-

Posts

326 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 78zlt1

-

The clamps work great but can be a pain sometimes you do need access to the back, there is a square pin that you insert thru a hole in the part that extends between the panels, get out your magnetic pickup tool to fish the pins out when removing them or drill a hole and insert a sting in the pin. Here is a pic of the tabco panels installed , the rockers and doglegs fit pretty well , but do need a little massaging here and there.

-

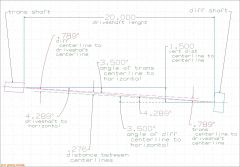

I was able to find the 300zxt Shaft info. from my measurements if I add the 3/32nds of the boss on the outer mating flange to it , the short shaft is the same within a 1/32nd , but the long shaft is an 1/8th longer. getz , Are you testing with the endcaps on or off now?

-

I just ordered from Tabco monday and recieved the panels today (Wed), The prices are higher than what they have listed on thier webpage, but service is good. I'd butt weld them like TravRMK & v8wannabe2 described , and get some of these clamps, It makes it alot easier keeps the panels aligned and keeps the gap needed. Got mine at Harbor Freight.

-

I think I will have the same problem you have so I'm gonna hang on to both sets till I get the car together. Give us an update how your setup works , hopefully it will seal well and eliminate the binding problem.

-

I took some measurements today of my non-rebuilt shafts. These DO NOT have the cages flipped. and they are compressed , hitting the cover of the outside CV. What lenghts do you guys have with the cages flipped?

-

One thing you might want to check is if the inner cv is on the right shaft I have 2 sets of 300zxt CVshafts I got of Ebay, one that doesnt seem to have been rebuilt outer set( green) and a set that was rebuilt (inner set). Short shafts on the left , long shafts on the right. As you can see the rebuilt set have the inner CV's reversed , the short stub should be on the short shaft ( the shaft below the spline that has the spiral cuts one is longer than the other) The outer (green cv set is correct) Please correct me if I'm wrong!

-

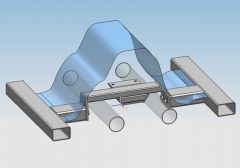

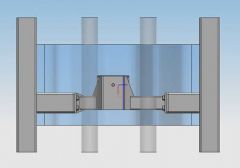

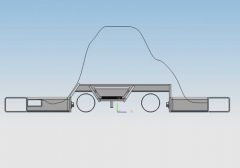

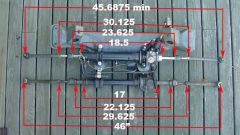

Here is my setup with the 2004 forrester rack , and the stock Datsun rack. The Datsun rack is as it was on the car when I took it off , and the Volvo/Datsun combo is screwed in till it stopped on the jam nuts so this is the minimum distance for the setup , the datsun rack can be adjusted in more. I wont really know if this will be good enough till I get the car back together.

-

I think I should reiterate that I have a 2004 Subaru Forrester rack, all my info applies to it, I dont know if earlier racks have the same specs, Maybe we should comeup with a set of common dimensions/data and post it for each rack to see how they compare, I do know that the Subi inner tierods on my rack without the outers on were longer than the datsun's rack with its outers on, But the Subi's outer tirerod taper fit the datsun steering arm. I'll try to take som pictures and measurements today, My cars on the rotissery and wont be back together till bodywork and paint is done, God only knows how long that will be.

-

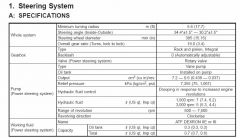

I did some work on my rack after hours of searching I found these parts that seem to work. TIE ROD INNER Volvo S80 01-05 part # 274179 These have the same inner thread as the subaru and the correct outer thread for the stock datsun outer tie rod. They do need to be slightly modified as seen in the photo. top is stock bottom both ends are cut down a bit, the reason they have to be shortened is they would otherwise bottom out. The stock datsun tie rods also needs to be shortened slightly. Top is stock , bottom is modified version. The U-joint adapter I found was. BORGESON part #012564 11/16-36 X 3/4 U-JOINTSMOOTH This has the correct spline to fit the subaru rack , I found a spacer in the tool box that was the correct OD, I just need to bore out the hole to the correct ID to slip on the datsun steering shaft that will need to be cut to the correct length and then weld these together. I was also able to use the subarus steel lines I just had to "massage them" to have them fit . I just need to adapt the supply and return to the GM pump and reservoir. I found some fittings that may work for the large ports on the rack GM TBI adapter fittings here : http://www.russellperformance.com/auto/adapt/adapt_fit_fuel-3-27.shtml This is the closest setup that I could come up with that is almost bolt on, there are probably other inner/outer combos that will work, But after many hours of research this is what I found.