-

Posts

229 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by supernova_6969

-

-

hey!

no a great solution, but if they seal and if the paint and the body is fine under the seals, i'd just leave them there, tape 'em and paint over them.

like I said, not an awesome solution, but it should work for everything but a close inspection, or a full stock restoration.

S.

ps: you could try to separate the very top of the seal from the body to let some paint go under that first 1/16th of an inch, and then glue the strip back with weatherstripping glue. if you do, make sure to use it properly (I didn't): you need to spread the minimal amount on each side, super extra thin, let it dry, and then mate them. It's like contact cement...

-

Thanks g-tech.

I'll see what i can do for making the striker part with that. Anything less than 10 years old should be pretty acurate...

As for ebay, i'd check before, and just did again because i didn't remember the results. The rubber cover can be had for less than 10$ each, which is not so bad. But the strikers are all more than 40-50$.. Good to know!

-

madkaw:

Wouldn't longer runner steal some of the low end torque? (Or is it the opposite?)

As for the bigger plenum, what are the advantages? Is it because it's simply a bigger container from which the pistons can "suck" from or are there other advantages? Wouldn't having a efficient (i.e. less restriction) pre-plenum system make up for that?

Got a build thread or some photos of what you are building?

-

Hi!

The doors on my 280zx are rattling (partly cause the striker is worn) and the rubber cover/ bumper on the drivers side door switch is worn through, which makes the metal striker hit the door AND makes the door light turn on all the time (its great when the car thinks your door is opened overnight. Does wonder to battery charge)

Two questions:

1. Can anyone tell me the original, brand new diameter for the plastic part of the door striker? I'll try to 3d print a replacement and see if that can work (possibly with a rubber core.. I'll post something somewhere if it works)

2. Can anyone tell me of a good place to buy the rubber cover for the door switches? Looking for price as a primary criteria...

Thanks!

Seb

-

Hey Guys.

any new trips to the dyno, anyone?

s.

-

Thanks dexter.... I appreciate de extra info, i would never have thought of it...

-

I'm thinking since the pump is higher then the oil level in the pan, it should not start to flow from there but i'm not certain.

Any one ever tried?

-

again, hijacking. about that awesome sound. I have a turbo car, and i'm thinking there is no way, even if I change the headers and the turbo-back to the same as yours or so, that I can achieve a similar sound because of the turbo acts as a kind of muffler....

is that right or am I mistaken? I don't know much, it's my first experience with turbos...

-

so, ok.

your car, at least the exhaust, sounds godly. just the other day, I was listening to a vid with a vintage 1950s aston martin (http://jalopnik.com/aston-martins-answer-to-ferrari-in-the-late-1950s-sound-1790551967) and your vid reminded me of that.

yours is a bit more throaty but god does it sound good. what kinds of revs did you go up to, when you were really punching it?

let me hijack your thread for about two posts (mine and yours) and ask you what is your exhaust (I've seen your custom headers, but I forget what you're running for pipe and muffler)..

thanks! and I wish my car sounded as good as yours....

seb

-

looks fantastic. but can you dim the gauge faces ( I forget if you mentioned it before)? looks like they could be very very bright against the night.

but very cool looking...

-

hey

I did mine in a '83 2 years ago, and i'm about to do it again.. I posted a full thread on that

http://forums.hybridz.org/topic/123168-changing-oil-pan-gasket-on-l28et-with-engine-in-car/

I hope you are luckier than I was..

s

-

that is stunning, tim. sorry to hear about the trouble at the dyno. sems like any regular old day at my house, but it sucks for a proper dyno day..

what a beast though, honnestly.

quick question. since the CR is so low, how does she feel under 3000 rpm? I know, when you're racing or even driving, it's rarely there, but i'm curious... seems like you have quite a lot of torque (around 200ftp starting off at 25000rpm), but not that much hp..

in the end though the real answer is not in the numbers, it's in driving it. so, while there is NO question your car pulls like a train above 4000, how is she down low?

s

-

so... anything new going on? can't wait to her where you are at with your Z!

-

hey guys.

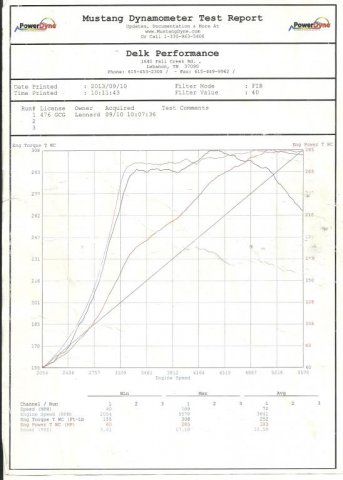

A new buddy of mine, David from the MsExtra forum (turbo conversion) shared this dyno sheet with me.. here are his basic stats:

1- 1976 Datsun 280Z L28ET

2- modified 2.8 turbo

3- 285 HP @ 5000rpm @ 17psi

4- 308 pd/ft @ 4000rpm @ 17psi (with a nice long flatline around 290 before that)

5- Megasquirt, modified 2.8, with Garrett GT35R T3-T04E stage3 50 trim 63 A/R housing (18 lbs. boost), custom grind cam 2000-6000 rpm, 440cc injectors, intercooler, 3" exhaust turbo back, LC-1 o2 sensor, Hallman manual boost controller, EDIS 6 ignition batch fire, 60mm throttle body.

