-

Posts

6292 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Mikelly

-

Small snag... Wrong pilot bearing for the combo... I need the smaller diameter unit to fit into the rear of the crank, instead of the larger unit I bought thinking it being bigger was a good thing...

-

Second pic was of the flush/pressure bleed of the clutch hydraulics. I still have the pressure bleeder on it to test for leaks...

-

-

Sasha's heart transplant is almost complete... PIcs coming soon...

-

Dry Sumpin' it... What worked for you?

Mikelly replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

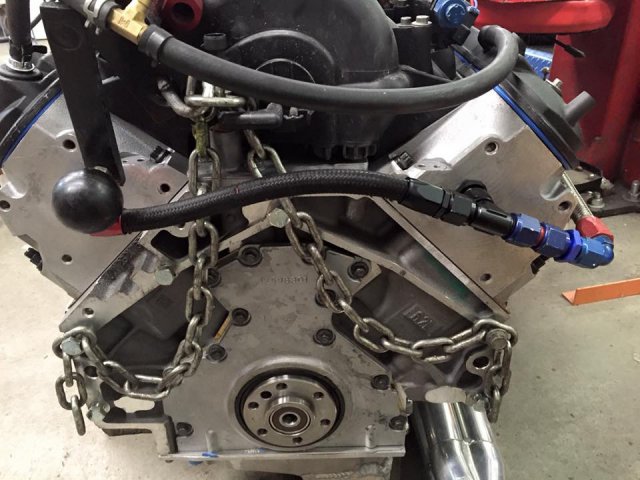

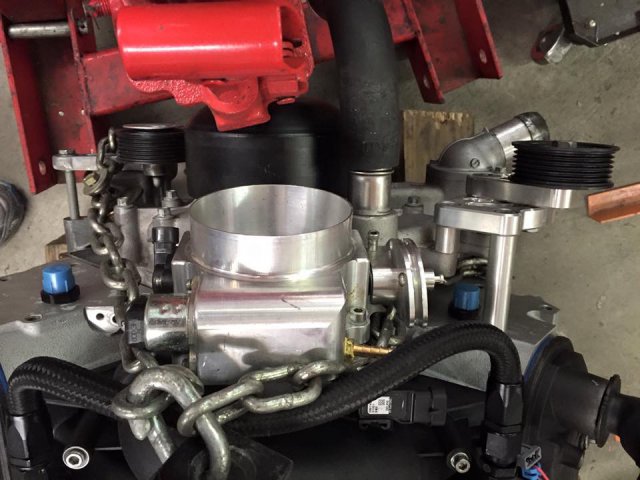

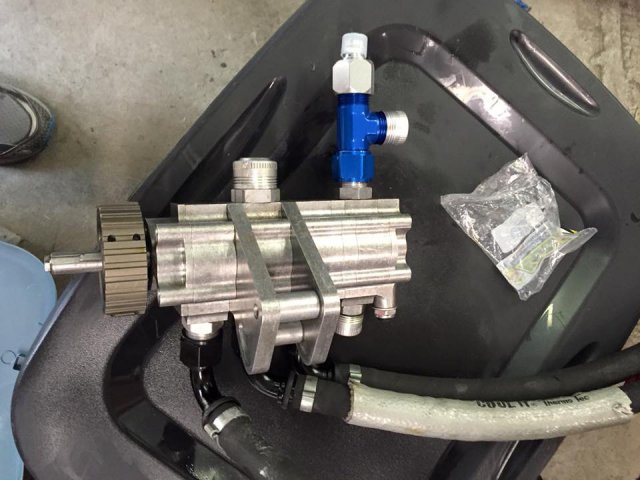

Based on the reading, and the three phone calls completed this week, I'm not concerned at this point with the hoses I chose causing issues on the scavenge side. I am running three scavenge stages, and from what I was told by John Barilka (Hendrick) and Steve Wilson (Childres) I shouldn't have issues. Motor won't spin north of 6500 and the vacuum is going to be right around 7-8. Shouldn't be an issue. Also, the hose manufacturer said there should be no issues at all with that hose collapsing. Pics of the head drains should be on my project page. Mike -

Got all the parts in that I needed to wrap up the re-install on the Motor and Trans for the Zcar. Hoping to wrap everything up and get the motor back in the car over this weekend and next... Getting there...

