-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by OhBilly

-

Don't forget to drive the car and have fun with it while you're chasing the noise down. At some point I believe you'll find that you can't get rid of all the noise in your AFR readings and will just have to accept it for what it is. I could be wrong but that's the impression I get from reading more and more about the LC-1. All the whiz-bang gadgetry we have access to makes it great for tuning and dialing things in just right, but for me it is becoming cumbersome. Before I got my wideband hooked up, I was stoked the car was actually running and idling smoothly. The one time I drove it, it actually drove quite well and I couldn't have been more pleased. Now that I've got the wideband telling me my AFRs are too rich at idle, I've been fiddling with it and trying to get it to idle smoothly at what I would call a reasonable AFR, but the car just doesn't want to cooperate. It wants to idle nice and rich, so who am I to tell it otherwise. I've learned a tremendous amount during my Megasquirt journey but I'm getting more inclined now to turn off the laptop and just drive it blind... like the good old days.

-

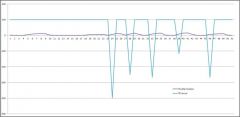

I had the car parked and was letting the car idle and revving it up a bit while datalogging. I have my accel enrich set to 100% TPS dot. I'm using a 240SX TPS and I believe it is wired the correct way because as I depress the pedal the TPS reading in Megatune increases. In looking at the datalog, whenever I revved it and got TPS accel to activate, the TPSacc value in my datalog is negative. Is this normal? EDIT: In searching a bit more, a few other posters had similar issues and it seems this problem is limited to the 029y4 code, which I am using. Is there a fix for this? Pic attached. Thanks. Bill

-

MSA downpipe, with an additional bung located at the downstream end of the pipe. Original bung is plugged.

-

Funny, but it's actually the other way around. The next time I started it I got the same goofy resets that I attributed to the coil wiring, but as the car warmed up the resets got farther apart and after a minute or so they were gone completely. The resets may coincide to the LC-1 sensor warming up but I'll have to experiment a little more with it to be sure. Only other thing I can think of is that it was running so rich during ASE and the first part of WUE that it caused an issue with the plugs or wideband. I say this because I did increase the ASE and WUE by a LOT based upon a few other posted settings from HybridZ members that seem to know their stuff. But the best part is that the car just starts right up without a hitch now and runs nice after the first minute or so of resets. Glad you got to drive your car... I never made it quite that far. But soon........... I using the MS relay board and it is grounded, along with everything else (TPS, IAT, distributor, LC-1) to the threaded hole in the block that sits right below #5 spark plug and above the oil dipstick. Right now I am using two separate lugs there because I don't have a single grounding lug big enough to hold all the wires. I'm using the stock single wire CLT sensor. I also do not have any additional ground wires running anywhere. The relay board case is screw-mounted to the firewall, so that case is grounded there.

-

Some success. Un-grounded the case and I got it to fire up fairly quickly. Far less resets but at least it was running. RPMs would surge, then I'd get a reset, it would stumble and repeat over and over. So, I disconnected the stock tach and fed the coil via the fuel pump output on the MS relay board and tried it out... she fired right up, idled nice with no resets. For now I'll call the problem solved. Hopefully you don't hear back from me for the same problem in a few days. Thanks for all of your help.

-

Nope, haven't tried that but it's a great idea! I have a remote starter thingy so it will be easy to try out.

