-

Posts

1761 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by thehelix112

-

Ah. My mistake. Dave

-

3 4-cylinder heads I thought. Dave

-

As Eric said, JohnC has posted on this before, which I assume you've seen. Otherwise I would have to say ``the search button is over there.''. Let us know how you do it as I want to do it at some point. Dave

-

The beauty of the rear flares on the 280YZ kit (I believe) is that the tyres have room to actually move upwards WITHIN the flares quite a distance. As compared with the ZG flares, where you are in essence relying on two things; 1, tyres that are too small for the rims so the sidewall angle inwards; and 2, the negative camber increase with compression due to the swing-arm suspension. 280YZ > ZG Dave

-

-

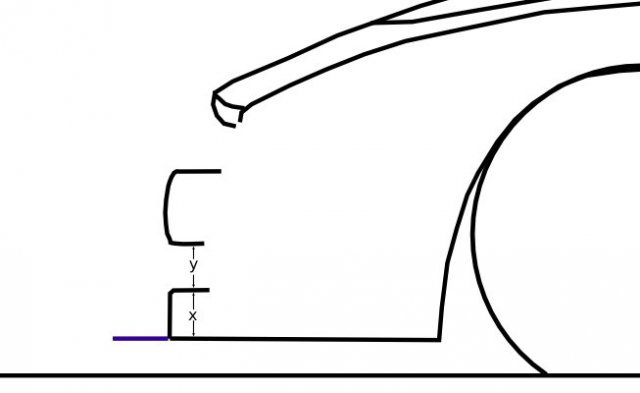

Affect of front air-dam opening on splitter effectiveness

thehelix112 replied to thehelix112's topic in Body Kits & Paint

demidion, The splitter is indeed the bit out from x, but really as johnc has pointed out, the whole front undertray is closely related. I'll have a hunt through the aero books I have to see if they mention the relationship between x and splitter length. From what I remember though, they only discuss the splitter length in isolation, but we'll see. BattleKat, Radiusing the front edges makes sense. Though I don't see why you wouldn't radius some trailing edges as well, depending on whether or not there is anything else downstream. In the case of the trailing edge of the front air-dam (that leads out into the side of the wheel), I will be radiusing the inner edge, and adding a small groove (will try to find the pic on mullannes corner) to redirect the air outwards. This is all in an attempt to give the high pressure zone in front of the wheel somewhere to bleed off (out the side). Thanks for your input, its always great to hear from people actually using this stuff day-to-day. Dave -

Correct. Not nit-picky, I would call it critical, but not in a negative way. I just finished my Phd so being critical is an excellent skill to have IMHO. I completely agree that unless the duct runs to something useful it would only have a negative effect on the car's aerodynamics. Some Porsches do come from the factory with ducts their though. Dave

-

Prox, As I understand it, basically the whole wheel well is high pressure. The air in front of the wheel is high pressure as its stagnant, and the air behind the wheel is high pressure as often the guard behind the wheel acts like a scoop. Jon, Porsches do have the thing that needs air second-most of all in a car in the back you know. Dave

-

Affect of front air-dam opening on splitter effectiveness

thehelix112 replied to thehelix112's topic in Body Kits & Paint

Also a good point there Beej. Maybe the bonnet's lower lip should be a tad more radiussed. Dave -

Affect of front air-dam opening on splitter effectiveness

thehelix112 replied to thehelix112's topic in Body Kits & Paint

John, I would dispute that that is not how a splitter works. A splitter does not have to be feeding a diffuser to act as a splitter and generate downforce. The latest trend for splitters is as an inverted aerofoil shape, as you say, for the purpose of accelerating the air up into the diffuser. Note: this will not compress the air, but will see a drop in static pressure along the underside surface. I don't find it that counter intuitive at all, a front diffuser will only ever work if its exit path is extremely low-resistance. Like out the side of the car where a very low pressure vortex exists (as generated by a dive plane). I definitely agree though that a splitter in complete isolation is far inferior to a splitter with a flat underbody, which is also far inferior to a splitter with a front diffuser. Dave -

I was just thinking the front could do with a little more neg camber. And the rear tyres could go 20mm skinnier and potentially be a better fit for the rims. But seriously, splitting hairs, that is one beautiful car. Dave

-

A water-cooled turbocharger centre assembly is designed to stabilize the assembly's temperate. An oil cooler is designed to stabilize the temperate of the oil for the entire engine (including turbocharger) system. Two rather different jobs in my opinion, and whether or not you need an oil cooler will depend more on the intended application than on whether or not the turbocharger is water-cooled. I think. Dave

-

Affect of front air-dam opening on splitter effectiveness

thehelix112 replied to thehelix112's topic in Body Kits & Paint

Who said I want less? I just want to understand how it works, specifically so I have a better chance of tuning the aerodynamics to work correctly. Dave -

Hey guys, I was pondering over coffee the possible effect of the front air-dam on the splitter's ability to generate downforce. From the diagram, if you increase Y (downwards) and decrease X, it would seem to me (assuming that the air flowing into this opening can do so at an adequate rate) that you will reduce the frontal downforce generated by the splitter. The way a splitter works is by placing a high static pressure (stagnation point) region on the upper surface, and allowing air to flow quickly underwards, creating a low static pressure region. High pressure on top, low pressure underneath means downforce. By reducing X (whether by increasing Y or not) we are reducing the amount of air that will slow down (and increase static pressure) on top, and thereby reducing the pressure differential and reducing downforce. Does that make sense? Dave

