Leaderboard

Popular Content

Showing content with the highest reputation on 09/26/20 in all areas

-

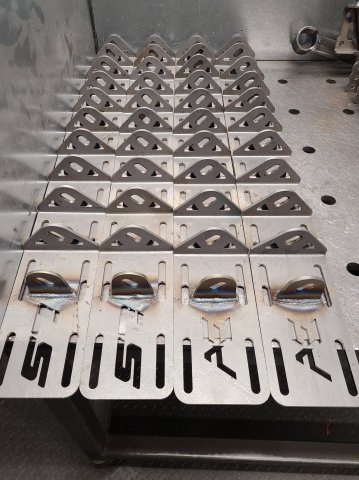

Hello, im adding back to this thread as i was tagged by a few people in it so i have copied my responce from another thread. Hello everyone Intro Its Ohm from Apex. A few guys linked me to this forum to chime in. First off, ill like to publicly appologize to ervyone who has encoutered frustation with axles and components from us. Those who have ordered the first few kits when we first released were impacted with long wait times, and missing hardware. When i first launched the product mid last year I didn't realize the demand it would cause (also from the Hellz youtube video) and the sourcing i needed to do in order to ensure met lead times. We rushed the product to the market in fear of competition and left alot of things open-ended. For example the fixture we made, was not at the production leve l they should have been. They were very heavy, not welder friendly and the welders were having to fight the figture to take the subframes out when they were fnished being welded. This caused long lead times, poor build quility in some cases and frustrated customers in most cases. Axles Secondly Axles, i dont even know where to begin with this, to start off we were un-familiar with the axles, how to machine them and manufacture them correctly and effiecently so we relyed on outsourcing them. Due to that we used aftermarket axles thinking "easier to find, and cheaper to buy, Win-Win" NOT THE CASE we realized that even if we bought from one company in the aftermarket world, there are too many variables and the aftermarket guys are constantly changing their axle splines or size or something, so if one year it works, they can come up with the update, and our axles are non-compatible. So, we had to chew the cost of new finished aftermarket axles and buy OEM ones for all of them and start fresh. We since had to fight with axle manufactuers to get the axles and / or continully find new ones. It wasnt untill last month when I pulled the trigger to buy our own CNC 5 axis machine to make the axles in house under our tollerance and guidlines, however we are still doing initial tests to get them into production and outsourcing the axles untill we can get it figured out on our end. For the customers who are waiting on axles we are giving them a refund cost of the axles along with the schematic print of the axles along with hardness tollerance. We are nearing our 4th vendor now and at this point we are still looking at new ones, i recently contacted RCV performance to see if they would be intersted if this one falls through. What ive learned is to just be proactive and tell the customers about delays instead of being fearful of their responce and agrivate them futher from them comming to me for an update, trying to find somone who can email faster than me or to set up a online order tracker. Improvements On the otherside i would like to point out the imporvements / changes made. since customers had missing hardware we purchased a packing machine that vaccume forms the hardware to a packing list of all the necessary hardware which also gets put on a scale to measure the weight of the packaged part to see if any hardware is missing (attached pitcures). We have also incorporated alot of automation into our product lines allowing us to have ALL OUR ITEMS in stock and ready to ship in the lead time shown on the site. (except for axles 😥) We have also finished / working on around on around 30 new products to various product lines however are we are having them tested on cars, and are making sure we can manufacture them in voluime with acceptable lead times before we release anything to not have this issue repeat itselt. Conclusion As a whole, we are a team of 5 employees. 2 welders, 1 machiest, 1 packaging/shipping and 1 powder coating guy and myself. I do the designing and product development along with take care of the customer service side. I try to get to my emails everyday and reply as fast as i can (and my wife helps me on emails too) but since covid we have been buiser then ever with everyone at home working on their builds i have had to assit on the floor untill i can find a empoyee who can fit our team. Im an engineer trying to learn the buisness side of things but am learing on the way (mostly from my mistakes) and reealsing this product as the single most frustraing mistake i made in the buisness (hopefully ever)1 point

-

Why do you want disc brakes on the rear? I ask because any kind of brake on the back is still only get the set amount of brake fluid pressure that the M/C and stock proportioning valve will allow and that amount is just right for the stock drums. Or I should say just the right amount for the rear wheel cylinders, it is engineered to be a balanced system. Putting disc brakes on the rear with everything else in the system being stock could lead to the calipers not applying enough pressure making stop times longer or they may lock up the rear sooner than the front which really is not a good thing. After having tried all the usual brake combinations that are popular for 240z's I can say with conviction, If you want better brakes then remove the stock balanced system and replace it with another balanced system, a system that has been designed to work together.1 point