-

Unfortunately Mike, I don't really have enough data to tell. Here's the history of it best I can remember: * Summer time, nice and warm. Stock tach not hooked up. Positive side of coil fed from fuel pump output on the MS relay board. MS box sitting on the seat of the car. LC-1 not installed. First start attempt, got it running and idling without much trouble but only one bank of injectors were firing, so the car was running horribly on three cylinders. I didn't datalog a start, but I did datalog once I got it running... no resets. Didn't notice any resets on cranking, but I wasn't really looking for them. * Pulled the MS board out and found bad solders (shorts) on a few of the tiny transistors that are part of the injector driver circuit. Pulled the resistors, cleaned up the excess solder and put them back on. * September, outside temp about 60 degrees. Everything still hooked up the same as before. Still no LC-1. Took a while to get it started by messing with the cranking pulsewidths and after start enrichment. Once it started the engine ran nice and smooth. Took it out for a drive around the neighborhood and it ran good. Parked it back in the garage, shut it off and started it back up to make sure it would restart (started right away, no stumbles). Didn't datalog a start, but did datalog while running. No resets during running, and didn't notice any during cranking but again, I wasn't looking for them. * Hooked stock tach and coil up the way it is now. Mounted MS box the way it is now. Wired in the LC-1 but didn't hook up power to it. * October, temp in the 50s. Tried like hell to start it but it wouldn't go. Best I could get was a few seconds of running. Fuel pump was randomly turning on and off and the readout in Megatune was very erratic. Didn't datalog anything. Turned out I messed up my grounds when wiring in the LC-1, so I pulled the grounds and cleaned them up real nice and reinstalled everything. LC-1 still wired in, but no power going to it yet. Didn't attempt to start it yet, but verified the strange fuel pump behavior and erratic readings in Megatune were fixed. * Late October, temp in the 50s. Spent about 5 minutes cranking on it until it finally fired up. Didn't drive it but I let it completely warm up. Idled nice and smooth. Didn't even start up the laptop so I didn't notice or suspect anything was wrong, but I did have a really hard time getting it to go. * Early November, temp in the 50s. Finished hooking up the LC-1 and calibrated it. Spent a bunch of time getting the car started, but she finally fired up and idled nice. During my start attempts, I notice the CLT and TPS readouts jumping wildly when it would try to start, and noticed the red flashing in the lower right corner of the Megatune screen indicating resets. But no resets after it got started up and idling. No datalogs. LC-1 was working and reading about 12.5 AFR at idle. Turned off the car and let it sit for about 3 hours. Went out to start it and it fired right up without any stumbling and idled very nice. And here we are now, with several days behind me trying to get it started. Had temps in the 50s yesterday and I tried to start it without any luck. Got it to try to run but my best was about 3 or 4 seconds. When the car tries to run, it throws resets like crazy. But it's very rare that I get a reset during cranking, I'd say 95% of them occur when it tries to start and I let off the key. The LC-1 is disconnected, and it doesn't seem to make any difference in the number of resets I see. I plan to try it again with the MS box lying on the seat like before, and eliminate the potential ground loop I caused by mounting the case to the transmission tunnel. If it still gives me fits, I'll eliminate my stock tach and wire the coil as I had it before. Thanks for the help.

-

I've cranked it with the fuel pump fuse pulled and I did get resets because it tried to start on residual fuel in the cylinder. I haven't tried pulling the injector fuses yet but will definitely do so and try it out. Regarding the coil, one thing I have done recently is hook my stock current sensing tach back up. Right now I have the stock black/white wire that comes from the stock tach feeding the positive side of the coil, rather than feeding power to the coil directly from Megasquirt via the fuel pump output on the relay board. Although the car is almost impossible to start, when it does start it seems to run just fine after that. Perhaps I should change this back to the way it was. Another thing I just realized this morning is that I could have created some bad grounding issues. When I had the car starting halfway reliably, I just had the MS box sitting on the passenger seat. Now it is attached to the transmission tunnel in the passenger compartment with screws going into the sheetmetal there. This is grounding the case, very poorly, through this attachment and likely creating a ground loop. I'm sure this isn't good so will try fixing this first and see what happens. Thanks for the help.

-

Another update: I've reflashed the firmware in the hopes of that solving something but didn't have any luck. Spent about 5 minutes cranking on it and got over 100 resets during that time. Resets almost always correspond to when the RPMs get above my cranking threshold. Even if I hold the ignition in the "start" position when it tries to start, I still get a reset so I'm sure it isn't due to the starter. What happens inside of MS when it transitions from cranking mode to running mode? Since I'm running PWM on my low impedance injectors, could it have something to do with the flyback circuit? Getting very frustrated...

