been known over 50 years! It was decided at Nissan that there were high specific output heads which addressed the issue, and cheap to make production heads for the millions of vehicles they planned on selling with the head in it. It's not "addressed" because most people aren't making over 220hp (which is where Nissan started using those heads...) and because people think a $5,000 bare head is somehow 'unrealistic' for purchase. And $35,000 for a bare vintage FIA Group 4 or LY head is absolutely out of the question. Note the aftermarket heads use the "take it off each cylinder" model, either integrated, or external.

-

Those bolts are there for alignment off-block. The towers are NOT line-bored, they are assembled on a mandrel. If you make an installation mandrel you can get them installed in one shot-but you need those bolts to secure the towers in the proper orientation. The production mandrel was expandable, so it held them centered till pulldown, and then retracted into itself for production removal. To make one you just duplicate a cam bearing diameter minus about half the normal clearance. It is a BITCH to get the mandrel out if the head is not properly decked and warped on the top! You can set it up near full clearance but the real answer is to align them properly on a properly decked head and then effortlessly install your cam without any adjustment necessary. You can centerless-grind the mandrel, but the one I made was just turned on a lathe. If you find the right size of pipe/heavy walled tubing (like Schedule 80) you can set up the mandrel (tight clearance tolerance) and then pack the core with dry ice and alcohol and pull it right out loose as a dockside er... "sporting lady"...

-

He's diagnosed it properly, and this is a known issue. The angle the injectors enter the bodies will impact the wall of the curved runners and make one hell of a Tau Layer causing those cylinder to run richer. The issue isn't really 3/4 running rich, its that the other four are running lean and the spark knock is coming from the hottest cylinders. Cool off 5/6 at a minimum to resist hotter conditions that promote the knock, as well as dropping the thermostat value to 160/72C. Jet/Tune for 1-2-5-6 best lean torque or best rich torque depending on your tuner's preference and learn to live with that compromise.... Or switch to a Sequential Unit like MOTEC and then cut cylinder fuelling on 3 & 4, (and maybe ignition if necessary) on those two cylinders. This is common in high end turbo builds where you have to pull timing per cylinder based on the results from the dyno pulls. Make sure you have EGT and/or WBO2 on EACH cylinder and data log it during the pulls and you can dial it out with a MOTEC (maybe others, I've only been around MOTECs doing this type of tuning.) For the $5000 the MOTEC will cost to fix it... likely just instrumenting up properly, fixing the cooling on the rear cylinders, and tuning for them and not off 3 & 4 and leaving them run rich will be the chosen approach. NOW ALL THAT SAID... For all those who poo-poo the Shorty Mikuni Manifold, these issues DO NOT exist with it, because almost every injector angle will impinge on it's back wall and make a big Tau Layer of fuel on which to draw... it's make for hell tuning for transitional emissions, but for quick and dirty tuning where you are not very strictly emissions controlled that is a way you get homogenized fuel mix in each cylinder because all the cylinders make the same "sharp turn down" before making any other adjustments for the head entry. If you can find one, that is a cheaper option than going fully sequential and all that it entails.

-

I have seen both the wiring and the AC lines run through those tubes-they access straight into the cabin where all the connectors are, so it's a pretty easy way to do it, just put some chafe guard on it (nylon spiral wrap) and you can probably get away with it forever. I only say that because there's really no practical way to secure the bundle inside like on top of the frame rail, so it's bound to move and start chafing. You can pull your wires out to the necessary components as necessary. Running the alternator wire through the frame rail and everything else into the ventilation tube would virtually keep all wires only visible from where they break out to where they connect to the alternator and coil. And those could be very short indeed!

-

I have to admit, I buy it by the case, and smuggle it in across the CA border (same like buying some of those engine powered devices from Harbor Freight 'not available in CA'...but they sure ship to Phoenix!) See if you can find it on Amazon and get it shipped... Grainger won't so don't try there. The key is the methylene chloride content, that makes RTV lift and pucker like crazy. We use RTV on large gearboxes and yeah.... you can scrape it with a razor, but when the flange is 4 to 6" wide, and about 20 linear feet.... I get the spray-on gasket remover and spraying that stuff on it and just wiping it off after it sits for a while leaving a clean residue-free surface really has appeal. See if you can find Loctite Chisel Gasket Remover. Just mask well because it takes EVERYTHING off if you let it sit long enough! https://www.cbrg.net/chisel-gasket-remover

-

Twin cam head for the L6 from Derek at Datsunworks

Tony D replied to Derek's topic in Nissan L6 Forum

I can think of one or two... and it's right in the running horsepower-wise both N/A and potentially turbocharged. -

Twin cam head for the L6 from Derek at Datsunworks

Tony D replied to Derek's topic in Nissan L6 Forum

For repetition and completeness sake, that is possible on the current non-crossflow head. Add about 400HP to that estimate for this head... if you can keep the bottom from moving around. -

Yep, you would be wrong. At least you're open to that idea. There is no reason whatsoever why an L28 isn't an 8,500-9,500 powerplant same as an L24. No "large bore" necessary, we were limited by class rules to no more than 3.0 and if anything we would have stroked it for power more than bore it. The L20A was pretty much capacity classed at 1998CC, needed stock bore and stroke on that one, and it went to well over 12,500 without any valvetrain issues whatsoever. The limitation is breathing ability of the head N/A moreso than anything in the bottom end. That's benchracing in the extreme. We built both the L28 and the L20A in a home garage in Clairmont, CA. The head work was farmed out, everything else save the balancing (which was done by Electronic Balancing in Long Beach, just down the road from the old Datsun Alley and with a nice view of the C17 taxing area at Long Beach Airport)... Fitting the pistons to the combustion chamber, pre-balancing weight matching, deburring, polishing or grinding internals, etc... all done at home with Sears Craftsman Tools and whatever I and Andy had kicking around our tool boxes.

-

Sadly, before the Koreans hijacked my YouTube Channel, I had videos of us making runs at El Mirage where we shifted at 9,500, and 9,300 depending on the gearing or tire height. No titanium Retainers or Spring Caps, and we ran that engine to over 12,500 doing valvetrain stability tests without any issues whatsoever. An L24 will do it easier than an L28 or larger simply because you are limited on flow through the ports on the non-crossflow head (about 240-250cfm max) and that will cap your power peak realistically in the 8,700 rpm range. Been there, done that, got the videos to prove it. Got the land speed record plaques and jacket as well...

-

RT Diff Mount with Energy Suspension top mount and L28

Tony D replied to wheee!'s topic in Drivetrain

For all this talk of OCD.... nobody has specified which mount they used cutting the urethane to match the nose of the R200. Whee! did a great writeup, photos, dimensions, etc.... but never said if he started with the 3-1108R or the 3-1158G! There's roughly an 8mm difference in height between the two and that looks to be what he cut in the arch when you take into account the bottom doubler strap is removed to make the ears fit "flat"! So there's the big question: Are you arching the 1108 or did you arc cut the 1158? Inquiring minds want to know! -

COVID-19 will make Facistbook go savage eating the young...and people will get bored at the nonsense... and flick back to see what's up. Hell, JeffP got with Cometic an had them make an all-new gasket to his specs!

-

Have those cars sat out back for 20 years now? Damn, I guess they have!