-

Am I mistaken, or did you actually make the front air-dam's intake even larger than it already was? Might one ask why? That is kinda counterproductive to both cooling, and drag. Especially if you are going to leave the gap between the front air-dam and the bonnet open. Also the front splitter looks very nice, how securely is it attached? I would be interested to hear how effective it is as it looks to my inexperienced eyes good enough to rip itself off. Did I mention the paint looks awesome? Dave

-

I wrote the ozdat utility. I initially copied the values over from the L building program, but was informed by a L20A owner the length was wrong and corrected it based on his info. I stand to be corrected again. Dave

-

Oh thats what I was going to say, I completely acknowledge the points johnc refers to: that brake feel, balance, initial bite, and quick release are very important. Balance can be tuned on the fly with an appropriate dual master/pedal box arrangement. Initial bite and quick release are things I hadn't really thought about to be honest. At first glance I would think that this is all a big juggling act with brake feel. If you want quick bite you want the pressure to come up ASAP, but that likely means a high pedal ratio and sensitive brakes which means more driver control is required and locking/flatspotting is easier. How quickly the pads release from the rotor will (barring any jamming in the caliper) depend on any deformation of the pad (hopefully minimal?) caused by the pistons, and how quickly the pressure in the line drops to normal. The speed of this drop (ie, the system reaching equilibrium with the increased volume caused by the piston(s) in the master cylinder(s) retracting) will depend on how high the pressure is. The higher the pressure the faster the drop. I think, been a while since I learnt about equilibrium. So from that, I guess you would want to operate your brakes at approximately the highest pressure the brake fluid can stand while not overheating the fluid during consistent hard braking. Everything in automotion is a compromise. Very sad really. Dave

-

It appears to me that there are perfectly valid reasons to increase both the size of rotors, the size of the calipers, and the number of pistons in the calipers. Whether they are the reasons why most people run such a setup is open for debate. I would think it useful to increase the size of the rotor if you wanted more braking torque for a given brake system pressure. It would seem logical to do this when you are at the practical limits of acceptable system pressure; whether it be because the master cylinder(s) can't generate any more, or your brake fluid isn't rated to the heat involved in going higher. Increasing the size of the calipers would seem to have two effects, one almost certain, and the other only potential. The certain effect is that you are going to increase the size of the brake pad the caliper takes. I think you might want this because you want more life out of a given set of brake pads. A larger caliper means larger brake pads, which means not only higher thermal mass, but more longevity. This would probably only be important on endurance racing cars? The possible effect is that you are getting more piston area. The more piston area, the more force is applied to the pads (and rotor) for a given brake system pressure, and hence, more braking torque. Obviously with an increase in piston area you will require additional volume in master cylinder(s) to maintain the same pressure/pedal-travel relationship (read: pedal feel). And lastly, increasing the number of pistons in the calipers: I only mention this as this is what people are doing when they purchase the 6-piston wilwood superlite versus the 4-piston (as sold by AZC). They are not getting any advantage in terms of brake pad thermal mass as both calipers accept the same pad. The only advantage aside from increased piston area (as discussed above) is in terms of pad wear. The pressure from the 6 piston caliper will be applied more evenly along the pad surface, thus it is more likely to wear evenly. Ok I got distracted with work and can't remember if I was going to say anything else. So i'll quite while I'm behind. Dave

-

Choosing a camshaft.. and how to match a turbo

thehelix112 replied to proxlamus©'s topic in Turbo / Supercharger

Jeff, In almost all cases, more information is better. Blindly going by advertised duration and not paying any heed to the potential differences in ramp rate (and hence 0.05 duration) is not a particularly intelligent way to select a camshaft for any application. 250/270 is a relatively large split for intake/exhaust 0.05 durations I would have thought? Dave -

Sounds great. Time is one of those things most are gaurunteed to have too little of. I am sorry this opportunity for scale testing has come a little soon for me. I have some significant plans for my track car, and would love the opportunity to test them. Maybe we can do a repeat in 18 months or so? Anyway, back on topic. I would maybe suggest, though I know its a lot more work, making as much parts adjustable as possible. That would include front splitter, rear diffuser (rear extension, height, number and orentiation of strakes), spoiler, and wings. Dave

-

Are you sure that the front dipping was not cutting the feed to the rear diffuser? Thats how I read `the front splitter nearly touched the ground'' What springs were in the car? How close was the front splitter to the ground at static? Did the splitter have a raised middle section to reduce pitch sensitivity? I think that your synopsis assumes an awful lot, the main one being that someone has not taken into account the effects (read: benefits) of aerodynamics when designing the rest (read: suspension) of the car. If you have soft springs like a lot of people here seem attached to, you are going to have a chassis that is significantly affected by aerodynamic forces, and will have to tune accordingly. Just because someone you know didn't, does not mean underbody aerodynamics are ``more dangerous than is tolerable''. It means more development/tuning is required, and/or some proper rate springs for racing. Dave

-

Choosing a camshaft.. and how to match a turbo

thehelix112 replied to proxlamus©'s topic in Turbo / Supercharger

Dude, Next to useless without 0.05 duration information. Dave -

So this is a drag strip only car? Dave

-

Not to mention a straight 6 in a car designed for a v6 will move the CoG forwards and upwards, which I somehow doubt will have a favourable impact on handling. Dave