-

83 ZXT distributor and coil, running it in MSnS mode.

-

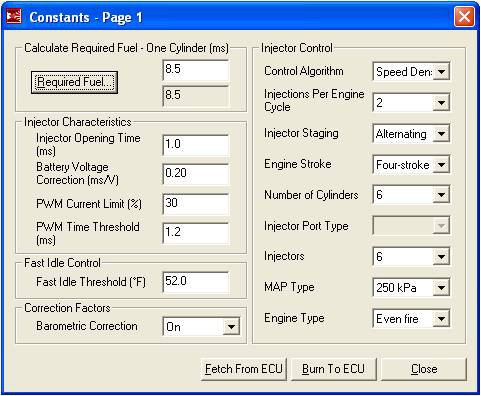

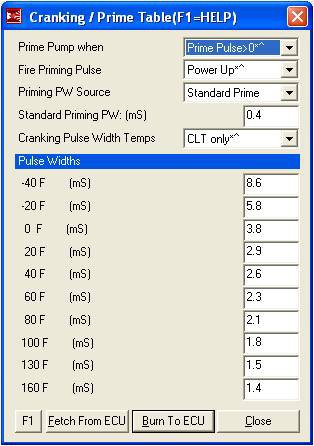

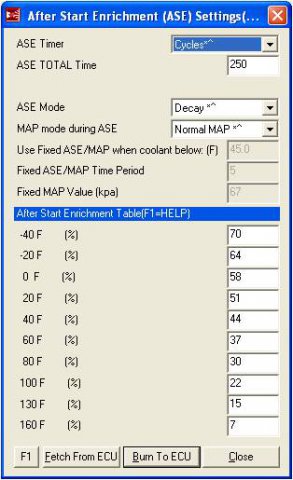

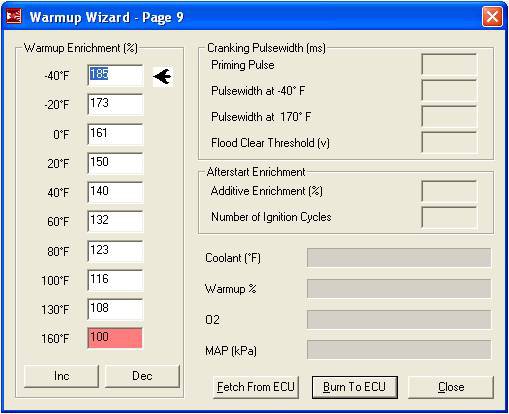

I did some more testing with it last night and it doesn't look like the resets are being caused by feedback from the starter solenoid. I installed a relay on the starter circuit and I still got the same effect: reset during transition from cranking to running. But I also noticed something else: if I crank it just momentarily, not giving it enough time to attempt to start, I do not get a reset. I only get a reset when the RPMs get above my cranking threshold, which is set at 300 RPM in my case. I am using Supra 440cc low impedance injectors and driving them utilizing PWM on the MS board. Perhaps something is goofy with the injector flyback circuit, but keep in mind that if I can actually get it to start, it runs very good with no resets. Also, when I do happen to get it started and let it warm up, if I shut it down it will restart again without difficulty. Could it be that my cold cranking PWs are so off that it's just not getting a good clean "kick" to get it going, and the subsequent engine stumbling is causing the resets? Could it be that the starter is not disengaging cleanly when it tries to start, and that's causing something to go amiss? Mike, the issue isn't really new, at least I don't think. I just got the soldering on the board fixed up a few months ago (shorted transistors), and I've only had the car started a few times since then. The first time I got it started the outside temp was about 65 degrees, but it took me a long time to get it going. I got it started again last week but it was also on a warmer day, about 60 or so. But each time I've got it started and warmed up, it restarted easily after turning it off. Last week I ran the car, warmed it up and turned it off. Three hours later I went out and bang, the car fired right up. Also, the battery is new but I have had to recharge it multiple times due to many failed start attempts. Attached are screenshots of my constants, cranking, after start and warm up tables. If anybody sees anything suspect here, let me know. Any ideas would be very helpful. Thanks.

-

I tested it last night, and the ignition switch isn't causing the problem. I disconnected the starter solenoid and datalogged multiple "fake" starts, turning the key back and forth between Start and Run and it never caused a reset. At this point it looks like the starter solenoid is causing the problem when power gets cut to it going from Start to Run. Someone on msextra.com suggested the hold-in coil is causing the problem and advises to install a diode from the start terminal to ground. Does this sound like a good plan? Thanks.

-

I've already posted the following on MSEFI, but thought I'd give it a shot here as well: Running MS1 V3.0 with Extra 029y3 code. Installed on a Datsun 240Z with an L28ET, with the following relevant setup info: * Using Megasquirt Relay Board * Innovate LC-1 getting power from the +12V switched terminal on the Megasquirt relay board * LC-1 is wired to a relay so it cuts power to it during cranking * All sensors (except CLT), injectors and the Megasquirt board are all grounded to the same location on the engine block * Using stock single wire coolant sensor * Low impedance injectors utilizing PWM on the MS board Car runs very well once I get it started, but getting it started is next to impossible. It starts easier when it is warm out, but it is still difficult. I'm getting resets during the transition from cranking to running, and I suspect it is due to the way I have wired up my LC-1. If you look at the datalog, you'll see that during cranking the O2 sensor voltage goes to zero (like it should because of the relay), then when the engine fires and I release the ignition key to running position, I get a spike in the O2 sensor voltage and battery voltage, followed by an ECU reset. You'll also notice a corresponding spike in the coolant temperature. Now I don't really know which is happening first, the resets or the spikes. In most cases it looks like the spikes happen, followed by the resets, but a few of them are reversed. My theory is that when I release the key from cranking, the LC-1 is immediately switching on and creating noise that is causing the ECU to reset, but I'd like some expert opinions before I make any changes. I plan to try to start the car without the LC-1 hooked up and see if I get the same result, but I haven't tried it yet. Hoping someone can chime in first. MSQ and datalog are attached. Thanks for the help. Bill rustbucket_11-14-12.zip

