All Activity

- Today

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

05-24-2025. I got the clips and screws to finish up landing the wiring down for the lighting I added, and got other little things here and there taken care of, I installed the plaque I had made to label the switches on the dash, then I went to the carb, and changed out my accelerator pump nozzle to a larger nozzle, from a 70 to a 90. a custom 90 that is made by V performance development. car is still lean below 3000 and giving it any more that 1/8 throttle below 3000 it just falls flat, so I took the needle out and taped it off and did some grinding on it and re-installed it.....MUCh better but needs just a hair more. I took it out and ground on it, but I think I left it too rough, as it doesn't want to move cleanly in the needle jet. I went ahead and ordered 2 needles for the carb in the richest one they offer.....stock is 97, these will be 95's. I will put one in the carb as-is drive it, and mod the second LIGHTLY and gently and keep playing with it. Everything is great except for the transition from the pilot jet to the needle....TOO LEAN, so it's just trial and error now. Pics follow. -

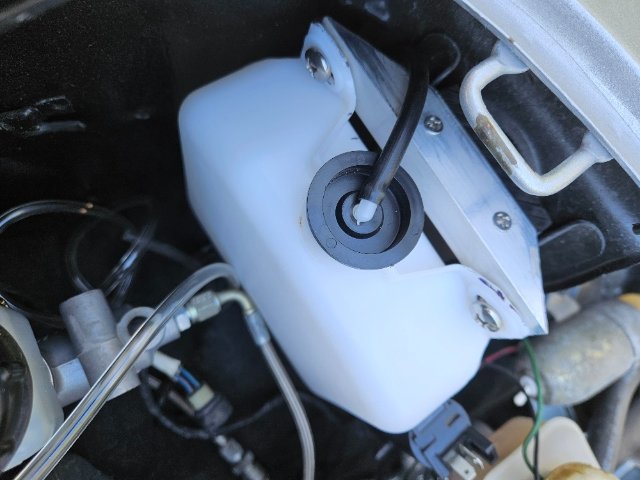

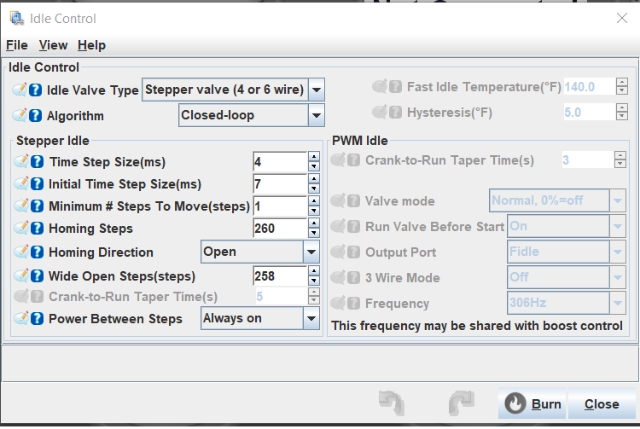

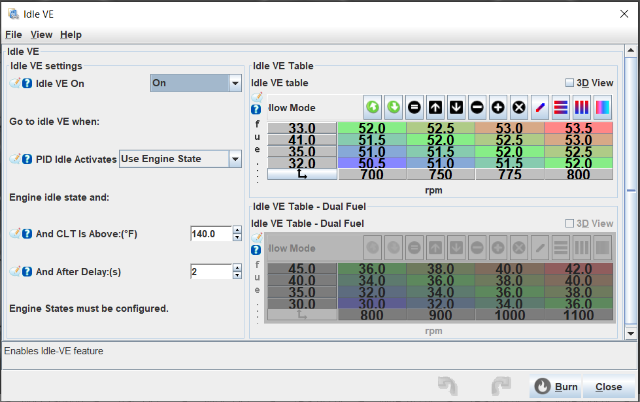

Darom, I agree with you that the ProtunerZ guys are very helpful, and stand behand their products. I am so glad that the car doesn't whistle anymore. I am no expert here, so take this as advice. Your mileage my vary. 🙂 The car is a 71 240z. I live at 8,000 feet and I see a lot of altitude change to 5,600 feet in CO, so I am running %Baro. Here is the setup on my engine: 3L Turbo Stroker, 88mm JE forged pistons 8.43:1, Max Speed rods, ARP head, rod, main bolts, Electramotive L7 Cam, Garret GTX Gen II 3071 turbo, Water-to-Air Intercooler, ProtunerZ intake, turbo manifold, downpipe, Arizona Z Car 7 QT oil pan. Megasquirt V 3.57 with the expansion daughter board, sequential injection, 280zx Turbo CAS, GM Truck COP, Bosch 440CC injectors with 43 Psi. This is a new engine that has about 2,000 miles on it. Its running very well over the stock turbo engine I had in the car. I did set up the throttle blade to be completely closed and then configured the IAC to provide additional air to get to the target of 750 rpm. This has allowed me to have it start in the cold at -10F and 90F and warm up properly. I do find it likes a AFR of 13.5 for a good smooth idle at 17 degrees of timing at 750RPM. I enclosed my MSQ tune file Looking over your setup I noticed a couple things you should check. I will make the assumption the engine is stock with no cam and stock cam timing. 1. The throttle position sensor: You have 464 steps where mine has 679 steps. I would make sure it has full travel and re-calibrate it. I also noticed that your sensors are unlocked. This could be the sensitive throttle you mentioned. 2. MAP sensor: Looking at the one warm up idle log. The timing moves from 19 to 23 degrees with no TPS input. Then is settles down to 14.8 while the MAP remained fairly steady at 41 kPa. You would think this would change with the timing swings, so check your MAP hose to the MAP sensor and the MAP sensor wiring. I see you have a GM-1Bar sensor configured. On my engine I have a vacuum of 27 kPa. It could be normal for your engine but check for vacuum leaks also. Here is a great article from DIY Auto Tune on closed loop ldle. MS3Pro Closed Loop Idle - Stepper Valve - DIYAutoTune.com 3. I would adjust your timing at the lower values. Set it up so you have 500 = 19 and have 17 degrees at 750. this way it will give you a little timing when the electrical load increases to bring the RPM back up. Looking over the idle/accel tab I have more settings available and a 16x16 table to play with. I think this is the limitation on the Microsquirt vs the Megasquirt. 4. it can't hurt to double check your base timing. I would confirm it at (Fixed Timing setting set to 15 degrees) with a timing light. Make sure you confirm zero TDC with the piston at TDC. I have had a couple harmonic balancers spin on me. I am not sure how the missing tooth crank wheel bolts to the balancer. I included my current tune and a data log. In the middle and end of the log you can see how it idles. Hope this helps. CurrentTune.msq 2025-05-21_16.32.19.mlg