7- has a r200 and spins wheels in first and second. seems like a sick machine.

feel free to comment or question, he's curious as to what people will say.

-

one thing you can do also to increase compression without changing very much about your engine if you think it's solid is to change the head gasket to a fancy, super thin one. you might be able to get yourself a few points there, without touching the shape of the head or the piston.

alternatively, you could keep the short block as is (in the truck even) remove the head and have it machined/shaved. but you'd need to verify valve clearance on the pistons and make certain of the type of gaskets you'd need, in case the shaving changed the shape of the head to block contact.

alternatively-alternatively (

), you could have the block shaved a little bit, and keep your dished pistons and your head... again, if the valve clear them, and if your head is flat enough to bolt right on to a new, shinny flat block surface.

), you could have the block shaved a little bit, and keep your dished pistons and your head... again, if the valve clear them, and if your head is flat enough to bolt right on to a new, shinny flat block surface. be careful in setting your cam timing after any of these though as the difference in deck height screws it up some.

-

hi!

this is old, but did you ever figure out how to hook up the stock knock sensor to your megasquirt?

s.

-

Hi!

quick update to an old thread.

the stock pump was doing ok (I used a t junction after the fuel filter, and ran a hose from that, outside the engine bay through the open hood, right in front of the driver; i was able to monitor fp in real time..)... but I still decided to change it, just in case. I installed the walbro 255 on my car, complete with a fresh new 12 ga wire straight from the battery (through a fuse and a relay triggered by the original wire)...

Walbro pumps have a stupid metric thread and it's hard to find the proper fittings, so I ended up having to use 1/8 npt that I re-thread to M10 (they are almost the same, so that was VERY easy) on the "out" side, and on the "in" side I ended up making my own fitting with a lathe... the "in" side comes from a 12mm hose which is too big for anything that is commonly available in 1/8npt...

long story short, the regulator is still alive, regulating away like a champ... as far as i know..

case closed

-

mmm...

on my car, I only hit 0 psi (aftermarket gauge, and on the Megasquirt reading, which has it's own pressure sensor) when I am at WOT. anything less than WOT has at least some vacuum. at least when i'm driving, I've never WOT while the car is standing still, I've had it drilled in me that you shouldn't rev without load if you can help it..

do you happen to have a vacuum gauge around that you could use and compare that reading with your car's gauge's reading?

-

hi!

resurrecting here, but I have some new, significant info about this.

I did end up moving my IAT sensor to the pipe that I insulated, over from the manifold. measured temperatures when from anywhere between 100f and 200F, with wild, rapid ups and downs based on throttle (closed throttle = hot open throttle/boost, cold).

since I've moved it, anytime the car is moving the recorded temps are about 10-20 above ambient (these days 65-70), and they haven't gotten past 102 (in heavy traffic). And there is no wild see-saw based on throttle, it's just a very stable reading that only slowly increases when the engine bay increases..

I've checked the pipe temperature (with my hand) after a drive, with and without the wrapping, and if it's not insulated, the pipe is warm-ish. insulated, it's actually cool... so the insulation makes a difference in the pipe temp. does that translate to air temp? I'm doubtful.

HOWEVER! I've realised that the insulation could actually increase the hot start heat soaking issue; an hour or so after the engine is shut off, the pipe is actually mildly warm while everything else is mostly cool (not the engine, but the surrounding metal). so, yeah..... I think it could help with very short term hot start (say, you shut the engine off and start it again withing 10-20 mins), but anything longer than that and there might be a slight downside..... IF it actually does anything.

I'm still considering doing something in the same family of a cold air intake, but have changed my mind about how I would do this (I originally thought of moving the filter down low where it could breather the cold air from under the car, with or without some kind of splash guard)... My new Idea is to drill holes in the sheet metal under the air filter (the very front part of the wheel well, between the light and the stock coil location) and building an air box that will only allow the filter to breathe from there and not from the hot engine bay. that should make certain that the engine breathes cold air no matter what the engine bay temps. and yes, i'lll do something to prevent water coming from the wheel to splash up, right into the intake...

I guess I'll try and then post about it.

I guess I'll try and then post about it. -

Hey!

I was wondering if an admin could change the title of this thread to:

SOLVED!! - Air intake temperature SOAR when I step off the gas

thanks!

seb

-

so, yeah, you do know what you are talking about; I'm the one who completely misunderstood what you were talking about re: the flapper.

I just watched your video, and I was wondering if it was me, or if the car sounds like it's struggling the whole time? It might be me or the sound recording, but it sounds like it runs rough the whole way, and worse so when you get close to WOT....

Is the AFM output testing included in the tests you did as per the FSM?

