Leaderboard

Popular Content

Showing content with the highest reputation since 02/25/26 in all areas

-

1 point

-

Thanks jhm — appreciate the honest response, and totally understand the bind. Obviously, I'm shooting in the dark here. I don't know the traffic, active users, new users etc. Firstly: you are correct, ad block exists. I could do something like that for mobile too just like desktop versions. Out of curiosity, has there ever been any thought toward a paid ad-free tier? Honestly, if it was under $5-10 a month I'd sign up today, I pay $9 a month to Skooler.com, I've used it once, but have never bothered to cancel the membership. Feels like there might be others who'd rather pay a small amount than fight the ads, not a one time donation, but an a subscription and a badge. Are the ads currently through something like AdSense, or do you have any direct vendor relationships? I can't help but notice a Ford Mustang dealership ad on a 280ZX forum and wonder if there's a more Z-relevant way to fill that space. Not trying to armchair quarterback, just genuinely want to see this place thrive. Self Acknowledgment: these things could have been tried during my time away and that is on me.1 point

-

1 point

-

I just posted this to ZCAR: “Receiving periodic/automatic emails that say: ‘Come back, we’ve missed you!’ Sometimes life gets busy enough that I forget to login. I appreciate getting occasional emails reminding me of this great resource. I also think it helps keep the involvement up in the forum. Excellent idea. Thank you.”1 point

-

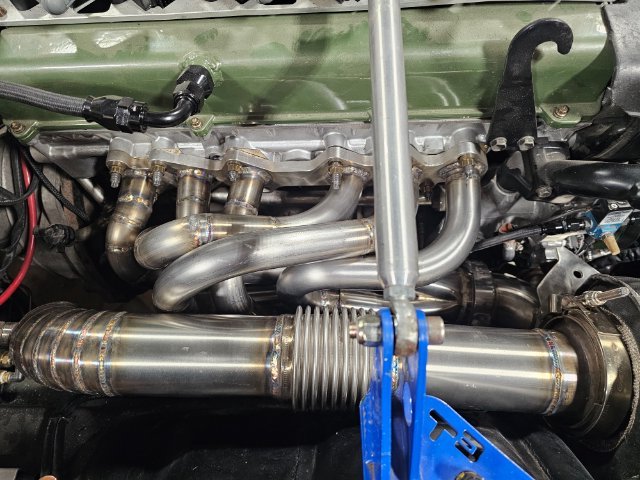

02-26-2026 ATLAS Z UPDATE: Today I got my rollbar and rear strut brace back from the powdercoater as well as the tunnel I dropped off to sandblast. The rubber is still on there, but this yucky sticky layer of honey look goos (glue) is gone. I also picked up my trans mount, he welded it up and added gussets on both sides out of 1/4" plate. I painted the back side quickly before I ran out of paint. Ready for the next day in the garage! P.S. self tapping screws and sheet metal (18 ga) here and ready to built it back, then the welder will stitch weld it and weld the plates over the top and over on both sides to the door jambs. 1/4" thick, 4 inch wide plate. Car will be overbuilt int his area like I did with the radiator support. 350-400 horsepower you really have to, even with the reinforced floor I have.1 point

-

this is very cool, I will be following along. Love the custom work. I am doing a 1jz swap myself at the moment so nice to see another with another person fab ideas1 point

-

1 point

-

Looking GREAT!! 👍👍 I really like the metalwork....makes you look like a skilled Italian craftsman (whereas mine makes me look like a one-armed monkey with a rock and a baseball bat.)1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point