- Yesterday

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Got brake and clutch master cylinders off, and booster off. Booster bolts were a pain. I hate working under the dash area. Need to clean up a few more things then wash and prep engine bay for paint. -

1978 Datsun 280z No Acceleration Above 4000 RPMs

A to Z replied to Kad77's topic in S30 Series - 240z, 260z, 280z

Sure, no problem! again, when putting the needles into the piston, it is recommended to use a straight edge and set the needle at the level of the piston, not the indented place where the needle goes. ~Joe -

angle iron is about 1/8" thick in a 90 degree bend. incredibly strong. It is just an idea. you lay the piece against the car with spacers so the body is a few inches from the bar. centered is where it is either welded or bolted to the center post of the rotisserie. It might be a good idea to go to YouTube and type in how to make a car rotisserie. Some guys have used 2 engine stands, that have been cut and lengthened, so they are taller. You could buy a rotisserie but they ARE pricy. how to make a car rotisserie - YouTube Good luck! be careful. New a fire extinguisher in the garage, gloves and eye protection, and do NOT rush! This kind of stuff can lead to divorce.\

-

Hi @Datsunpowers Tom! I appreciate your time posting your IAC setup here. I wish Protunerz would grind the sharp edges at their factory. I talked to them, they are aware of all this whistling business with their intakes. They are great guys and I got quick tech question responses from them. But the noise is an embarrassment to a pricey car part. I have a few questions for you: - Do you set up your throttle blade to be completely closed and then configure your IAC to provide additional air to get your target 750 rpm? I went over this subject on a msextra forum as well, and it appears there are 2 ways to do it. One is to open the blade a little and IAC completely closed at idle. Another - the throttle blade is physically closed and IAC is providing air for idling target speed. I went with the 1st option, since I couldn't get my IAC to provide predictable behavior. One day it would be idling at 900 rpms, next day - 800-850 rpm, another - around 1000 rpm. I figured the IAC's min steps and step size needed to be played with and per Madcaw's advice, I left it on 'Always On'. This helped somewhat. I also bought another IAC for a 1999 Camaro V8 (Ultra-Power AC162) to test (10$ special from Rockauto), but I haven't installed it yet. I suspect my IAC is not completely sealing the opening, thus these fluctuations. - Open-loop vs closed-loop question I removed my a/c a while back, and I have a 5-speed. I thought the closed-loop idle control is suited for the cars with big electrical loads (like electric fans, a/c compressor kicking in) or an automatic transmission. I have a belt driven fan. All my headlights are converted to using relays. I set up the open-loop since it was the easiest option. Would you recommend for my car to switch to the closed-loop idle control? If you don't mind checking my tune/idle and a driving log, I'd appreciate it. What are your car's specs? Can you share your tune? Thanks! Den 2025-05-18_13.51.43.mlg 2025-05-18-adj-IAC.msq 2025-05-10_11.12.19-driving.mlg