I know you tried to change the AFM settings (moving the teeth so it to thinks it's got more air coming in) and it didn't help all that much.... I find it weird that when you fool it into thinking that it's getting more air by setting up the mechanism differently, there is no change, but when you fool it manually by physically opening it more (which in the end should be exactly the same thing as jumping some teeth I guess), then it works.. have you been able to see if there is a significant difference in how much each technique is changing the AFM output? maybe the teeth changing thing gives it too much or too little, and the screwdriver forcing it open gives it just enough....

one thing you can do I guess is to see if, when you do the screwdriver but push it all the way open and see if it makes it soooooo rich that it stalls the car out, or at least start smelling very rich (that can be done at idle, I suppose). that could validate that the AFM is working (not necessarily well though).

another option (I don't think so, but...) is that you might have the right amount gas going in, but that for some reason (I wouldn't know what) you engine has a problem that makes it want more, want to run rich. When you do the test with the screwdriver thing, does the exhaust smell like it's too rich (provided that the person holding the screwdriver is holding the flap up JUST ENOUGH to make it run well, not all the way up)?

-

looks really good. make certain you don't back up into anything; without the shocks in tehre, there is going to be significantly more damage.

but it looks REALLY good. more modern.

-

you said:

"When I have the air box off and rev it to where it starts to cut out and have a friend push the flapper open a little more with a screw driver it goes away and revs strong like it always has...."

what flapper do you mean? the throttle body valve? that circle that blocks the throttle body and turns to open up when you press the gas pedal? sorry if you know what I'm talking about but are talking about something else (you seem to know what you are talking about, so i might be misunderstanding what you're talking about).

If opening it more seems to be helping a whole lot, then I'd start looking at that. for example, does the throttle plate open all the way if you press the pedal (for that one you'll need someone to press the pedal all the way in while you look, and you shouldn't be able to force it open any more than it opens on it's own)? if so, then i'd check if the TPS is well hooked/attached to the throttle plate; it might think that the plate is not fully open and tell the ECU to send less gas that it needs...

if pressing the pedal does not fully open it, then i'd all the elements between the pedal and the throttle plate. you might need to adjust something or another for wear or stretch.

all that said, a throttle plate that does not fully open would not produce the symptoms you mention (unless there is an issue in the connection with the tps, like I said), they'd just make is like you haven't pressed the pedal all the way. I'd still check it, but...

if you meant that you only open it a little bit more and it solves the issue, then it could be that for some reason, your engine is getting too much gas/too little air (my car runs insanely rich, i'm working on that, and when it's too rich, it'll just bog down.. same as if too lean.. it's just creating misfires, one way or the other). does the exhaust smell rich?

have you checked your fuel pressure? a new pump might be overpowering the stock regulator, if it was old and tired to begin with. it might even leak into the intake, although that would create issues at idle. an easy way to test the regulator is to unplug it's vacuum line and smell it. if it smells like gas, it's done for. if not, then plug it back, start the car, unplug it and either blow in it and suck (really hard) to see if that changes way the engine runs. it's rudimentary, but shows you that it works (not necessarily well)....

let us know.

-

so it's been a full year since anyone wrote here. this is a bit of a resurection, but there is a good reason for it.

I 100% figured out what the problem was. well., I didn't figure it out. i fixed it.

Pretty much everyone was right: it was the location. I had a friend weld a bung in the pipe right before the throttle body, and the temperature went from:

- anywhere between 100 and 200 degrees F, along with wild spikes based on when I'd open or close the throttle,

to

- anywhere between 60 and 100, with no spikes at all, and the temperature only slowly climbing when i'm stuck in traffic (which is probably a combination of very mild pipe heat soak and significant high temps in the engine bay, where i currently get my air).

I wanted to thanks the guys who did suggest I do this. I also want to put out there that i don't think that the intake is a good location, no matter how well you tune for it (against it?). Even if you use the air temperature correction thing to make up for heat soak, or the cold start enrichening (?) thing, you're going to correct for when the MS2 thinks it's hot, but if you ever actually do get some hot air, it'll screw your tune.

Thanks again, and i hope that comes to someone's help in the future.

s130 l28et z31 engine harness and ecu swap

in S130 Series - 280ZX

Posted

Hey.

what's your goal in this swap? I'm not familiar with that specific swap, but i see some potential issues right off the bat:

-the harness PROBABLY aren't compatible. that means a lot of late night soldering.

-the EC you mention is for a N/A car. problem with that (unless it gets flashed, and I'm not certain if that's what you want to) is that the fueling tables won't have any data for boosted areas..

-that ECU is either made for a 3l or a 2l engine. that would mean either too right or WAY to lean all the time...

-timing tables are made for a more modern engine, which could mean potentially better designed, which could mean potentially with more advance (better design = less pinging potential).

I don't know how much you'd pay for your ecu, but it might be worth looking at aftermarket fully programable ECUs. they'd work once tuned, and plenty of people have done it. Megasquirt (supercheap, can work awesome), wolf, I think makes some, haltech does, and a few others.

actually, with all the mods you're planning on making, especially with the new turbo and the injectors, one way or the other, if you want your car to work well, you'll need to put it on a dyno. unless you have the ecu for free and it's easily reprogrammable, i'd just simply look for aftermarket. ask your favorite local dyno shop for their favorites, and pick one.