-

Thanks, and no problem trying to help you out with your injector issues... that's what this place is about.

-

injector banks not firing and fidle not engaging relay

OhBilly replied to softopz's topic in MegaSquirt

The resistance of injector #2 is not close to infinite, it is close to zero (you said it measured 0.6 Ohms). I think this could cause the trouble you are seeing because that injector would draw too much current, which I think can shut down that whole bank. As a test (if you haven't done it already), is connect all your injectors except #2, and the car should start up and run on 5 total cylinders. -

Mike, I'll definitely be taking it easy for a while, even after the wideband is hooked up. Luckily I'm pretty patient about these things. Andy, I haven't had it running long enough to know if I have any return issues yet. But so far at idle (worst condition) it seems to be working fine. I do have a question though about fuel pressure. I have my static pressure (engine not running) set at 42psi, but at idle it sits at about 32psi or so. Is this normal? ** EDIT: Figured out the fuel pressure drop at idle, and it is okay. Since the FPR has a pressure reference port, the spring pressure automatically adjusts with manifold pressure. My MAP at idle is about 30kPA which would drop the fuel pressure by about 10psi, which is exactly what I am seeing.

-

Nothing out of the ordinary. The board is setup to run MSnS, so any modifications are easily done. The main issue is that you have to have the MSExtra code uploaded to the ECU. Much more information can be found here: http://www.msextra.com/doc/index.html#ms1 The modifications necessary to get it running with the ZXT dizzy are very straightforward and can be found here: http://www.diyautotune.com/tech_articles/how_to_megasquirt_your_280zx_turbo.htm Hope this helps.

-

For those who are interested, I just thought I'd post a turbo conversion success story. It's been a 3 year process, but it's finally running pretty well. Here's the detailed info on the setup: * '72 240Z * L28, N42/N42 combo (8.3 CR I believe...?) * Stock T3 turbo and exhaust manifold from an '83 ZXT * Supra 440cc injectors * Aluminum fuel rail from Andrew McCalip (Cold Fusion CNC) * Aeromotive FPR * TRE 255 LPH fuel pump * Stock 240Z fuel tank * Using stock 240Z hard lines for fuel supply and return (5/16 supply, 1/4 return) * Fuel injection rated rubber hose on supply side (from hard supply line to fuel rail) * Standard rubber fuel hose for return (from FPR to hard return line) * Threaded wastegate actuator, currently set at about 7psi * '83 ZXT distributor and coil * 240SX throttle body * N42 intake manifold * Stock L28 oil pan with oil return bung welded on * Stock '83ZXT turbo oil feed line, DIY silicone hose for oil return * Stock L28 oil pump * Treadstone single-sided intercooler, model TRV125 * DIY intercooler piping with T-bolt clamps * MSA downpipe, with O2 bung relocated downstream * 2.5" exhaust * K&N conical filter mounted directly to turbo inlet * Knockoff Greddy Type-RS BOV vented to atmosphere * NGK BPR6ES plugs * Magnecor spark plug wires * Unknown clutch and flywheel... not sure if it will hold or not with increased boost * MS1, V3.0 ECU running MSnS, with relay board * Innovate LC-1 wideband, but not hooked up yet The conversion took so long mainly because I just didn't (and currently still don't) have much time to work on it. It's been a great learning experience, and all the work I've put into it has finally paid off. I still have a lot of fine tuning to do with the Megasquirt once I get the wideband hooked up, but the car is running quite well now, good enough to drive at least. I'm sure there are issues that will creep up, especially where I skimped on things due to cost and/or effort involved to complete. But for now, I'm just going to try and drive the thing as much as I can and enjoy it. To those that have helped me with my questions and troubles, thank you. And a great thanks to HybridZ in general with a wealth of valuable information. Cheers, Bill ** Edited to add downpipe and exhaust info **