- Last week

-

1978 Datsun 280z No Acceleration Above 4000 RPMs

Kad77 replied to Kad77's topic in S30 Series - 240z, 260z, 280z

Thanks for the help! I just ordered those needles you gave the link for. Once they show up, I'll install them and give an update on the results. Thanks again!! -

1978 Datsun 280z No Acceleration Above 4000 RPMs

A to Z replied to Kad77's topic in S30 Series - 240z, 260z, 280z

"SM" needles. They are made specifically for this issue. I had the same problem as you, changed to these, and no more problems. They give you more fuel up there. here is a link to some I quickly found on eBay for you. when installing the needle height, you want to use a straightedge to make sure the level is correct and not too far "in" before tightening. Datsun 240z SU Carburetor "SM" Race Needles Triumph TR3 .100 | eBay Butterfly shaft leak, you may be able to smear a thin coat of grease around the shafts. to stop the Leak, if you take your time, it won't even be noticeable to the naked eye. Let me know how it goes. Please. -

The thinnest bottle I could find was an EMPI 15-2060-0 from Amazon. https://www.amazon.com/dp/B00FB83UUI?ref_=ppx_hzsearch_conn_dt_b_fed_asin_title_1 I got a piece of ABS from McMaster Carr that was 2.5" wide x 1" thick and shaped it to fit the bracket the best I could. I have it installed but waiting on a plug to come in to wire it up. I ordered this https://www.amazon.com/dp/B01N0E7S8I?ref=ppx_yo2ov_dt_b_fed_asin_title, so hoping this is the correct plug for it. Will see when it comes in.

- 1 reply

-

- 1

-

-

Hey - sorry if this is in the wrong section, would be happy to movie it. I thought about putting it in buy/sell/trade, but wasn't since I couldn't fund these anywhere, I thought it might be something I should ask fabricators. Anyways, I need a set of mounting brackets for the 280Z - Basically I would like to buy a set of front and rear rotisserie mounts. I normally do my own fabrication, but am in the process of moving, and my new place isn't wired for the welder, and honestly, the work I am doing on the car at the minute doesn't require welding, so I really just want to get it on the rotisserie instead of spending a month trying to get an electrician just yet. Mods : Please let me know if you need this post moved - anyone else, please let me know if you can help with the request! Thanks

-

Awesome!! That's a good read. I have been struggling to find that answer. Thanks guys. I really appreciate it!! That solves as lot of problems for me. Now I don't have to spend a million bucks on some odd CV conversion. Least not yet.

-

Datsunpowers started following 76 280z microsquirt project

-

Darom, wanted to say a big thank you. My PTZ throttle body was making the same whistling noise, and it was driving me crazy. Grinding the sharp edges off tonight reduced the noise to an acceptable level. It's much improved now! I hope I can help you out with your closed loop idle settings. I spent a lot of time working to get my car to idle properly at 750 RPMs with the PTZ throttle body. I had to recenter the throttle plate and close the throttle screw closed more with a little grinding on the stop. I also had to change out the GM IAC motor with a different model. The one that came with the throttle body would not close and seal for me all the way. So, I went to the junk yard and pulled several different GM IAC models. The IAC that is working for me I think it came from a Grandprix V6. Here are my Megasquirt closed loop settings. I hope this helps you out. Thanks, Tom

-

JerseyZ joined the community

-

Here's an old halfshaft thread that covers the length, binding, and shortening. Might be the best of what's out there.