-

Dry Sumpin' it... What worked for you?

Mikelly replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

OK so interesting reading on this site... http://www.race-dezert.com/forum/threads/dry-sump-plumbing-advice.76641/ -

Dry Sumpin' it... What worked for you?

Mikelly replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

I couldn't find ANY info on Vacuum springs in the scavenge hoses or where anyone has said "You must instal these or else." I also have found exactly one source for the springs, Pegasus... Cary, You're a wealth of knowledge and I value your experience. Please elaborate on this... Mike -

Dry Sumpin' it... What worked for you?

Mikelly replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

My setup is what this guy recommended: http://nutterracingengines.com/racing_oil_pumps/about_dry_sump_oil_pumps.html -

It is very much still for sale...

-

Dry Sumpin' it... What worked for you?

Mikelly replied to Mikelly's topic in Gen III & IV Chevy V8Z Tech Board

FYI, After my motor had to be pulled, and rebuilt with new block, and internals, I wanted to have head drains installed in the heads to aid in reducing the volume of trapped oil in the heads. Jamie Taylor installed head drains in the L92s for me. Now I have issues again with lines and those headers. So.... I inquired about potentially tapping into the drysump system. The short answer there from TWO industry leaders was NO. You can't tap into the system, because it will interfere in the balance of the pressure in the system. I wanted to put this in this thread so others doing research later may save themselves some headache down the road. -

LS1 240 mounts (facts not opinion???)

Mikelly replied to trackzpeed's topic in Gen III & IV Chevy V8Z Tech Board

I'd go with Austin Hoke's kit. Two reasons: He worked with us on the wind tunnel testing at Aerodyn (solid engineering skills) and I've bought other quality stuff from him. Austin is a Looooong time member of HZ and just look at the parts... That stuff looks factory... Well done Austin!! -

Well the final word on the head drains, from the folks who made the pump and hardware for this kit, is nowhere... If I can't run them to the oil pan, then they can't be in the system. A.C. said otherwise the balance of pressure is disturbed and the pump would not function properly. So... I'm capping them for now, and will look at my options once I get the bits all bolted together to see if there is any room on the pan anywhere once the headers are on and the motor is in the car. This pan comes right off without having to move the motor, so that won''t be an issue. Mike

-

-

JOhn, We're saying the same thing...Feed would be the side that draws from the tank.

-

My solution for the head drains is running the lines (four -AN8s) into the -AN12 FEED line for the drysump. It pulls the oil from the oil tank, so I'm thinking it'll pull any oil from the heads... Only issue is possibly pulling AIR? Anyway, that's where I'm at so far... ordered some fittings to mock it all up. I've got a call in to AC Nutter to discuss this to make sure I'm on the right track. Mike

-

Needs to be a -10 male to -10 female 90 degree bend...Pretty sure I will have to get Jamie to relocate the drains.

-

Sadly I dont think they will clear the header... Ugh... Really need something that is a 90 degree and ultra tight fitting. I only have 1.5 inches clearance with an airgap... 2 inches and it touches the header.

-

No, but I will now... Thanks for the tip on AN Fittings Direct...Going there now!

-

Ordered a set of comp-cams upgraded LS trunions for the LS3 rockers. Going to install those before I get to carried away. Still need to find some tight clearance -10 90 degree hose fittings for the head drains... Then I'll be ready to button up the lines on the motor...I may actually do this on the daily driver Grandsport as well.

-

Hahahaha That guy... Ugh...Car probably weighs 1500# as it sits with nothing in it. It's essentially a SHELL with a cage. That guy just wanted to be Mr. Helper and Capt. Assh-at. Moved the car into the lift bay and I expect to start on the project in earnest in about 1.5 weeks. We'll see how she goes back together... HOPEFULLY we'll have a running car before thanksgiving.

-

-

Jamie welded bungs into the oil pan.

-

Couple things I will say about LS Build 2.0... Jamie Taylor ported the hell out of those heads... They turned out very well. And... Head drains... I now have FOUR head drains... 2 in the front and 2 in the rear. Jamie expects this motor to make 500 Wheel HP at a minimum. We'll see sometime this winter.

-