-

Just want to say thanks to everybody who has helped me out with my issues. I appreciate all of your help. As far as lessons learned, I learned that I wasn't the great solderer I thought I was. My first trouble was not being able to load firmware onto the CPU, and the culprit there ended up being a solder bridge on the MAX232. The second trouble was a failure of the bank 2 injectors to fire, and the culprit there ended up being solder bridges on several of the tiny transistors that make up the injector driver circuit. I thought I was being ultra-careful soldering those damn things, but I botched it up nonetheless. But now it's running pretty good. I still have to hook up the wideband O2 and get to tuning it, but right now it's starting, idling and running well enough to drive it around close to home. Cheers, Bill

-

injector banks not firing and fidle not engaging relay

OhBilly replied to softopz's topic in MegaSquirt

Just because it clicks it doesn't mean something isn't wrong with it. Whether it is clicking or not, it isn't working. At a minimum, get those three injectors out of there and fix them or replace them. -

injector banks not firing and fidle not engaging relay

OhBilly replied to softopz's topic in MegaSquirt

Even though injector #5 is measuring too low of a resistance, keep in mind that cylinder #5 is still working, at least for now. It may be that that injector is on its last legs. But you do have an issue with injectors 1, 2 and 3. Even though those injectors Ohm out correctly, it doesn't mean there isn't something wrong with them. In summary, you definitely have something wrong with injectors 1, 2 and 3, and it sounds like injector 5 might be getting ready to give up also. Since you need to pull injectors out anyway, I'd pull them all and get them all checked out. There are people that do fuel injector service, like these guys: http://www.witchhunter.com/ or it may be worth it at this point to buy 6 new injectors and call it a day. -

injector banks not firing and fidle not engaging relay

OhBilly replied to softopz's topic in MegaSquirt

Sorry, my bad... I meant to say "ground" instead of "+12V". Anyway, what you are saying above and what your video shows is contradictory. In your video, you were never able to get injectors 1, 2 or 3 to work, regardless of which pigtail connectors you put on them. And injectors 4, 5 and 6 always worked, regardless of which pigtail connectors you put on them. Since this is the case, you do not have an injector driver issue, you have a fuel injector issue. Keep in mind that it does not really matter which pigtail connectors you have connected to your injectors, the car will run regardless of what order they are in. When you Ohm out the injectors, do you get a zero reading on all of them, or just 1, 2 and 3? If you get zero on all of them, something is wrong with your multimeter. -

injector banks not firing and fidle not engaging relay

OhBilly replied to softopz's topic in MegaSquirt

I just watched your video. I am going to try to summarize/simplify what I saw. One bank of injectors gets its +12V from the brown wire, the other bank of injectors gets its +12V from the red wire. At first, you have the "brown wire" bank hooked up to injectors 4, 5 and 6. You have the "red wire" bank hooked up to injectors 1, 2 and 3. When you start the car in this configuration, the "brown wire" bank fires just fine (injectors 4, 5 and 6), and the "red wire" bank does not fire (injectors 1, 2 and 3). Then you turn off the car, and swap out your injector connectors, putting the "brown wire" ones on injectors 1, 2 and 3 and the "red wire" ones on injectors 4, 5 and 6. When you start the car now, the "red wire" bank fires just fine (injectors 4, 5 and 6), and the "brown wire" bank does not fire (injectors 1, 2 and 3). Have I got this right? If what I said is true, then I can determine that both "banks" of your injector drivers are working, since both the "brown wire" bank and the "red wire" bank are both capable of firing injectors 4, 5 and 6. I can also determine that you are getting spark to plugs 4, 5 and 6. You also mention that when you ground out injectors 1, 2 and 3 you don't hear them click, but when you ground out injectors 4, 5 and 6 you do hear them click. This says to me that you have something going on with injectors 1, 2 and 3 themselves. The problem seems to be with the injectors, not your wiring. If your wiring was messed up, you wouldn't be able to get both INJ1 and INJ2 banks to fire. Since you stated earlier in this thread that when you ground out injectors 1, 2 and 3 they don't click but give a "whine" instead, I would start thinking about pulling those injectors out. It's possible that whatever happened to start all your problems overheated those injectors. I'd start looking there. Good luck. **EDIT: Have you tried using a 9V battery to test injectors 1, 2 and 3 completely isolated from your wiring? Remove the connectors on those injectors and just use your 9V battery to quickly power each one up. If they don't click like they should, there's your problem. If they do click like they should, you've got quite the mystery.