-

The halfshafts are all the same, even the 280ZX shafts. One of the Hybridz members compared a range of years and determined that, but, unfortunately his web page with the data is gone. The 240Z's seem to be slightly narrower between the wheel flanges than the 280Z's, but that has not been confirmed. It's not the halfshafts, it's the cars. The binding issue doesn't seem to be a big problem but you can find threads about people grinding areas of the halfshafts to shorten them at full compression. In short, all you really need is the correct pinion shaft flange. Or a 75 280Z propeller (drive) shaft. Or, maybe there's a flange that you can swap on to your 240Z shaft, see link below. I haven't gone through the actual measurements so don't know for sure if this guy's parts work. Some of his information is wrong, like the part about the 79-83 differentials. 76-83 R200's all have the same dimensions, I have had several across the full range. I've also seen square flanges (78) and circular flanges (76) that fit the same way. Shape does not correlate to fit. Anyway, worth some measuring. Check the bolt hole diameters. Make sure the u-joints will fit. Good luck. https://jagsthatrun.com/products/adaptor-flange-for-datsun-z-v8

-

That figures. I don't remember what year the listing said it was from other than a 280z. I just have to find a flange now I guess..Ugg. While I am full of questions? What year 280z half shafts do I need for the swap? I keep reading 240 axles will bind and need 280z w an R200 diff to fit properly. Thanks for taking time to help. I appreciate it:)

-

Lots of folks have had to adapt their steering setup for various reasons; and I haven't seen any that complained of negative issues afterwards. Most of the adaptations that I've seen have been custom fabrication; but if you've found a good kit, go for it. Main thing would be to ensure the functional hardware is good quality and the installation is solid....competent welds, stiff bracing, etc.

-

Is the R200 from a 1975 280Z? They had an odd flange size. The other 280Z R200's will swap over directly. Your original 240Z driveshaft should work with those. The R180 and the R200 are the same length. The 75 280Z R200 flange is an oddball.

-

I am confused about which driveshaft to use. I am swapping in an R200 diff into my 72 20Z. I had thought that the stock driveshaft pinion flange would swap onto the new differential. That is not the case sadly. The 240z flange is too small. The diff is from a 280z and I am trying to figure out which driveshaft I can use? From what I have read the 240Z shaft is a little too short but I can't really find a definitive answer. Any help appreciated.

-

2jzge, single turbo

-

What engine is going in?

-

1978 Datsun 280z No Acceleration Above 4000 RPMs

Kad77 replied to Kad77's topic in S30 Series - 240z, 260z, 280z

Sorry for no updates for awhile. I dug into the carbs and figured out that my float levels were completely off. One was set very rich and the other was set very lean. After properly setting the float levels, the car accelerates much smoother and does not feel like it is going to rattle itself apart above 4500 rpms. It will rev up to the yellow line now, and has better power above 4500 now, and it is smooth revs. It still feels like it is missing some power above 4000rpms, but it is way better than before. I believe the issue is that my carbs are still running lean. No matter what adjustments I make, they run lean. I do have a very small air leak at the butterfly valve shafts. Not much I can do about that right now. Z therapy carbs are out of the budget at the moment. I have not yet purchased SM needles, I will do this soon, and i am hoping that they will help get the carbs to run a little more rich. Thanks for all the help! Any further advice is appreciated! -

Hey guys, I'm in the process of an engine swap in my 280z. The revised motor mount makes it necessary to change up the steering linkage, does anyone have experience with using an aftermarket steering linkage kit? I'm looking at the ones that add a joint to work around the mount. Do these negatively affect the steering feel? Anything not obvious I need to keep in mind, or is it pretty straight forward?

-

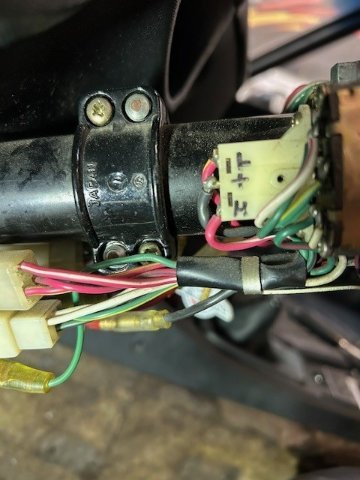

Here is a quick way to check the polarity and the high low switch. Use a voltmeter and ground the negative side of the meter to the car ground. Take the positive lead and touch it to the center of the high low switch. You should have positive +12V with the headlight switch turned on. The low beam wire (Red/Yellow) is at the top and the high beam is (Red/White) at the bottom. The positive +12v will toggle between the two when the turn signal switch is toggled. I enclosed the switch and labeled the different terminals. If that is correct check the polarity at the headlight plug. You should have one ground and +12V at low beam and +12v at high beam. One other thought is check the fuse block and make sure the two headlight fuses are good. You will have one for the left and on for the right light. Hope it helps.

-

Who's Online 0 Members, 0 Anonymous, 297 Guests (See full list)

- There are no registered users currently online